weight LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 268 of 3229

10.

Installation 1. CAUTION: Make s ure that new bolt s are ins tal led.

Inst all t he s hock abs orber to t he hub as s embl y.

T orque: 110 Nm 1.

Inst all t he s hock abs orber and spring as s embl y.

T orque: 32 Nm 2.

3. CAUTION: Nut s and bol ts mus t be ti ght ened wit h t he weight

of t he vehi cl e on t he s us pensi on.

Inst all t he lower s uspens ion arms.

3.

Inst all t he brake li ne and wheel speed s ensor brackets .

T orque: 10 Nm 4.

5. W ARNING: Make sure t hat a new nut is i nst all ed.

Secure t he s tabil izer bar l ink.

T orque: 60 Nm 5.

6. CAUTIONS: Make s ure that t he mat ing faces are clean and free of foreign

mat eri al . Make s ure that t he brake hos e is not t wis t ed and is correctl y

l ocated.

Secure t he brake caliper and anchor plat e t o t he wheel knuckl e.

T orque: 110 Nm 6.

7. CAUTION: Nut s and bol ts mus t be ti ght ened wit h t he weight

of t he vehi cl e on t he s us pensi on.

Support weight of vehi cl e on a jack at the rear hub.

7.

Tight en the trai li ng arm nut and bol t.

8.

Page 308 of 3229

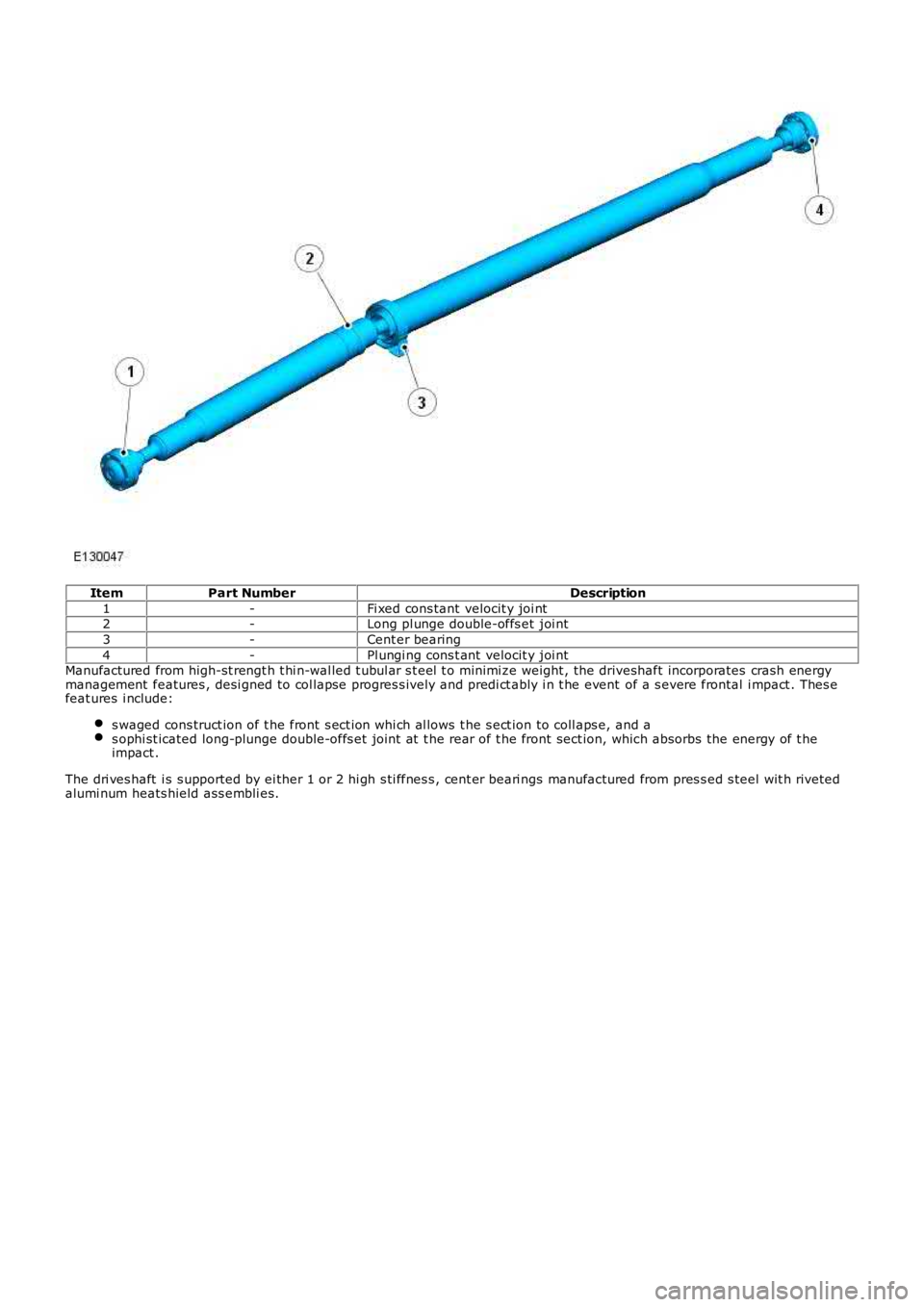

ItemPart NumberDescription

1-Fi xed cons tant velocit y joi nt2-Long pl unge double-offs et joi nt

3-Cent er bearing

4-Pl ungi ng cons t ant velocit y joi ntManufactured from high-st rengt h t hi n-wal led t ubul ar s t eel t o minimi ze weight , the driveshaft incorporates crash energymanagement features , desi gned to col lapse progres s ively and predi ct ably i n t he event of a s evere frontal i mpact . Thes efeat ures i nclude:

