engine coolant LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1108 of 3229

however remain i ll uminated.

A ‘st all recovery’ event is the onl y s tat e when t he Stop/St art s yst em wil l permit t he engine t o be s t art ed when thet ransmis s ion i s in gear; hence t he requirement for t he cl utch pedal to be full y depres sed. If the s t all recovery fai ls and t heengi ne does not res tart, t he dri ver wi ll be reques ted vi a t he Mess age Center t o ‘s elect neutral ’ to at t empt anot her rest art .

If the engine does not res t art aft er thi s request t he ‘st all recovery’ mode wil l ti me-out and deact ivate. At t his point t he‘Eco’ i con in t he i ns t rument panel wi ll exti ngui sh and the light s usual ly as s ociat ed wi th an engi ne st all wi ll il lumi nat e. As ares ult t he dri ver will be requi red to perform a convent ional engi ne res tart.

Alt hough st all recovery i s a feat ure of t he St op/Start sys t em i t is pos si ble for it t o acti vat e i ndependent ly from t heStop/St art parameters . For exampl e:

If the St op/Start s ys t em has been deact ivated by the driver st all recovery wi ll s ti ll funct ion.Stal l recovery wil l act ivate at ambi ent temperat ures as l ow as (minus ) - 2°C, whereas the St op/Syst em operat ingt emperature threshold is above 4°C.Different t o t he operat ion of t he Stop/St art s yst em, s tal l recovery wil l st il l functi on when the vehicle is t owing;refer to the ‘Trail er Towi ng’ s ect ion.

• NOTE: As t he neces s ary cri teria will not have been sat is fi ed when t he vehi cl e i s at the beginning of a journey s t allrecovery wi ll not functi on. For exampl e, if t he vehi cl e s tal ls when l eavi ng the garage or driveway a convent ional engineres t art wi ll be required.

Trailer Towing

The Stop/St art s ys tem wil l aut omati cal ly di sabl e when t rail er light s are det ect ed by t he CJB via s ignals from t he t rail ermodule, t hi s informat ion i s t hen trans mi tt ed t o t he ECM. It i s not pos s ibl e for t he s ys t em t o det ect when a trai ler powerplug i s ins ert ed i n the vehicl e’s t owi ng s ocket s o it us es operat ion of t he trail er l ights as it s indi cat or.

The t rail er towing sys tem inhi bi ts St op/St art as i t is pos s ible that trail er power requirements could interfere wit h t heoperati on of the bat tery monit ori ng s ys t em. In parti cul ar, a t rai ler batt ery could revers e t he feed current t o t he vehicleduri ng an engi ne cranking event , t hi s coul d pos si bly:

Confus e t he bat t ery monit ori ng s ys t em i nto det ect ing an unreal is t ically smal l current at engi ne cranking.Rupture the fus e as sociat ed wit h t he t rail er modul e.

Climate Control System

• NOTE: The ‘ECON’ butt on has been renamed ‘A/C’ to prevent confus ion wi th the St op/St art s yst em ‘Eco’ s wit ch.

A number of changes have been made to the l ogi c and operati on of climat e control system, wit hi n a St op/St art cycle to:

maint ain occupant comfortprevent winds hi eld mis ti ngcons erve bat tery power.

This has been achi eved by the ATC (automat ic t emperat ure control) module monit oring and varyi ng, as necess ary variousclimate control funct ions wi thi n a St op/Start cycle.

In s ome circums t ances t he ATC has t he capabil it y to inhibit an engi ne s hut down or init iat e an engine rest art wit hi n aStop/St art cycle. Thi s i s achi eved by t he ATC module communi cat ing wit h t he CJB on the medi um s peed CAN. The variousoverri de functi ons the ATC has in a St op/St art cycl e are di s cus s ed bel ow:

Coolant temperat ure

The ATC module wil l i nhibit an engine shut down or i nit iat e an engine res t art wi thi n a St op/Start cycle if t he coolantt emperature fal ls below the calculat ed t hreshol d to s upport t he cabin t emperat ure s et by t he vehi cl e occupant s .

W i nds hiel d demis t ing

The variant of cli mate control fi tt ed t o the vehicl e influences t he s oft ware changes that have been made. For exampl e, thebase cl imat e-control s ys tem does not have a humi dit y s ens or, as us ed on a highline sys tem t o ini ti at e a winds hi elddemis t . Therefore, a calculat ion for demis ti ng the winds hi eld i s made us ing t he s ignals from t he rai n s ens or and ambientt emperature s ens or. Us i ng the probabi lit y t hat windshi eld mis ti ng wil l occur if i t is raining and t he ambi ent t emperat ure i scool , the ATC wil l presume a wi nds hiel d demis t is required and s tart the engine when i n a St op/St art cycl e.

Evaporat or temperat ure the main cause of windshi eld mis ti ng is al s o monit ored and t he high-line cl imat e cont rol s yst emwil l periodicall y cool t he evaporat or as neces s ary t o reduce mi s ti ng during a Stop/St art cycl e. The sys tem operates thewinds hield demis t s hut ter and i f the evaporator i s wet t he shut ter wi ll remai n clos ed for a few seconds after an engineres t art unti l the vapor is di ss ipat ed.

If the driver sel ect s eit her ‘programmed defros t ’ or t he ‘wi ndshi el d heater’ i t is as s umed t hat a qui ck demis t of thewinds hield is requi red. Therefore, t he ATC vi a the CJB will ei ther: i nhibit an engine shut down or i nit iat e an engine res t art .

Heater fan speed

Duri ng an engine s hutdown t he ATC monit ors cabin temperat ure and maint ai ns the fan speed at a l evel that wi ll cons erve,for as l ong as poss ibl e t he heat i n t he core of t he cabi n heat er. If the driver s elect s a hi gher fan s peed and the heatcannot be mai ntained i n t he heat er core, the engine will rest art .

Heated rear window and heated s eats

If the heated rear window or heated s eats are acti ve or act ivated during an engine shut down event t he power out put oft he relevant s ys t em wi ll be i nt errupted unt il the engi ne is rest art ed. The tell -t ale light i n t he relevant s wit ch wil lil lumi nat e t o i ndi cat e t he s ys t em i s act ive even t hough the s ys tem is recei vi ng no power. This feature is us ed t o conservebatt ery power.

Page 1115 of 3229

Publi s hed: 11-May-2011

Engine Ignition - Engine Ignition

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the ignit ion s yst em, refer to the relevant Des cri pti on and Operati on s ect ion i n t he works hopmanual.REFER to: Engine Ignit ion (303-07A Engi ne Igni ti on, Des cript ion and O perati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

