engine LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 66 of 3229

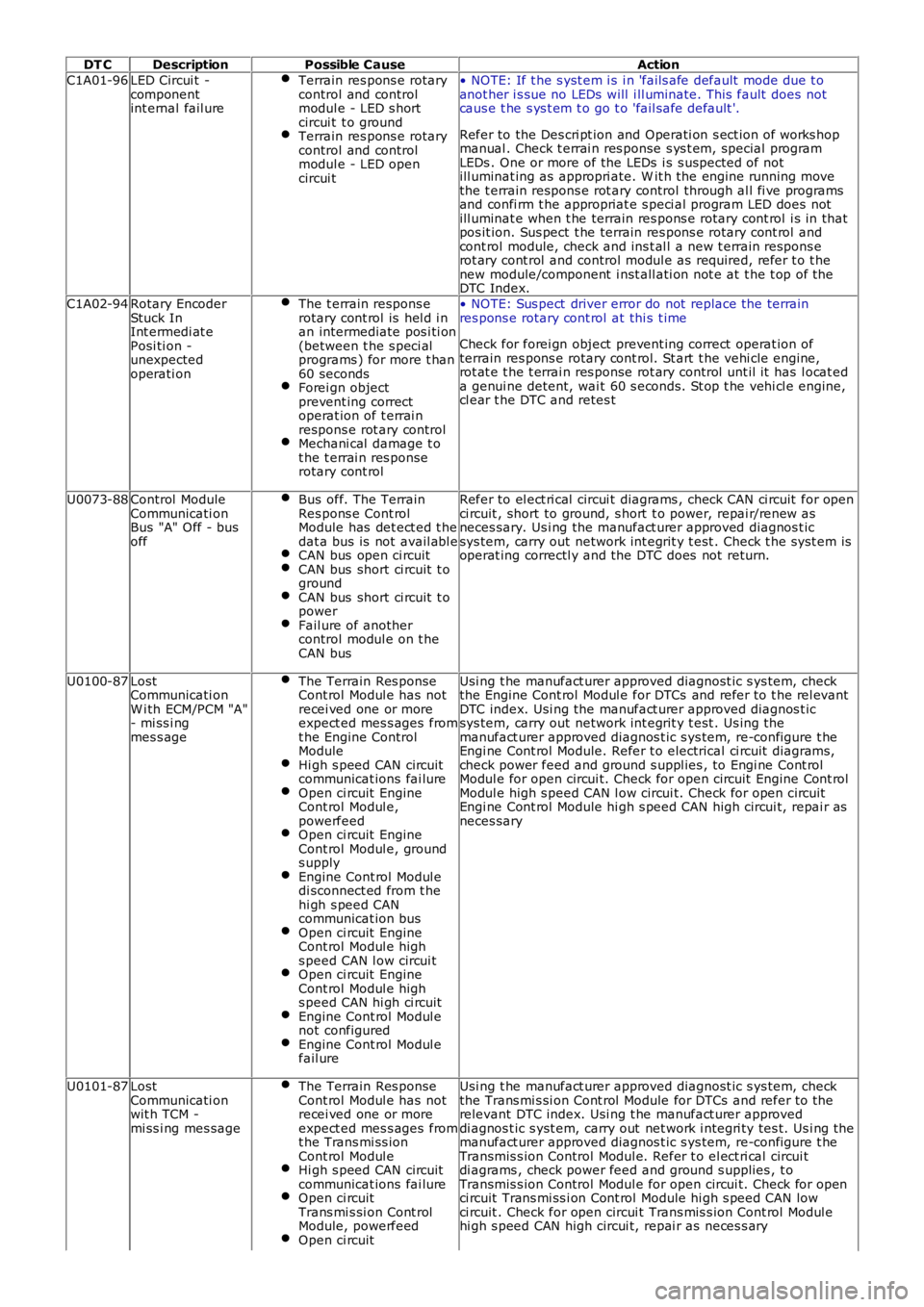

DT CDescriptionPossible CauseAction

C1A01-96LED Circui t -componentint ernal fail ure

Terrain res pons e rotarycontrol and controlmodul e - LED s hortcircui t t o groundTerrain res pons e rotarycontrol and controlmodul e - LED opencircui t

• NOTE: If t he s yst em i s i n 'fails afe default mode due t oanot her i s sue no LEDs will i ll uminate. This fault does notcaus e t he s ys t em t o go t o 'fail safe default '.

Refer to the Des cri pt ion and Operati on s ect ion of works hopmanual . Check t errai n res ponse s ys t em, special programLEDs . One or more of the LEDs i s s uspected of notill uminat ing as appropri ate. W it h the engi ne running movethe t errain respons e rot ary control through al l fi ve programsand confi rm t he appropriat e s peci al program LED does notill uminat e when t he terrain res pons e rotary cont rol i s in thatpos it ion. Sus pect t he terrain res pons e rotary cont rol andcont rol module, check and ins t al l a new t errain respons erot ary cont rol and control modul e as required, refer t o t henew module/component i nst all ati on not e at t he t op of theDTC Index.

C1A02-94Rotary EncoderStuck InInt ermedi at ePosi ti on -unexpectedoperati on

The t errain respons erotary cont rol is hel d i nan intermediate pos i ti on(between t he s peci alprograms ) for more t han60 secondsForei gn objectprevent ing correctoperat ion of t errai nrespons e rot ary controlMechani cal damage t ot he t errai n res ponserotary cont rol

• NOTE: Sus pect driver error do not replace the terrainres pons e rotary cont rol at thi s t ime

Check for forei gn object prevent ing correct operat ion ofterrain res pons e rotary cont rol. St art t he vehi cle engine,rot at e t he t errai n res ponse rot ary control unt il it has l ocat eda genui ne detent, wai t 60 s econds. St op t he vehi cl e engine,cl ear t he DTC and retes t

U0073-88Control ModuleCommunicati onBus "A" Off - busoff

Bus off. The TerrainRes pons e Cont rolModule has det ect ed t hedat a bus is not avail abl eCAN bus open ci rcuitCAN bus short ci rcuit t ogroundCAN bus short ci rcuit t opowerFail ure of anothercontrol modul e on t heCAN bus

Refer to el ect ri cal circui t diagrams , check CAN ci rcuit for openci rcuit , short to ground, s hort t o power, repai r/renew asneces sary. Us i ng the manufact urer approved diagnos t icsys tem, carry out network int egrit y t est . Check t he s yst em isoperat ing correctl y and the DTC does not return.

U0100-87LostCommunicati onW i th ECM/PCM "A"- mi ss i ngmes s age

The Terrain Res ponseCont rol Modul e has notrecei ved one or moreexpect ed mes s ages fromt he Engine ControlModuleHi gh s peed CAN circuitcommunicat ions fai lureOpen ci rcuit EngineCont rol Modul e,powerfeedOpen ci rcuit EngineCont rol Modul e, grounds upplyEngine Cont rol Modul edi sconnect ed from t hehi gh s peed CANcommunicat ion busOpen ci rcuit EngineCont rol Modul e highs peed CAN l ow circui tOpen ci rcuit EngineCont rol Modul e highs peed CAN hi gh ci rcuitEngine Cont rol Modul enot configuredEngine Cont rol Modul efail ure

Usi ng t he manufact urer approved diagnost ic s ys tem, checkthe Engine Cont rol Modul e for DTCs and refer t o t he rel evantDTC index. Usi ng the manufact urer approved diagnos t icsys tem, carry out network int egrit y t est . Us ing t hemanufact urer approved diagnos t ic s ys tem, re-configure t heEngi ne Cont rol Module. Refer t o electrical ci rcuit diagrams,check power feed and ground s uppl ies , to Engi ne Cont rolModul e for open circui t. Check for open circuit Engine Cont rolModul e high s peed CAN l ow circui t. Check for open circuitEngi ne Cont rol Module hi gh s peed CAN high circui t, repai r asneces sary

U0101-87LostCommunicati onwit h TCM -mi ss i ng mes sage

The Terrain Res ponseCont rol Modul e has notrecei ved one or moreexpect ed mes s ages fromt he Trans mi ss ionCont rol Modul eHi gh s peed CAN circuitcommunicat ions fai lureOpen ci rcuitTrans mi s si on Cont rolModule, powerfeedOpen ci rcuit

Usi ng t he manufact urer approved diagnost ic s ys tem, checkthe Trans mi s si on Cont rol Module for DTCs and refer to therelevant DTC index. Usi ng t he manufact urer approveddi agnos t ic s yst em, carry out net work i ntegri ty tes t. Us i ng themanufact urer approved diagnos t ic s ys tem, re-configure t heTransmis s ion Control Modul e. Refer t o el ect ri cal circui tdi agrams , check power feed and ground s upplies , t oTransmis s ion Control Modul e for open circui t. Check for openci rcuit Trans mi ss i on Cont rol Module hi gh s peed CAN lowci rcuit . Check for open circui t Trans mis s ion Cont rol Modul ehi gh s peed CAN high circui t, repai r as neces s ary

