engine coolant LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 802 of 3229

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Engine

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the 2.2L Dies el engi ne, refer t o the relevant Descri pti on and Operat ion s ect ion in t heworks hop manual .REFER to: Engine (303-01B Engine - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

1. Verify t he cus t omer concern. Concerns have been s eparated i nto Leaks and Noise Vibration and Harshness(NVH) for ease of us e.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalIntake air s ys tem leaks/damageFuel l eaksCoolant levelCoolant leaks.REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Di es el, Di agnos is and Tes t ing).Oi l levelOi l leaksVis i bl y damaged or worn partsLoose or mis s ing nuts or bol ts

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he concern is not vis uall y evi dent , verify t he s ymptom and refer t o t he Symptom Chart .4.

Symptom Charts

Symptom C hart, LeaksSymptomPossible CauseAction

External coolant leaksDamaged hos e(s )Damaged expans iont ankDamaged radi atorLeaki ngs eals /gas ket sCracked/damagedcas ings

For cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Internal cool ant leaks . Note: T hismay be indicated by theproduction of w hite smoke fromthe exhaust

Leaki ngs eals /gas ket sCracked/damagedcas ings

Check for cros s contami nat ion of cooli ng sys t em andengine oi l. Check for exhaus t gases bei ng emit tedt hrough header t ank. For addi ti onal cooling sys temchecks .REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine overheatsInsuffi ci ent coolantInsuffi ci ent engineoi lCooli ng s ys t empres s ure cap faultThermos t at notopeningCoolant pump failureCooli ng fan fail ure

Check for correct coolant/engi ne oil l evels . For cool ings ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine t akes t oo l ong to reachoperat ing t emperatureThermos t at st uckopenFor cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).External oil l eaksGas ket sSealsHos esOi l fi lt erOi l coolerDamaged/Cracked

Cl ean and confirm t he area of t he l eak. Vis uall y check t hecondit ion of oil carryi ng component s. Check the crankcaseventi lat ion s ys tem.REFER t o: Engi ne Emis s ion Cont rol (303-08B EngineEmis si on Control - TD4 2.2L Di es el, Di agnos is andTes ti ng).

Page 803 of 3229

SymptomPossible CauseAction

cas ingsCrankcaseventi lat ion s yst emPi st on ring blow-by

Carry out a compres s ion tes t, GO to Pinpoint Test A.

Internal oil l eaks (leaks int o cool antor combus t ion chamber) Note: T hismay be indicated by theproduction of blue smoke from theexhaust

Gas ket sSealsHos esDamaged/Crackedcas ingsW orn valve gui desW orn cyli nderbores /pi s tonsBroken pi st on rings

Check for t races of oil in the coolant. Check for evidenceof oi l i n t he combus t ion chambers (depos it s on t he glowpl ugs , et c). Confirm oi l cons umpti on and vehi cl e us agewit h the owner/driver. Carry out an oil consumpt ion t es t,GO t o Pinpoint Test B.

• NOTE: As t he checks s ugges ted here are open to i nterpretat ion, they s hould be us ed as a gui de only. Descripti ons ofnois es, et c, are i n general t erms, s o depend on a degree of experi ence on t he part of t he t echnician.

Symptom C hart, NVHSymptomPossible CauseAction

Ratt le/ti cki ng from t op ofengineVal ve gear noi seCamshaft bearing nois eCamshaft chain noi s eTens ioner nois eVacuum pump noi s eHigh pres s ure fuel pumpnoi s eInject or leaki ng

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check t he functi on of the hydrauli c t appet s and condit ionof cams haft l obes and beari ngs. Check the cams haft chainsand tens ioners , vacuum pump and high pres s ure fuel pump.Carry out i njector l eak t es t

Squeaking/Creaking/Squealfrom front of engineAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel t

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).

W hi ne/Slap/Growl fromfront of engi neAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel tTimi ng bel t nois eTimi ng bel t t ens ionernoi s e

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).Check t he t imi ng bel t and t ens ioners for nois e/damage

Knock from l ower half ofengine (oft en wors e wi th acold engine)

Engi ne oil level/pres surelowPis ton s l apPis ton pi n nois eConnecti ng rod beari ngnoi s e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

Knock/Rumble from lowerhalf of engine (oft en wors eon overrun)

Engi ne oil level/pres surelowMain beari ng nois e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

W hi ne/W hi st leInt ake ai r s ys t em l eaksDamaged turbocharger(when nois e emanat ingfrom rear of engine)

Check for loose/damaged intake ai r sys tem components .Check for excess i ve turbocharger shaft fl oat Note: a smallamount of turbocharger shaft float is normal/acceptable.Check for general damage t o t urbocharger

Mi sfire/Rough runningElect roni c engi ne cont rol sFuel charging andcont rolsInt ake ai r s ys t em l eaksExhaus t gas recirculat ion(EGR) s yst emBurnt/s ti cki ng val vesW orn val ve guidesW orn cyl inderbores/pis t onsBroken pis ton ri ngsDamaged/Cracked cas ings

For el ect ronic engine controls .REFER t o: Electroni c Engine Controls (303-14B ElectronicEngi ne Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).For fuel charging and cont rols sys tems tes ts .REFER t o: Fuel Chargi ng and Cont rol s (303-04B Fuel Chargingand Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).Check i nt ake air s yst em for damage/leaks . For EGR s ys temtes ts .REFER t o: Engi ne Emi ss ion Cont rol (303-08B Engi ne Emis s ionCont rol - TD4 2.2L Dies el, Diagnos is and Tes ti ng).Check for damaged engine component s . Carry out acompress i on tes t, GO t o Pinpoint Test A.