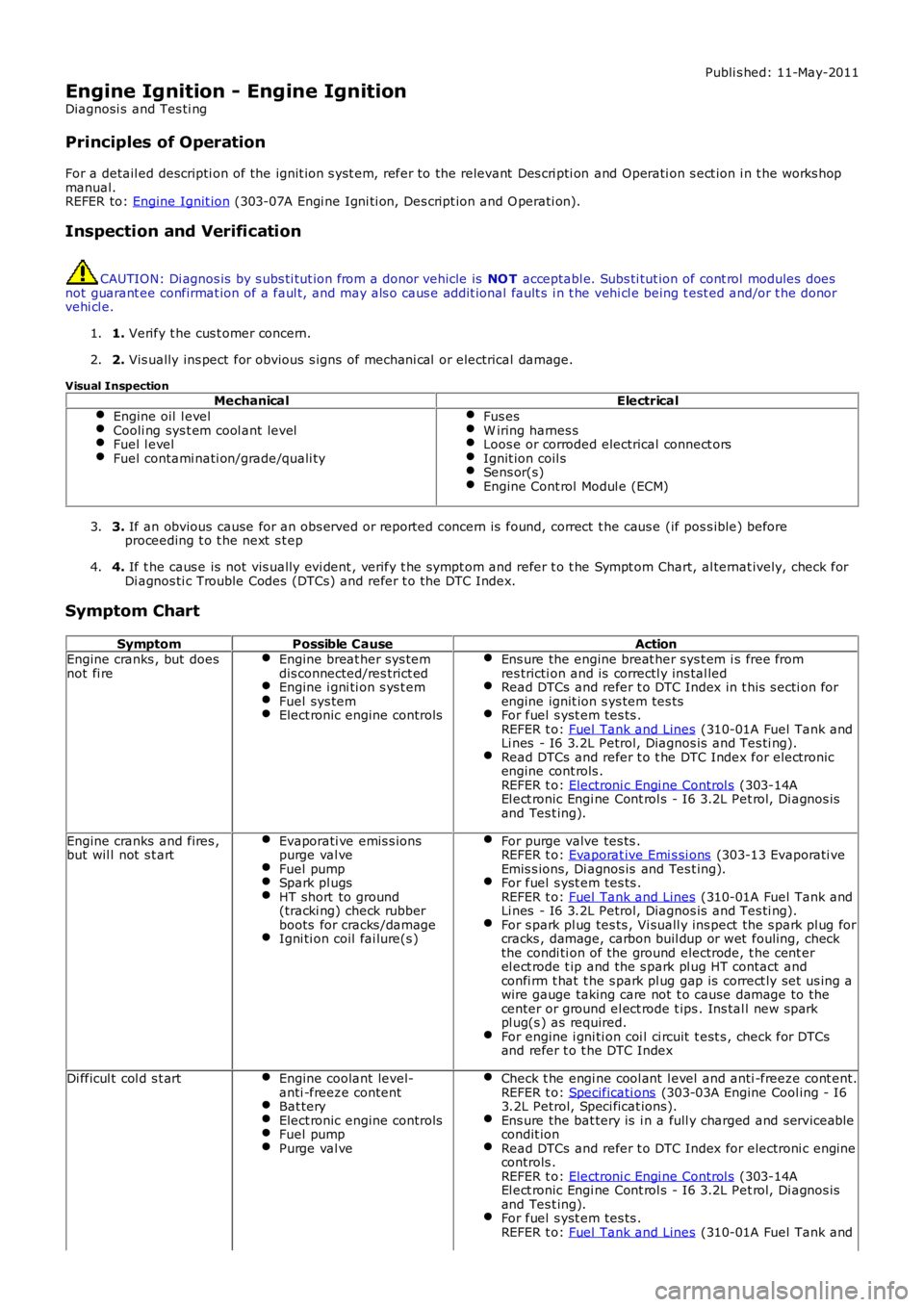

Visual InspectionMechanicalElectrical

Engine oil l evelCooli ng sys t em cool ant levelFuel l evelFuel contami nati on/grade/quali ty

Fus esW iring harnes sLoos e or corroded electrical connect orsIgnit ion coil sSens or(s)Engine Cont rol Modul e (ECM)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseActionEngine cranks , but doesnot fi reEngine breat her sys temdis connected/res trict edEngine i gni ti on s ys t emFuel sys temElect ronic engine controls

Ens ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledRead DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes tsFor fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Read DTCs and refer t o t he DTC Index for elect roni cengine cont rols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).

Engine cranks and fires ,but wil l not s t artEvaporati ve emis s ionspurge val veFuel pumpSpark pl ugsHT short to ground(tracki ng) check rubberboots for cracks /damageIgni ti on coil fai lure(s )

For purge valve tes ts .REFER t o: Evaporat ive Emi s si ons (303-13 Evaporati veEmis s ions, Di agnos is and Tes t ing).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).For s park pl ug tes ts , Vi suall y ins pect t he s park pl ug forcracks , damage, carbon buil dup or wet fouling, checkthe condi ti on of the ground electrode, t he cent erel ect rode t ip and the s park pl ug HT contact andconfi rm t hat t he s park pl ug gap is correct ly set us ing awire gauge taking care not t o cause damage to thecenter or ground el ect rode t ips . Ins tal l new s parkpl ug(s ) as required.For engine i gni ti on coi l ci rcuit t est s , check for DTCsand refer t o t he DTC Index

Di fficul t col d s t artEngine coolant level-anti -freeze contentBat teryElect ronic engine controlsFuel pumpPurge val ve

Check t he engi ne cool ant l evel and anti -freeze cont ent.REFER t o: Specificati ons (303-03A Engine Cool ing - I63.2L Petrol, Speci ficat ions).Ens ure the bat tery is i n a full y charged and s erviceabl econdit ionRead DTCs and refer t o DTC Index for electroni c enginecontrols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank and