Page 68 of 3229

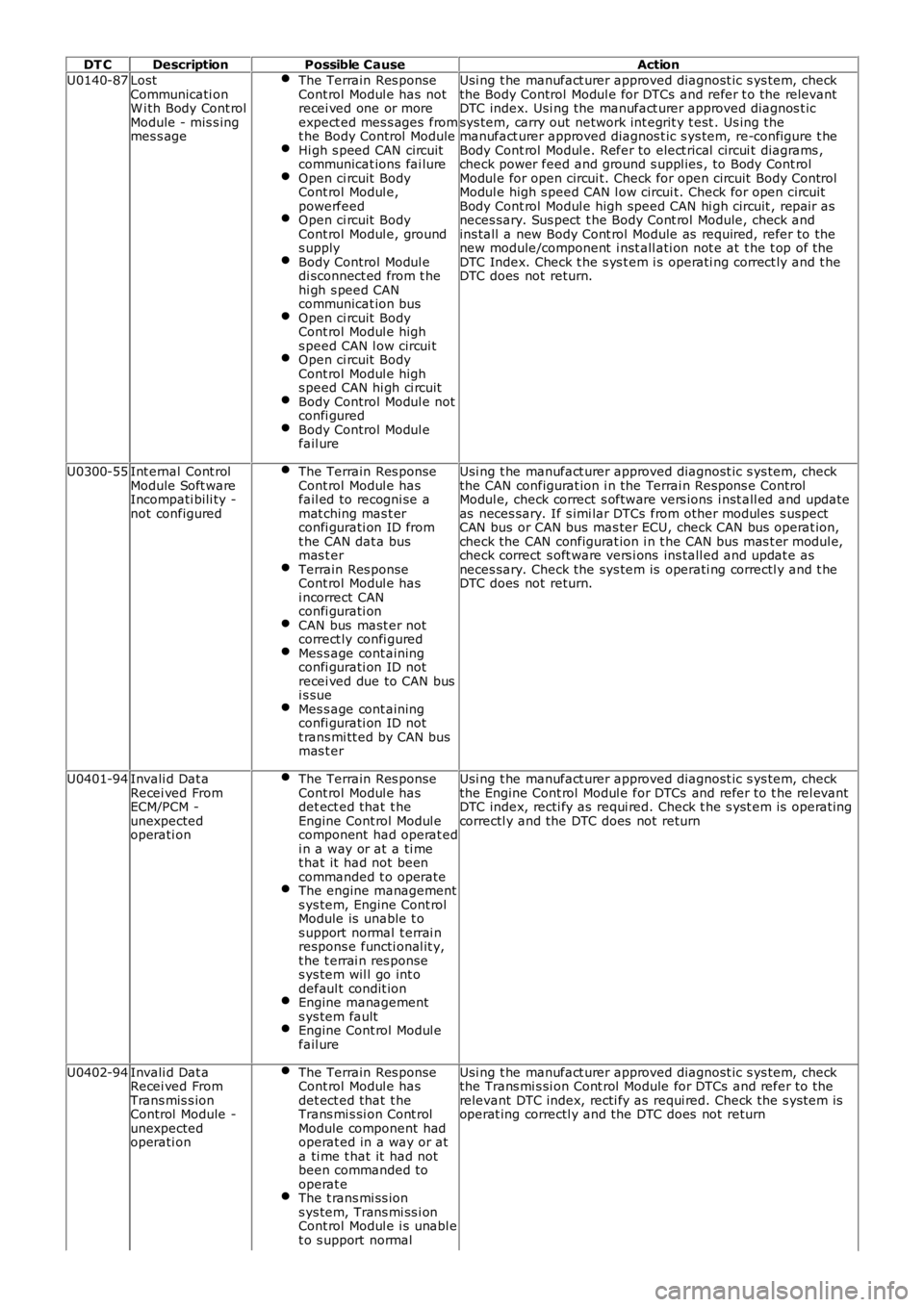

DT CDescriptionPossible CauseAction

U0140-87LostCommunicati onW i th Body Cont rolModule - mis s ingmes s age

The Terrain Res ponseCont rol Modul e has notrecei ved one or moreexpect ed mes s ages fromt he Body Control ModuleHi gh s peed CAN circuitcommunicat ions fai lureOpen ci rcuit BodyCont rol Modul e,powerfeedOpen ci rcuit BodyCont rol Modul e, grounds upplyBody Control Modul edi sconnect ed from t hehi gh s peed CANcommunicat ion busOpen ci rcuit BodyCont rol Modul e highs peed CAN l ow circui tOpen ci rcuit BodyCont rol Modul e highs peed CAN hi gh ci rcuitBody Control Modul e notconfi guredBody Control Modul efail ure

Usi ng t he manufact urer approved diagnost ic s ys tem, checkthe Body Control Modul e for DTCs and refer t o the relevantDTC index. Usi ng the manufact urer approved diagnos t icsys tem, carry out network int egrit y t est . Us ing t hemanufact urer approved diagnos t ic s ys tem, re-configure t heBody Cont rol Modul e. Refer to elect rical circui t diagrams ,check power feed and ground s uppl ies , to Body Cont rolModul e for open circui t. Check for open circuit Body ControlModul e high s peed CAN l ow circui t. Check for open circuitBody Cont rol Modul e high speed CAN hi gh circuit , repair asneces sary. Sus pect t he Body Cont rol Module, check andins tall a new Body Cont rol Module as required, refer to thenew module/component i nst all ati on not e at t he t op of theDTC Index. Check t he s ys t em i s operati ng correct ly and t heDTC does not return.

U0300-55Int ernal Cont rolModule Soft wareIncompati bili ty -not configured

The Terrain Res ponseCont rol Modul e hasfail ed to recogni se amat ching mas t erconfi gurati on ID fromt he CAN dat a busmas t erTerrain Res ponseCont rol Modul e hasi ncorrect CANconfi gurati onCAN bus mast er notcorrect ly confi guredMes s age cont ainingconfi gurati on ID notrecei ved due to CAN busi s sueMes s age cont ainingconfi gurati on ID nott rans mi tt ed by CAN busmas t er

Usi ng t he manufact urer approved diagnost ic s ys tem, checkthe CAN configurat ion i n the Terrai n Respons e ControlModul e, check correct s oftware vers ions i nst all ed and updat eas neces sary. If s imi lar DTCs from other modules s uspectCAN bus or CAN bus mas ter ECU, check CAN bus operat ion,check the CAN configurat ion i n t he CAN bus mas t er modul e,check correct s oft ware vers i ons ins tall ed and updat e asneces sary. Check the sys tem is operati ng correctl y and t heDTC does not return.

U0401-94Invali d Dat aRecei ved FromECM/PCM -unexpectedoperati on

The Terrain Res ponseCont rol Modul e hasdet ect ed that t heEngine Cont rol Modul ecomponent had operat edi n a way or at a ti met hat it had not beencommanded t o operateThe engine managements ys tem, Engine Cont rolModule is unable t os upport normal t errai nrespons e functi onal it y,t he t errai n res ponses ys tem wil l go int odefaul t condit ionEngine managements ys tem faultEngine Cont rol Modul efail ure

Usi ng t he manufact urer approved diagnost ic s ys tem, checkthe Engine Cont rol Modul e for DTCs and refer t o t he rel evantDTC index, recti fy as requi red. Check t he s yst em is operat ingcorrectl y and the DTC does not return

U0402-94Invali d Dat aRecei ved FromTrans mis s ionControl Module -unexpectedoperati on

The Terrain Res ponseCont rol Modul e hasdet ect ed that t heTrans mi s si on Cont rolModule component hadoperat ed in a way or ata ti me t hat it had notbeen commanded tooperat eThe t rans mi ss ions ys tem, Trans mi ss i onCont rol Modul e i s unabl et o s upport normal

Usi ng t he manufact urer approved diagnost ic s ys tem, checkthe Trans mi s si on Cont rol Module for DTCs and refer to therelevant DTC index, recti fy as requi red. Check the s ys tem isoperat ing correctl y and the DTC does not return