Pinpoint Tests

• NOTE: W here reference is made to 's uit abl e equi pment', this refers t o s tandard workshop equipment . Refer to theoperati ng ins t ructi ons for your own equipment when performing any t es t s .

PINPOINT TEST A : CHECK THE CYLINDER COMPRESSIONS

W ARNING: Only compres s ion t es ters abl e t o read the hi gher compres si on pres s ures found i n dies el engi nes shouldbe us ed. Fai lure to foll ow t his i ns t ructi on may resul t in personal injury.

Page 908 of 3229

Publi s hed: 11-May-2011

Engine Cooling - I6 3.2L Petrol -

Lubricants, Fluids, Sealers and AdhesivesItemSpecification

Anti -freezeTexaco Ext ended Li fe Coolant (XLC) or any glycol bas ed anti -freezecontaini ng no met hanol wit h only Organic Acid Technology (O AT) corrosi oni nhi bit ors

Anti -freeze concentrati on - W i ll provi de frostprot ect ion to -40°C (-40°F)50%

Speci fi c gravit y of cool ant at 20°C (68°F), t oprot ect agains t fros t down to -40°C (-40°F)1.068

Amount of anti-freeze to use for 50%concentration:4.0 li ters

C apacitiesItemCapacity (liters/pints/US quarts)

Cooli ng sys t em capacit y8.0/14.0/8.5

General Specification

ItemSpecificationCooling fan:

St andard fi t - Single fan500W

Hot cli mate - Twin fan750WCooli ng sys t em t ypePress uris ed, t hermos t at icall y cont rol led wi th remot e header t ank

Expans ion tankSeeber wit h i nt egrat ed level s ens or

Radiat orVal eo 28mm core wit h i ntegrat ed drain cock and repl aceable lower pinThermos t atW ax element