Page 1122 of 3229

Publi s hed: 11-May-2011

Glow Plug System - Glow Plug System

Des cript ion and Operat ion

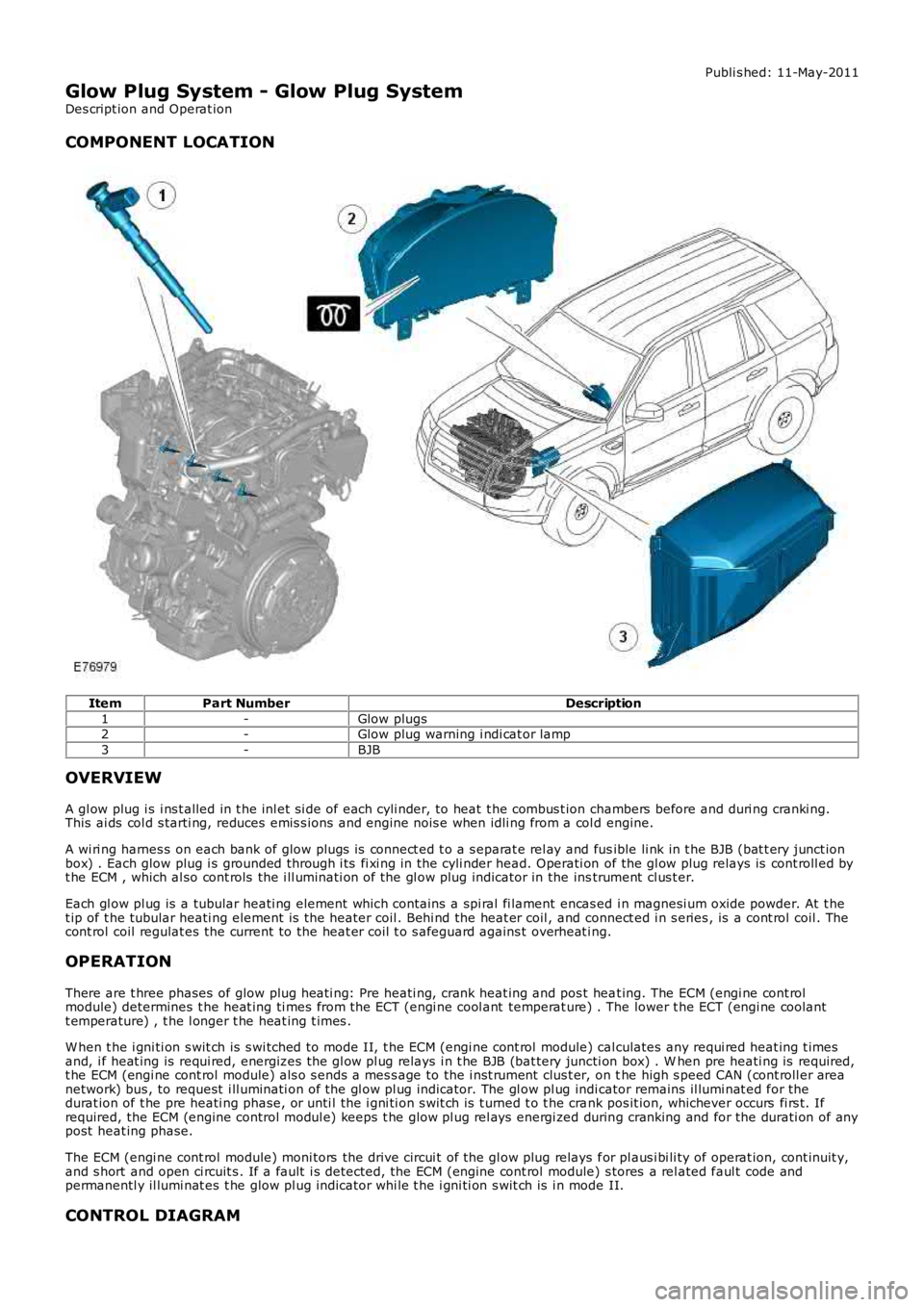

COMPONENT LOCATION

ItemPart NumberDescription

1-Glow plugs2-Glow plug warning i ndi cat or lamp

3-BJB

OVERVIEW

A gl ow plug i s i ns t alled in t he inl et si de of each cyli nder, to heat t he combus t ion chambers before and duri ng cranki ng.This ai ds col d s tarti ng, reduces emis s ions and engine nois e when idli ng from a col d engine.

A wi ri ng harnes s on each bank of glow plugs is connect ed t o a s eparat e rel ay and fusible li nk in t he BJB (bat t ery junct ionbox) . Each glow plug i s grounded through i ts fi xi ng in the cyli nder head. Operati on of the gl ow plug relays is cont roll ed byt he ECM , which al so cont rols the i ll uminati on of the gl ow plug indicator in the instrument cl us t er.

Each gl ow pl ug is a tubular heati ng element which cont ains a spi ral fi lament encas ed i n magnesi um oxide powder. At t het ip of t he tubular heati ng element is the heater coil . Behi nd the heat er coil , and connect ed i n s eries , is a cont rol coil . Thecont rol coil regulat es the current to the heat er coil t o s afeguard agains t overheat ing.

OPERATION

There are t hree phases of glow plug heati ng: Pre heati ng, crank heat ing and pos t heat ing. The ECM (engi ne cont rolmodule) determines t he heat ing ti mes from the ECT (engi ne cool ant temperat ure) . The lower t he ECT (engi ne coolantt emperature) , t he l onger t he heat ing t imes .

W hen t he i gni ti on s wit ch is s wi tched to mode II, t he ECM (engi ne cont rol module) calculates any requi red heat ing t imesand, i f heat ing is requi red, energizes the gl ow pl ug relays i n t he BJB (bat tery juncti on box) . W hen pre heati ng is required,t he ECM (engi ne cont rol module) als o s ends a mes s age to the i nst rument clus t er, on the high s peed CAN (cont roll er areanetwork) bus , to request i ll uminati on of the gl ow pl ug indicator. The gl ow pl ug indicator remains il lumi nat ed for thedurat ion of t he pre heati ng phase, or unti l the i gni ti on s wit ch is t urned t o t he crank pos it ion, whichever occurs fi rs t. Ifrequired, the ECM (engine control modul e) keeps t he glow pl ug rel ays energi zed during cranking and for the durati on of anypost heat ing phase.

The ECM (engi ne cont rol module) moni tors the drive circui t of the gl ow plug relays for pl aus i bi li ty of operat ion, cont inuit y,and s hort and open ci rcuit s . If a fault i s detected, the ECM (engine cont rol module) s tores a rel ated faul t code andpermanentl y il lumi nat es t he glow pl ug indicator whi le t he i gni ti on s wit ch is i n mode II.

CONTROL DIAGRAM

Page 1133 of 3229

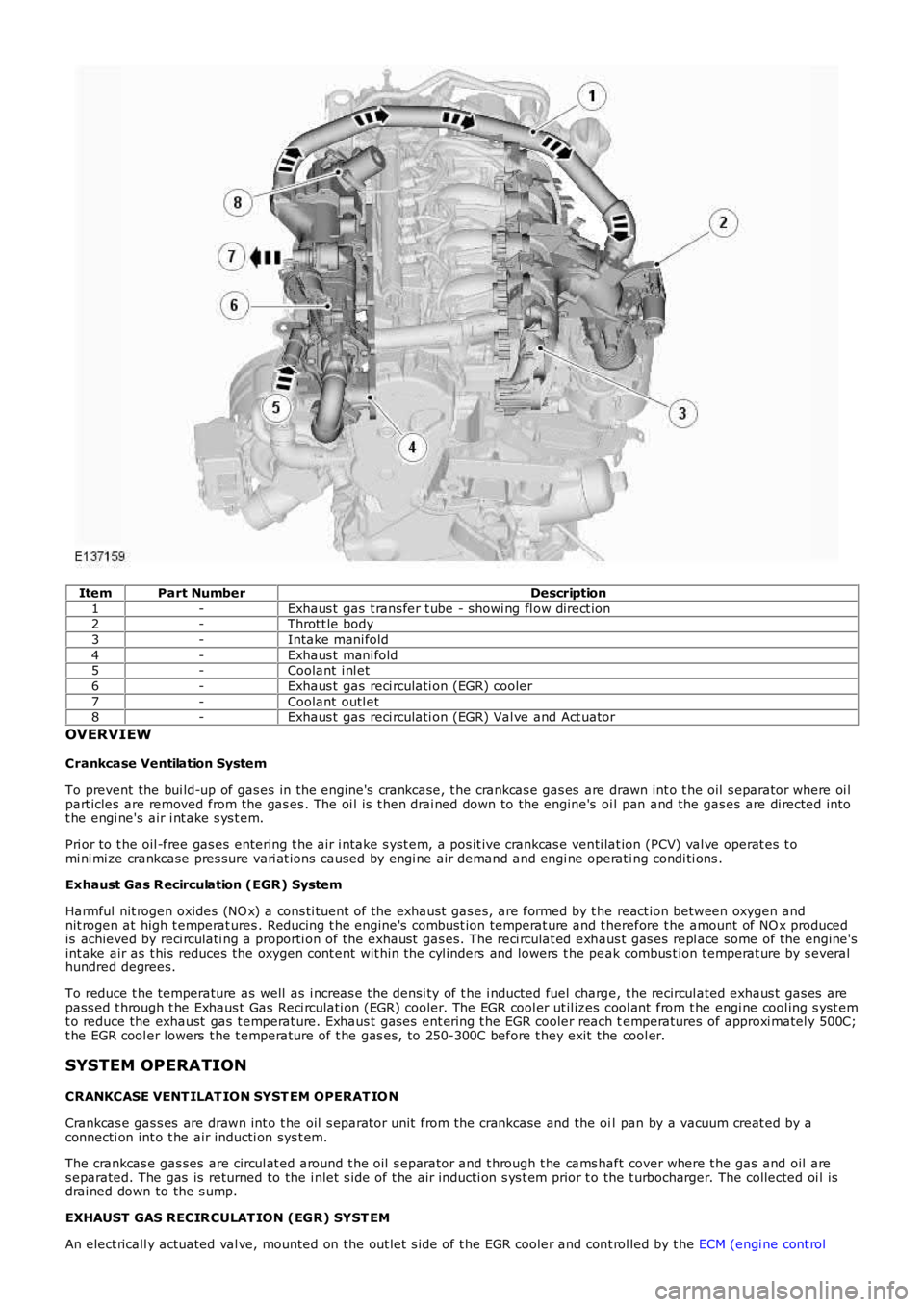

ItemPart NumberDescription

1-Exhaus t gas t rans fer t ube - showi ng fl ow direct ion2-Throt t le body

3-Intake mani fold

4-Exhaus t mani fold5-Coolant i nl et

6-Exhaus t gas reci rculati on (EGR) cooler

7-Coolant outl et8-Exhaus t gas reci rculati on (EGR) Val ve and Act uator

OVERVIEW

Crankcase Ventilation System

To prevent the bui ld-up of gas es in the engine's crankcase, t he crankcas e gas es are drawn int o t he oil s eparator where oi lpart icles are removed from the gas es . The oi l is t hen drai ned down to the engine's oi l pan and the gas es are di rected intot he engi ne's air i nt ake s ys t em.