Page 72 of 3229

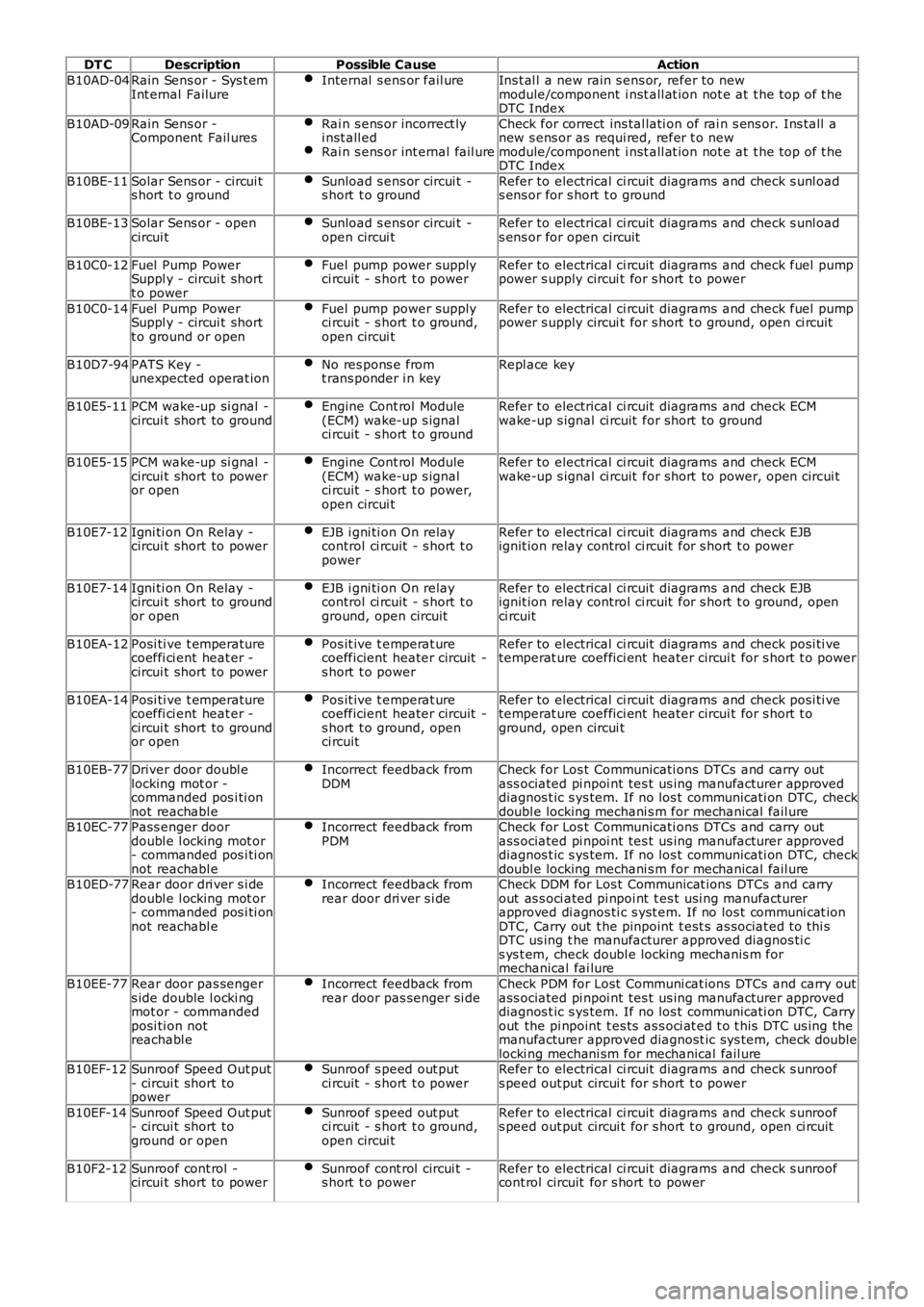

DT CDescriptionPossible CauseAction

B10AD-04Rain Sens or - Sys t emInt ernal FailureInternal s ens or fail ureIns t al l a new rain s ens or, refer to newmodule/component i nst all at ion not e at t he top of t heDTC Index

B10AD-09Rain Sens or -Component Fail uresRai n s ens or incorrect lyi nst all edRai n s ens or int ernal fail ure

Check for correct ins tal lati on of rai n s ens or. Ins tall anew s ens or as requi red, refer t o newmodule/component i nst all at ion not e at t he top of t heDTC Index

B10BE-11Solar Sens or - circui ts hort t o groundSunload s ens or circui t -s hort t o groundRefer to electrical ci rcuit diagrams and check s unl oads ens or for s hort t o ground

B10BE-13Solar Sens or - opencircui tSunload s ens or circui t -open circui tRefer to electrical ci rcuit diagrams and check s unl oads ens or for open circuit

B10C0-12Fuel Pump PowerSuppl y - circui t shortt o power

Fuel pump power supplyci rcuit - s hort t o powerRefer to electrical ci rcuit diagrams and check fuel pumppower s upply circui t for s hort t o power

B10C0-14Fuel Pump PowerSuppl y - circui t shortt o ground or open

Fuel pump power supplyci rcuit - s hort t o ground,open circui t

Refer to electrical ci rcuit diagrams and check fuel pumppower s upply circui t for s hort t o ground, open ci rcuit

B10D7-94PATS Key -unexpected operat ionNo res pons e fromt rans ponder i n keyRepl ace key

B10E5-11PCM wake-up si gnal -circui t short to groundEngine Cont rol Module(ECM) wake-up s ignalci rcuit - s hort t o ground

Refer to electrical ci rcuit diagrams and check ECMwake-up s ignal ci rcuit for short to ground

B10E5-15PCM wake-up si gnal -circui t short to poweror open

Engine Cont rol Module(ECM) wake-up s ignalci rcuit - s hort t o power,open circui t

Refer to electrical ci rcuit diagrams and check ECMwake-up s ignal ci rcuit for short to power, open circui t

B10E7-12Igni ti on On Relay -circui t short to powerEJB i gni ti on On relaycontrol ci rcuit - s hort t opower

Refer to electrical ci rcuit diagrams and check EJBignit ion relay control ci rcuit for s hort t o power

B10E7-14Igni ti on On Relay -circui t short to groundor open

EJB i gni ti on On relaycontrol ci rcuit - s hort t oground, open circuit

Refer to electrical ci rcuit diagrams and check EJBignit ion relay control ci rcuit for s hort t o ground, openci rcuit

B10EA-12Posi ti ve t emperaturecoeffi ci ent heat er -circui t short to power

Pos it ive t emperat urecoefficient heater circuit -s hort t o power

Refer to electrical ci rcuit diagrams and check posi ti vetemperat ure coeffici ent heater circui t for s hort t o power

B10EA-14Posi ti ve t emperaturecoeffi ci ent heat er -circui t short to groundor open

Pos it ive t emperat urecoefficient heater circuit -s hort t o ground, openci rcuit

Refer to electrical ci rcuit diagrams and check posi ti vetemperat ure coeffici ent heater circui t for s hort t oground, open circui t

B10EB-77Driver door doubl elocking mot or -commanded pos i ti onnot reachabl e

Incorrect feedback fromDDMCheck for Los t Communicati ons DTCs and carry outass ociated pi npoi nt tes t us ing manufacturer approveddiagnos t ic s ys tem. If no los t communicati on DTC, checkdoubl e locking mechani s m for mechanical fail ureB10EC-77Pass enger doordoubl e l ocking mot or- commanded pos i ti onnot reachabl e

Incorrect feedback fromPDMCheck for Los t Communicati ons DTCs and carry outass ociated pi npoi nt tes t us ing manufacturer approveddiagnos t ic s ys tem. If no los t communicati on DTC, checkdoubl e locking mechani s m for mechanical fail ureB10ED-77Rear door dri ver s i dedoubl e l ocking mot or- commanded pos i ti onnot reachabl e

Incorrect feedback fromrear door dri ver s i deCheck DDM for Los t Communicat ions DTCs and carryout as s oci ated pi npoi nt t es t usi ng manufacturerapproved di agnos ti c s yst em. If no los t communi cat ionDTC, Carry out t he pinpoint t est s as sociat ed t o thi sDTC us ing t he manufacturer approved diagnos ti cs ys t em, check doubl e locking mechanis m formechanical fai lure

B10EE-77Rear door pas sengers ide double l ocki ngmot or - commandedposi ti on notreachabl e

Incorrect feedback fromrear door pas senger si deCheck PDM for Lost Communi cat ions DTCs and carry outass ociated pi npoi nt tes t us ing manufacturer approveddiagnos t ic s ys tem. If no los t communicati on DTC, Carryout the pi npoint t es ts as s oci at ed t o t his DTC us ing themanufacturer approved diagnost ic sys tem, check doublelocki ng mechani sm for mechanical fail ureB10EF-12Sunroof Speed Out put- circui t short topower

Sunroof s peed out putci rcuit - s hort t o powerRefer to electrical ci rcuit diagrams and check s unroofs peed out put circui t for s hort t o power

B10EF-14Sunroof Speed Out put- circui t short toground or open

Sunroof s peed out putci rcuit - s hort t o ground,open circui t

Refer to electrical ci rcuit diagrams and check s unroofs peed out put circui t for s hort t o ground, open ci rcuit

B10F2-12Sunroof cont rol -circui t short to powerSunroof cont rol circui t -s hort t o powerRefer to electrical ci rcuit diagrams and check s unroofcont rol circuit for s hort to power

Page 91 of 3229

Publ is hed: 01-Oct -2011

General Information - Diagnostic Trouble Code (DTC) IndexTD4 2.2L Diesel,

DTC: Engine Control Module (ECM)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For addit ional informat ion on t he des cript ion and operat ion of t he sys t em: For additional informati on, refer t o: Engi ne(303-01B Engi ne - TD4 2.2L Di esel , Descri pti on and Operat ion).