s waged cons truct ion of t he front s ect ion whi ch al lows t he s ect ion to coll aps e, and as ophi st icated long-plunge double-offs et joi nt at t he rear of t he front sect ion, which absorbs the energy of t heimpact .

The dri ves haft i s s upported by ei ther 1 or 2 hi gh s ti ffnes s , cent er beari ngs manufactured from pres s ed s teel wit h rivetedalumi num heats hield ass embli es.

Page 394 of 3229

Stage 1:

Stage 2:

Secure t he parking brake cable.

8.

Support the weight of the vehicle us i ng a jack under the rear hub.

9.

10. CAUTIONS: Nut s and bolt s mus t be t ightened wi th the wei ght of t he

vehicle on the s us pens ion. Do not us e ai r tools to i nst all t he nut. Fail ure t o follow thi s

i ns t ructi on may resul t in damage t o t he component.

Tight en bot h l ower arm nut s and bolt s .

T orque: 175 Nm Tight en the trai li ng arm nut and bol t.

T orque: 270 Nm Tight en the rear hal fs haft nut .

T orque: 330 Nm 30°

St ake t he hub nut.10.

Inst all t he s tabil izer bar l ink.

Refer t o: Rear St abi li zer Bar Link (204-02 Rear Sus pensi on, Removal

and Inst all at ion).

11.

Inst all t he wheel and t ire.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal and

Inst all at ion).

12.

13. CAUTION: Do not fill t he different ial wi th lubri cant up t o

t he fi ll er pl ug. The fil ler plug i s only us ed t o fill t he different ial wi th

l ubricant , and not to act as a level i ndicat or.

Fil l the di fferenti al wi th the correct amount of l ubricant .

Refer t o: Different ial Drai ni ng and Fil ling (205-02 Rear Drive

Axle/Different ial, General Procedures).

13.

Page 399 of 3229

Stage 1:

Stage 2:

Secure t he parking brake cable.

8.

Support the weight of the vehicle us i ng a jack under the rear hub.

9.

10. CAUTIONS: Nut s and bolt s mus t be t ightened wi th the wei ght of t he

vehicle on the s us pens ion. Do not us e ai r tools to i nst all t he nut. Fail ure t o follow thi s

i ns t ructi on may resul t in damage t o t he component.

Tight en bot h l ower arm nut s and bolt s .

T orque: 175 Nm Tight en the trai li ng arm nut and bol t.

T orque: 270 Nm Tight en the rear hal fs haft nut .

T orque: 330 Nm 30°

St ake t he hub nut.10.

Inst all t he s tabil izer bar l ink.

Refer t o: Rear St abi li zer Bar Link (204-02 Rear Sus pensi on, Removal

and Inst all at ion).

11.

Inst all t he wheel and t ire.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal and

Inst all at ion).

12.

13. CAUTION: Do not fill t he different ial wi th lubri cant up t o

t he fi ll er pl ug. The fil ler plug i s only us ed t o fill t he different ial wi th

l ubricant , and not to act as a level i ndicat or.

Fil l the di fferenti al wi th the correct amount of l ubricant .

13.

