service LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 774 of 3229

For furt her det ail s on connecti ng rod bi g-end beari ng ins tal lati on, refer t o t he relevant Service Repair Procedures (SRP).

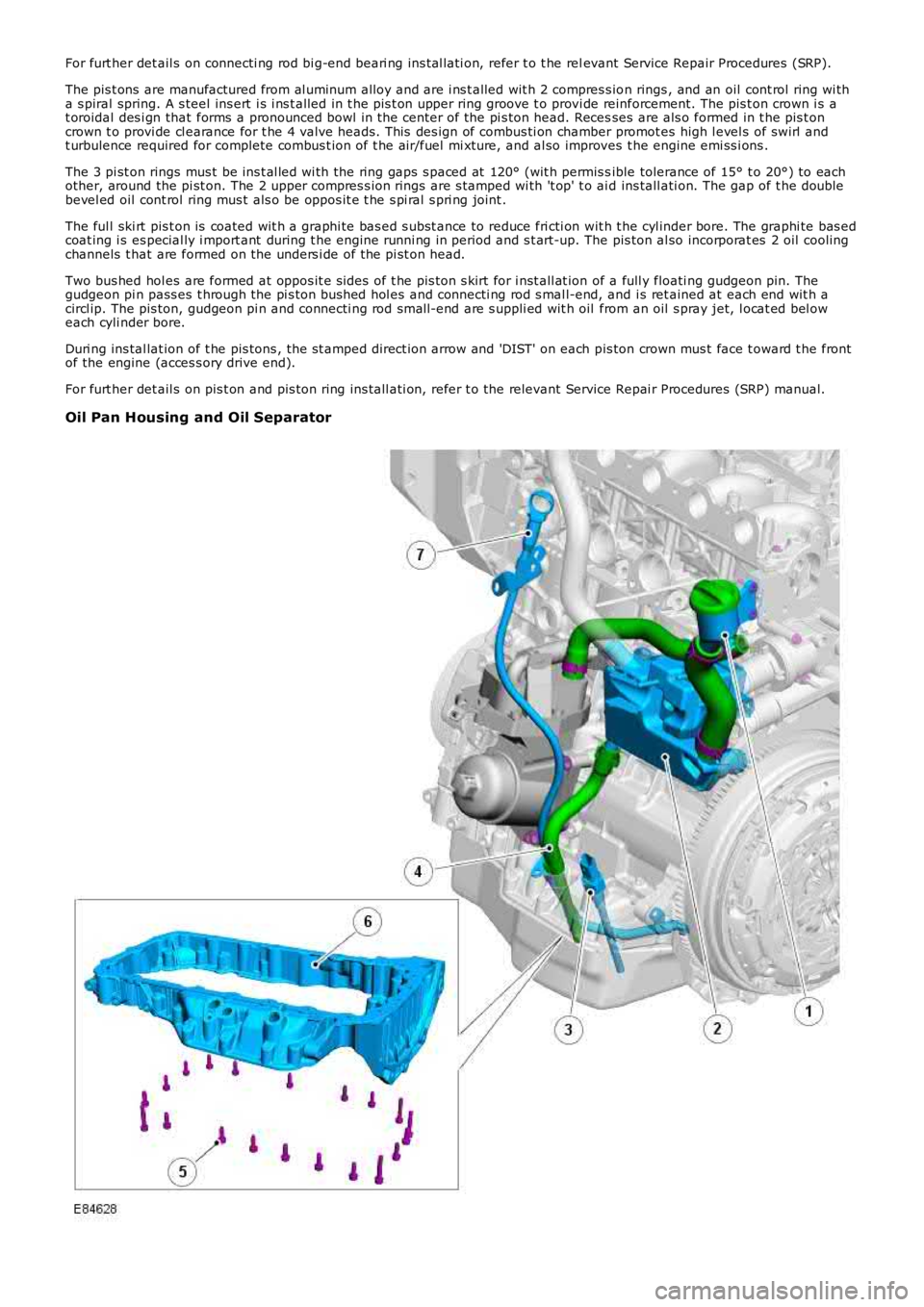

The pis t ons are manufactured from al uminum alloy and are i ns t alled wit h 2 compres s ion rings , and an oil cont rol ring wi tha s piral spring. A s teel ins ert i s i ns t alled in t he pis t on upper ring groove t o provi de reinforcement. The pis t on crown i s at oroidal des i gn that forms a pronounced bowl in t he center of the pi s ton head. Recesses are als o formed in t he pis t oncrown t o provi de cl earance for t he 4 valve heads. This des ign of combus ti on chamber promot es high l evel s of swirl andt urbulence required for complete combus t ion of t he air/fuel mi xture, and al so improves t he engine emi ss i ons .