Powertrain control module diesel (PC MD)

DT CDescriptionPossible CauseAction

B10A2-68Cras h Input - Eventinformat ionAi r bag event detectedUsi ng t he manufacturer approveddiagnos t ic s yst em, check rest rai ntscont rol module, for related DTCs andrefer t o t he rel evant DTC i ndex

P0016-00Cranks haft Pos i ti on -Cams haft Posi ti on Correlati on- Bank 1 Sensor A - No s ubt ype i nformati on

Engine t iming i ncorrectTiming chain i nst all edi ncorrect lyThe relati ve posi ti ons oft he crankshaft pos it ions ensor and cam t imingplat e t eet h are not correct

Check engine t imingCheck cams haft s ens or t imi ng plate isins tal led correct lyCheck valve t imingCheck t imi ng chai n i ns t alled correctl y

P0030-12HO2S Heater Control Circuit(Bank 1, Sensor 1) - Ci rcuits hort t o batt ery

• NO TE: - Ci rcuit O_T_SHT1 -

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t opowerFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t opowerCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0030-13HO2S Heater Control Circuit(Bank 1, Sensor 1) - Ci rcuitopen

• NO TE: - Ci rcuit O_T_SHT1 -

Front heated oxygens ensor heater cont rolcircui t high resi st ance,open circui tFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check t he front heat ed oxygensens or heat er cont rol ci rcuit for highres is t ance, open ci rcuitCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0031-11HO2S Heater Control CircuitLow (Bank 1, Sens or 1) -Circui t s hort to ground

• NO TE: - Ci rcuit O_T_SHT1 -

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t ogroundFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t ogroundCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0031-16HO2S Heater Control CircuitLow (Bank 1, Sens or 1) -Circui t vol tage belowt hreshol d

• NO TE: - Ci rcuit O_T_SHT1 -

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t ogroundFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t ogroundCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t he

Page 93 of 3229

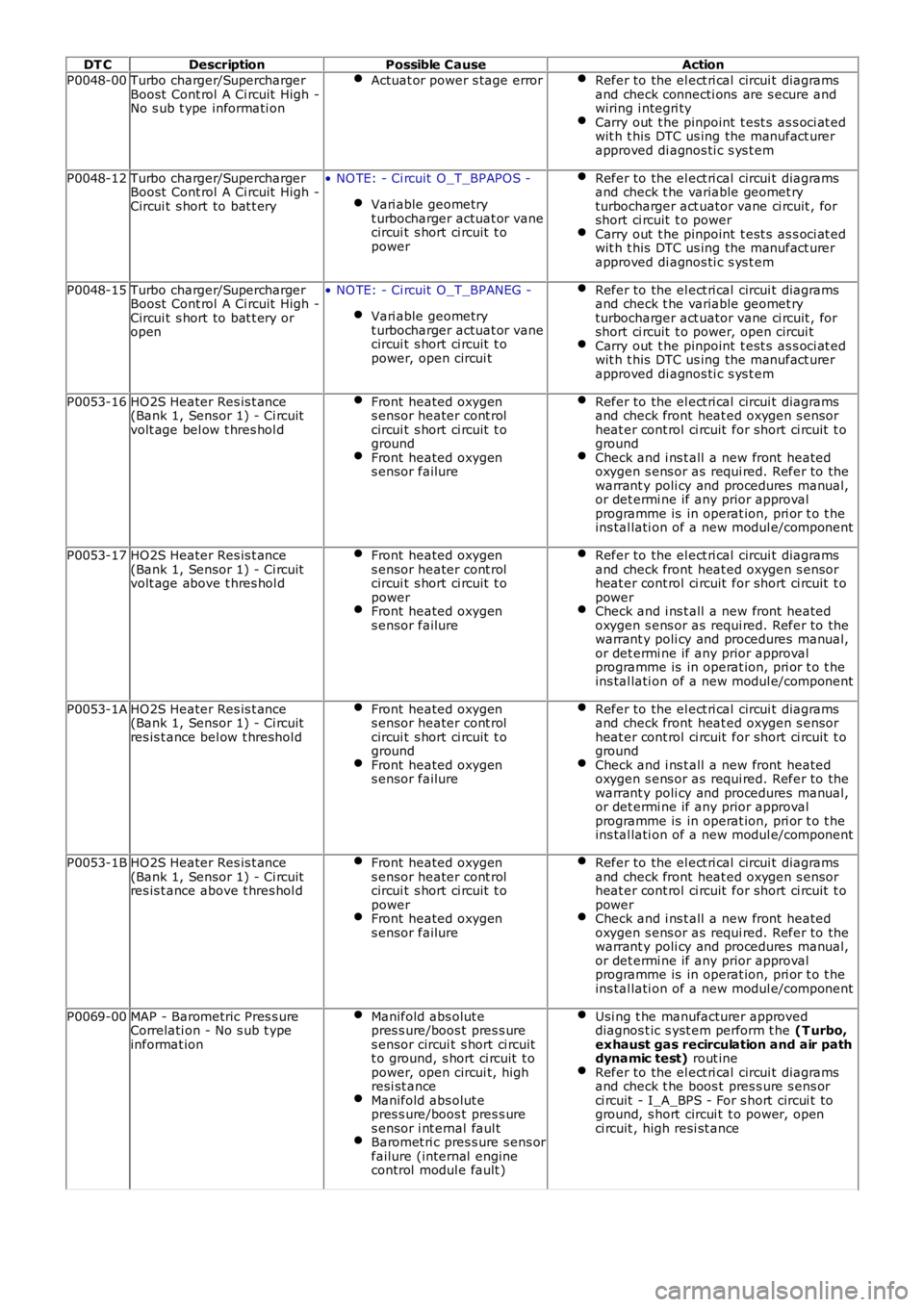

DT CDescriptionPossible CauseAction

P0048-00Turbo charger/SuperchargerBoost Cont rol A Ci rcuit High -No s ub t ype informati on

Actuat or power s tage errorRefer to the el ect ri cal circui t diagramsand check connecti ons are s ecure andwiring i ntegri tyCarry out t he pinpoint t est s as s oci at edwit h t his DTC us ing the manufact urerapproved di agnos ti c s ys t em

P0048-12Turbo charger/SuperchargerBoost Cont rol A Ci rcuit High -Circui t s hort to bat t ery

• NO TE: - Ci rcuit O_T_BPAPOS -

Vari able geometryt urbocharger actuat or vanecircui t s hort ci rcuit t opower

Refer to the el ect ri cal circui t diagramsand check t he variable geomet ryturbocharger act uator vane ci rcuit , forshort ci rcuit t o powerCarry out t he pinpoint t est s as s oci at edwit h t his DTC us ing the manufact urerapproved di agnos ti c s ys t em

P0048-15Turbo charger/SuperchargerBoost Cont rol A Ci rcuit High -Circui t s hort to bat t ery oropen

• NO TE: - Ci rcuit O_T_BPANEG -

Vari able geometryt urbocharger actuat or vanecircui t s hort ci rcuit t opower, open circui t

Refer to the el ect ri cal circui t diagramsand check t he variable geomet ryturbocharger act uator vane ci rcuit , forshort ci rcuit t o power, open circui tCarry out t he pinpoint t est s as s oci at edwit h t his DTC us ing the manufact urerapproved di agnos ti c s ys t em

P0053-16HO2S Heater Res is t ance(Bank 1, Sensor 1) - Ci rcuitvolt age bel ow t hres hol d

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t ogroundFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t ogroundCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0053-17HO2S Heater Res is t ance(Bank 1, Sensor 1) - Ci rcuitvolt age above t hres hol d

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t opowerFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t opowerCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0053-1AHO2S Heater Res is t ance(Bank 1, Sensor 1) - Ci rcuitres is t ance bel ow t hreshol d

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t ogroundFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t ogroundCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0053-1BHO2S Heater Res is t ance(Bank 1, Sensor 1) - Ci rcuitres is t ance above t hres hol d

Front heated oxygens ensor heater cont rolcircui t s hort ci rcuit t opowerFront heated oxygens ensor failure

Refer to the el ect ri cal circui t diagramsand check front heat ed oxygen s ensorheat er cont rol ci rcuit for short ci rcuit t opowerCheck and i ns t all a new front heatedoxygen s ens or as requi red. Refer to thewarrant y poli cy and procedures manual,or det ermi ne if any prior approvalprogramme is in operat ion, pri or t o t heins tal lati on of a new modul e/component

P0069-00MAP - Barometric Pres s ureCorrelati on - No s ub t ypeinformat ion

Manifold abs olut epres s ure/boos t pres s ures ensor circui t s hort ci rcuitt o ground, s hort ci rcuit t opower, open circui t, highresi st anceManifold abs olut epres s ure/boos t pres s ures ensor i nt ernal faul tBaromet ri c pres s ure s ens orfailure (internal enginecontrol modul e fault )

Usi ng t he manufacturer approveddiagnos t ic s yst em perform t he (T urbo,exhaust gas recirculation and air pathdynamic test) rout ineRefer to the el ect ri cal circui t diagramsand check t he boos t pres s ure s ens orci rcuit - I_A_BPS - For s hort circui t toground, s hort circui t t o power, openci rcuit , high resi st ance