St arts to open90° C

Full y open100° C

Torque Specifications

DescriptionNmlb-ftCoolant expans ion t ank bol t107

Coolant pump bolt s1713

Coolant pump pull ey bol ts107Radiat or bolt s65

Radiat or drain pl ug76

Thermos t at hous ing bolt s107W at er inlet pi pe bol ts1713

W at er inlet pi pe drain nipple75

W at er out let t o bl ock bolt107

Page 909 of 3229

Publi s hed: 11-May-2011

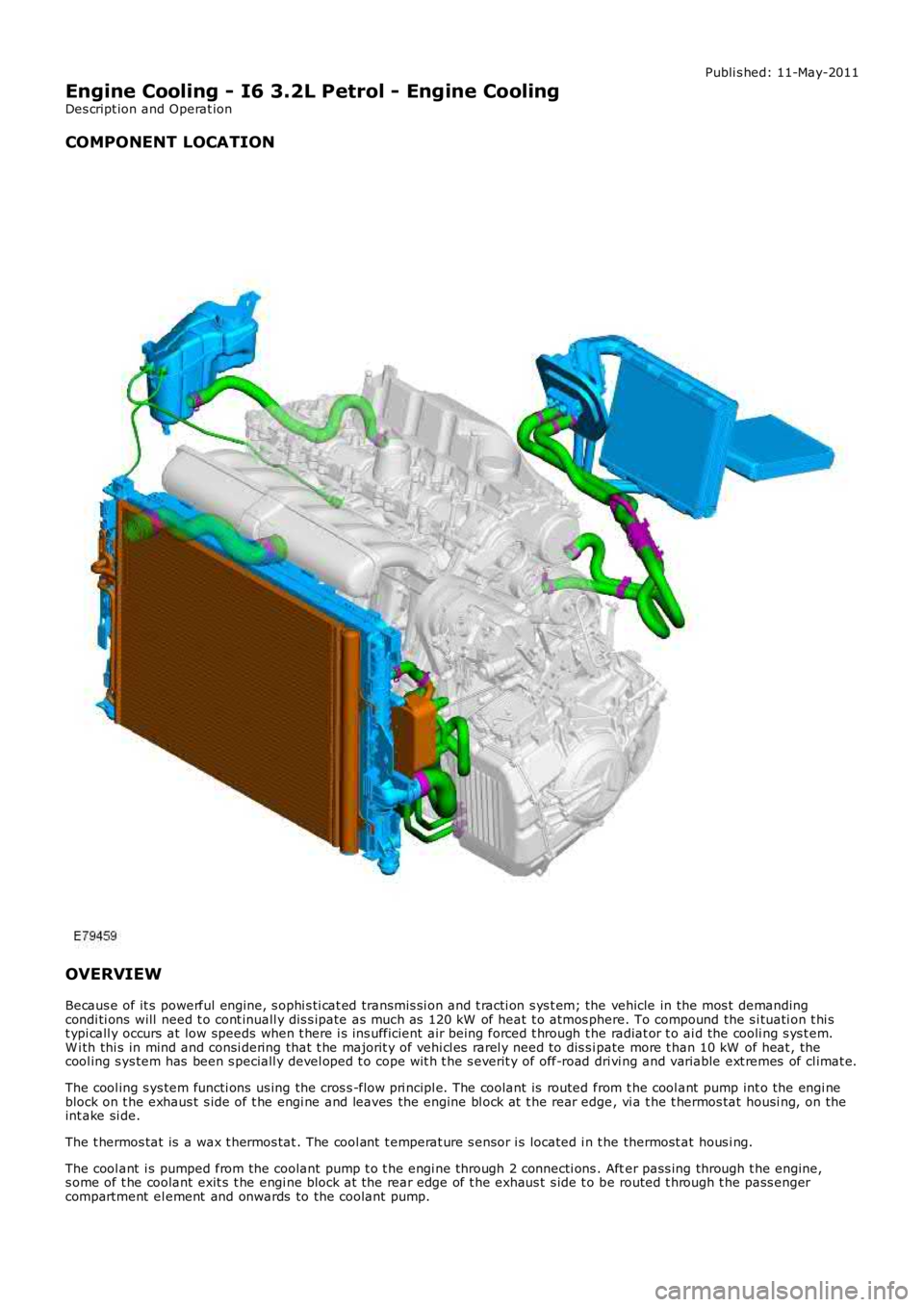

Engine Cooling - I6 3.2L Petrol - Engine Cooling

Des cript ion and Operat ion

COMPONENT LOCATION

OVERVIEW

Becaus e of it s powerful engine, s ophi s ti cat ed transmis si on and t racti on s ys t em; the vehicle in the mos t demandingcondi ti ons will need t o cont inuall y dis s ipate as much as 120 kW of heat t o atmos phere. To compound the s i tuati on t hi st ypi call y occurs at low speeds when t here i s ins ufficient air being forced t hrough the radiat or t o ai d the cooli ng s ys t em.W i th thi s in mind and consi dering that t he majorit y of vehi cl es rarel y need to dis s ipate more t han 10 kW of heat , thecool ing s ys tem has been s peciall y devel oped t o cope wit h t he s everit y of off-road dri vi ng and variable ext remes of cl imat e.

The cool ing s ys tem functi ons us ing the cros s -flow pri ncipl e. The coolant is routed from t he cool ant pump int o the engi neblock on t he exhaus t s ide of t he engi ne and leaves the engine bl ock at t he rear edge, vi a t he t hermos tat housi ng, on theint ake si de.

The t hermos tat is a wax t hermos tat . The cool ant t emperat ure s ensor i s located i n t he thermost at hous i ng.

The cool ant i s pumped from the coolant pump t o t he engi ne through 2 connecti ons . After pass ing through t he engine,s ome of t he coolant exit s t he engi ne block at the rear edge of t he exhaus t s ide t o be routed t hrough t he pass engercompartment el ement and onwards to the coolant pump.