The 3 pi st on rings mus t be ins t al led wi th the ring gaps s paced at 120° (wit h permis sible tolerance of 15° t o 20°) to eachother, around the pi st on. The 2 upper compres s ion rings are s tamped wi th 't op' t o aid ins tall ati on. The gap of t he doubl ebevel ed oil cont rol ring mus t als o be oppos it e t he s pi ral s pri ng joint .

The ful l ski rt pis t on is coated wit h a graphi te bas ed s ubst ance to reduce fri cti on wit h t he cyl inder bore. The graphi te bas edcoat ing i s es pecial ly i mport ant during t he engine runni ng in period and s t art-up. The pis ton al so incorporat es 2 oil coolingchannels t hat are formed on the unders i de of the pi st on head.

Two bus hed hol es are formed at oppos it e s ides of t he pis ton s kirt for i nst all at ion of a full y floati ng gudgeon pin. Thegudgeon pi n pass es t hrough the pi s ton bus hed hol es and connecti ng rod s mal l-end, and i s ret ained at each end wit h acircl ip. The pis ton, gudgeon pi n and connecti ng rod smal l-end are s uppli ed wit h oil from an oil s pray jet, l ocat ed bel oweach cyli nder bore.

Duri ng ins tal lat ion of t he pis tons , the s t amped direct ion arrow and 'DIST' on each pis ton crown mus t face t oward t he frontof the engine (acces s ory drive end).

For furt her det ail s on pis t on and pis ton ring ins tall ati on, refer t o the relevant Service Repai r Procedures (SRP) manual.