Page 94 of 3229

DT CDescriptionPossible CauseAction

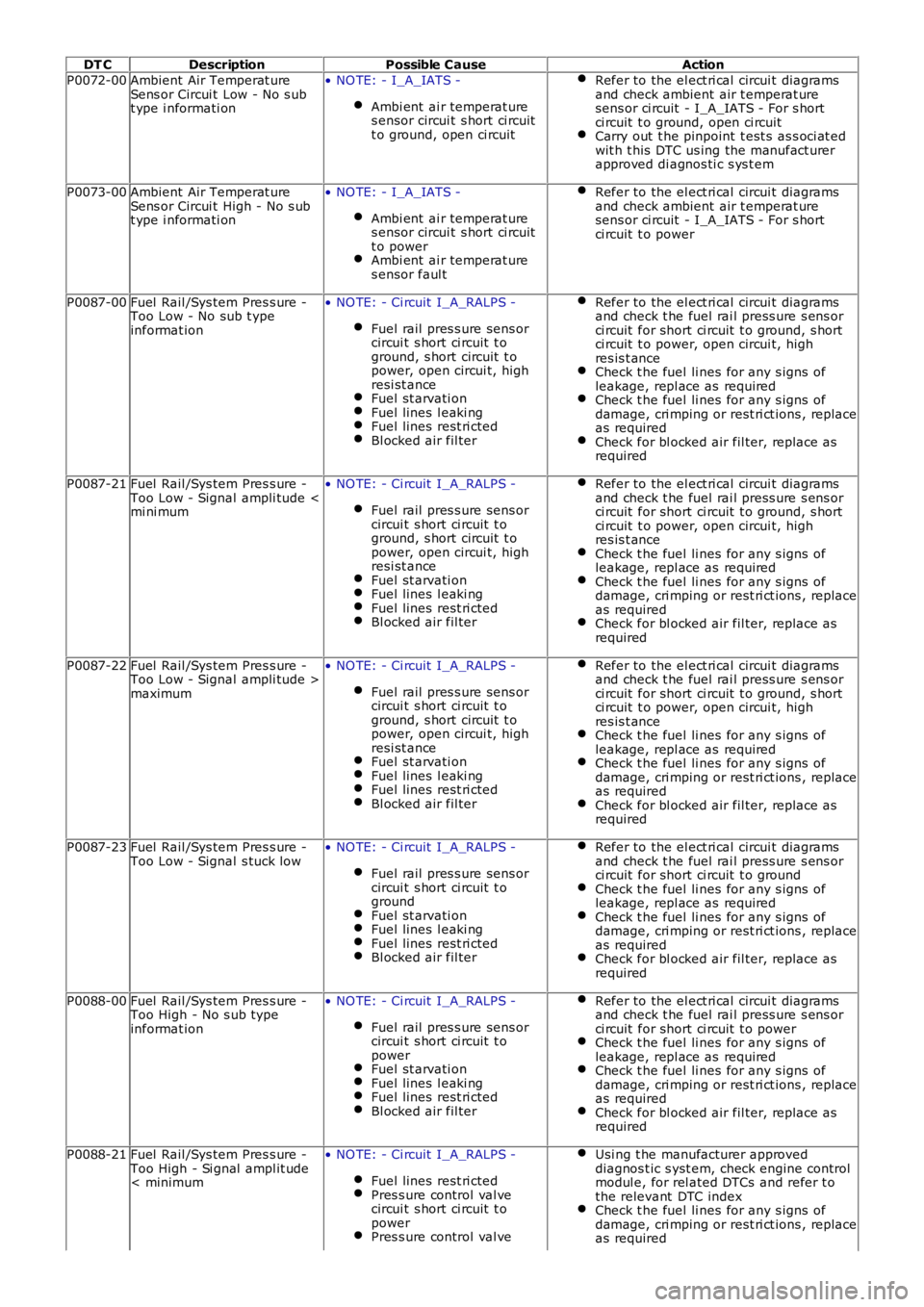

P0072-00Ambient Air Temperat ureSens or Circui t Low - No s ubt ype i nformati on

• NO TE: - I_A_IATS -

Ambi ent ai r temperat ures ensor circui t s hort ci rcuitt o ground, open ci rcuit

Refer to the el ect ri cal circui t diagramsand check ambient air t emperat uresens or ci rcuit - I_A_IATS - For s hortci rcuit t o ground, open ci rcuitCarry out t he pinpoint t est s as s oci at edwit h t his DTC us ing the manufact urerapproved di agnos ti c s ys t em

P0073-00Ambient Air Temperat ureSens or Circui t High - No s ubt ype i nformati on

• NO TE: - I_A_IATS -

Ambi ent ai r temperat ures ensor circui t s hort ci rcuitt o powerAmbi ent ai r temperat ures ensor faul t

Refer to the el ect ri cal circui t diagramsand check ambient air t emperat uresens or ci rcuit - I_A_IATS - For s hortci rcuit t o power

P0087-00Fuel Rail /Sys tem Pres s ure -Too Low - No sub t ypeinformat ion

• NO TE: - Ci rcuit I_A_RALPS -

Fuel rail pres s ure sens orcircui t s hort ci rcuit t oground, s hort circuit t opower, open circui t, highresi st anceFuel st arvati onFuel lines l eaki ngFuel lines rest ri ctedBl ocked air fil ter

Refer to the el ect ri cal circui t diagramsand check t he fuel rai l press ure s ens orci rcuit for short ci rcuit t o ground, s hortci rcuit t o power, open circui t, highres is t anceCheck t he fuel li nes for any s igns ofleakage, repl ace as requiredCheck t he fuel li nes for any s igns ofdamage, cri mping or rest ri ct ions , replaceas requiredCheck for bl ocked air fil ter, replace asrequired

P0087-21Fuel Rail /Sys tem Pres s ure -Too Low - Signal ampli tude

Fuel rail pres s ure sens orcircui t s hort ci rcuit t oground, s hort circuit t opower, open circui t, highresi st anceFuel st arvati onFuel lines l eaki ngFuel lines rest ri ctedBl ocked air fil ter

Refer to the el ect ri cal circui t diagramsand check t he fuel rai l press ure s ens orci rcuit for short ci rcuit t o ground, s hortci rcuit t o power, open circui t, highres is t anceCheck t he fuel li nes for any s igns ofleakage, repl ace as requiredCheck t he fuel li nes for any s igns ofdamage, cri mping or rest ri ct ions , replaceas requiredCheck for bl ocked air fil ter, replace asrequired

P0087-22Fuel Rail /Sys tem Pres s ure -Too Low - Signal ampli tude >maximum

• NO TE: - Ci rcuit I_A_RALPS -

Fuel rail pres s ure sens orcircui t s hort ci rcuit t oground, s hort circuit t opower, open circui t, highresi st anceFuel st arvati onFuel lines l eaki ngFuel lines rest ri ctedBl ocked air fil ter

Refer to the el ect ri cal circui t diagramsand check t he fuel rai l press ure s ens orci rcuit for short ci rcuit t o ground, s hortci rcuit t o power, open circui t, highres is t anceCheck t he fuel li nes for any s igns ofleakage, repl ace as requiredCheck t he fuel li nes for any s igns ofdamage, cri mping or rest ri ct ions , replaceas requiredCheck for bl ocked air fil ter, replace asrequired

P0087-23Fuel Rail /Sys tem Pres s ure -Too Low - Signal s tuck low• NO TE: - Ci rcuit I_A_RALPS -

Fuel rail pres s ure sens orcircui t s hort ci rcuit t ogroundFuel st arvati onFuel lines l eaki ngFuel lines rest ri ctedBl ocked air fil ter

Refer to the el ect ri cal circui t diagramsand check t he fuel rai l press ure s ens orci rcuit for short ci rcuit t o groundCheck t he fuel li nes for any s igns ofleakage, repl ace as requiredCheck t he fuel li nes for any s igns ofdamage, cri mping or rest ri ct ions , replaceas requiredCheck for bl ocked air fil ter, replace asrequired

P0088-00Fuel Rail /Sys tem Pres s ure -Too High - No s ub typeinformat ion

• NO TE: - Ci rcuit I_A_RALPS -

Fuel rail pres s ure sens orcircui t s hort ci rcuit t opowerFuel st arvati onFuel lines l eaki ngFuel lines rest ri ctedBl ocked air fil ter

Refer to the el ect ri cal circui t diagramsand check t he fuel rai l press ure s ens orci rcuit for short ci rcuit t o powerCheck t he fuel li nes for any s igns ofleakage, repl ace as requiredCheck t he fuel li nes for any s igns ofdamage, cri mping or rest ri ct ions , replaceas requiredCheck for bl ocked air fil ter, replace asrequired

P0088-21Fuel Rail /Sys tem Pres s ure -Too High - Si gnal ampl it ude< minimum

• NO TE: - Ci rcuit I_A_RALPS -

Fuel lines rest ri ctedPres s ure control val vecircui t s hort ci rcuit t opowerPres s ure control val ve

Usi ng t he manufacturer approveddiagnos t ic s yst em, check engine controlmodul e, for rel ated DTCs and refer t othe relevant DTC indexCheck t he fuel li nes for any s igns ofdamage, cri mping or rest ri ct ions , replaceas required