Pri or to t he oil -free gas es entering t he air i ntake s yst em, a pos it ive crankcas e venti lat ion (PCV) val ve operat es t omi ni mi ze crankcase pres sure vari at ions caused by engi ne air demand and engi ne operati ng condi ti ons .

Exhaust Gas R ecirculation (EGR) System

Harmful nit rogen oxides (NO x) a cons ti tuent of the exhaust gas es, are formed by t he react ion between oxygen andnit rogen at high t emperat ures . Reducing t he engine's combust ion temperat ure and t herefore t he amount of NO x producedis achieved by reci rculati ng a proporti on of the exhaust gas es. The reci rculat ed exhaus t gas es repl ace some of the engine'sint ake air as t hi s reduces the oxygen cont ent wit hin t he cyl inders and lowers t he peak combus t ion t emperat ure by s everalhundred degrees.

To reduce t he temperature as well as i ncreas e t he densi ty of t he i nducted fuel charge, t he recircul ated exhaus t gas es arepass ed t hrough t he Exhaus t Gas Reci rculati on (EGR) cooler. The EGR cool er ut il izes cool ant from t he engi ne cool ing s yst emt o reduce the exhaust gas t emperat ure. Exhaus t gas es ent ering t he EGR cooler reach temperatures of approxi matel y 500C;t he EGR cool er lowers t he t emperature of t he gas es , to 250-300C before t hey exit t he cool er.

SYSTEM OPERATION

CRANKCASE VENT ILAT ION SYST EM OPERAT IO N

Crankcas e gas s es are drawn int o t he oil s eparator unit from the crankcase and the oil pan by a vacuum creat ed by aconnecti on int o t he air inducti on sys t em.

The crankcas e gas ses are circul at ed around t he oil s eparator and t hrough t he cams haft cover where t he gas and oil ares eparated. The gas is returned to the i nlet s ide of t he air inducti on s ys t em prior to the t urbocharger. The collected oi l isdrai ned down to the s ump.

EXHAUST GAS RECIR CULAT ION (EGR) SYST EM

An elect ricall y actuated val ve, mounted on the out let s ide of t he EGR cooler and cont rol led by t he ECM (engi ne cont rol

Page 1134 of 3229

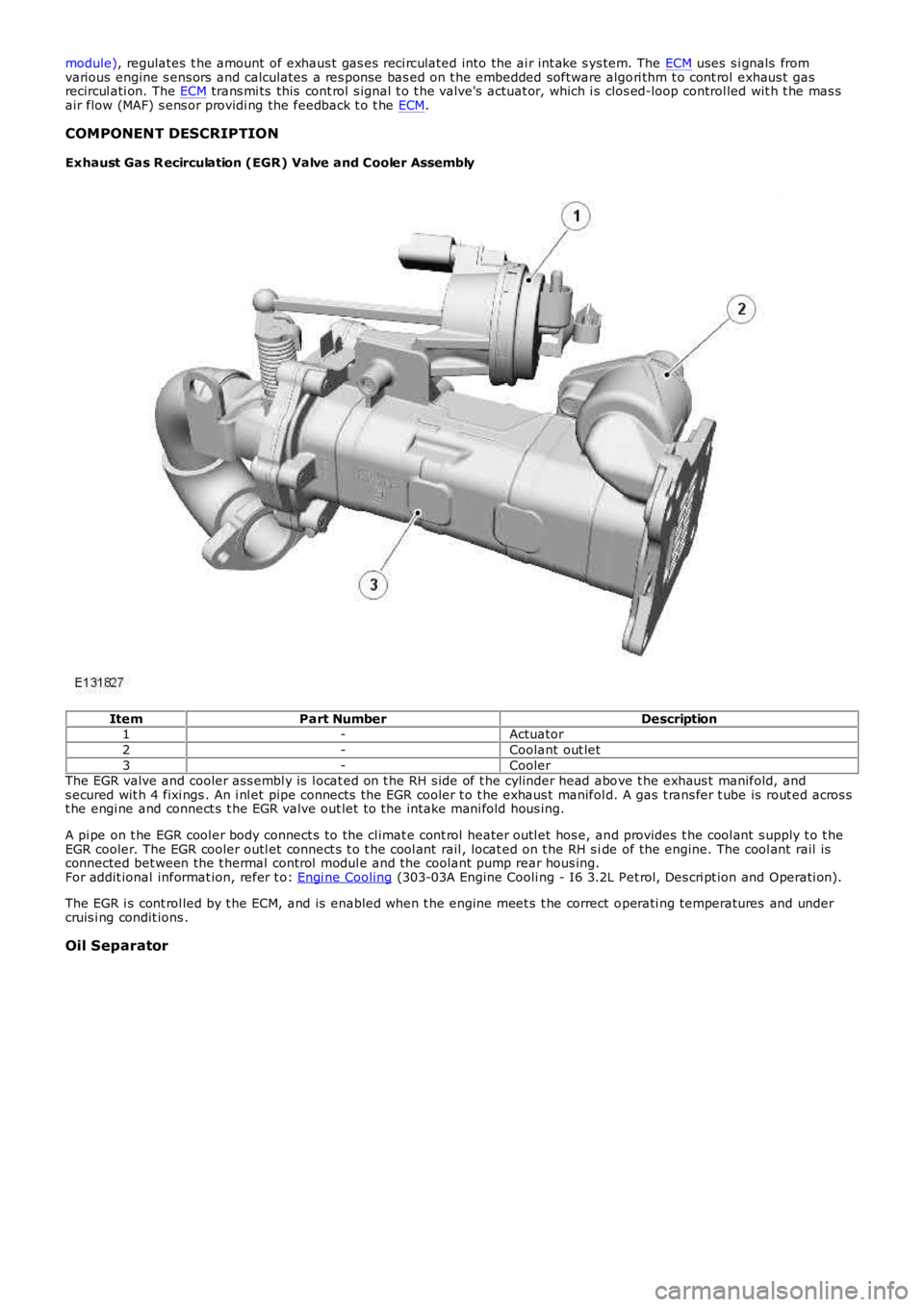

module), regulates t he amount of exhaus t gas es reci rculated into the ai r int ake s ys tem. The ECM uses s i gnals fromvarious engine s ens ors and calculates a res pons e bas ed on t he embedded software algori thm t o cont rol exhaus t gasrecircul ati on. The ECM trans mi ts this cont rol s ignal t o t he valve's actuat or, which i s clos ed-loop controlled wit h t he mas sair flow (MAF) s ens or providi ng the feedback t o t he ECM.