Oil Pan Housing and Oil Separator

Page 780 of 3229

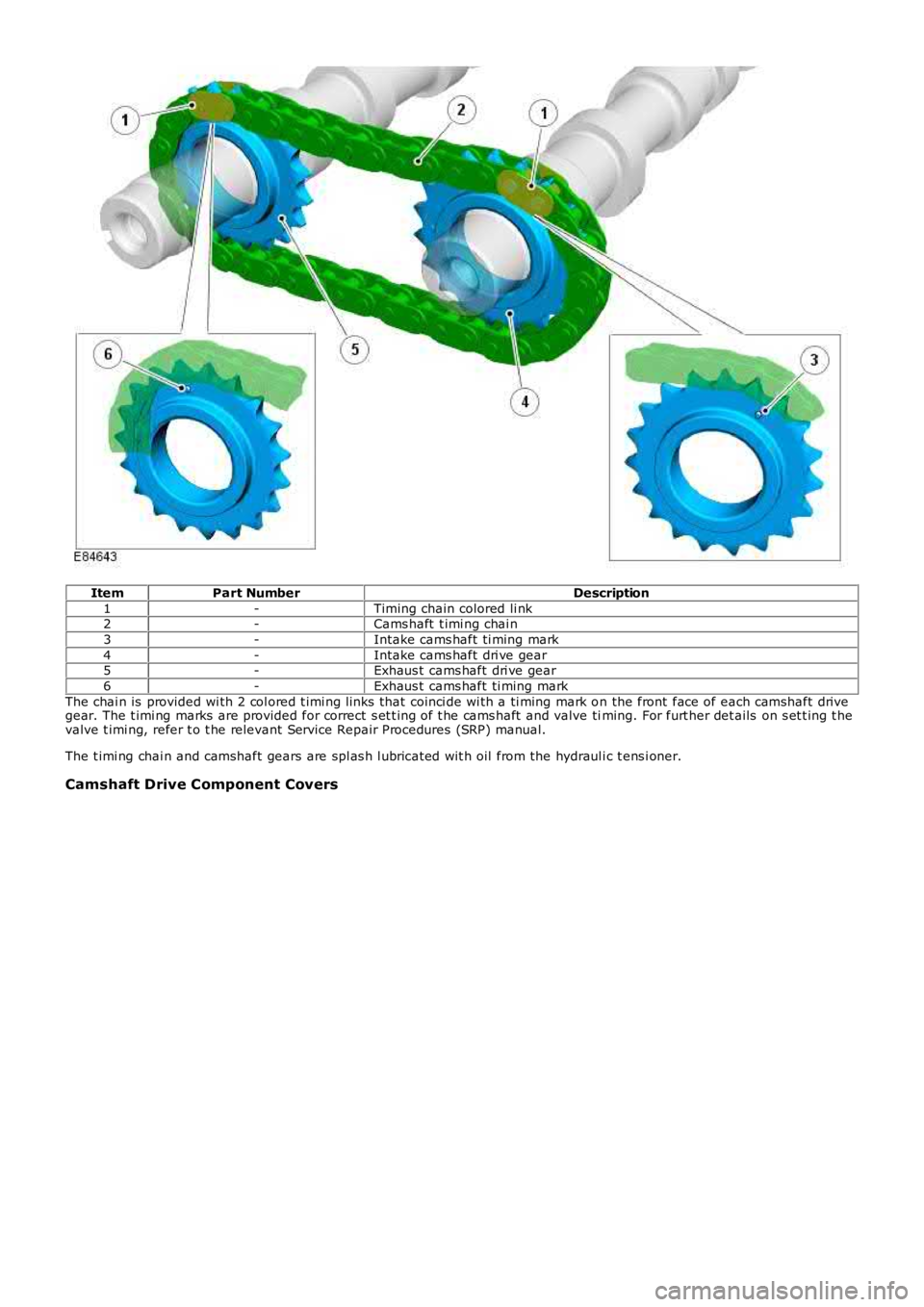

ItemPart NumberDescription

1-Timing chain colored li nk2-Cams haft t imi ng chai n

3-Intake cams haft ti ming mark

4-Intake cams haft dri ve gear5-Exhaus t cams haft dri ve gear

6-Exhaus t cams haft ti ming mark

The chai n is provided wi th 2 col ored t imi ng li nks that coinci de wi th a ti ming mark on the front face of each camshaft drivegear. The t imi ng marks are provided for correct s et t ing of t he cams haft and valve timing. For furt her det ails on s et t ing t hevalve t imi ng, refer t o t he relevant Service Repair Procedures (SRP) manual.

The t imi ng chai n and camshaft gears are spl as h l ubricat ed wit h oil from the hydraul ic t ens i oner.