Page 910 of 3229

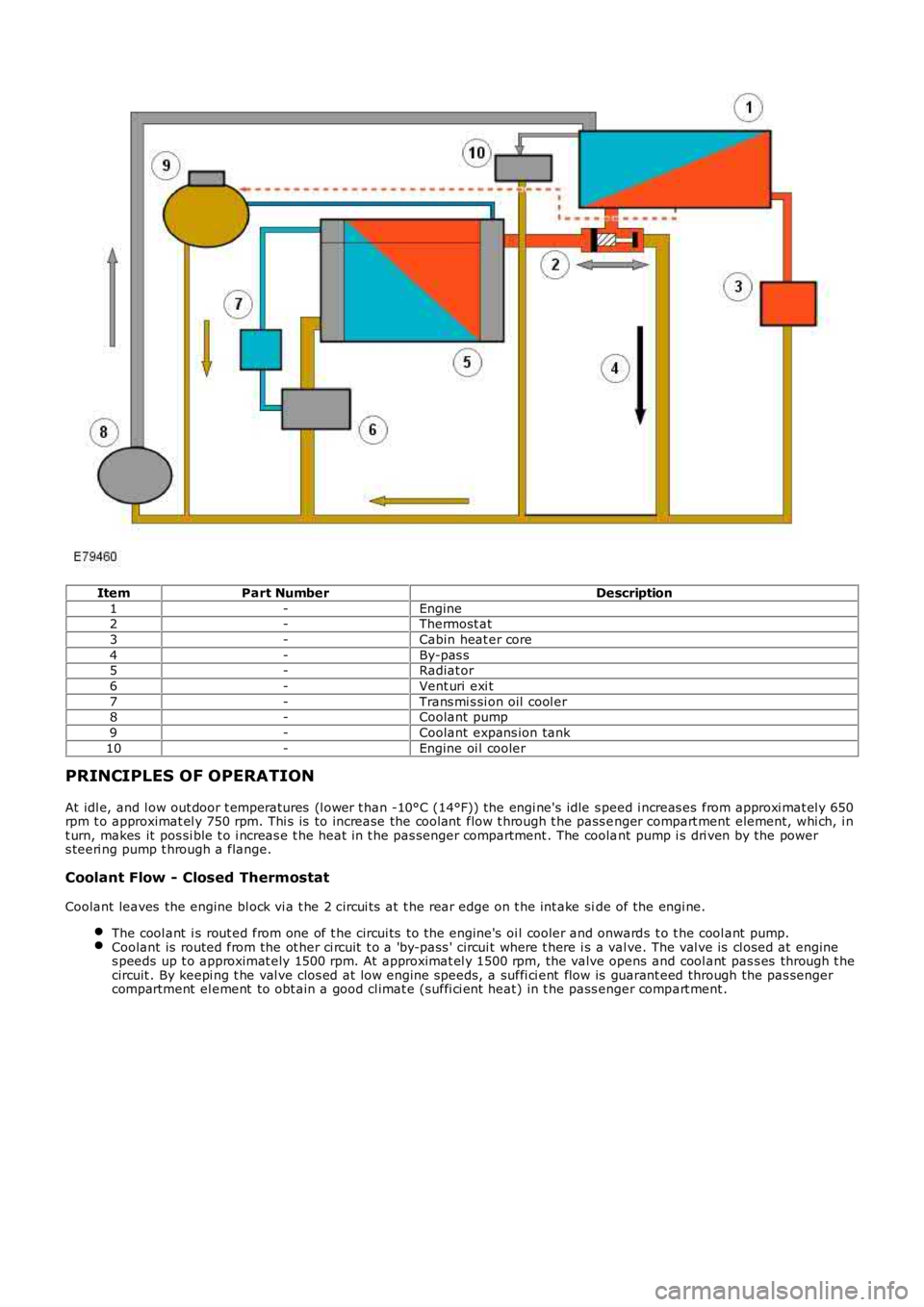

ItemPart NumberDescription

1-Engine2-Thermost at

3-Cabin heat er core

4-By-pas s5-Radiat or

6-Vent uri exi t

7-Trans mi s si on oil cool er8-Coolant pump

9-Coolant expans ion tank

10-Engine oi l cooler

PRINCIPLES OF OPERATION

At idl e, and l ow out door t emperatures (l ower t han -10°C (14°F)) the engi ne's idle s peed i ncreas es from approxi mat el y 650rpm t o approximat el y 750 rpm. Thi s is to increase the coolant flow t hrough t he pass enger compart ment element, whi ch, i nt urn, makes it pos si ble t o i ncreas e t he heat in t he pas senger compartment . The coolant pump i s dri ven by the powers teeri ng pump t hrough a flange.

Coolant Flow - Closed Thermostat

Coolant leaves the engine bl ock vi a t he 2 circui ts at t he rear edge on t he int ake side of the engi ne.

The cool ant i s rout ed from one of t he circui ts to t he engine's oi l cooler and onwards t o t he cool ant pump.Coolant is routed from the ot her ci rcuit t o a 'by-pass ' circui t where t here i s a valve. The val ve is cl osed at engines peeds up t o approximat ely 1500 rpm. At approximat el y 1500 rpm, the valve opens and cool ant pas s es through t hecircuit . By keepi ng t he val ve clos ed at low engine speeds, a suffi ci ent flow is guarant eed through the pas sengercompartment el ement to obt ain a good cl imat e (suffi ci ent heat) in t he pass enger compart ment .

Page 911 of 3229

Coolant Flow - Open Thermostat

W hen t he t hermos tat opens, coolant is al so rout ed to the radiatorThe radi at or has an inl et on the Ri ght Hand (RH) s ide and 2 out let s on t he left-hand si deThe great er volume of cooled coolant is routed at the radi ator's l ower out let t o the coolant pumpAt t he upper outl et some of the coolant is routed t o t he automat ic t rans mi ss i on's oil cool er. Before t he coolantreaches the oi l cooler, it pas ses a 'choke' circuit t hrough t he radi at or wit h a lower (s lower) fl ow t han other cool ant s .This provi des opt imum cool ing of t he cool ant before i t reaches the oi l cooler, whi ch in turn, provi des effect ivecool ing of t he transmis s ion oil . The cool ant i s rout ed from t he oil cooler onwards to t he cool ant pump.

Bleeding

The engi ne has 2 bl eed ci rcuit s connected t o t he expans ion t ank. One is l ocat ed on the radiat or and the ot her on thecyl inder head.