COMPONENT DESCRIPTION

Exhaust Gas R ecirculation (EGR) Valve and Cooler Assembly

ItemPart NumberDescription1-Actuator

2-Coolant out let

3-CoolerThe EGR valve and cooler ass embl y is l ocat ed on t he RH s ide of t he cylinder head above t he exhaus t manifold, ands ecured wit h 4 fixi ngs . An i nl et pipe connects the EGR cooler t o t he exhaus t manifold. A gas t rans fer t ube is rout ed acros st he engi ne and connect s t he EGR valve out let t o the intake mani fold hous ing.

A pi pe on t he EGR cool er body connect s to the cl imat e cont rol heater outl et hos e, and provides t he cool ant s upply t o t heEGR cooler. The EGR cooler outl et connect s t o t he cool ant rail , locat ed on t he RH s ide of the engine. The cool ant rail isconnected bet ween the t hermal control modul e and the coolant pump rear hous ing.For addit ional informat ion, refer t o: Engi ne Cooling (303-03A Engine Cooli ng - I6 3.2L Pet rol, Des cri pt ion and Operati on).

The EGR i s cont rol led by t he ECM, and is enabled when t he engine meet s t he correct operati ng temperatures and undercruis i ng condit ions .

Oil Separator

Page 1162 of 3229

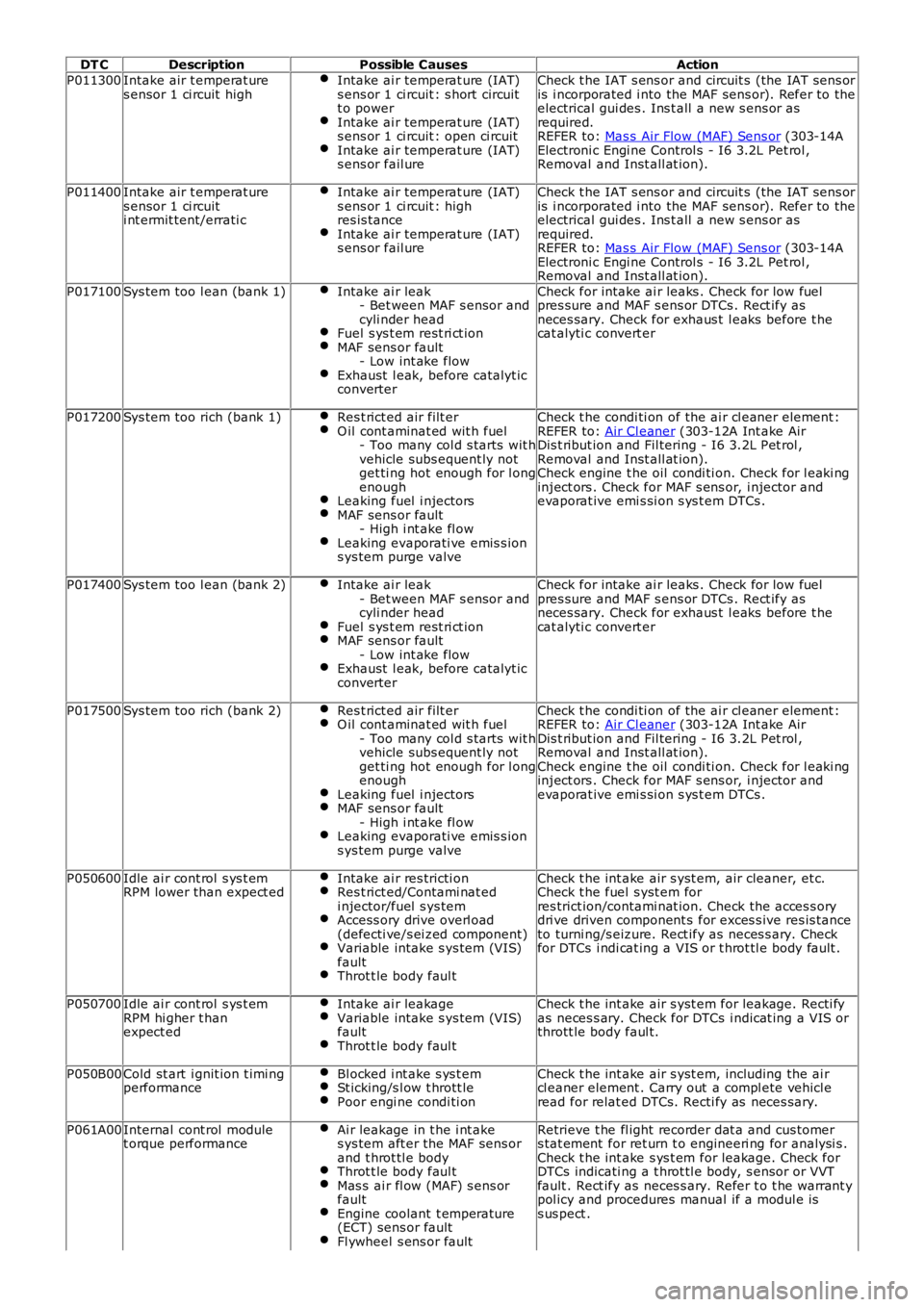

DT C

Description Possible Causes Action

P011300 Intake air t emperat ure

s ensor 1 ci rcuit high Intake ai r temperat ure (IAT)

s ens or 1 ci rcuit : s hort circuit

t o power Intake ai r temperat ure (IAT)

s ens or 1 ci rcuit : open ci rcuit Intake ai r temperat ure (IAT)

s ens or fail ure Check t he IAT s ens or and circuit s (the IAT s ens or

is i ncorporated i nto the MAF sens or). Refer to the

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P011400 Intake air t emperat ure

s ensor 1 ci rcuit

i nt ermit tent/errati c Intake ai r temperat ure (IAT)

s ens or 1 ci rcuit : high

res is tance Intake ai r temperat ure (IAT)

s ens or fail ure Check t he IAT s ens or and circuit s (the IAT s ens or

is i ncorporated i nto the MAF sens or). Refer to the

electrical gui des . Ins t all a new s ens or as

required.

REFER to: Mas s Air Flow (MAF) Sens or (303-14A

Electroni c Engi ne Control s - I6 3.2L Pet rol ,

Removal and Inst all at ion).

P017100 Sys tem too l ean (bank 1) Intake ai r leak

- Bet ween MAF s ensor and

cyli nder head Fuel s ys t em rest ri ct ion

MAF sens or fault

- Low int ake flow Exhaust l eak, before catalyt ic

converter Check for intake ai r leaks . Check for low fuel

pres sure and MAF s ens or DTCs . Rect ify as

neces sary. Check for exhaus t l eaks before t he

cat alyti c convert er

P017200 Sys tem too rich (bank 1) Res t rict ed air filt er O il cont aminat ed wit h fuel

- Too many col d s tarts wit h

vehicle subs equent ly not

get ti ng hot enough for l ong

enough Leaking fuel i njectors

MAF sens or fault

- High i nt ake fl ow Leaking evaporati ve emis s ion

s ys tem purge valve Check t he condi ti on of the ai r cl eaner element :

REFER to: Air Cl eaner (303-12A Int ake Air

Dis t ribut ion and Fil tering - I6 3.2L Pet rol ,

Removal and Inst all at ion).

Check engine t he oil condi ti on. Check for l eaki ng

inject ors . Check for MAF s ens or, i njector and

evaporat ive emi s si on s ys t em DTCs .

