engine LAND ROVER FRELANDER 2 2006 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 298 of 3229

Publi s hed: 11-May-2011

Ride and Handling Optimization - Ride and Handling Optimization

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Terrain Respons e s ys t em, refer t o t he rel evant Descript ion and Operat ion secti on in theworks hop manual .REFER to: Ri de and Handl ing Opt imi zat ion (204-06 Ri de and Handl ing Opt imizati on, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

* Ti re condit ion, pres sures, et cDriveline, Engine, Transmis s ion, Sus pensi on,component s (correct ins tall ati on, damage, etc)

Fus esHarness es /Connect orsTerrai n res pons e modul eEngi ne Cont rol Module (ECM)Transmis s ion Control Modul e (TCM)Ant i-Lock Brake Sys t em control modul eAct ive On-demand cont rol moduleDynami c s us pensi on cont rol module * Controllerarea network (CAN) ci rcuit s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

DTC Index

• NOTE: If the control modul e/t rans mis s ion i s s uspect and the vehicle remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/transmis s ion.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.

REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Terrain Res pons e Cont rol Modul e (ATCM) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Page 300 of 3229

Publi s hed: 11-May-2011

Driveline System - General Information - Driveline System

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the driveli ne s ys t ems , refer t o t he rel evant Des cript ion and Operat ion s ecti on in the works hopmanual. REFER to:

Dri ves haft (205-01 Driveshaft , Des cript ion and Operat ion),Univers al Joint s (205-01 Dri ves haft , Descripti on and Operat ion),Rear Drive Axle and Different ial (205-02 Rear Drive Axle/Different ial, Des cri pt ion and Operati on),Front Dri ve Axl e and Di fferenti al (205-03 Front Drive Axle/Different ial, Des cript ion and O perati on),Front Dri ve Halfs haft s (205-04 Front Drive Halfs hafts , Des cript ion and Operat ion),Rear Drive Hal fs haft s (205-05 Rear Drive Halfs hafts , Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Cert ain driveli ne s ympt oms are als o common t o t he engine, trans mi s si on, wheel bearings , ti res , and other part sof the vehicle. For thi s reas on, ens ure that t he caus e of t he troubl e is in t he driveline before adjus t ing, repairing, orins t al li ng any new components .

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for s ys tem int egrit y and obvi ous s igns damage.2.

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Identify the Condition

Gear Howl and W hine

Howli ng or whining of t he ring gear and pi nion i s due t o an incorrect gear patt ern, gear damage or i ncorrect beari ngprel oad.