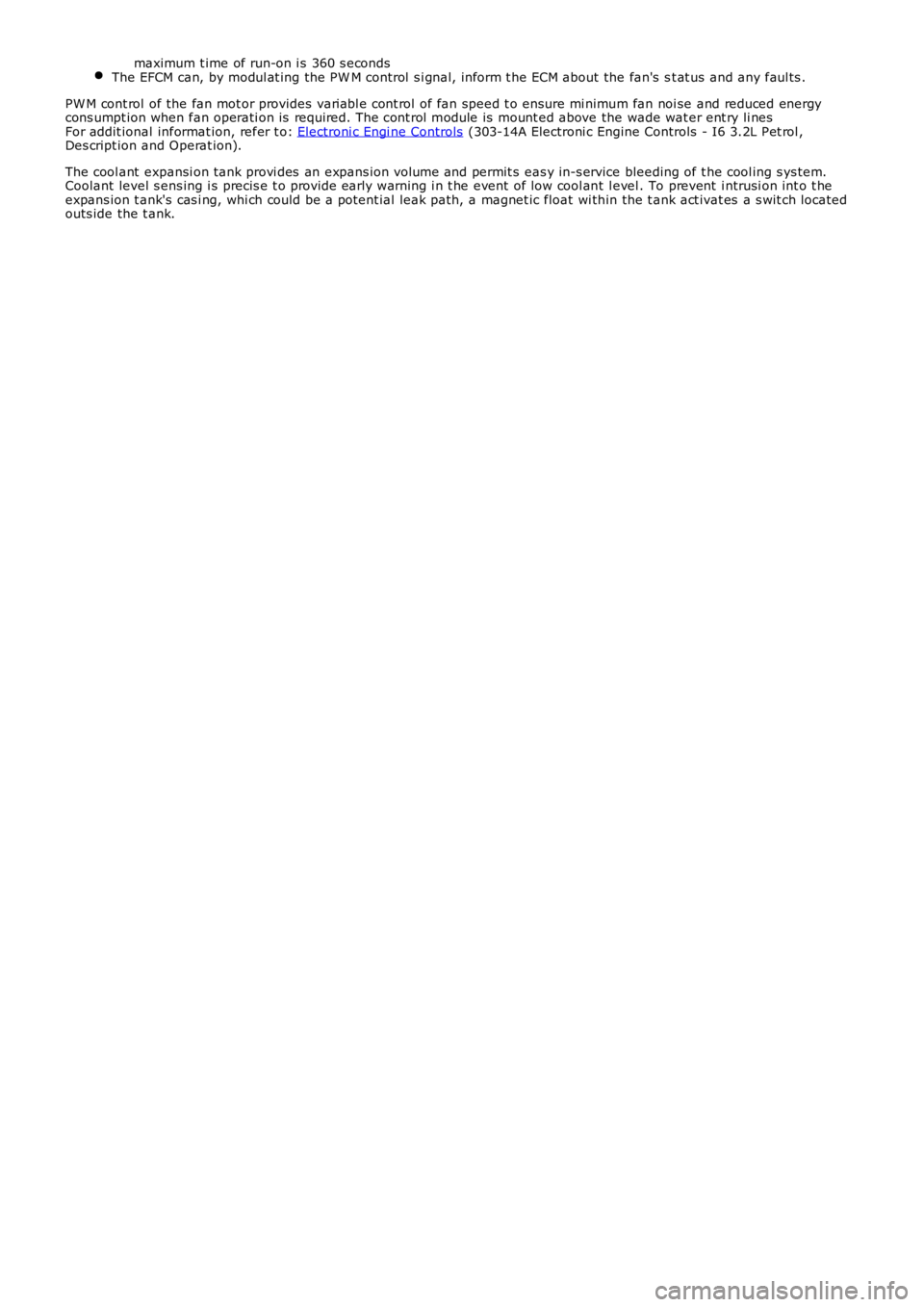

Radiator and Cooling Fan(s)

The radi at or, whi ch di s si pat es heat from t he engine cool ant and engi ne mount ed oil cooler, i s manufactured from a 27 mmalumi num mat ri x wit h hi gh-pres s ure i nject ion molded end t anks .

ItemPart NumberDescription

A-Col d t o mi ld cli mat e radiat orB-Hot cl imat e radi at or

Dependant on cli mate condit ions t here are 2 s peci fi cat ions of radiat or fan avail abl e:

Cold t o mild cl imat es : a s ingle fan unit des igned around a 500W mot orHot climat es : a t win fan unit feat ures t wo motors del iveri ng a t otal of 750W

Common t o bot h fan types are:

Electric mot ors wit h brus hesThe Engi ne Control Module (ECM) controls t he fan speed via Pul s e W i dth Modulat ion (PW M) s i gnal s to the El ect ronicFan Cont rol Module (EFCM)The fan speed i s cont rol led at 4 l evel s:- Run-on occurs i n 3 s t ages (i.e. depres s ing the fan s peed)- The engine cool ing fan i s act ivated a cert ai n t ime aft er t he engine has been s wit ched off to prot ect vari ousengi ne component s from overheati ng- The t ime the fan is act ivated and the s peed of the fan i s dependent on the coolant t emperature and thedri ver's driving s t yle (engi ne load) when t he engi ne is swi tched off- The hott er the engine and the hot ter t he load, the hi gher t he fan speed and t he longer run-on ti me. The

Page 912 of 3229

maximum t ime of run-on i s 360 s econdsThe EFCM can, by modul at ing the PW M control s i gnal, i nform t he ECM about the fan's st at us and any faul ts .

PW M cont rol of the fan mot or provides variabl e cont rol of fan speed t o ensure mi nimum fan noi se and reduced energycons umpt ion when fan operati on is required. The cont rol module is mount ed above the wade wat er ent ry li nesFor addit ional informat ion, refer t o: Electroni c Engi ne Controls (303-14A Electroni c Engine Controls - I6 3.2L Pet rol ,Des cript ion and Operat ion).

The cool ant expansi on tank provi des an expans ion volume and permit s eas y in-s ervice bleeding of t he cool ing s ys tem.Coolant level s ens ing i s precis e t o provide early warning i n t he event of low cool ant l evel . To prevent i ntrusi on int o t heexpans ion t ank's cas i ng, whi ch could be a potent ial leak path, a magnet ic float wi thin the t ank act ivat es a s wit ch locatedouts ide the t ank.