P017400 Sys tem too l ean (bank 2) Intake ai r leak

- Bet ween MAF s ensor and

cyli nder head Fuel s ys t em rest ri ct ion

MAF sens or fault

- Low int ake flow Exhaust l eak, before catalyt ic

converter Check for intake ai r leaks . Check for low fuel

pres sure and MAF s ens or DTCs . Rect ify as

neces sary. Check for exhaus t l eaks before t he

cat alyti c convert er

P017500 Sys tem too rich (bank 2) Res t rict ed air filt er O il cont aminat ed wit h fuel

- Too many col d s tarts wit h

vehicle subs equent ly not

get ti ng hot enough for l ong

enough Leaking fuel i njectors

MAF sens or fault

- High i nt ake fl ow Leaking evaporati ve emis s ion

s ys tem purge valve Check t he condi ti on of the ai r cl eaner element :

REFER to: Air Cl eaner (303-12A Int ake Air

Dis t ribut ion and Fil tering - I6 3.2L Pet rol ,

Removal and Inst all at ion).

Check engine t he oil condi ti on. Check for l eaki ng

inject ors . Check for MAF s ens or, i njector and

evaporat ive emi s si on s ys t em DTCs .

P050600 Idle ai r cont rol s ys t em

RPM lower than expect ed Intake ai r res tricti on Res t rict ed/Contami nat ed

i njector/fuel s ys tem Access ory drive overl oad

(defecti ve/s ei zed component) Variable intake s ys tem (VIS)

fault Throt t le body faul t Check t he int ake air s yst em, air cleaner, et c.

Check t he fuel s yst em for

res trict ion/contami nat ion. Check the acces s ory

dri ve driven component s for exces s ive res is tance

to turni ng/s eizure. Rect ify as neces s ary. Check

for DTCs i ndi cat ing a VIS or t hrot tl e body fault .

P050700 Idle ai r cont rol s ys t em

RPM hi gher t han

expect ed Intake ai r leakage Variable intake s ys tem (VIS)

fault Throt t le body faul t Check t he int ake air s yst em for leakage. Recti fy

as neces s ary. Check for DTCs i ndicat ing a VIS or

thrott le body faul t.

P050B00 Cold st art i gnit ion t imi ng

performance Bl ocked i nt ake s ys t em St icking/s l ow t hrott le

Poor engi ne condi ti on Check t he int ake air s yst em, including the ai r

cl eaner element . Carry out a compl ete vehicl e

read for relat ed DTCs. Recti fy as neces sary.

P061A00 Internal cont rol module

t orque performance Ai r leakage in t he i nt ake

s ys tem aft er the MAF sens or

and t hrot tl e body Throt t le body faul t

Mas s ai r fl ow (MAF) s ens or

fault Engine coolant t emperature

(ECT) sens or fault Fl ywheel s ens or fault Retrieve t he fl ight recorder dat a and cus tomer

s tat ement for ret urn t o engineeri ng for analysi s .

Check t he int ake s ys t em for leakage. Check for

DTCs indicati ng a t hrot tl e body, s ensor or VVT

fault . Rect ify as neces s ary. Refer t o t he warrant y

pol icy and procedures manual if a modul e is

s us pect .

Page 1163 of 3229

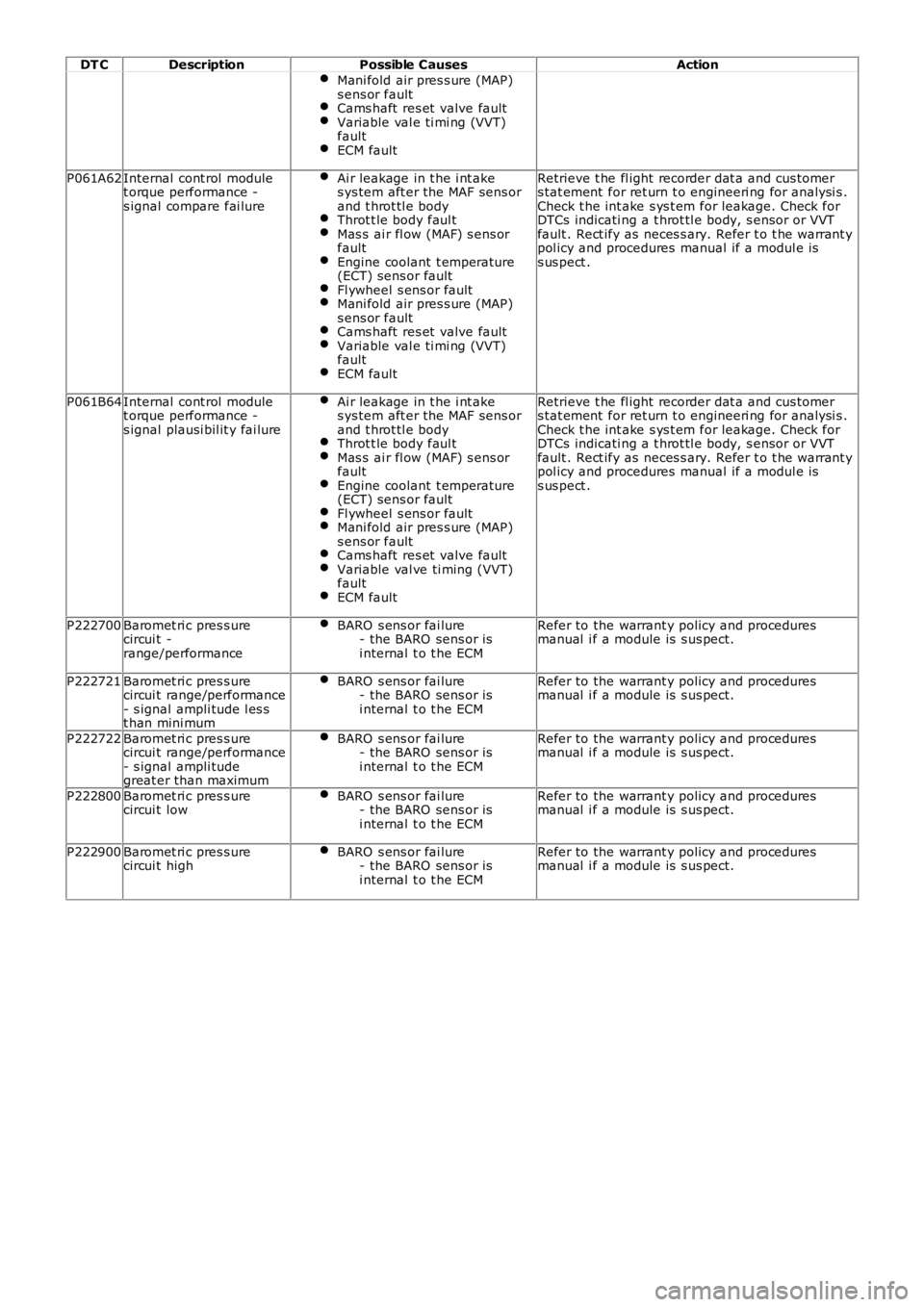

DT C

Description Possible Causes Action

Mani fold air pres s ure (MAP)

s ens or fault Cams haft res et valve fault

Variable val e ti mi ng (VVT)

fault ECM fault

P061A62

Internal cont rol module

t orque performance -

s ignal compare fai lure Ai r leakage in t he i nt ake

s ys tem aft er the MAF sens or

and t hrot tl e body Throt t le body faul t

Mas s ai r fl ow (MAF) s ens or

fault Engine coolant t emperature

(ECT) sens or fault Fl ywheel s ens or fault

Mani fold air pres s ure (MAP)

s ens or fault Cams haft res et valve fault

Variable val e ti mi ng (VVT)

fault ECM fault Retrieve t he fl ight recorder dat a and cus tomer

s tat ement for ret urn t o engineeri ng for analysi s .