Page 571 of 3229

Publi s hed: 11-May-2011

Steering Column - Steering Column

Des cript ion and Operat ion

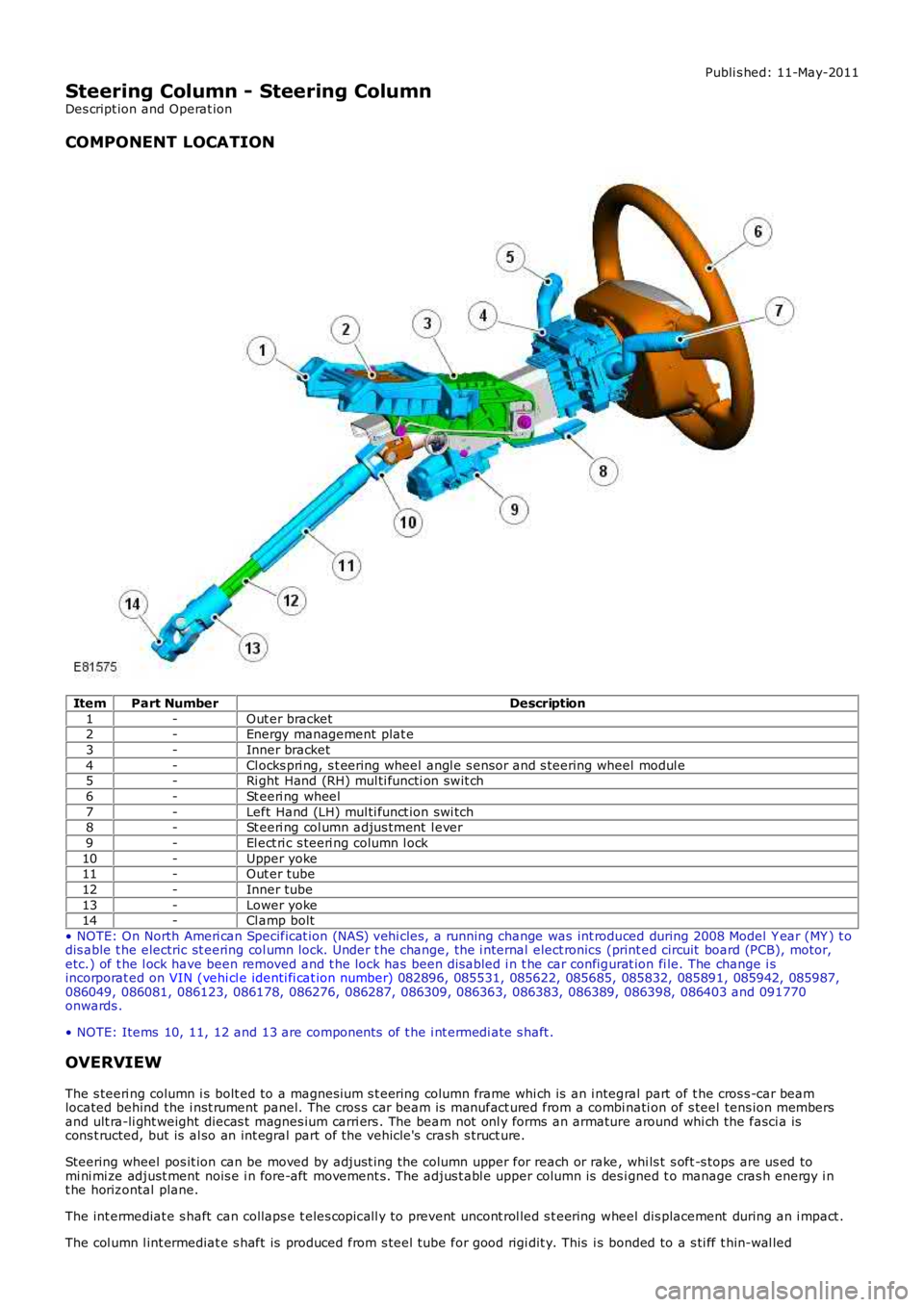

COMPONENT LOCATION

ItemPart NumberDescription

1-Out er bracket2-Energy management plat e

3-Inner bracket

4-Cl ocks pri ng, s t eering wheel angl e s ensor and s teering wheel modul e5-Ri ght Hand (RH) mul ti functi on swit ch

6-St eeri ng wheel

7-Left Hand (LH) mul ti funct ion swi tch8-St eeri ng col umn adjus tment l ever

9-El ect ri c s teeri ng column l ock

10-Upper yoke11-Out er tube

12-Inner tube

13-Lower yoke14-Cl amp bolt

• NOTE: On North Ameri can Specificat ion (NAS) vehi cles , a running change was int roduced during 2008 Model Y ear (MY ) t odis able t he electric st eering col umn lock. Under t he change, the i nternal elect ronics (print ed circuit board (PCB), motor,etc.) of t he l ock have been removed and t he lock has been dis abled i n t he car configurat ion fi le. The change i sincorporat ed on VIN (vehi cl e identi fi cat ion number) 082896, 085531, 085622, 085685, 085832, 085891, 085942, 085987,086049, 086081, 086123, 086178, 086276, 086287, 086309, 086363, 086383, 086389, 086398, 086403 and 091770onwards .

• NOTE: Items 10, 11, 12 and 13 are components of t he i nt ermedi ate s haft .

OVERVIEW

The s teeri ng column i s bolt ed to a magnesi um s t eering column frame whi ch is an i ntegral part of t he cros s -car beamlocated behind the i nst rument panel. The cros s car beam is manufact ured from a combinati on of s teel tens ion membersand ult ra-li ght weight diecas t magnes ium carri ers . The beam not onl y forms an armature around whi ch the fasci a iscons t ructed, but is al so an int egral part of the vehicle's crash s truct ure.

Steering wheel pos it ion can be moved by adjust ing the column upper for reach or rake, whi ls t s oft -s tops are us ed tomi ni mi ze adjust ment nois e i n fore-aft movement s. The adjus t abl e upper column is des igned t o manage cras h energy i nt he horizontal plane.

The int ermediat e s haft can collaps e t eles copicall y to prevent uncont rol led s t eering wheel dis placement during an i mpact .