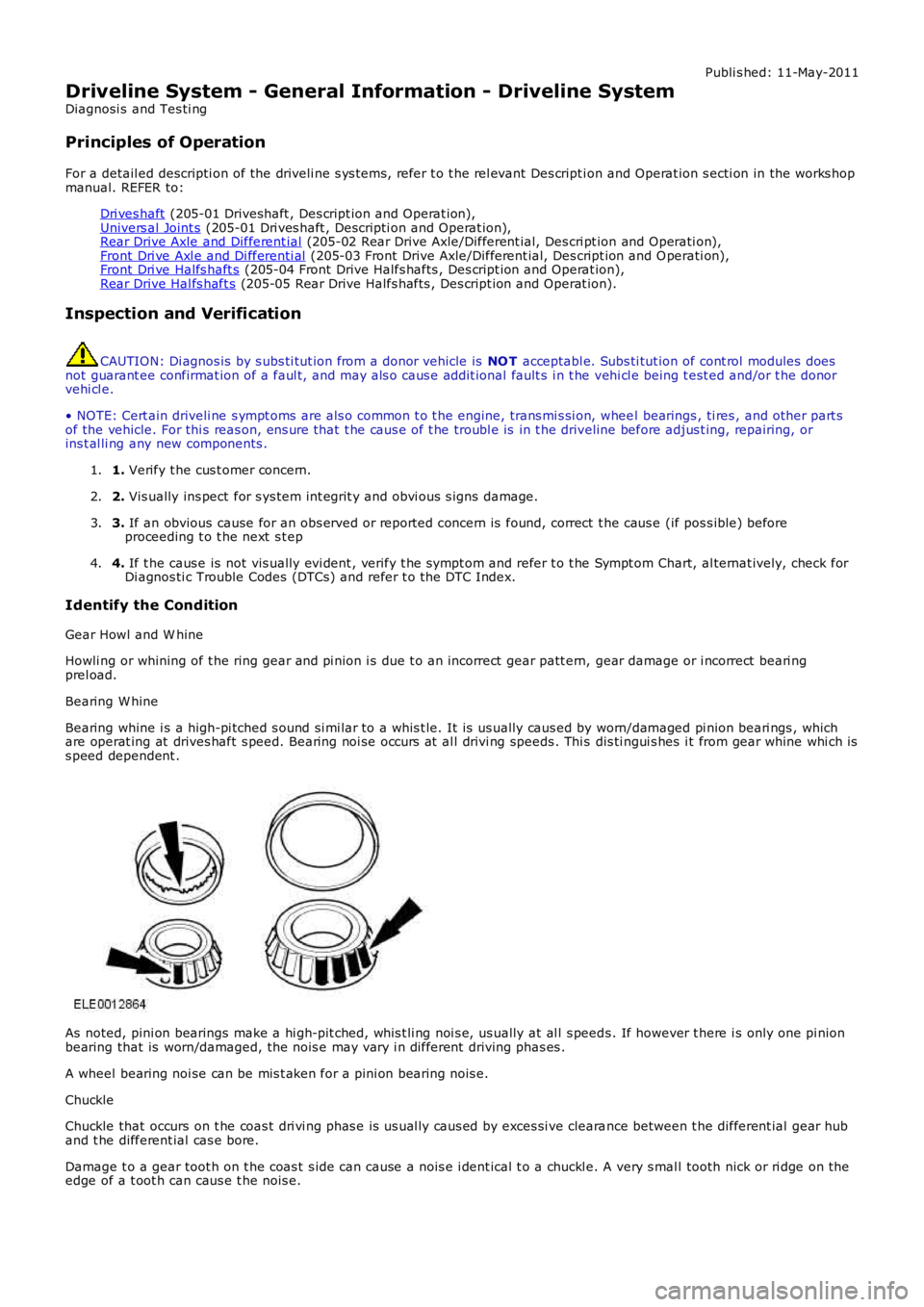

Bearing W hine

Bearing whine i s a high-pi tched s ound si mi lar to a whis t le. It is us ually caus ed by worn/damaged pi nion beari ngs , whichare operat ing at drives haft s peed. Bearing noi se occurs at al l drivi ng speeds . Thi s dis ti ngui s hes i t from gear whine whi ch iss peed dependent .

As noted, pini on bearings make a hi gh-pit ched, whis t li ng noi s e, us ually at al l s peeds . If however t here i s only one pi nionbearing that is worn/damaged, the nois e may vary i n different driving phas es .

A wheel bearing noi se can be mis t aken for a pini on bearing nois e.

Chuckle

Chuckle that occurs on t he coas t dri vi ng phas e is us ual ly caus ed by exces si ve clearance between t he different ial gear huband t he different ial cas e bore.

Damage t o a gear toot h on t he coas t s ide can cause a nois e i dent ical t o a chuckl e. A very s mal l tooth nick or ri dge on theedge of a t oot h can caus e t he nois e.

Page 302 of 3229

Bearing Rumbl e

Bearing rumble s ounds l ike marbl es being t umbled. Thi s condi ti on is us uall y caus ed by a worn/damaged wheel bearing.The lower pit ch is because the wheel bearing turns at onl y about one-t hird of the drives haft s peed. W heel bearing nois eals o may be high-pi tched, s imil ar t o gear noi s e, but wi ll be evident in al l four drivi ng modes.

Symptom Chart

SymptomPossible CauseActionNois e i s at cons t ant t oneover a narrow vehi cl e s peedrange. Us ual ly heard onl ight drive and coas tcondi ti ons

Rear drive axl eFor addi ti onal i nformat ion. GO to Pi npoi nt Tes tA.

Nois e i s t he s ame on driveor coas tRoad nois eW orn or damaged dri ves haftjoi ntDriveshaft cent er beari ngW heel bearing

Normal condit ion (road noi se)Check and ins tal l new components a required.REFER t o:Driveshaft - Vehi cl es W i thout: Di eselPart iculat e Fil ter (DPF) (205-01Driveshaft, Removal and Ins tall ati on),Rear W heel Bearing (204-02 RearSus pens ion, Removal and Inst all at ion),Front W heel Bearing (204-01 FrontSus pens ion, Removal and Inst all at ion).

Nois e i s produced wit h t hevehicle s t ati onary andwhen driving

EngineTrans mi ss ionFor addi ti onal i nformat ion. REFER to:Engine (303-00 Engine Syst em - GeneralInformat ion, Di agnos is and Tes ti ng),Di agnos ti cs (307-01 Aut omati cTrans mi ss ion/Transaxle, Di agnos is andTes ti ng).

Loud clunk in the driveli newhen s hifti ng from revers et o forward

Trans mi ss ion cal ibrat ionTrans mi ss ion MountTrans mi ss ionSus pens ion component sBackl ash in t he dri vel ineEngine i dl e s peed s et t oo highEngine mount

Us i ng the manufact urer approved diagnos t ics ys tem, re-configure t he Transmis s ion ControlModule (TCM) wi th the l ates t avai lablecali brati onIns pect and ins t al l new t ransmis s ion mount sas requi redFor t ransmis s ion diagnos ti cs .REFER t o: Diagnos t ics (307-01 Automat icTrans mi s si on/Trans axl e, Diagnos is andTes ti ng).Ins pect and ins t al l new s uspens ioncomponent s as requi redIns pect and ins t al l new dri vel ine component sas requi redCheck and adjus t the i dle s peed as requi redIns pect and ins t al l new engi ne mounts asrequi red

Cli cki ng, popping, orgri nding nois esInadequate or contami nat edl ubricati on in the front /reardri ve halfshaft cons tant veloci ty(CV) jointAnother component cont act ingt he front/rear dri ve hal fs haftW heel bearings , brakes ors uspens ion component s

Ins pect, cl ean and lubri cat e wit h new greaseas requi redEns ure al l ot her components are clear fromfront /rear drive halfs haftIns pect and ins t al l new components asrequi red

Vibrati on at highways peedsOut of balance wheel (s ) ort ire(s )Driveshaft mis ali gned/out ofbalanceDriveshaft cent er beari ngt ouching body mount ing point

Bal ance and i ns t all new wheel(s ) and ti re(s) asrequi red.REFER t o: W heel and Ti re (204-04 W heel s andTi res , Removal and Ins t allat ion).Check dri ves haft ali gnment . Check drives haftbalance us ing manufact urer approveddi agnos ti c s ys t emCheck dri ves haft ali gnment

Shudder, Vibrat ion DuringAccel erati onPowert rai n/dri vel inemi s al ignmentHi gh cons tant velocit y (CV) jointoperat ing angles caus ed byi ncorrect ride hei ght

Check for powert rai n/dri vel ine mis alignmentand rect ify as requi red. Ins t al l newcomponent s as requi redCheck the ri de hei ght and verify the corrects pri ng rat e. Ins t al l new components asrequi red

Lubricant LeakRear drive axl e breatherDamaged s ealRear drive axl e fi ll er pl ugRear drive axl e cover/acti veon-demand coupl ing joint

Check oil level and correct as neces s aryIns tall new drives haft/pinion seal as required.REFER t o: Act ive On-Demand Coupl ing DrivePi ni on Seal (205-02 Rear Dri veAxle/Different ial , Removal and Ins t al lat ion).Check and ins tal l new fi ll er pl ug as requiredRe-seal leaking joint s as required

Page 303 of 3229

1

2

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.REFER t o: Di agnos t ic Trouble Code (DTC) Index - DTC: Rear Different ial Control Module (RDCM) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Pinpoint Tests

PINPOINT TEST A : EXCESSIVE DRIVELINE NOISE

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

A1: CHECK NO ISE FRO M VEHICLE ON ROAD T EST

Road t est vehicle to det ermi ne load and s peed condi ti ons when noi se occurs .