Camshaft Drive Component Covers

Page 785 of 3229

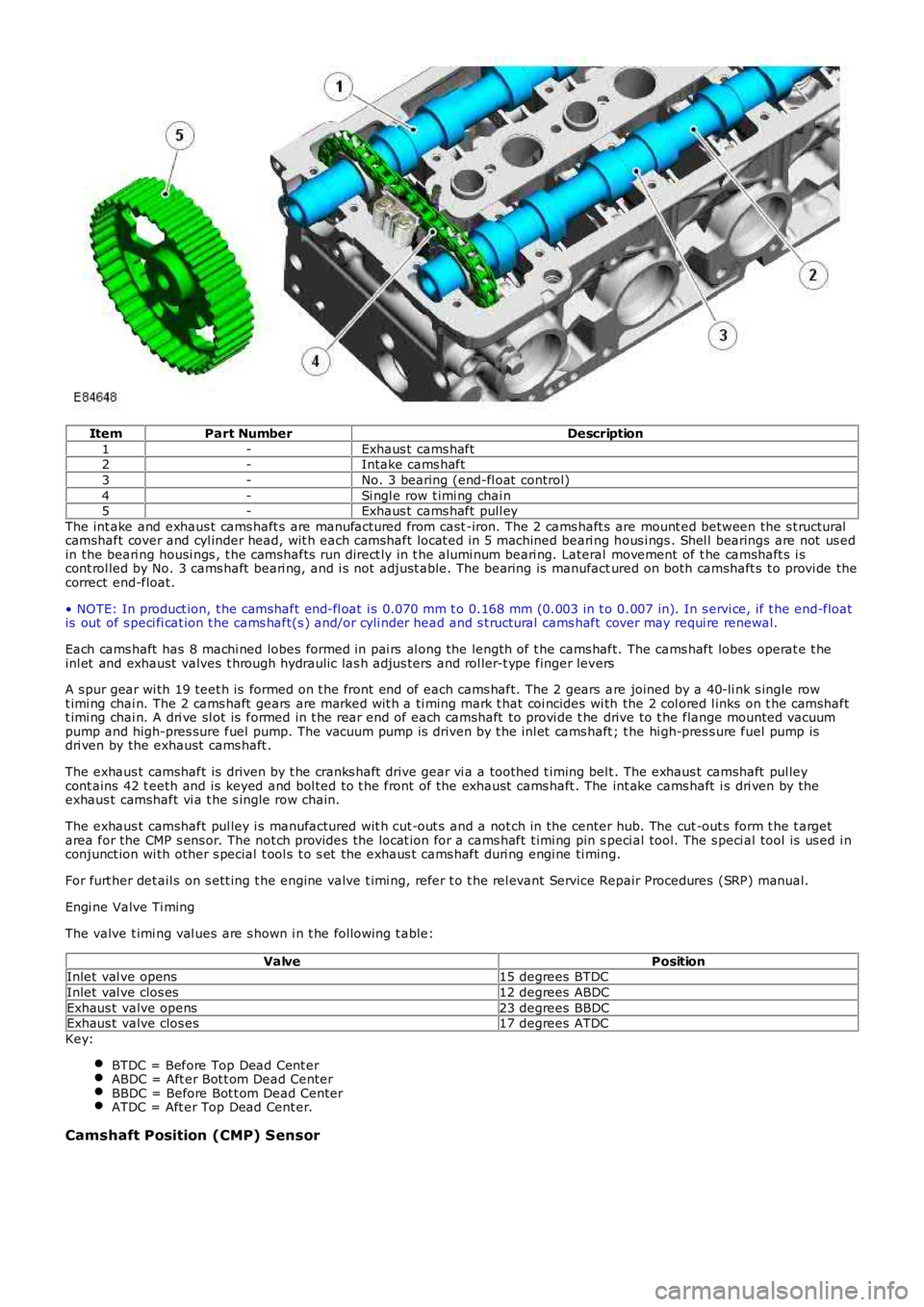

ItemPart NumberDescription

1-Exhaus t cams haft2-Intake cams haft

3-No. 3 bearing (end-fl oat control)

4-Si ngl e row t imi ng chai n5-Exhaus t cams haft pull ey

The int ake and exhaus t cams haft s are manufactured from cast -iron. The 2 cams haft s are mount ed between the s t ructuralcamshaft cover and cyl inder head, wit h each camshaft locat ed i n 5 machined beari ng hous i ngs . Shel l bearings are not us edin the beari ng housi ngs , t he camshafts run direct ly in t he alumi num beari ng. Lateral movement of t he camshaft s i scont rol led by No. 3 cams haft beari ng, and i s not adjust able. The bearing is manufactured on both camshaft s t o provi de thecorrect end-float.

• NOTE: In product ion, t he camshaft end-fl oat i s 0.070 mm t o 0.168 mm (0.003 in t o 0.007 in). In s ervi ce, if t he end-floatis out of s peci fi cat ion t he cams haft(s ) and/or cyli nder head and s t ructural cams haft cover may requi re renewal.

Each cams haft has 8 machi ned lobes formed in pai rs al ong the length of t he cams haft. The cams haft lobes operat e t heinl et and exhaust valves t hrough hydraulic las h adjus ters and rol ler-t ype finger levers

A s pur gear wi th 19 teet h is formed on t he front end of each cams haft. The 2 gears are joined by a 40-li nk s ingle rowt imi ng chai n. The 2 cams haft gears are marked wit h a ti ming mark t hat coi ncides wi th the 2 col ored l inks on t he camshaftt imi ng chai n. A dri ve sl ot is formed in t he rear end of each camshaft to provi de t he drive to t he flange mounted vacuumpump and high-pres sure fuel pump. The vacuum pump is driven by t he inl et cams haft ; the hi gh-pres s ure fuel pump isdri ven by the exhaust cams haft .

The exhaus t camshaft is driven by t he cranks haft drive gear vi a a toothed t iming belt . The exhaus t camshaft pul leycont ains 42 t eeth and is keyed and bol ted to t he front of the exhaust cams haft . The int ake cams haft i s dri ven by theexhaus t camshaft vi a t he s ingle row chain.

The exhaus t camshaft pul ley i s manufactured wit h cut-out s and a not ch in the center hub. The cut -out s form t he t argetarea for the CMP s ens or. The not ch provides the locat ion for a cams haft t imi ng pin speci al tool. The s peci al tool is us ed i nconjunct ion wi th other s pecial t ool s t o s et the exhaus t cams haft duri ng engi ne ti ming.

For furt her det ail s on s ett ing t he engine valve t imi ng, refer t o t he rel evant Service Repair Procedures (SRP) manual.

Engi ne Valve Ti ming

The valve t imi ng val ues are s hown i n t he fol lowing t able:

ValvePositionInlet val ve opens15 degrees BTDC

Inlet val ve clos es12 degrees ABDC

Exhaus t valve opens23 degrees BBDCExhaus t valve clos es17 degrees ATDC

Key:

BTDC = Before Top Dead Cent erABDC = Aft er Bot t om Dead CenterBBDC = Before Bot t om Dead CenterATDC = Aft er Top Dead Cent er.