Page 97 of 3229

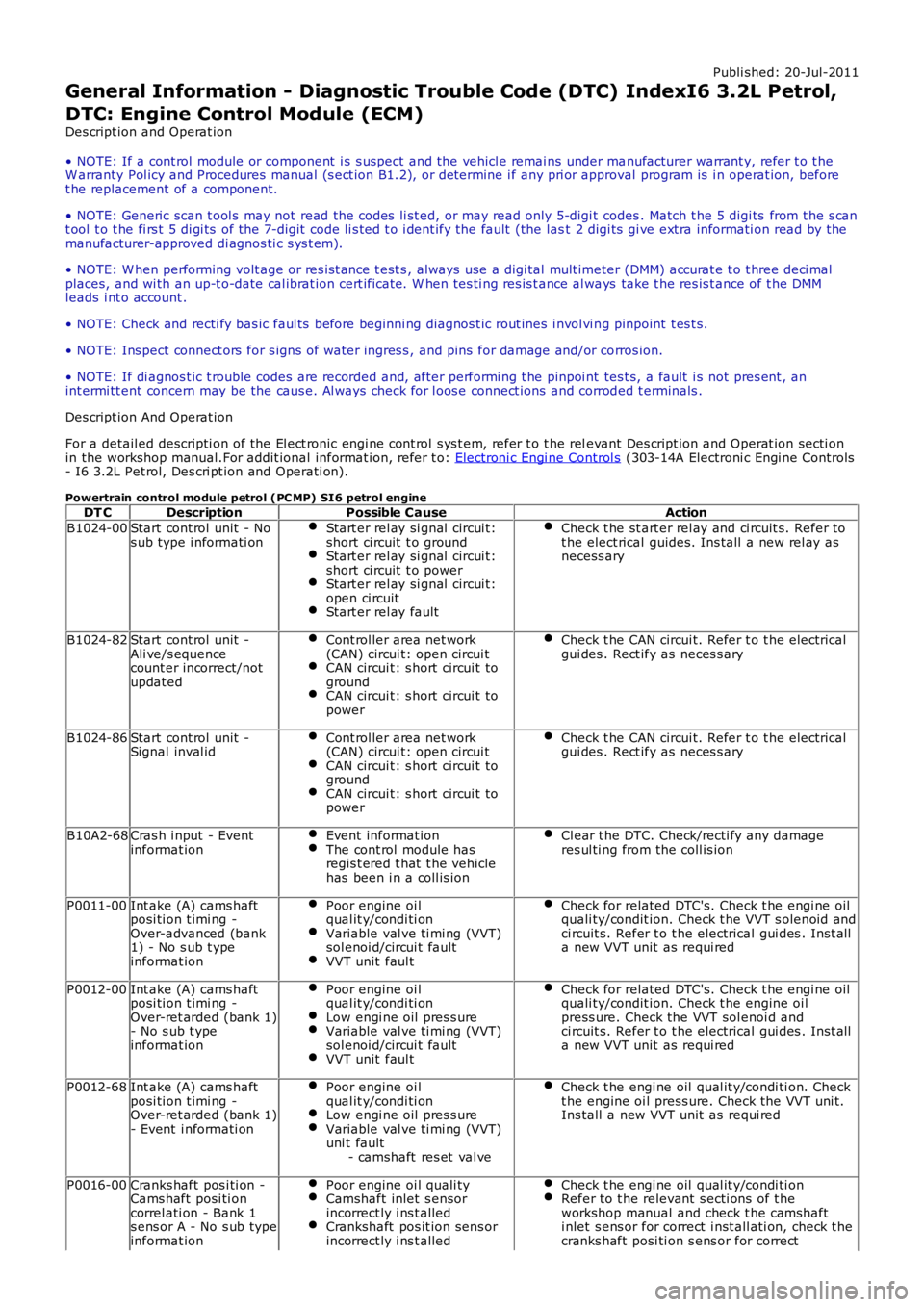

Publi shed: 20-Jul-2011

General Information - Diagnostic Trouble Code (DTC) IndexI6 3.2L Petrol,

DTC: Engine Control Module (ECM)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If di agnos t ic t rouble codes are recorded and, after performi ng t he pinpoi nt tes t s, a fault i s not pres ent , anint ermi tt ent concern may be the caus e. Al ways check for l oos e connect ions and corroded t erminals .

Des cript ion And Operat ion

For a detail ed descripti on of the El ect ronic engi ne cont rol s ys t em, refer t o t he relevant Des cript ion and Operat ion secti onin the workshop manual.For addit ional informat ion, refer t o: Electroni c Engi ne Control s (303-14A Electroni c Engi ne Controls- I6 3.2L Pet rol, Des cri pt ion and Operati on).

Powertrain control module petrol (PC MP) SI6 petrol engineDT CDescriptionPossible CauseAction

B1024-00Start cont rol unit - Nos ub type i nformati onStart er rel ay si gnal circui t:short ci rcuit t o groundStart er rel ay si gnal circui t:short ci rcuit t o powerStart er rel ay si gnal circui t:open ci rcuitStart er rel ay fault

Check t he st art er rel ay and ci rcuit s. Refer tot he elect rical guides. Ins tall a new rel ay asnecess ary

B1024-82Start cont rol unit -Ali ve/s equencecount er incorrect/notupdat ed

Cont rol ler area net work(CAN) circui t: open circui tCAN circui t: s hort circui t togroundCAN circui t: s hort circui t topower

Check t he CAN circui t. Refer t o t he electricalgui des . Rect ify as neces s ary

B1024-86Start cont rol unit -Signal inval idCont rol ler area net work(CAN) circui t: open circui tCAN circui t: s hort circui t togroundCAN circui t: s hort circui t topower

Check t he CAN circui t. Refer t o t he electricalgui des . Rect ify as neces s ary

B10A2-68Cras h i nput - Eventinformat ionEvent informat ionThe cont rol module hasregis t ered t hat t he vehiclehas been i n a coll is ion

Cl ear t he DTC. Check/recti fy any damageres ul ti ng from the coll is ion

P0011-00Int ake (A) cams haftposi ti on t imi ng -Over-advanced (bank1) - No s ub t ypeinformat ion

Poor engine oi lqual it y/condi ti onVariable val ve ti mi ng (VVT)sol enoi d/circui t faultVVT unit faul t

Check for related DTC's. Check t he engi ne oilquali ty/condit ion. Check t he VVT s olenoid andci rcuit s. Refer t o t he electrical gui des . Inst alla new VVT unit as requi red

P0012-00Int ake (A) cams haftposi ti on t imi ng -Over-ret arded (bank 1)- No s ub t ypeinformat ion

Poor engine oi lqual it y/condi ti onLow engi ne oil pres s ureVariable val ve ti mi ng (VVT)sol enoi d/circui t faultVVT unit faul t

Check for related DTC's. Check t he engi ne oilquali ty/condit ion. Check t he engine oi lpress ure. Check the VVT sol enoi d andci rcuit s. Refer t o t he electrical gui des . Inst alla new VVT unit as requi red

P0012-68Int ake (A) cams haftposi ti on t imi ng -Over-ret arded (bank 1)- Event i nformati on

Poor engine oi lqual it y/condi ti onLow engi ne oil pres s ureVariable val ve ti mi ng (VVT)uni t fault- camshaft res et val ve

Check t he engi ne oil qual it y/condi ti on. Checkt he engine oi l press ure. Check the VVT uni t.Ins tall a new VVT unit as requi red

P0016-00Cranks haft pos i ti on -Cams haft posi ti oncorrel ati on - Bank 1s ens or A - No s ub typeinformat ion

Poor engine oi l quali tyCamshaft inlet s ensorincorrect ly i ns t alledCrankshaft pos it ion sens orincorrect ly i ns t alled

Check t he engi ne oil qual it y/condi ti onRefer to t he relevant s ecti ons of t heworkshop manual and check t he camshafti nlet s ens or for correct i nst all ati on, check t hecranks haft posi ti on s ens or for correct

Page 98 of 3229

DT CDescriptionPossible CauseAction

Camshaft inlet s ensor, s hortci rcuit t o ground, s hortci rcuit t o power, open circui t,high res i st anceCamshaft inlet s ensorair-gap t o t arget rot orgreater t han specificati onExces si ve run out on t argetrot orLoos e vari abl e valve t imi ngact uat or chai n dri ve ortens ionersDamaged, worn ti mi ng chain

i nst all ati onRefer to el ect ri cal circui t diagrams and checkt he cams haft inl et sens or ci rcuit for s hortci rcuit t o ground, short ci rcuit t o power, openci rcuit , hi gh res is t anceRefer to t he relevant s ecti ons of t heworkshop manual and check t he camshafti nlet s ens or for correct ai r-gap to target rotors pacing, check target run out is tos pecifi cat ion, check vari abl e valve t imingact uat or chain drive or t ensi oners areoperat ing t o s peci fi cat ion

P0018-00Cranks haft pos i ti on -Cams haft posi ti oncorrel ati on - Bank 2s ens or A - No s ub typeinformat ion

Poor engine oi lqual it y/condi ti onIncorrect ly adjus t edcams haft sDamaged (worn) ti mingchainVariable val ve ti mi ng (VVT)sol enoi d/circui t faultVVT unit faul t

Check t he engi ne oil qual it y/condi ti on. Checkt he cams haft t imi ng and chai n. Recti fy asnecess ary. Check the VVT sol enoi d andci rcuit s. Refer t o t he electrical gui des Ins tal la new VVT unit as requi red

P001A-00Int ake (A) cam profi lecont rol circui t/open(bank 1) - No sub typeinformat ion