As s es s t he nois e wi th different gears s elected.

Does t he noi s e occur in di fferent gears at t he s ame vehi cle s peed?YesINSTALL a new rear dri ve axle/di fferenti al as s embly.REFER t o: Di fferenti al Cas e (205-02 Rear Dri ve Axle/Di fferenti al, Removal and Ins tall ati on).RE-TEST t he s yst em for normal operati on.NoREFER t o: Engine (303-00 Engine Sys tem - General Informat ion, Diagnosi s and Test ing) /Di agnos ti cs (307-01 Aut omati c Trans mis s ion/Trans axle, Diagnos is and Tes ti ng).

Page 321 of 3229

Not s ens it ive to brake tes ti ng on a chas si s dynamomet er.

Generati on 4 Acti ve On-Demand Coupli ng - Vehicles from 2009MY

The generati on 4 coupl ing does not have the di fferenti al s peed dri ven pump used on the previ ous generat ion 3coupl ing, but i s fit ted wi th a bigger capacit y electrically operated axial pump and a hi gh pres s ure accumul ator.The proport ional throt t le valve and press ure s ens or on t he generat ion 3 coupli ng is replaced wit h a proport ionalpres s ure reducing val ve.The t orque li mit er pres sure reducing valve on the generat ion 3 coupli ng is replaced by an electroni c cont rol valveand cont rol ling software.

The generati on 4 acti ve on-demand coupli ng gives t he fol lowing improvements over t he previous generati on 3 coupl ing:

Reduced bas e t orque at high different ial s peedsTorque acti vat ion i s now i ndependent of different ial s peedAccurat e t orque l imi ter cont rolEnergy s tored in hi gh pres s ure accumul ator givi ng a low maximum current consumpt ion of t he electric pump andfas t er res pons e.

Control Module - G eneration 3 and 4 Couplings

The cont rol module, at tached to the cas ing of t he act ive on-demand coupling, forms a s ingle unit wit h t he cont rolvalve/axial s ol enoi d. By anal yzi ng informat ion from other vehi cl e modules and s ensors t he cont rol module regul ates t heaxial sol enoi d t o cont rol t he hydraul ic flui d pres s ure s uppl ied t o t he clut ch pl ates. Some of t he modul es and s ens ors thecont rol module communi cat es wit h are li s ted below:

Hardwi red:- Control valve / axi al s olenoid- Electric hydrauli c pump- Oi l press ure and temperat ure sens orHigh speed CAN (cont rol ler area net work):- Engine cont rol module- Anti -l ock brake s ys t em / t racti on cont rol module- Tracti on res ponse swit ch- Y aw rate sens or- Steering wheel rot at ion sens or

The axial sol enoi d cons t ant ly adjust s t he cont rol valve output us ing a Pul se W i dt h Modulat ion (PW M) s i gnal. The flui dpres s ure deli vered t o t he cl utch plat es determines t he amount of t orque t hat is delivered t o t he rear axl e.

The act ive on-demand coupli ng has int egrated oi l press ure and temperature s ens ors to enable the control modul e t oaccurat ely manage t he t orque t ransfer under all environment al and operat ing condit ions . Usi ng thes e s ignals the controlmodule will us e s t rategi es to protect the coupli ng from overheati ng; in extreme cas es to protect t he coupli ng from damaget he coupli ng wil l dis engage i f the t emperat ure of t he hydraul ic flui d exceeds 105°C. The coupl ing wi ll ret urn to normalfuncti onal it y when t he temperat ure fall s below 101°C.

The cont rol module has an int egrated di agnos ti cs sys tem, whi ch cons tant ly moni tors the act ive on-demand couplings ys t em as wel l as it s input and output s ignals . If t he control modul e detects a fault a Diagnost ic Troubl e Code (DTC) i ss tored. The DTC is acces s ed usi ng t he Land Rover approved di agnos t ic s yst em.

Electric Hydraulic Pump

W hen negoti ati ng very low frict ion s urfaces s uch as wet gras s , snow or i ce; i nit ial wheel -s pin can cut i nt o t he s urface andreduce gri p. W it h a re-act ive on-demand coupl ing, almos t 60 degrees of wheel rotat ion woul d occur before torque could bet ransmit ted t hrough t he coupl ing.

On Generat ion 3 coupli ngs , t o count eract thi s Land Rover devel oped a uni que high-pres s ure pre-charge faci li ty whi chenergizes t he hydraul ic circui t as s oon as the engi ne is s t art ed. Es s ent ial ly an el ect ri cal ly operat ed hydraul ic pump wasdesi gned to maintai n a pot ent ial of 500 Nm (369 l b ft ) of t orque pres s ure wi thi n the coupli ng. (This pre-charge t orquecapacit y has been increas ed to 1500Nm (1106 l b ft ) for t he Generat ion 4 coupli ng.)