Camshaft Position (CMP) Sensor

Page 862 of 3229

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Cylinder Head

Removal and Inst all ati on

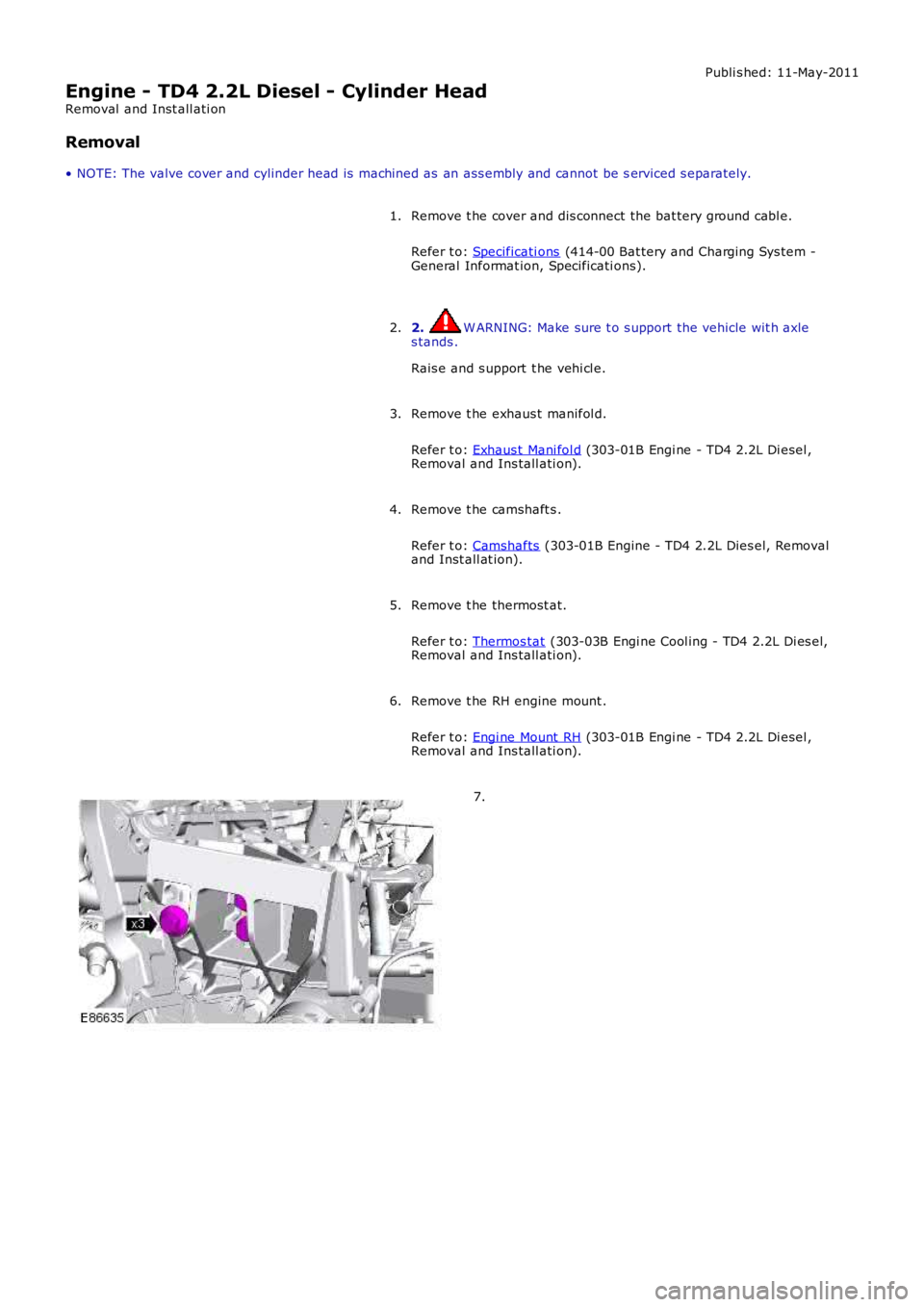

Removal

• NOTE: The valve cover and cylinder head is machined as an ass embly and cannot be serviced s eparately.

Remove t he cover and dis connect the bat tery ground cabl e.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

2. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

2.

Remove t he exhaus t manifol d.

Refer t o: Exhaus t Mani fol d (303-01B Engi ne - TD4 2.2L Di esel ,Removal and Ins tall ati on).

3.

Remove t he camshaft s .

Refer t o: Camshafts (303-01B Engine - TD4 2.2L Dies el, Removaland Inst all at ion).

4.

Remove t he thermost at.

Refer t o: Thermos tat (303-03B Engi ne Cool ing - TD4 2.2L Di es el,Removal and Ins tall ati on).

5.

Remove t he RH engine mount .

Refer t o: Engi ne Mount RH (303-01B Engi ne - TD4 2.2L Di esel ,Removal and Ins tall ati on).

6.

7.