Camshaft profi le controlci rcuit : open ci rcuitCamshaft profi le controlci rcuit : s hort circuit t ogroundCamshaft profi le act uat orfault

Check t he cams haft profi le actuat or andci rcuit s. Refer t o t he electrical gui des . Recti fyas necess ary

P001B-00Int ake (A) cam profi lecont rol circui t low(bank 1) - No sub typeinformat ion

Camshaft profi le controlci rcuit : open ci rcuitCamshaft profi le controlci rcuit : s hort circuit t ogroundCamshaft profi le act uat orfault

Check t he cams haft profi le actuat or andci rcuit s. Refer t o t he electrical gui des . Recti fyas necess ary

P001C-00Int ake (A) cams haftprofile cont rol circuithigh (bank 1) - No s ubt ype i nformati on

Camshaft profi le controlci rcuit : s hort circuit t o powerCamshaft profi le act uat orfault

Check t he cams haft profi le actuat or andci rcuit s. Refer t o t he electrical gui des . Recti fyas necess ary

P001D-00Int ake (A) cam profi lecont rol circui t/open(bank 2) - No sub typeinformat ion

Camshaft profi le controlci rcuit : open ci rcuitCamshaft profi le controlci rcuit : s hort circuit t ogroundCamshaft profi le act uat orfault

Check t he cams haft profi le actuat or andci rcuit s. Refer t o t he electrical gui des . Recti fyas necess ary

P001E-00Int ake (A) cams haftprofile cont rol circuitlow (bank 2) - No s ubt ype i nformati on

Camshaft profi le controlci rcuit : open ci rcuitCamshaft profi le controlci rcuit : s hort circuit t ogroundCamshaft profi le act uat orfault

Check t he cams haft profi le actuat or andci rcuit s. Refer t o t he electrical gui des . Recti fyas necess ary

P001F-00Int ake (A) cams haftprofile cont rol circuithigh (bank 2) - No s ubt ype i nformati on

Camshaft profi le controlci rcuit : s hort circuit t o powerCamshaft profi le act uat orfault

Check t he cams haft profi le actuat or andci rcuit s. Refer t o t he electrical gui des . Recti fyas necess ary

P0021-00Int ake (A) cams haftposi ti on t imi ng overadvanced (bank 2) -No s ub t ypeinformat ion

Poor engine oi lqual it y/condi ti onVariable val ve ti mi ng (VVT)sol enoi d/circui t faultVVT unit faul t

Check for related DTC's. Check t he engi ne oilquali ty/condit ion. Check t he VVT s olenoid andci rcuit s. Refer t o t he electrical gui des . Inst alla new VVT unit as requi red

P0022-00Int ake (A) cams haftposi ti on t imi ng overret arded (bank 2) - Nos ub type i nformati on

Poor engine oi lqual it y/condi ti onLow engi ne oil pres s ureVariable val ve ti mi ng (VVT)sol enoi d/circui t faultVVT unit faul t

Check for related DTC's. Check t he engi ne oilquali ty/condit ion. Check t he engine oi lpress ure. Check the VVT sol enoi d andci rcuit s. Refer t o t he electrical gui des . Inst alla new VVT unit as requi red

P0031-00HO2S Heater controlcircuit low (bank 1,s ens or 1) - No s ubt ype i nformati on

HO2S heat er cont rol circui t:short ci rcuit t o groundHO2S heat er cont rol circui t:open ci rcuitHO2S faul t

Check t he HO2S and circuit s . Refer to theel ect ri cal guides . Ins tal l a new s ensor asrequi red

Page 121 of 3229

DT CDescriptionPossible CauseAction

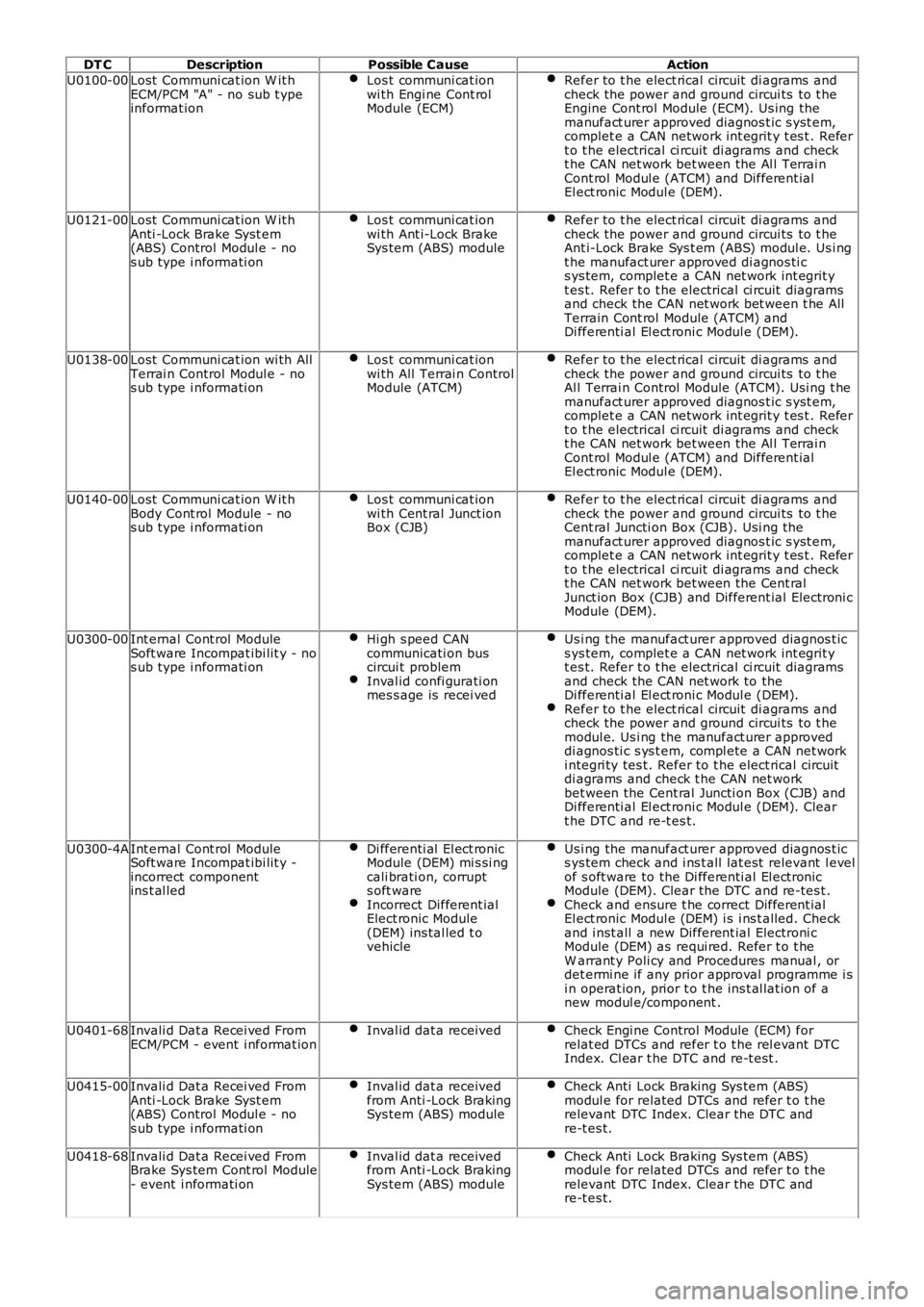

U0100-00Lost Communi cat ion W it hECM/PCM "A" - no sub t ypeinformat ion

Los t communi cat ionwi th Engi ne Cont rolModule (ECM)

Refer to t he elect rical circuit di agrams andcheck the power and ground circui ts to t heEngine Cont rol Module (ECM). Us ing themanufact urer approved diagnos t ic s yst em,complet e a CAN network int egrit y t es t . Refert o t he electrical ci rcuit di agrams and checkt he CAN net work bet ween the Al l Terrai nCont rol Modul e (ATCM) and Different ialEl ect ronic Modul e (DEM).

U0121-00Lost Communi cat ion W it hAnti -Lock Brake Syst em(ABS) Control Modul e - nos ub type i nformati on

Los t communi cat ionwi th Ant i-Lock BrakeSys tem (ABS) module

Refer to t he elect rical circuit di agrams andcheck the power and ground circui ts to t heAnt i-Lock Brake Sys t em (ABS) modul e. Us i ngt he manufact urer approved di agnos ti cs ys tem, complet e a CAN net work int egrit yt es t. Refer t o t he electrical ci rcuit diagramsand check the CAN net work bet ween t he AllTerrain Cont rol Module (ATCM) andDi fferenti al El ect roni c Modul e (DEM).

U0138-00Lost Communi cat ion wi th AllTerrai n Control Modul e - nos ub type i nformati on

Los t communi cat ionwi th All Terrai n ControlModule (ATCM)

Refer to t he elect rical circuit di agrams andcheck the power and ground circui ts to t heAl l Terrai n Control Module (ATCM). Usi ng t hemanufact urer approved diagnos t ic s yst em,complet e a CAN network int egrit y t es t . Refert o t he electrical ci rcuit di agrams and checkt he CAN net work bet ween the Al l Terrai nCont rol Modul e (ATCM) and Different ialEl ect ronic Modul e (DEM).