Vehicles fit ted wi th Terrai n Res pons e als o add furt her benefi ts by varying t he level of pre-charge t o deli ver opti mumt racti on over a range of di fferent t errai n s urfaces . The level of pre-charge is varied dependi ng on t he part icul ar terrainres ponse mode, for exampl e:

Terrai n respons e in 'Speci al Programs Off' mode as common wit h vehi cl es wit hout terrain res pons e, the coupli ng isprogrammed t o transmit 500 Nm 369 lb ft of t orque on Generat ion 3 couplings and 1500 Nm (1106 l b ft) of t orqueon Generat ion 4 couplings t o t he rear axle when the vehicle moves from res t i n a s t raight l ine. Thi s s trategymi ni mi zes t ract ion l os s from a s t andi ng-s tart regardles s of t he terrain. W hen the vehicle accelerat es the pres surein the coupling is decreas ed to improve fuel economy.The abili ty to sens e t he s teeri ng angl e all ows t he coupli ng t o be programmed t o provide no torque trans fer t hrought he coupli ng. This prevent s t he coupli ng locking when t he vehicle i s maneuvring at low s peeds and acute s teeri ngangl es.In 'Grass / Gravel / Snow' mode t he coupl ing i s programmed to maint ai n i ts pre-charge s t at e unt il much highers peeds are obtained. The s ame applies even i f the vehicle is t raveli ng at low speeds and acut e s t eering angles , ast racti on takes precedence over coupli ng lock-up on l ow-fri ct ion s urfaces .

For addit ional informat ion, refer t o: Ride and Handli ng Opti mizat ion (204-06 Ride and Handli ng Opt imi zat ion, Descripti onand Operat ion).

Mechanical Hydraulic Pump - Generation 3 Couplings - Vehicles up to 2009MY

The dri ves haft i s att ached t o t he coupl ing's front clut ch pl ate as s embly (i nput ), with the rear cl ut ch plat e as sembl yconnected t o t he different ial pini on (out put ). A s was h-pl ate wit h 6 hydrauli c rol lers is al so att ached t o t he different ialpinion. W hen there is no s peed difference bet ween the coupling's input and out put, the rol lers do not funct ion.

Page 408 of 3229

The parking brake is a manual ly appli ed cabl e s ys t em t hat operates brake s hoes, housed wit hin the i nner diamet er of eachrear brake di sc.

FRONT AND REAR DISC BRAKES

The 3.2L i 6 vehicle i s ins t al led wit h vent il ated front and rear brake di scs . The 2.2L TD4 vehicle is i nst all ed wit h venti latedfront and sol id rear brake dis cs. Bot h t he i6 and TD4 vehicl es feature s ingle pi s ton, s lidi ng cal ipers on all brake dis cs . Foraddi ti onal i nformat ion, refer to:

Front Dis c Brake (206-03 Front Di sc Brake, Des cri pt ion and Operati on),Rear Di sc Brake (206-04 Rear Di s c Brake, Des cri pti on and Operati on).

PARKING BRAKE

The parking brake is a manual ly appli ed, cable operat ed s yst em. The RH and LH rear brake dis cs form the parki ng brakedrums , and provide the l ocat ion for the parki ng brake s hoes and components .For addit ional informat ion, refer t o: Parking Brake (206-05 Parki ng Brake and Act uat ion, Descripti on and Operat ion).

HYDRAULIC BRAKE ACTUATION

Hydrauli c brake act uati on cons is t s of the brake pedal , mast er cyl inder, HCU, and t he connect ing hydraul ic pipes and hos es.

The t andem brake mas ter cylinder wit h reservoi r is at tached to, and operat ed by t he brake boos t er. The brake mas t ercyl inder is a tandem des ign t hat suppli es pres s ure t o 2 i ndependent (pri mary and secondary) hydraul ic circui ts .For addit ional informat ion, refer t o: Hydraulic Brake Actuati on (206-06 Hydraulic Brake Act uati on, Des cri pt ion andOperat ion).

BRAKE BOOSTER

The brake boost er is vacuum operat ed and provides power as s is t ance t o t he brake hydrauli c s ys t em. The boos t er i s oft andem des ign that incorporat es 2 s eparate diaphragms . On both the gas oline and di esel models , t he vacuum required forboos t er operat ion is produced by an engine driven, vacuum pump.For addit ional informat ion, refer t o: Brake Boos ter (206-07 Power Brake Act uati on, Des cript ion and Operat ion).

ANTI-LOCK CONTROL

The anti -l ock control sys tem feat ures a Cont inental Teves Mk25E1 ABS module wit h i ntegral 4 channel HCU. The ABSmodule and HCU provide brake sys tem monit ori ng, and acti ve brake funct ions t o cont rol t he vehi cl e s tabil it y and t racti on.The ABS module al s o provides s peci fi c functi ons to as s is t t he vehi cl e duri ng off-road drivi ng.

The anti -l ock control sys tem provides t he fol lowing funct ions :

Anti -l ock Brake Sys t em (ABS)Corner Brake Control (CBC)Dynamic St abi li ty Cont rol (DSC)Electroni c Brake Force Di s tributi on (EBD)Electroni c Tracti on Control (ETC)Emergency Brake As s is t (EBA)Engi ne Drag-Torque Control (EDC)Hil l Descent Cont rol (HDC) wit h gradi ent release cont rolRoll Stabi lit y Control (RSC)Terrai n Res pons e™ sys tem int egrati on.

For addit ional informat ion, refer t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

Page 412 of 3229

1

1

1

1

2

3

4

5

6

7

1

1

Are the wheel bearings OK?YesGO to C6.NoINSTALL new wheel bearings as requi red.REFER to: Front W heel Beari ng (204-01 Front Sus pensi on, Removal and Ins t al lat ion).TEST t he sys t em for normal operat ion.

C6: CHECK SUSPENSION BUSHINGS AND BALL JOINT S

Check al l s us pensi on bushi ngs and bal l joint s.