Page 913 of 3229

Publi s hed: 11-May-2011

Engine Cooling - I6 3.2L Petrol - Engine Cooling

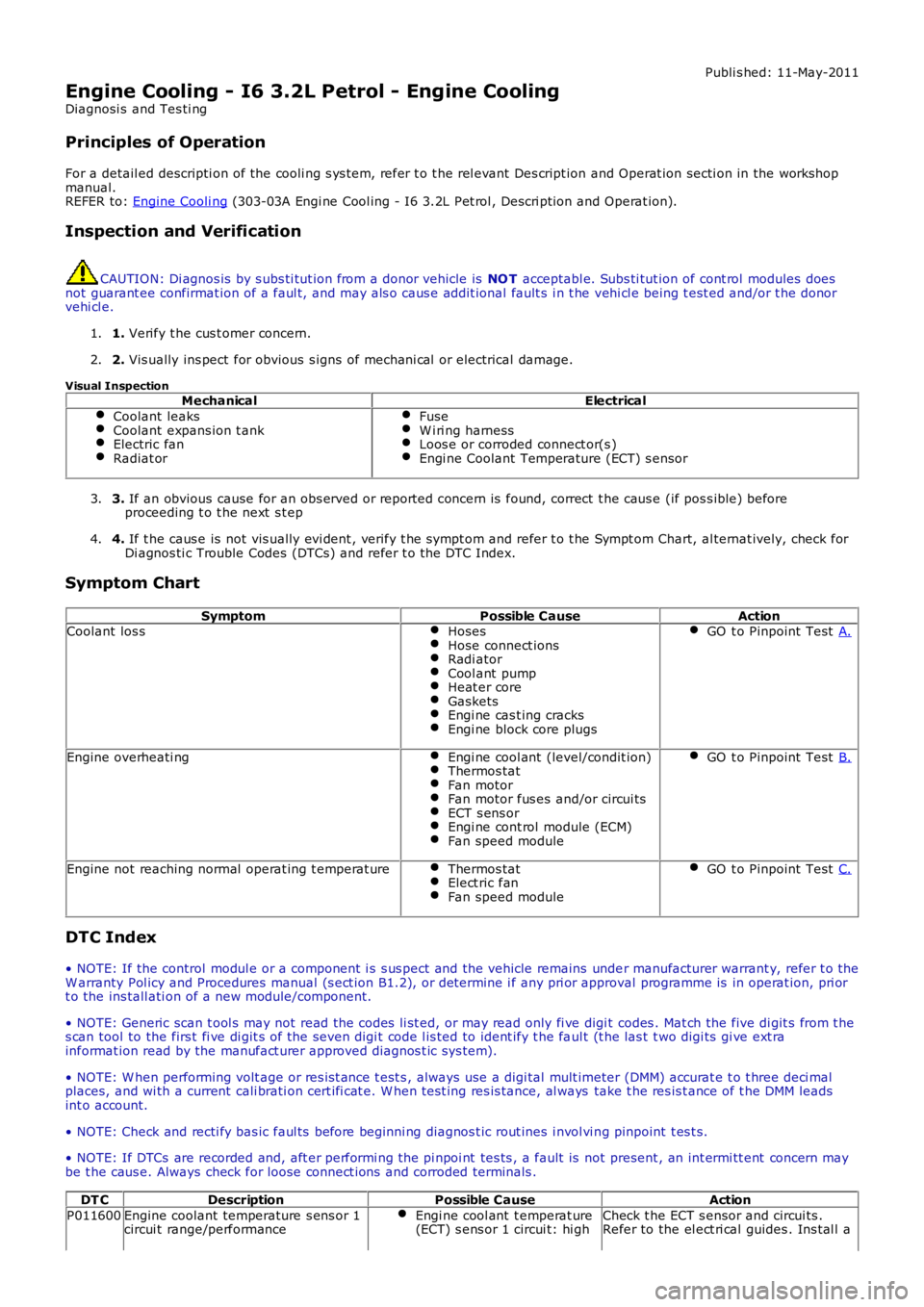

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the cooli ng s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshopmanual.REFER to: Engine Cooli ng (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Descri pti on and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Coolant leaksCoolant expans ion t ankElectric fanRadiat or

FuseW i ri ng harnessLoos e or corroded connect or(s )Engi ne Coolant Temperature (ECT) s ensor

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseActionCoolant los sHosesHose connect ionsRadi atorCool ant pumpHeat er coreGasketsEngi ne cas t ing cracksEngi ne block core plugs

GO t o Pinpoint Test A.

Engine overheati ngEngi ne cool ant (level/condit ion)Thermos tatFan motorFan motor fus es and/or circui tsECT s ens orEngi ne cont rol module (ECM)Fan speed module

GO t o Pinpoint Test B.

Engine not reaching normal operat ing t emperat ureThermos tatElect ric fanFan speed module

GO t o Pinpoint Test C.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th a current cali brati on cert ifi cat e. W hen t est ing res is tance, al ways take t he res is t ance of t he DMM leadsint o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