The col umn l int ermediat e s haft is produced from s teel tube for good rigi dit y. This is bonded to a s ti ff t hin-wal led

Page 607 of 3229

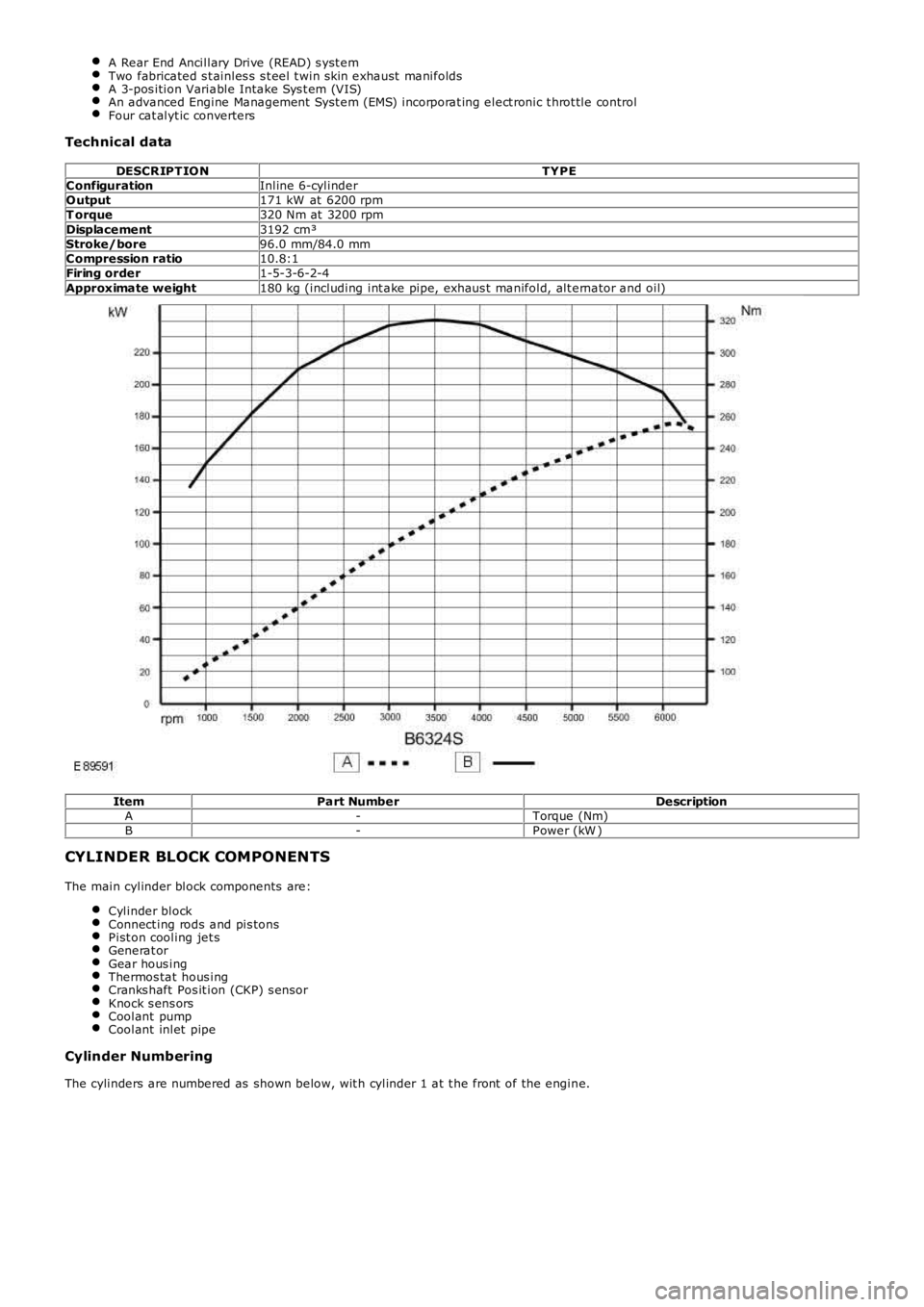

A Rear End Ancillary Drive (READ) s yst emTwo fabricated s t ainles s s t eel t win s kin exhaust manifoldsA 3-pos ition Variable Intake Sys t em (VIS)An advanced Engine Management Syst em (EMS) incorporat ing elect ronic t hrot tle controlFour cat alyt ic converters

Technical data

DESCR IPT IO NT YPEConfigurationInline 6-cylinderO utput171 kW at 6200 rpmT orque320 Nm at 3200 rpmDisplacement3192 cm³Stroke/bore96.0 mm/84.0 mmCompression ratio10.8:1Firing order1-5-3-6-2-4Approximate weight180 kg (including int ake pipe, exhaus t manifold, alt ernator and oil)

ItemPart NumberDescriptionA-Torque (Nm)B-Power (kW )

CYLINDER BLOCK COMPONENTS

The main cylinder block components are:

Cylinder blockConnect ing rods and pis tonsPist on cooling jet sGenerat orGear hous ingThermos tat hous ingCranks haft Pos it ion (CKP) s ensorKnock s ens orsCoolant pumpCoolant inlet pipe

Cylinder Numbering

The cylinders are numbered as shown below, wit h cylinder 1 at t he front of the engine.