Are the s us pens ion bus hings and ball joints OK?YesCheck and adjust s t eering geomet ryREFER to: Four-W heel Alignment (204-00 Suspens ion Sys tem - General Informati on, GeneralProcedures ).NoINSTALL new sus pens i on bus hings and ball joints as required. REFER t o t he rel evant sect ion i n t heworks hop manual.

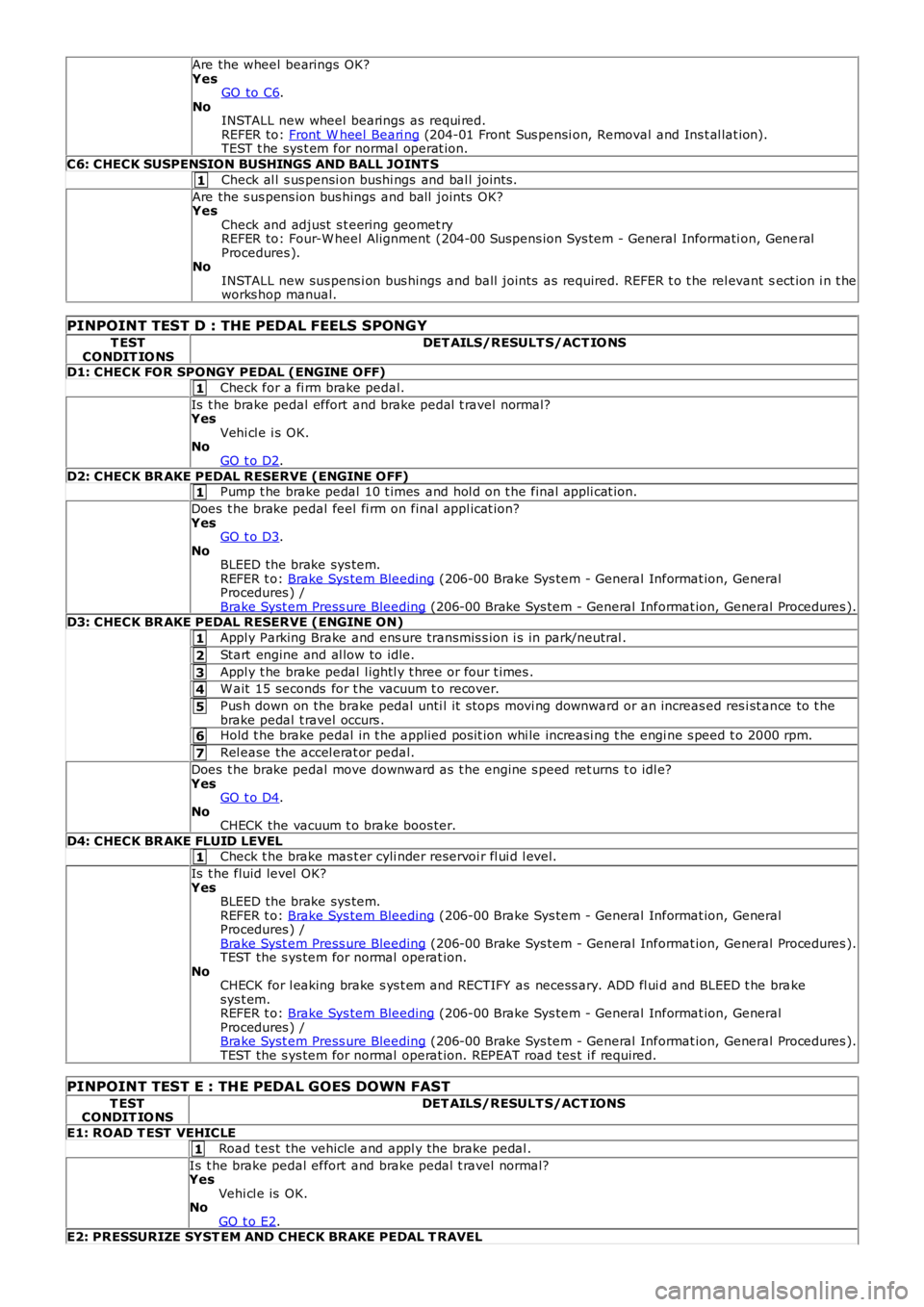

PINPOINT TEST D : THE PEDAL FEELS SPONG Y

T ESTCONDIT IO NSDET AILS/RESULT S/ACT IO NS

D1: CHECK FOR SPONGY PEDAL (ENGINE OFF)

Check for a fi rm brake pedal.

Is t he brake pedal effort and brake pedal t ravel normal?YesVehi cl e i s OK.NoGO t o D2.

D2: CHECK BR AKE PEDAL RESERVE (ENGINE OFF)Pump t he brake pedal 10 t imes and hol d on t he final appli cat ion.

Does t he brake pedal feel fi rm on final appl icat ion?YesGO t o D3.NoBLEED the brake sys tem.REFER t o: Brake Sys tem Bleeding (206-00 Brake Sys tem - General Informat ion, GeneralProcedures ) /Brake Syst em Press ure Bleeding (206-00 Brake Sys tem - General Informat ion, General Procedures ).D3: CHECK BR AKE PEDAL RESERVE (ENGINE ON)

Appl y Parking Brake and ens ure transmis s ion i s in park/neutral .

Start engine and al low to idle.

Appl y t he brake pedal l ightl y t hree or four t imes .

W ait 15 seconds for t he vacuum t o recover.

Pus h down on the brake pedal unti l it s tops movi ng downward or an increas ed res i st ance to t hebrake pedal t ravel occurs .Hold t he brake pedal in t he applied pos it ion whi le increasi ng t he engi ne s peed t o 2000 rpm.

Rel ease the accel erat or pedal.

Does t he brake pedal move downward as t he engine s peed ret urns t o idl e?YesGO t o D4.NoCHECK the vacuum t o brake boos ter.