Page 1000 of 3229

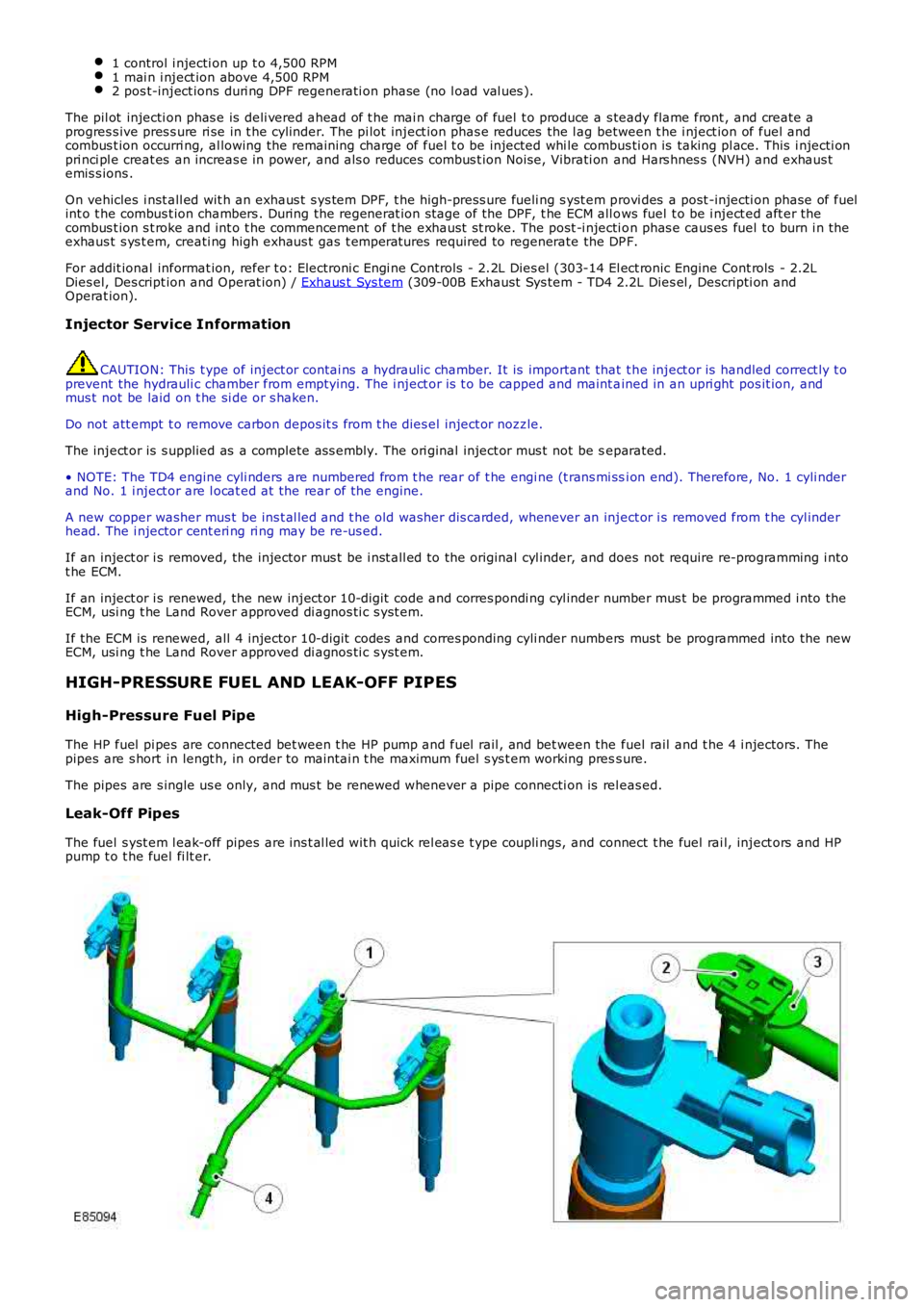

1 control i njecti on up t o 4,500 RPM1 mai n i nject ion above 4,500 RPM2 pos t-inject ions duri ng DPF regenerati on phase (no l oad val ues ).

The pil ot injecti on phas e is deli vered ahead of t he mai n charge of fuel t o produce a s teady flame front , and create aprogres s ive pres s ure ri se in t he cylinder. The pi lot inject ion phas e reduces the l ag between t he i nject ion of fuel andcombus t ion occurri ng, al lowing the remaining charge of fuel t o be injected whi le combus ti on is taking pl ace. This i njecti onpri nci pl e creat es an increas e in power, and als o reduces combus t ion Noi se, Vibrati on and Hars hnes s (NVH) and exhaus temis s ions .

On vehicles i nst all ed wit h an exhaus t s ys tem DPF, t he high-press ure fueli ng s yst em provi des a post -injecti on phase of fuelint o t he combus t ion chambers . During the regenerat ion st age of the DPF, t he ECM all ows fuel t o be i nject ed aft er thecombus t ion s t roke and int o t he commencement of t he exhaus t st roke. The post -i njecti on phas e caus es fuel to burn i n theexhaus t s ys t em, creati ng high exhaus t gas t emperatures required to regenerate the DPF.

For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion) / Exhaus t Sys tem (309-00B Exhaust Sys tem - TD4 2.2L Dies el , Descripti on andOperat ion).