Check t he int ake s ys t em for leakage. Check for

DTCs indicati ng a t hrot tl e body, s ensor or VVT

fault . Rect ify as neces s ary. Refer t o t he warrant y

pol icy and procedures manual if a modul e is

s us pect .

P061B64 Internal cont rol module

t orque performance -

s ignal plausi bil it y fai lure Ai r leakage in t he i nt ake

s ys tem aft er the MAF sens or

and t hrot tl e body Throt t le body faul t

Mas s ai r fl ow (MAF) s ens or

fault Engine coolant t emperature

(ECT) sens or fault Fl ywheel s ens or fault

Mani fold air pres s ure (MAP)

s ens or fault Cams haft res et valve fault

Variable val ve ti ming (VVT)

fault ECM fault Retrieve t he fl ight recorder dat a and cus tomer

s tat ement for ret urn t o engineeri ng for analysi s .

Check t he int ake s ys t em for leakage. Check for

DTCs indicati ng a t hrot tl e body, s ensor or VVT

fault . Rect ify as neces s ary. Refer t o t he warrant y

pol icy and procedures manual if a modul e is

s us pect .

P222700 Baromet ri c pres s ure

circui t -

range/performance BARO s ens or fai lure

- the BARO sens or is

i nternal t o t he ECM Refer to the warrant y policy and procedures

manual i f a module is s us pect.

P222721 Baromet ri c pres s ure

circui t range/performance

- s ignal ampli tude l es s

t han mini mum BARO s ens or fai lure

- the BARO sens or is

i nternal t o t he ECM Refer to the warrant y policy and procedures

manual i f a module is s us pect.

P222722 Baromet ri c pres s ure

circui t range/performance

- s ignal ampli tude

great er than maximum BARO s ens or fai lure

- the BARO sens or is

i nternal t o t he ECM Refer to the warrant y policy and procedures

manual i f a module is s us pect.

P222800 Baromet ri c pres s ure

circui t low BARO s ens or fai lure

- the BARO sens or is

i nternal t o t he ECM Refer to the warrant y policy and procedures

manual i f a module is s us pect.

P222900 Baromet ri c pres s ure

circui t high BARO s ens or fai lure

- the BARO sens or is

i nternal t o t he ECM Refer to the warrant y policy and procedures

manual i f a module is s us pect.

Page 1171 of 3229

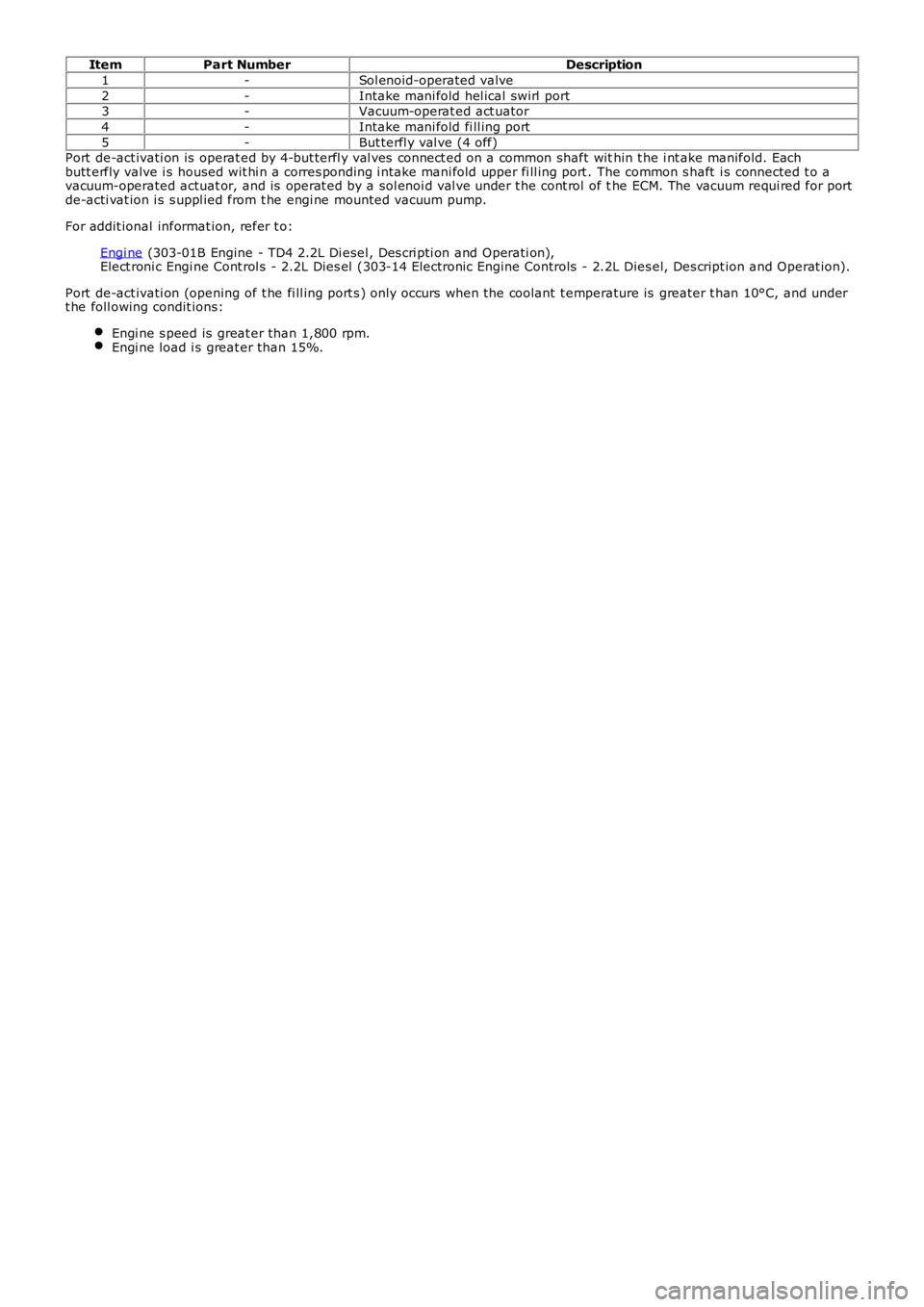

ItemPart NumberDescription

1-Sol enoid-operated valve

2-Intake mani fold hel ical swirl port3-Vacuum-operat ed act uator

4-Intake mani fold fi ll ing port

5-But terfl y val ve (4 off)Port de-act ivati on is operat ed by 4-but terfl y val ves connect ed on a common shaft within t he i nt ake manifold. Eachbutt erfly valve i s housed wit hi n a corres ponding i ntake mani fold upper fi ll ing port . The common s haft i s connected t o avacuum-operated actuat or, and is operat ed by a sol enoi d val ve under t he cont rol of the ECM. The vacuum requi red for portde-acti vat ion i s s uppl ied from t he engi ne mounted vacuum pump.

For addit ional informat ion, refer t o:

Engi ne (303-01B Engine - TD4 2.2L Di esel , Des cri pti on and Operati on),Elect roni c Engi ne Cont rol s - 2.2L Dies el (303-14 Electronic Engine Controls - 2.2L Dies el, Des cript ion and Operat ion).

Port de-act ivati on (opening of t he fi ll ing port s ) onl y occurs when the coolant t emperature is greater t han 10°C, and undert he foll owing condit ions:

Engi ne s peed is great er than 1,800 rpm.Engi ne load i s great er than 15%.

Page 1205 of 3229

t he ignit ion t imingt he engi ne load.

The ECM moni tors the MAF s ens or for faul ts and can s t ore fault rel ated codes. Thes e can be ret ri eved us ing a Land Roverapproved diagnos t ic s yst em.