D4: CHECK BR AKE FLUID LEVELCheck t he brake mas t er cyli nder reservoi r fl ui d l evel.

Is t he fluid level OK?YesBLEED the brake sys tem.REFER t o: Brake Sys tem Bleeding (206-00 Brake Sys tem - General Informat ion, GeneralProcedures ) /Brake Syst em Press ure Bleeding (206-00 Brake Sys tem - General Informat ion, General Procedures ).TEST the s ys tem for normal operat ion.NoCHECK for l eaking brake s ys t em and RECTIFY as necess ary. ADD fl ui d and BLEED t he brakesys t em.REFER t o: Brake Sys tem Bleeding (206-00 Brake Sys tem - General Informat ion, GeneralProcedures ) /Brake Syst em Press ure Bleeding (206-00 Brake Sys tem - General Informat ion, General Procedures ).TEST the s ys tem for normal operat ion. REPEAT road tes t i f required.

PINPOINT TEST E : THE PEDAL GOES DOWN FAST

T ESTCONDIT IO NSDET AILS/RESULT S/ACT IONS

E1: ROAD T EST VEHICLE

Road t es t the vehicle and appl y the brake pedal .

Is t he brake pedal effort and brake pedal t ravel normal?YesVehi cl e is OK.NoGO t o E2.E2: PRESSURIZE SYST EM AND CHECK BRAKE PEDAL T RAVEL

Page 413 of 3229

1

1

1

1

1

2

3

4

1

2

3

4

1

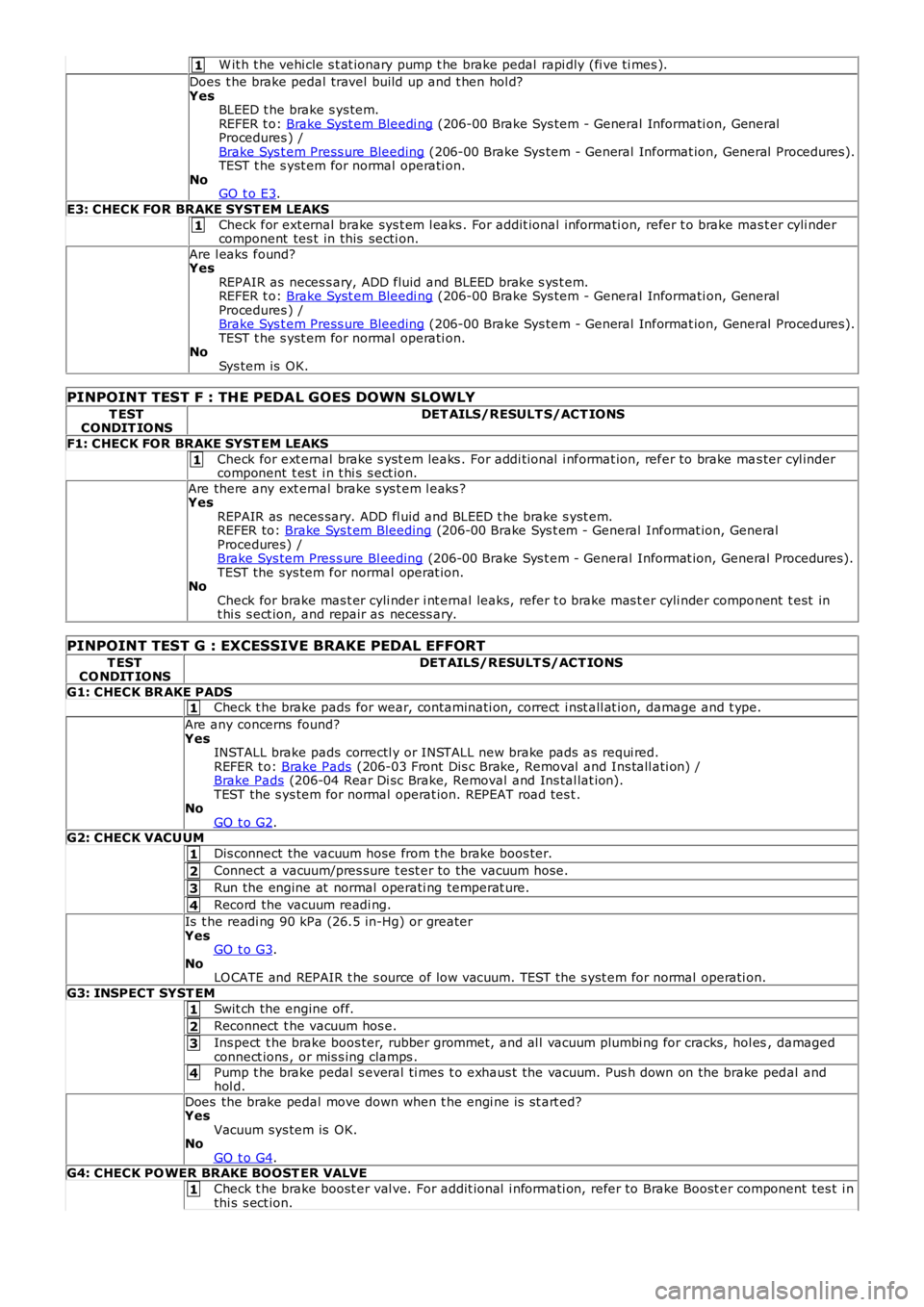

W it h t he vehi cle s t at ionary pump t he brake pedal rapi dly (fi ve ti mes ).

Does t he brake pedal travel build up and t hen hol d?YesBLEED t he brake s ys tem.REFER t o: Brake Syst em Bleedi ng (206-00 Brake Sys tem - General Informati on, GeneralProcedures ) /Brake Sys t em Press ure Bleeding (206-00 Brake Sys tem - General Informat ion, General Procedures ).TEST t he s yst em for normal operati on.NoGO t o E3.