Page 609 of 3229

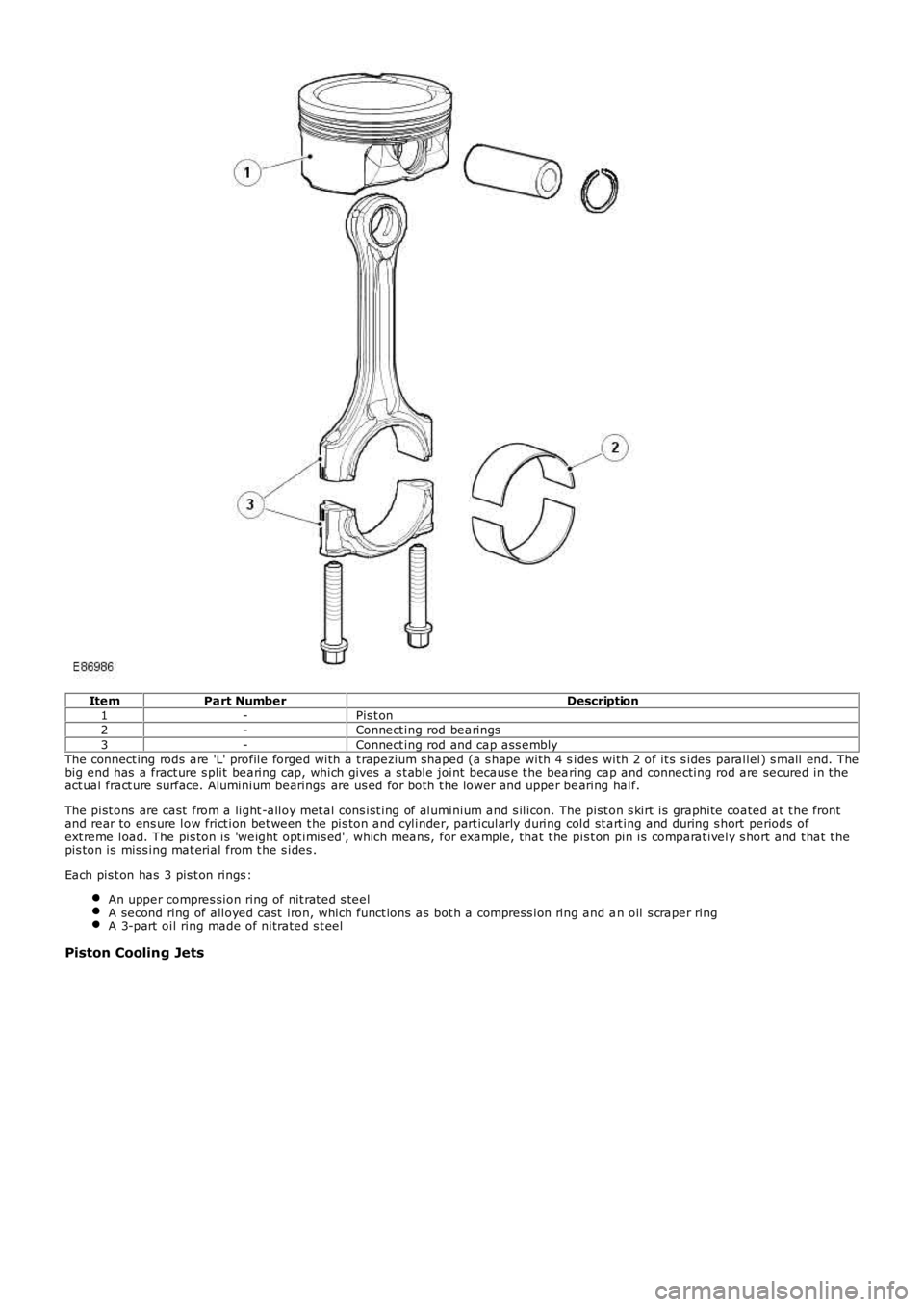

ItemPart NumberDescription1-Pis t on2-Connect ing rod bearings3-Connect ing rod and cap ass emblyThe connect ing rods are 'L' profile forged with a t rapezium shaped (a s hape with 4 sides with 2 of it s s ides parallel) s mall end. Thebig end has a fract ure s plit bearing cap, which gives a s t able joint becaus e t he bearing cap and connecting rod are secured in t heact ual fract ure surface. Aluminium bearings are us ed for both t he lower and upper bearing half.

The pist ons are cast from a light -alloy met al cons ist ing of aluminium and s ilicon. The pist on s kirt is graphite coated at t he frontand rear to ens ure low frict ion bet ween t he pis ton and cylinder, part icularly during cold st art ing and during s hort periods ofext reme load. The pis ton is 'weight opt imis ed', which means, for example, that t he pis t on pin is comparat ively s hort and t hat t hepis ton is miss ing mat erial from t he s ides .