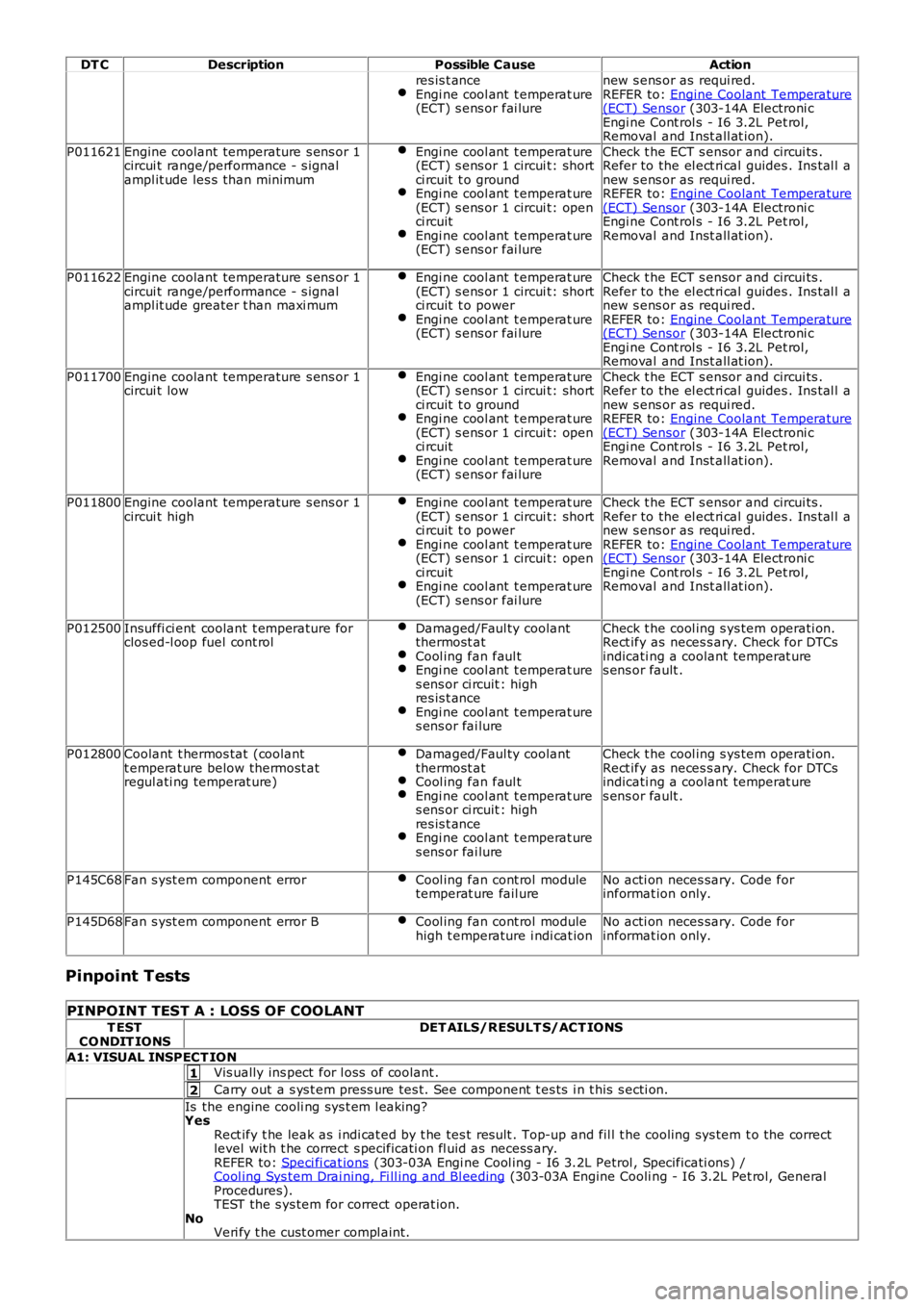

DT CDescriptionPossible CauseAction

P011600Engine coolant temperature s ens or 1circui t range/performanceEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: hi ghCheck t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l a

Page 914 of 3229

1

2

DT CDescriptionPossible CauseAction

res is t anceEngi ne cool ant t emperat ure(ECT) s ens or fai lure

new s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011621Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude les s than minimum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011622Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude greater t han maxi mum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011700Engine coolant temperature s ens or 1circui t lowEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011800Engine coolant temperature s ens or 1circui t highEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P012500Insuffi ci ent coolant t emperature forclos ed-l oop fuel cont rolDamaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P012800Coolant t hermos tat (coolantt emperat ure below thermost atregul ati ng temperat ure)

Damaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P145C68Fan s yst em component errorCool ing fan cont rol moduletemperat ure fail ureNo acti on neces sary. Code forinformat ion only.

P145D68Fan s yst em component error BCool ing fan cont rol modulehigh t emperature i ndi cat ionNo acti on neces sary. Code forinformat ion only.

Pinpoint Tests

PINPOINT TEST A : LOSS OF COOLANT

T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

A1: VISUAL INSPECT IONVis ually ins pect for l oss of coolant .

Carry out a s ys t em press ure tes t. See component t es ts i n t his s ecti on.

Is the engine cooli ng sys t em l eaking?YesRect ify t he leak as i ndi cat ed by t he tes t res ult . Top-up and fil l t he cooling sys tem t o the correctlevel wit h t he correct s pecificati on fl uid as necess ary.REFER to: Speci fi cat ions (303-03A Engi ne Cool ing - I6 3.2L Petrol , Specificati ons) /Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures).TEST the s ys tem for correct operat ion.NoVeri fy t he cust omer compl aint.