U0140-00Lost Communi cat ion W it hBody Cont rol Module - nos ub type i nformati on

Los t communi cat ionwi th Cent ral Junct ionBox (CJB)

Refer to t he elect rical circuit di agrams andcheck the power and ground circui ts to t heCent ral Juncti on Box (CJB). Usi ng themanufact urer approved diagnos t ic s yst em,complet e a CAN network int egrit y t es t . Refert o t he electrical ci rcuit di agrams and checkt he CAN net work bet ween the Cent ralJunct ion Box (CJB) and Different ial Electroni cModule (DEM).

U0300-00Int ernal Cont rol ModuleSoft ware Incompat ibi lit y - nos ub type i nformati on

Hi gh s peed CANcommunicati on buscircui t problemInval id confi gurati onmes s age is recei ved

Us i ng the manufact urer approved diagnos t ics ys tem, complet e a CAN net work int egrit yt es t. Refer t o t he electrical ci rcuit diagramsand check the CAN net work to theDi fferenti al El ect roni c Modul e (DEM).Refer to t he elect rical circuit di agrams andcheck the power and ground circui ts to t hemodul e. Us i ng the manufact urer approveddi agnos ti c s ys t em, compl ete a CAN net worki ntegri ty tes t. Refer to t he elect rical circuitdi agrams and check t he CAN net workbet ween the Cent ral Juncti on Box (CJB) andDi fferenti al El ect roni c Modul e (DEM). Cleart he DTC and re-t es t.

U0300-4AInt ernal Cont rol ModuleSoft ware Incompat ibi lit y -incorrect componentins t al led

Di fferenti al El ect ronicModule (DEM) mi s si ngcali brati on, corrupts oft wareIncorrect Different ialElect ronic Module(DEM) ins tal led t ovehicle

Us i ng the manufact urer approved diagnos t ics ys tem check and i ns t all lat est relevant l evelof s oft ware to the Di fferenti al El ect ronicModule (DEM). Clear the DTC and re-tes t .Check and ensure t he correct Different ialEl ect ronic Modul e (DEM) i s i ns t alled. Checkand i nst all a new Different ial Electroni cModule (DEM) as requi red. Refer t o t heW arrant y Poli cy and Procedures manual , ordet ermi ne if any prior approval programme i si n operat ion, prior t o t he ins t al lat ion of anew modul e/component .

U0401-68Invali d Dat a Recei ved FromECM/PCM - event i nformat ionInval id dat a receivedCheck Engi ne Control Module (ECM) forrelat ed DTCs and refer t o t he rel evant DTCIndex. Cl ear t he DTC and re-t est .

U0415-00Invali d Dat a Recei ved FromAnti -Lock Brake Syst em(ABS) Control Modul e - nos ub type i nformati on

Inval id dat a receivedfrom Anti -Lock BrakingSys tem (ABS) module

Check Anti Lock Braking Sys tem (ABS)modul e for related DTCs and refer t o t herelevant DTC Index. Clear the DTC andre-t es t.

U0418-68Invali d Dat a Recei ved FromBrake Sys tem Cont rol Module- event i nformati on

Inval id dat a receivedfrom Anti -Lock BrakingSys tem (ABS) module

Check Anti Lock Braking Sys tem (ABS)modul e for related DTCs and refer t o t herelevant DTC Index. Clear the DTC andre-t es t.

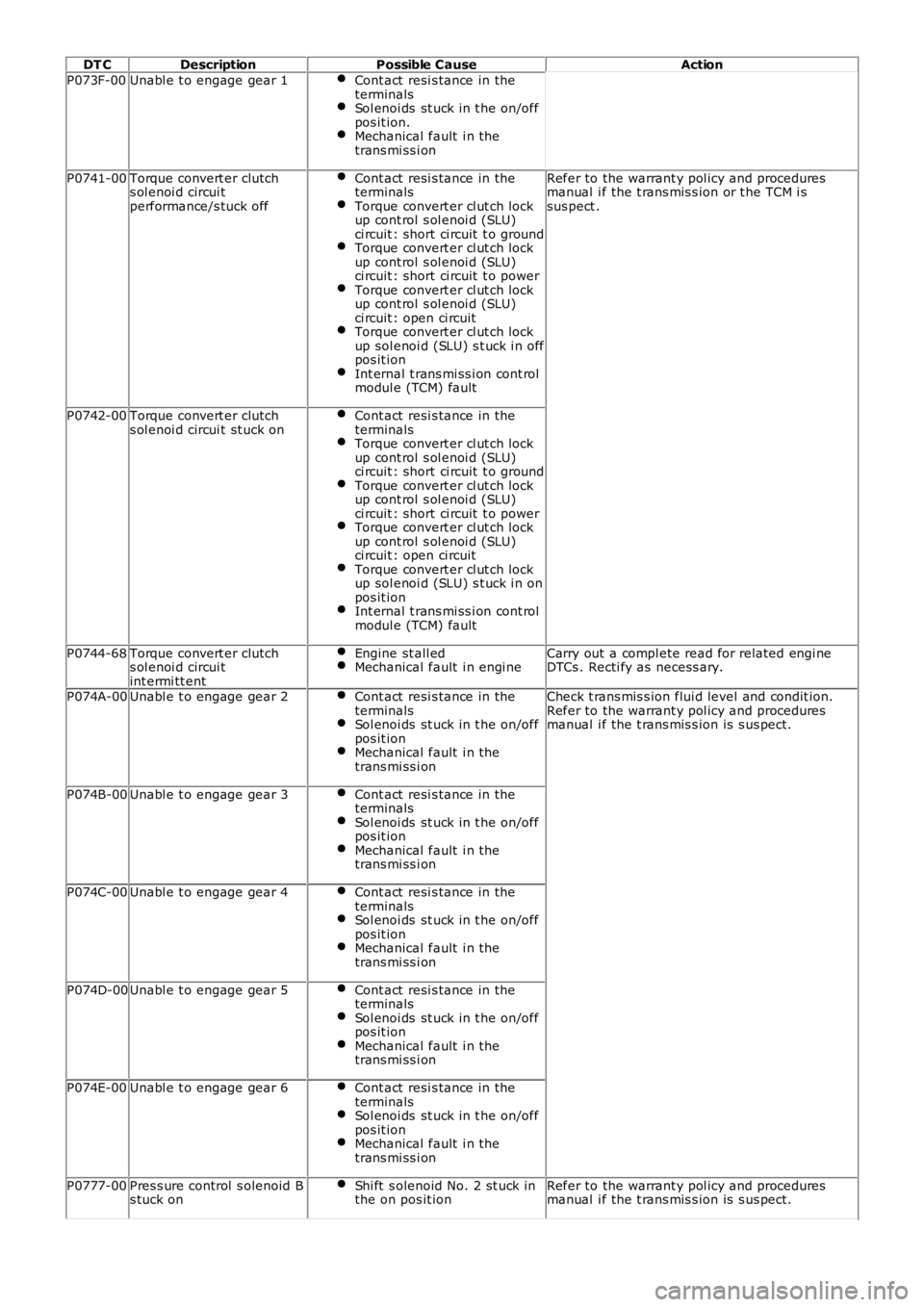

Page 144 of 3229

DT C

Description Possible Cause Action

P073F-00 Unabl e t o engage gear 1 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion. Mechanical fault i n the

trans mi ss i on P0741-00

Torque convert er clutch

s ol enoi d circui t

performance/s tuck off Cont act resi s tance in the

terminals Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o ground Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o power Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : open ci rcuit Torque convert er cl ut ch lock

up sol enoi d (SLU) s t uck i n off

pos it ion Int ernal t rans mi ss i on cont rol

modul e (TCM) fault Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion or t he TCM i s

sus pect .

P0742-00 Torque convert er clutch

s ol enoi d circui t st uck on Cont act resi s tance in the

terminals Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o ground Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : short ci rcuit t o power Torque convert er cl ut ch lock

up cont rol s ol enoi d (SLU)

ci rcuit : open ci rcuit Torque convert er cl ut ch lock

up sol enoi d (SLU) s t uck i n on

pos it ion Int ernal t rans mi ss i on cont rol

modul e (TCM) fault P0744-68

Torque convert er clutch

s ol enoi d circui t

int ermi tt ent Engine st all ed Mechanical fault i n engi ne Carry out a compl ete read for related engi ne

DTCs . Recti fy as necess ary.

P074A-00 Unabl e t o engage gear 2 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on Check t rans mis s ion flui d level and condit ion.

Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.

P074B-00 Unabl e t o engage gear 3 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P074C-00

Unabl e t o engage gear 4 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P074D-00

Unabl e t o engage gear 5 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P074E-00

Unabl e t o engage gear 6 Cont act resi s tance in the

terminals Sol enoi ds st uck in t he on/off

pos it ion Mechanical fault i n the

trans mi ss i on P0777-00

Pres s ure control s olenoid B

s tuck on Shi ft s olenoid No. 2 st uck in

the on pos it ion Refer to the warrant y pol icy and procedures

manual i f the t rans mis s ion is s us pect.