Each pis t on has 3 pis t on rings :

An upper compres sion ring of nit rat ed s teelA second ring of alloyed cast iron, which funct ions as bot h a compress ion ring and an oil s craper ringA 3-part oil ring made of nitrated s t eel

Piston Cooling Jets

Page 620 of 3229

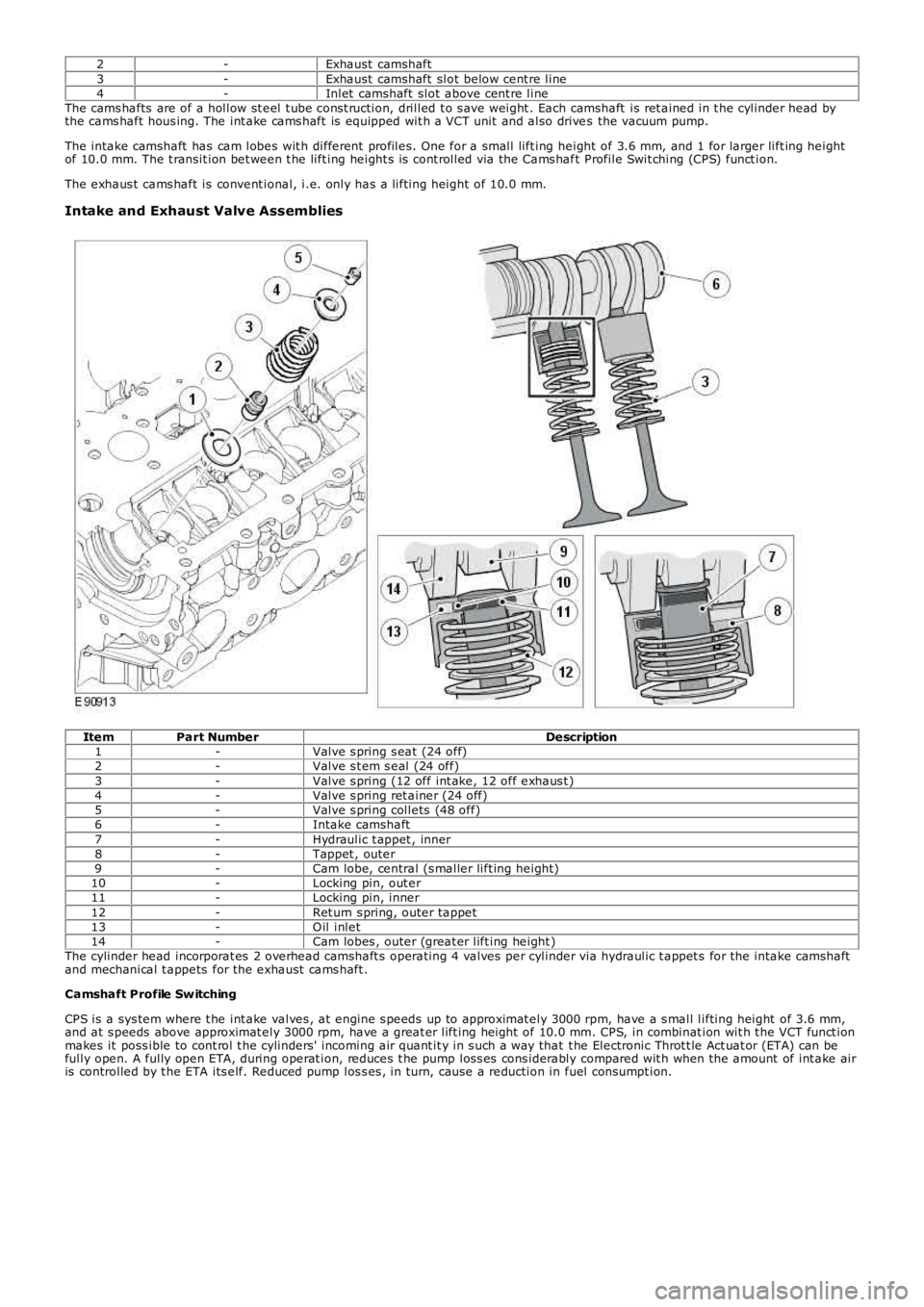

2-Exhaust camshaft3-Exhaust camshaft slot below cent re line4-Inlet camshaft slot above cent re lineThe cams hafts are of a hollow st eel t ube cons t ruction, drilled t o s ave weight . Each camshaft is ret ained in t he cylinder head bythe cams haft hous ing. The int ake cams haft is equipped wit h a VCT unit and also drives the vacuum pump.

The intake camshaft has cam lobes wit h different profiles. One for a small lift ing height of 3.6 mm, and 1 for larger lift ing heightof 10.0 mm. The t ransit ion bet ween t he lift ing height s is cont rolled via the Cams haft Profile Swit ching (CPS) funct ion.

The exhaus t cams haft is convent ional, i.e. only has a lifting height of 10.0 mm.

Intake and Exhaust Valve Assemblies

ItemPart NumberDescription1-Valve s pring s eat (24 off)2-Valve s t em s eal (24 off)3-Valve s pring (12 off int ake, 12 off exhaus t )4-Valve s pring ret ainer (24 off)5-Valve s pring collets (48 off)6-Intake camshaft7-Hydraulic t appet , inner8-Tappet , outer9-Cam lobe, central (s maller lift ing height)10-Locking pin, out er11-Locking pin, inner12-Ret urn s pring, outer tappet13-O il inlet14-Cam lobes , outer (great er lift ing height )The cylinder head incorporat es 2 overhead camshaft s operating 4 valves per cylinder via hydraulic t appet s for the intake camshaftand mechanical t appets for the exhaust cams haft .