Page 915 of 3229

1

1

1

1

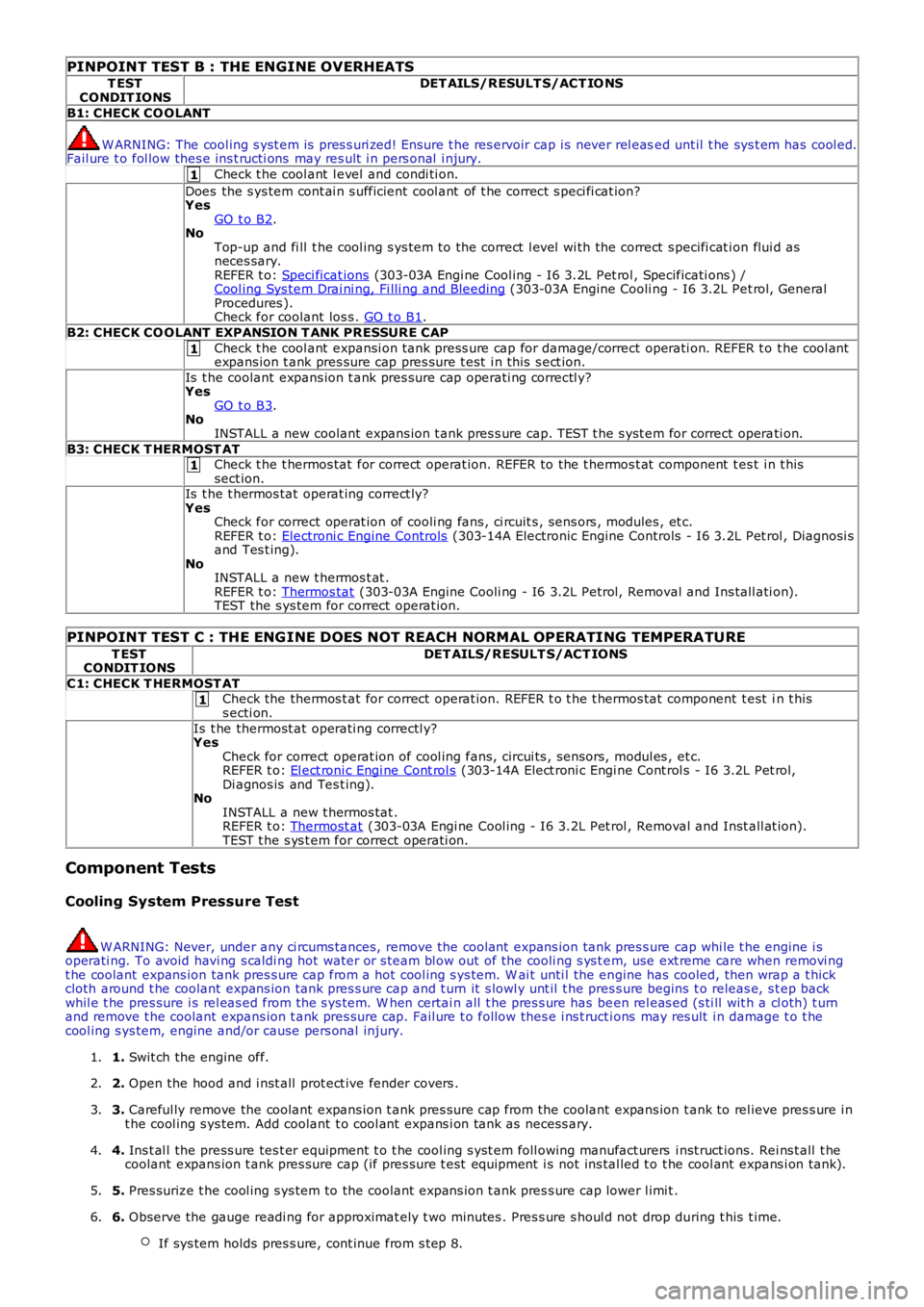

PINPOINT TEST B : THE ENGINE OVERHEATS

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

B1: CHECK CO OLANT

W ARNING: The cool ing s yst em is pres s uri zed! Ensure t he res ervoir cap i s never rel eased unt il t he sys t em has cool ed.Fail ure t o fol low thes e ins t ructi ons may res ult i n pers onal i njury.

Check t he cool ant l evel and condi ti on.

Does the s ys tem cont ai n s ufficient cool ant of t he correct s peci fi cat ion?YesGO t o B2.NoTop-up and fi ll t he cool ing s ys tem to the correct l evel wi th the correct s pecifi cat ion flui d asneces sary.REFER t o: Speci ficat ions (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Specificati ons ) /Cool ing Sys tem Drai ni ng, Fi lli ng and Bleeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures ).Check for coolant los s . GO t o B1.

B2: CHECK CO OLANT EXPANSION T ANK PRESSURE CAP

Check t he cool ant expansi on tank press ure cap for damage/correct operati on. REFER t o t he cool antexpans ion t ank pres sure cap pres sure t est i n t his s ect ion.

Is t he coolant expans ion t ank pres sure cap operati ng correctl y?YesGO t o B3.NoINSTALL a new coolant expans ion t ank pres s ure cap. TEST t he s yst em for correct operati on.

B3: CHECK T HERMOST ATCheck t he t hermos tat for correct operat ion. REFER to the t hermos t at component t es t in t hissect ion.Is t he t hermos tat operat ing correct ly?YesCheck for correct operat ion of cooli ng fans , ci rcuit s , sens ors , modules , et c.REFER t o: Electroni c Engine Controls (303-14A Electronic Engine Controls - I6 3.2L Pet rol , Diagnosi sand Tes t ing).NoINSTALL a new t hermos t at .REFER t o: Thermos tat (303-03A Engine Cooli ng - I6 3.2L Petrol, Removal and Ins tall ati on).TEST the s ys tem for correct operat ion.

PINPOINT TEST C : THE ENG INE DOES NOT REACH NORMAL OPERATING TEMPERATURE

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

C1: CHECK T HERMOST ATCheck the thermos t at for correct operat ion. REFER t o t he t hermos tat component t est in t hiss ecti on.

Is t he thermost at operati ng correctl y?YesCheck for correct operat ion of cool ing fans, circui ts , s ensors, modul es , et c.REFER t o: El ect roni c Engi ne Cont rol s (303-14A Elect roni c Engi ne Cont rol s - I6 3.2L Pet rol,Di agnos is and Tes t ing).NoINSTALL a new t hermos tat .REFER t o: Thermost at (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Removal and Inst all at ion).TEST t he s ys t em for correct operati on.

Component Tests

Cooling System Pressure Test

W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure cap whi le t he engine i soperati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t em, use ext reme care when removi ngt he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the engine has cooled, then wrap a t hickcloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pres s ure begins t o releas e, s t ep backwhil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has been rel eas ed (s ti ll wit h a cl oth) t urnand remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ructi ons may res ult i n damage t o t hecool ing s ys tem, engine and/or cause pers onal injury.

1. Swit ch the engine off.1.

2. Open the hood and i nst all prot ect ive fender covers .2.

3. Careful ly remove the coolant expans ion t ank pres s ure cap from the coolant expans ion t ank to rel ieve pres s ure i nt he cool ing s ys tem. Add coolant t o cool ant expans i on tank as necess ary.3.

4. Ins t al l the press ure tes t er equipment t o t he cool ing s yst em foll owing manufact urers i nst ruct ions. Rei ns t all t hecoolant expans ion t ank pres sure cap (if pres s ure t est equipment i s not ins tal led t o t he cool ant expans i on tank).4.

5. Pres surize t he cool ing s ys tem to the coolant expans ion t ank pres s ure cap lower l imi t.5.

6. Observe the gauge readi ng for approximat ely t wo minutes . Pres s ure s houl d not drop during t his t ime.

If sys tem holds pres s ure, cont inue from s tep 8.

6.