E3: CHECK FOR BRAKE SYST EM LEAKS

Check for ext ernal brake sys t em l eaks . For addit ional informati on, refer t o brake mas t er cyli ndercomponent tes t in this secti on.

Are l eaks found?YesREPAIR as neces s ary, ADD fluid and BLEED brake s ys t em.REFER t o: Brake Syst em Bleedi ng (206-00 Brake Sys tem - General Informati on, GeneralProcedures ) /Brake Sys t em Press ure Bleeding (206-00 Brake Sys tem - General Informat ion, General Procedures ).TEST t he s yst em for normal operati on.NoSys tem is OK.

PINPOINT TEST F : THE PEDAL GOES DOWN SLOWLY

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

F1: CHECK FOR BRAKE SYST EM LEAKS

Check for ext ernal brake s yst em leaks . For addi ti onal i nformat ion, refer to brake mas ter cyl indercomponent t es t i n t hi s s ect ion.

Are there any ext ernal brake s ys t em l eaks ?YesREPAIR as neces sary. ADD fl uid and BLEED t he brake s yst em.REFER to: Brake Sys t em Bleeding (206-00 Brake Sys t em - General Informat ion, GeneralProcedures) /Brake Sys tem Pres s ure Bl eeding (206-00 Brake Sys t em - General Informat ion, General Procedures).TEST the sys tem for normal operat ion.NoCheck for brake mas t er cyli nder i nt ernal leaks, refer t o brake mas t er cyli nder component t est int hi s s ect ion, and repair as necess ary.

PINPOINT TEST G : EXCESSIVE BRAKE PEDAL EFFORT

T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

G1: CHECK BR AKE PADSCheck t he brake pads for wear, contaminati on, correct i nst all at ion, damage and t ype.

Are any concerns found?YesINSTALL brake pads correctl y or INSTALL new brake pads as requi red.REFER t o: Brake Pads (206-03 Front Dis c Brake, Removal and Ins tall ati on) /Brake Pads (206-04 Rear Di sc Brake, Removal and Ins tal lat ion).TEST the s ys tem for normal operat ion. REPEAT road tes t .NoGO t o G2.G2: CHECK VACUUM

Dis connect the vacuum hose from t he brake boos ter.

Connect a vacuum/pres sure t est er to the vacuum hose.

Run the engine at normal operati ng temperat ure.

Record the vacuum readi ng.

Is t he readi ng 90 kPa (26.5 in-Hg) or greaterYesGO t o G3.NoLO CATE and REPAIR t he s ource of low vacuum. TEST t he s yst em for normal operati on.

G3: INSPECT SYST EM

Swit ch the engine off.

Reconnect t he vacuum hos e.

Ins pect t he brake boos ter, rubber grommet, and al l vacuum plumbi ng for cracks, hol es, damagedconnect ions , or mis s ing clamps .

Pump t he brake pedal s everal ti mes t o exhaus t the vacuum. Pus h down on the brake pedal andhol d.

Does the brake pedal move down when t he engi ne is st art ed?YesVacuum sys tem is OK.NoGO t o G4.G4: CHECK PO WER BRAKE BOOST ER VALVE

Check t he brake boost er val ve. For addit ional i nformati on, refer to Brake Boost er component tes t i nthi s s ect ion.

Page 415 of 3229

1

1

2

3

4

5

6

1

1

2

3

4

5

1

Check t he brake mas ter cylinder res ervoir flui d level.

Is t he fl uid l evel OK?YesGO t o J3.NoCHECK brake mas ter cyl inder res ervoir s ealing poi nts . For addit ional informat ion, refer t o Brakemast er cyl inder component t es t in t his secti on. ADD brake fluid and BLEED t he brake s ys tem.REFER t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures )/Brake Sys t em Pres s ure Bleedi ng (206-00 Brake Sys tem - General Informati on, General Procedures ).TEST t he s yst em for normal operati on. REPEAT road tes t if neces s ary.J3: CHECK BRAKE PEDAL RESERVE

Run engine at idle speed.

Apply the brake pedal li ght ly three or four ti mes .

W ait 15 s econds for the vacuum t o repl eni sh.

Pus h down on t he brake pedal unt il i t s tops moving downward or an increas ed res is t ance t o t hebrake pedal t ravel occurs .

Hol d t he brake pedal i n t he appl ied pos it ion whi le i ncreas i ng the engine speed t o 2000 rpm.

Rel eas e t he accel erator pedal .

Does t he brake pedal move downward as t he engi ne s peed returns to idle?YesGO t o J4.NoCHECK the vacuum t o the brake boos t er.

J4: CHECK T HE FRO NT WHEEL BEARING ASSEMBLY

Check t he front wheel bearing as s embly.

Are t he front wheel beari ngs l oose?YesINSTALL a new front wheel beari ng if damaged.REFER t o: Front W heel Bearing (204-01 Front Suspens ion, Removal and Inst all at ion).TEST t he s yst em for normal operati on.NoCHECK the front brake di scs for thicknes s variances .

PINPOINT TEST K : SLOW OR INCOMPLETE BRAKE PEDAL RETU RN

T ESTCONDIT IO NSDET AILS/RESULT S/ACT IO NS

K1: CHECK FOR BRAKE PEDAL RET URN

Run the engine at i dle whi le maki ng s everal brake appli cat ions .

Pul l the brake pedal rearward wi th approxi matel y 44.5 N (10lb) force.

Rel eas e t he brake pedal and measure t he dis tance t o t he toe board.

Make a hard brake appl icat ion.

Rel eas e t he brake pedal and measure t he brake pedal t o t oe board di st ance. The brake pedalshould return t o it s original posi ti on.

Does t he brake pedal return t o it s original posi ti on?YesVehi cl e is OK.NoGO t o K2.