Int ake Air Temperat ure (IAT) Sens or

The IAT s ens or measures the temperat ure of t he i nt ake air entering t he engine. The sens or is a temperat ure dependantres is t or (t hermi st or). The thermis t or i s a NTC sens or element. The el ement resi s tance decreas es as t he s ens ort emperature increas es. The ECM suppli es the sens or wit h a 5V reference volt age and a ground and meas ures the returneds ignal as a t emperature.

The res is t ance i n t he s ens or changes wi th i ntake air t emperat ure. A l ow i nt ake air temperature wi ll res ult i n a hi gh vol tagebeing returned t o t he ECM and hi gh int ake ai r temperature wil l ret urn a low volt age reading of bet ween 0 - 5V.

The ECM moni tors the IAT s ens or for fault s and can s tore faul t relat ed codes . Thes e can be retrieved us ing a Land Roverapproved diagnos t ic s yst em. If the IAT s ensor fails , t he ECM us es a defaul t temperature val ue usi ng the fuel railpres s ure/t emperat ure s ensor.

Knock Sensors

Two knock sens ors are located on the front of t he engi ne and are each s ecured to threaded holes in t he engine cylinderblock wit h a bol t. The knock sens ors are us ed by t he ECM t o monit or combus ti on knocking or vibrati on generat ed byignit ion combus ti on. The knock s ens ors are each connected t o t he ECM via a t wis t ed pai r of wires which reduces electricalint erference di s rupti ng t he si gnal produced.

Each knock s ens or cont ains a pei zo-ceramic crys t al whi ch produces a vol tage when an ext ernal force appli es pres s ure orload on it . W hen t he engi ne is runni ng, compres s ion waves produced by t he combus t ion proces s, creat es pres sure waveswhich pas s t hrough the engine cyli nder bl ock. Thes e press ure waves are detected by the knock s ens ors and the defl ect ionof the crys t al caus ed by the pres sure waves caus es the sens ors t o produce an out put s ignal. The s i gnals are pas s ed to theECM whi ch compares them wit h s tored mapped s ignal s i n it s memory.

The ECM can t hen det ermine when t he correct combus t ion occurs i n indivi dual cyl inders . If incorrect combus t ion detonat ionis det ect ed, the ECM can retard t he ignit ion ti ming on that cyl inder for a number of combus ti on cycl es . The i gni ti on ti mingwil l be gradually ret urned t o it s opti mal s et t ings. If t he knock is st il l det ected the ECM wi ll i ncreas e t he i nject ion period,which has a cooli ng effect on t hat cyl inder.

The s ignals from the knock s ens ors are us ed i n conjunct ion wi th the CMP sens ors and t he CKP s ens or t o det ermi ne theignit ion cycle and t herefore i dent ify which cylinder is knocki ng. The ECM is programmed to us e i gni ti on maps bas ed on highqual it y 95-98 RO N fuel . If fuel of a poor qual it y s uch as 91 RON i s us ed the engi ne may s uffer from knock (pinking) for aperi od of ti me. The ECM is capable of l earning and adapti ng to the l ow grade fuel and wil l modi fy it s int ernal ignit ionmapping t o compens at e for t he low grade fuel . Thi s feat ure of t he ECM i s called adapt ion.

If one or bot h knock s ensors fai l or the s ignal becomes i mplaus ible, t he ECM wi ll cancel clos ed loop cont rol of t he ignit ions ys t em. The ECM wi ll us e a defaul t 's afe' ignit ion map to ens ure the pre-det onat ion does not damage the engine bys ett ing maxi mum retard cont rol on s park advance. The dri ver may not ice 'pinking' under certai n dri vi ng condi ti ons and alos s of performance. The ECM monit ors t he knock s ens ors for fault s and can st ore fault relat ed codes . Thes e can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem.

Engine Coolant Temperature (ECT) Sensor

Page 1206 of 3229

The ECT s ens or is locat ed i n t he thermost at hous ing, on t he front of the engine, below t he i nl et manifol d. The ECT s ens oris a t hermis t or type s ens or us ed by the ECM t o monit or the engine coolant t emperature. The ECM uses t he t emperatureinformat ion for the foll owi ng functi ons:

regulat e t he inject ion peri ods et engi ne idle target s peedcont rol t he engi ne cool ing fan(s )determine operat ion of t he A/C compres sordetermine operat ion of t he purge valve and catal yt ic convert er heat ing funct ion.

The s ens or is a Negat ive Temperat ure Co-efficient (NTC) thermis tor element . The element res is t ance decreas es as thes ens or t emperature increas es. The ECM suppli es the sens or wit h a 5V reference volt age and a ground and meas ures theret urned s ignal as a t emperature.

The ECT s ens or is important to the correct running of t he engi ne as a richer mixt ure i s required at low engi ne cool antt emperatures for efficient s tarti ng and s mooth cold running. As t he engi ne cool ant temperat ure i ncreas es , the ECM usest he temperat ure si gnal from the sens or to l ean off t he fuel mi xt ure to maint ai n optimum emis s ions and performance.

The ECM moni tors the ECT sens or for faul ts and can s t ore faul t rel at ed codes . These can be ret ri eved us ing a Land Roverapproved diagnos t ic s yst em. If the ECT sens or fail s, t he ECM us es a defaul t val ue of 90°C (194°F). The electric fan cont rolmodule i s s ent a default coolant temperat ure val ue of 105°C (221°F) and s wit ches t he cooling fan on permanent ly.

Engine Oil Level/Temperature Sensor

The engi ne oil l evel/t emperature s ens or is locat ed on t he unders ide of t he engi ne and is secured i n t he engi ne oil pan wi th3 s crews and i s s eal ed wi th an O-ring s eal. The ECM suppli es the s ens or wit h a 5V reference volt age and two wires s uppl yt he temperat ure and oi l level si gnal s back t o t he ECM.

Two t ypes of engine oi l level /t emperat ure s ensor are us ed. On earli er model s a capacit ive oi l level s ens or i s fit ted and wasrepl aced by an ul trasound l evel s ens or on l at er models . The principl e of the temperat ure s ens or i s t he s ame in bot h s ens ort ypes . The sens ors can be i dent ified by di fferences in t he s ens or housi ngs ; t he capacit ive s ensor has t he electricalconnector moulded s quare t o t he bas e of the s ens or, t he ult ras oni c s ens or has the connect or moulded at a s li ght angle tot he bas e of t he s ens or.

The ECM us es both the oi l l evel and t emperature s ignals t o calculat e t he oil level. Temporary oil level changes caus ed byhil l driving or cornering are taken i nt o account by t he ECM us ing addit ional informat ion s uch as vehi cl e s peed and engi neload.

Engi ne Oi l Level Sens or - Capacit ance Type

The engi ne oil l evel s ens or compris es t wo capaci ti ve gauge el ement s . Thes e meas ure the resi s tance to elect rical currentpass i ng through t he engine oi l.

There are t wo capacit ors , one meas uring t he permit ti vi ty of t he oil and a second with t wo pl at es s et verti cal ly meas uri ngt he hei ght . The s econd capaci tor wil l have a proport ion of oil and ai r bet ween t he plates and s i nce t he permit ti vi ty of ai r isdifferent t o t hat of oi l, t he permi tt ivit y readi ng wil l change as t he level of oi l decreas es and the ai r between t he plat e gapincreas es. This permi tt ivit y readi ng is compared t o t hat of the oi l (t aken by t he first capaci tor) and an oil level is derived.

Engi ne Oi l Level Sens or - Ult ras ound Type