Injector Service Information

CAUTION: This t ype of inject or contai ns a hydraulic chamber. It is important that t he inject or is handled correct ly t oprevent the hydrauli c chamber from emptying. The i nject or is t o be capped and maint ained in an upri ght pos it ion, andmus t not be laid on t he si de or s haken.

Do not att empt t o remove carbon depos it s from t he dies el inject or nozzle.

The inject or is s upplied as a complete ass embly. The ori ginal inject or mus t not be separated.

• NOTE: The TD4 engine cyli nders are numbered from t he rear of t he engi ne (t rans mi ssi on end). Therefore, No. 1 cyli nderand No. 1 i nject or are l ocat ed at the rear of the engine.

A new copper washer mus t be ins t al led and t he old washer dis carded, whenever an inject or i s removed from t he cyl inderhead. The i njector cent eri ng ri ng may be re-us ed.

If an inject or i s removed, the injector mus t be i nst all ed to the original cyl inder, and does not require re-programming i ntot he ECM.

If an inject or i s renewed, the new inject or 10-digit code and corres pondi ng cyl inder number mus t be programmed i nto theECM, usi ng t he Land Rover approved di agnos ti c s yst em.

If the ECM is renewed, all 4 injector 10-di git codes and corres ponding cyli nder numbers must be programmed into the newECM, usi ng t he Land Rover approved di agnos ti c s yst em.

HIGH-PRESSURE FUEL AND LEAK-OFF PIPES

High-Pressure Fuel Pipe

The HP fuel pi pes are connected bet ween t he HP pump and fuel rail , and bet ween the fuel rail and t he 4 i njectors. Thepipes are s hort in lengt h, in order to maintai n t he maximum fuel s ys t em working press ure.

The pipes are s ingle us e only, and mus t be renewed whenever a pipe connecti on is releas ed.

Leak-Off Pipes

The fuel s yst em l eak-off pipes are ins t al led wit h quick rel eas e t ype coupli ngs, and connect t he fuel rai l, inject ors and HPpump t o t he fuel fi lt er.