Camshaft Profile Sw itching

CPS is a sys tem where t he int ake valves , at engine s peeds up to approximat ely 3000 rpm, have a s mall lifting height of 3.6 mm,and at s peeds above approximat ely 3000 rpm, have a great er lift ing height of 10.0 mm. CPS, in combinat ion wit h t he VCT funct ionmakes it poss ible to cont rol t he cylinders' incoming air quant it y in s uch a way that t he Electronic Throt t le Act uat or (ETA) can befully open. A fully open ETA, during operat ion, reduces t he pump los s es cons iderably compared wit h when the amount of int ake airis controlled by t he ETA its elf. Reduced pump los s es , in turn, cause a reduction in fuel consumpt ion.

Page 632 of 3229

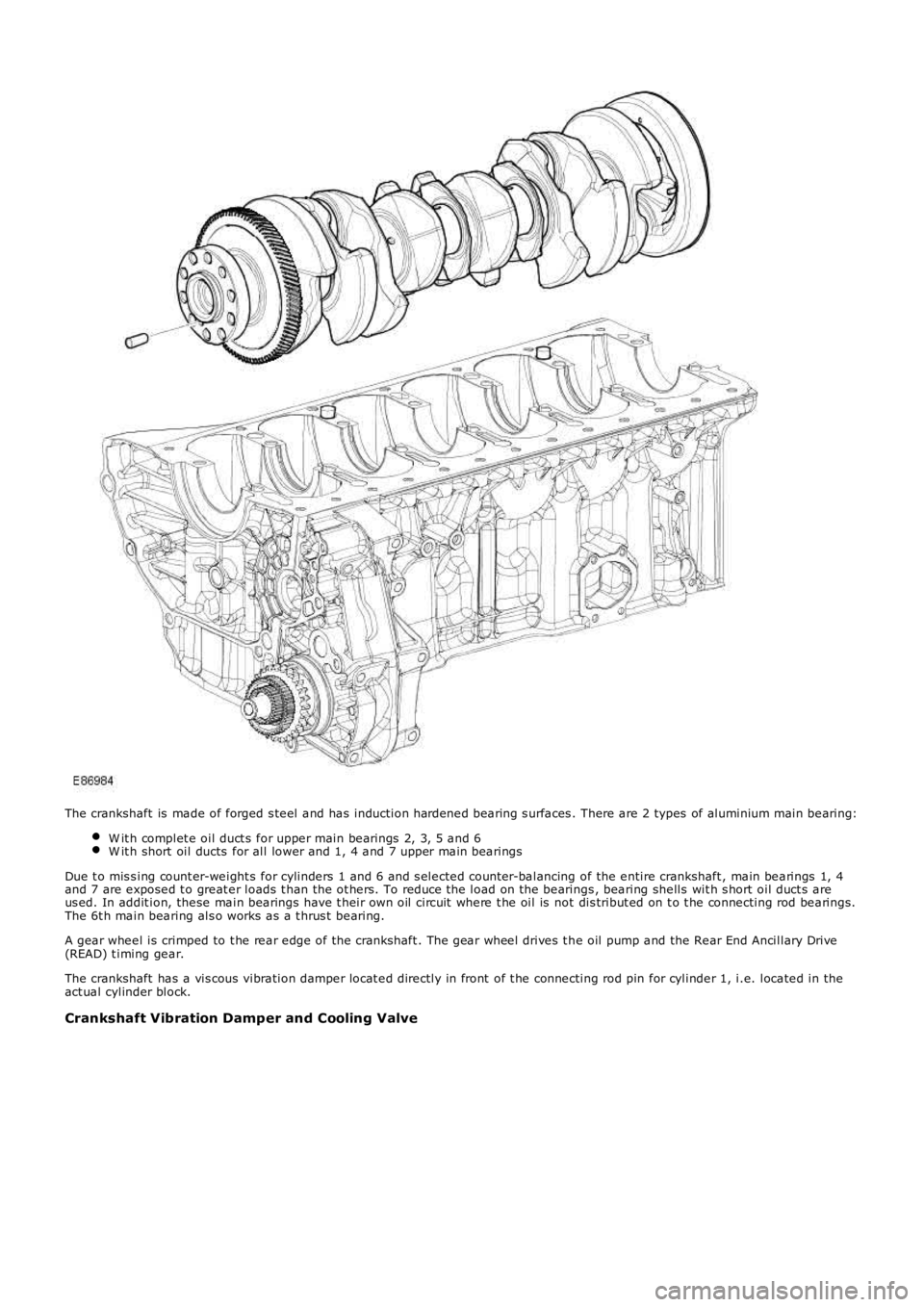

The crankshaft is made of forged s teel and has induction hardened bearing s urfaces . There are 2 types of aluminium main bearing:

W it h complet e oil duct s for upper main bearings 2, 3, 5 and 6W it h short oil ducts for all lower and 1, 4 and 7 upper main bearings

Due t o mis s ing count er-weight s for cylinders 1 and 6 and s elected count er-balancing of the entire crankshaft , main bearings 1, 4and 7 are exposed t o great er loads t han the ot hers. To reduce t he load on the bearings , bearing shells wit h s hort oil duct s areus ed. In addit ion, these main bearings have t heir own oil circuit where t he oil is not dis tribut ed on t o t he connecting rod bearings.The 6t h main bearing als o works as a t hrus t bearing.