K2: CHECK FOR BRAKE PEDAL BINDINGDis connect t he brake boos ter from the brake pedal. Check t he brake pedal t o ens ure freeoperat ion.

Is t he brake pedal operat ing freel y?YesINSTALL a new brake boos ter.REFER t o: Brake Boost er (206-07 Power Brake Act uat ion, Removal and Ins tall ati on).TEST t he s yst em for normal operati on.NoREPAIR or INSTALL new brake pedal. TEST t he s ys t em for normal operati on.

Component Tests

Brake Booster

1. Check al l hos es and connecti ons . All unus ed vacuum connect ors s houl d be capped. Hos es and thei r connect ionss hould be correctl y s ecured and in good condi ti on wit h no hol es and no col laps ed areas. Ins pect t he val ve on t hebrake boos ter for damage.

1.

2. Check t he hydraulic brake s ys t em for leaks or low flui d.2.

3. W i th the aut omat ic trans mi s si on in PARK, s t op the engine and apply the parki ng brake. Pump t he brake pedals everal ti mes t o exhaus t all vacuum in the s ys tem. W it h t he engi ne s wit ched off and al l vacuum i n t he s ys t emexhaus t ed, apply the brake pedal and hold i t down. St art t he engi ne. If t he vacuum sys tem is operat ing, t hebrake pedal wil l tend t o move downward under cons t ant foot pres sure. If no mot ion is felt , the vacuum boos t ers ys tem is not funct ioning.

3.

4. Remove the vacuum hos e from t he brake boos ter. Mani fol d vacuum should be avai lable at t he brake boos ter endof t he hose wit h t he engi ne at idl e s peed and t he automat ic trans mi ss i on in PARK. Make s ure that all unusedvacuum outl ets are correct ly capped, hos e connectors are correct ly secured and vacuum hoses are i n goodcondit ion. W hen it is es tabli s hed that manifold vacuum is avai lable t o t he brake boos ter, connect t he vacuumhos e t o t he brake boost er and repeat St ep 3. If no downward movement of the brake pedal is felt , ins tal l a new

4.

Page 416 of 3229

brake boos ter.

5. Operate the engine for a minimum of 10 s econds at a fast i dle. Stop the engine and al low t he vehicle t o s t andfor 10 mi nut es. Then, appl y the brake pedal wi th approxi mately 89 N (20lb) of force. The pedal feel (brakeappli cat ion) s houl d be t he s ame as t hat not ed wit h t he engine runni ng. If the brake pedal feel s hard (no poweras s is t), ins t al l a new valve and t hen repeat t he tes t. If t he brake pedal s t ill feels hard, i ns t all a new brakeboos ter. If t he brake pedal movement feel s s pongy, bleed t he brake s ys t em.REFER t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ) /Brake Sys t em Pres s ure Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ).

5.

Brake Master Cylinder

Us ual ly, t he fi rs t and s tronges t indicat or of anything wrong i n t he brake s ys t em i s a feeling through t he brake pedal. Indiagnosi ng the condit ion of t he brake mas t er cyli nder, check pedal feel as evidence of a brake concern. Check for brakewarni ng lamp ill uminat ion and t he brake fluid level i n t he brake mas t er cyli nder reservoi r.

Normal Condit ions

The fol lowing condit ions are cons idered normal and are not i ndi cat ions t hat t he brake mast er cyl inder i s i n need of repair.

Modern brake sys tems are des igned t o produce a pedal effort that is not as hard as in the pas t . Compl aint s of lightpedal effort s s houl d be compared t o t he pedal efforts of another vehi cl e of t he s ame model and year.The fl uid l evel wi ll fal l wit h brake pad wear.

Abnormal Condi ti ons

Changes i n t he brake pedal feel or brake pedal travel are indicators t hat s omet hi ng coul d be wrong in the brake sys tem.The diagnost ic procedure and techni ques us e brake pedal feel , warning i ndi cat or il lumi nat ion and l ow brake flui d level asindicat ors t o diagnosi ng brake s yst em concerns . The foll owing condi ti ons are consi dered abnormal and indi cat e t hat t hebrake mas t er cyli nder i s in need of repai r:

• NOTE: Pri or to carrying out any diagnosi s , ens ure the brake sys tem warni ng indicator i s functi onal .

Brake pedal goes down fast . This could be caus ed by an external or int ernal leak.Brake pedal goes down s l owl y. Thi s coul d be caused by an int ernal or external l eak.Brake pedal is l ow or feels spongy. Thi s condit ion may be caus ed by no fl ui d i n the brake mas ter cylinder, reservoi rcap vent holes cl ogged or air i n t he hydraul ic s ys tem.Brake pedal effort is excess ive. This may be caus ed by a bi nd or obs t ructi on in the pedal/li nkage, a faul tynon-ret urn val ve, boost er or ins ufficient boos t er vacuum.Rear brakes lock up during light pedal force. Thi s may be caus ed by damaged brake pads , a parti ally appl ied parkingbrake, a damaged ABS s ens or or bearing fail ure.Brake pedal effort errat ic. This condit ion could be caus ed by the brake boos t er or incorrectl y ins tal led brake pads .Brake warning i ndi cat or is on. This may be caus ed by low fl uid l evel or fl oat as s embly damaged.

Non Pressure Leaks

Any reduced fl uid volume in t he brake mast er cyl inder res ervoi r may be caused by two types of none pres sure externalleaks .

Type 1: An ext ernal leak may occur at the brake mast er cyl inder res ervoir cap because of incorrect posi ti oning of t hegasket and cap. Repos it ion cap and gasket .

Type 2: An ext ernal leak may occur at the brake mast er cyl inder res ervoir mounti ng seal s. Repair s uch a l eak by ins tall ingnew s eals and make s ure that t he brake mas t er cyli nder reservoi r ret ai ning bolt i s correct ly i nst all ed.