A gear wheel is crimped to t he rear edge of the crankshaft . The gear wheel drives t he oil pump and the Rear End Ancillary Drive(READ) t iming gear.

The crankshaft has a vis cous vibration damper locat ed directly in front of t he connecting rod pin for cylinder 1, i.e. located in theact ual cylinder block.

Crankshaft Vibration Damper and Cooling Valve

Page 641 of 3229

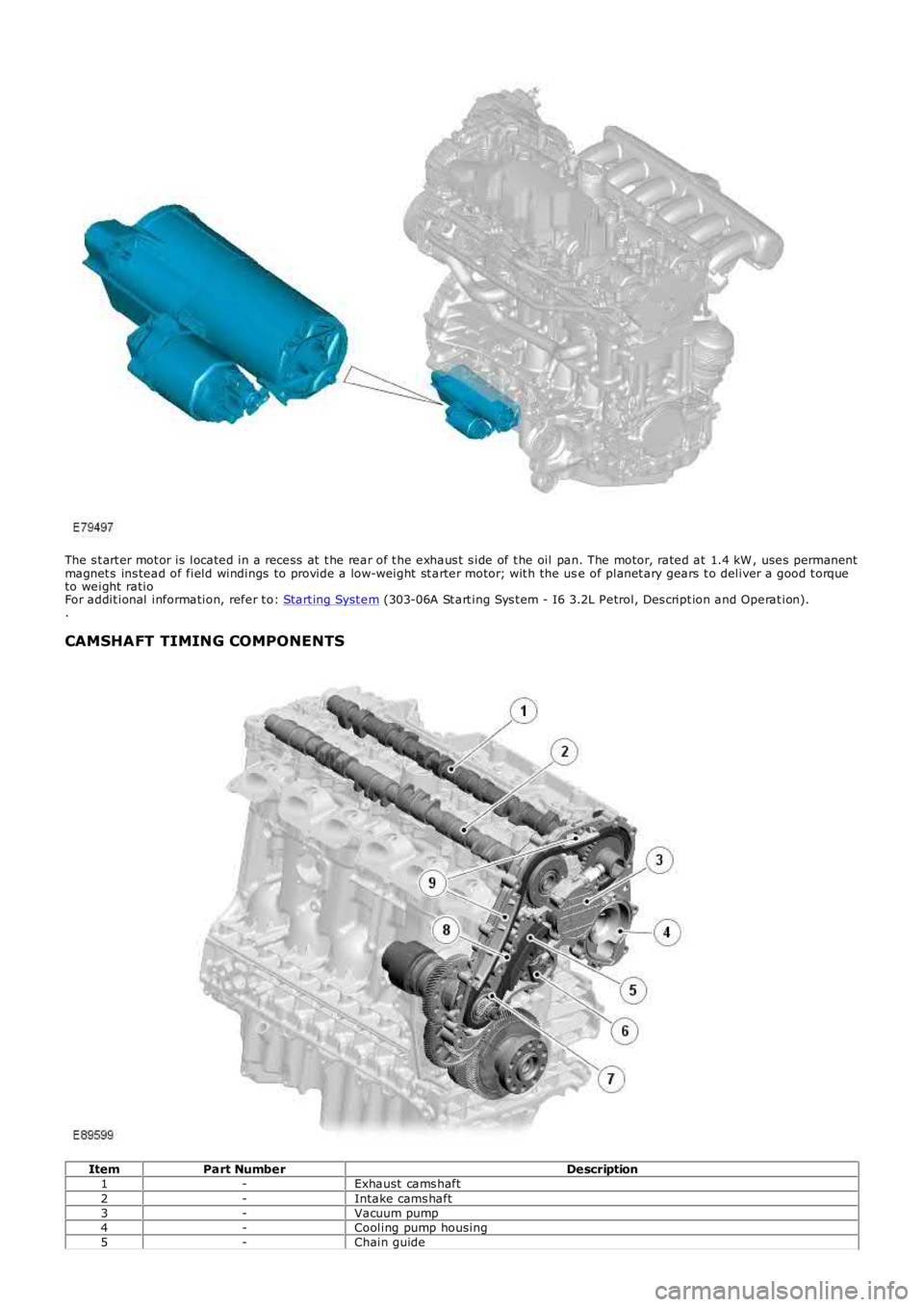

The s t art er mot or is located in a recess at t he rear of t he exhaus t s ide of t he oil pan. The motor, rated at 1.4 kW , uses permanentmagnet s ins tead of field windings to provide a low-weight st arter motor; wit h the use of planet ary gears t o deliver a good t orqueto weight ratioFor addit ional information, refer t o: Start ing Syst em (303-06A St art ing Sys t em - I6 3.2L Petrol, Des cript ion and Operat ion)..

CAMSHAFT TIMING COMPONENTS

ItemPart NumberDescription1-Exhaust cams haft2-Intake cams haft3-Vacuum pump4-Cooling pump housing5-Chain guide