Page 1248 of 3229

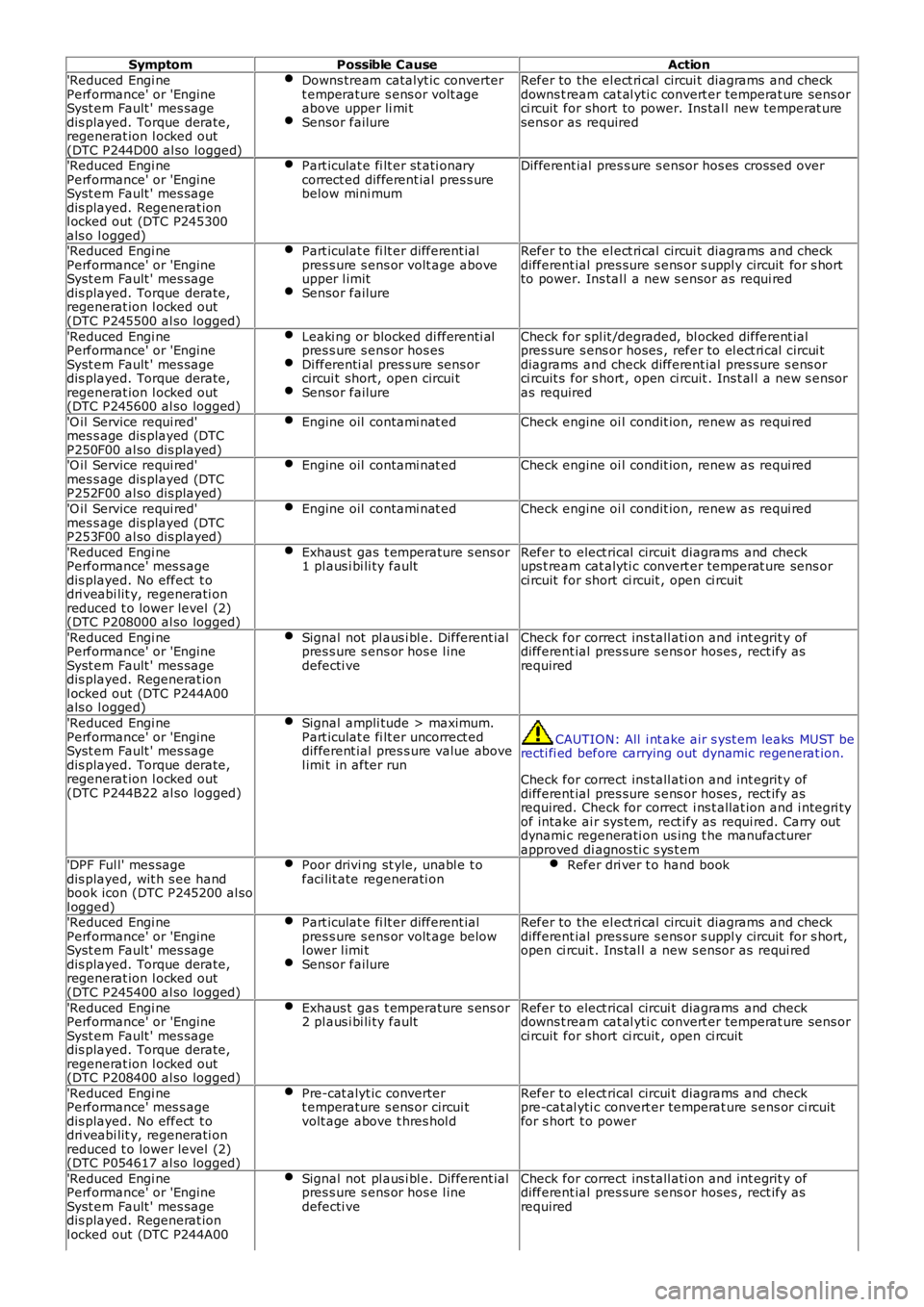

SymptomPossible CauseAction

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P244D00 al so logged)

Downs tream catalyt ic convertert emperature s ens or volt ageabove upper li mi tSensor failure

Refer to the el ect ri cal circui t diagrams and checkdowns t ream cat al yti c convert er temperat ure sens orci rcuit for short to power. Ins tal l new temperat uresens or as required

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Regenerat ionl ocked out (DTC P245300als o l ogged)

Part iculat e fi lt er st ati onarycorrect ed different ial pres s urebelow mini mum

Different ial pres s ure s ensor hos es cross ed over

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P245500 al so logged)

Part iculat e fi lt er different ialpres s ure s ens or volt age aboveupper l imitSensor failure

Refer to the el ect ri cal circui t diagrams and checkdifferent ial pres sure s ens or s uppl y circuit for s hortto power. Ins tal l a new s ensor as requi red

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P245600 al so logged)

Leaki ng or blocked di fferenti alpres s ure s ens or hos esDi fferenti al pres s ure sens orcircui t short, open circui tSensor failure

Check for spl it /degraded, bl ocked different ialpres sure s ens or hoses , refer to el ect ri cal circui tdiagrams and check different ial pres sure s ens orci rcuit s for s hort , open ci rcuit . Ins t al l a new s ensoras required

'O il Service requi red'mes s age dis played (DTCP250F00 al so dis played)

Engine oil contami nat edCheck engine oi l condit ion, renew as requi red

'O il Service requi red'mes s age dis played (DTCP252F00 al so dis played)

Engine oil contami nat edCheck engine oi l condit ion, renew as requi red

'O il Service requi red'mes s age dis played (DTCP253F00 al so dis played)

Engine oil contami nat edCheck engine oi l condit ion, renew as requi red

'Reduced Engi nePerformance' mes s agedis played. No effect t odri veabi lit y, regenerati onreduced t o lower level (2)(DTC P208000 al so logged)

Exhaus t gas t emperature s ens or1 pl aus i bi li ty faultRefer to elect rical circui t diagrams and checkups t ream cat alyti c convert er temperat ure sens orci rcuit for short ci rcuit , open ci rcuit

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Regenerat ionl ocked out (DTC P244A00als o l ogged)

Signal not pl aus i bl e. Different ialpres s ure s ens or hos e l inedefecti ve

Check for correct ins tall ati on and int egrit y ofdifferent ial pres sure s ens or hoses , rect ify asrequired

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P244B22 al so logged)

Signal ampli tude > maximum.Part iculat e fi lt er uncorrect eddifferent ial pres s ure value abovel imi t in after run

CAUTION: All i nt ake air s yst em leaks MUST berecti fi ed before carrying out dynamic regenerat ion.

Check for correct ins tall ati on and int egrit y ofdifferent ial pres sure s ens or hoses , rect ify asrequired. Check for correct i ns t allat ion and i ntegri tyof intake ai r sys tem, rect ify as requi red. Carry outdynami c regenerati on us ing t he manufacturerapproved di agnos ti c s ys t em'DPF Ful l' mes sagedis played, wit h s ee handbook icon (DTC P245200 al sol ogged)

Poor drivi ng st yle, unabl e t ofaci lit ate regenerati onRefer dri ver t o hand book

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P245400 al so logged)

Part iculat e fi lt er different ialpres s ure s ens or volt age belowl ower l imi tSensor failure

Refer to the el ect ri cal circui t diagrams and checkdifferent ial pres sure s ens or s uppl y circuit for s hort,open ci rcuit . Ins tal l a new s ensor as requi red

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Torque derate,regenerat ion l ocked out(DTC P208400 al so logged)

Exhaus t gas t emperature s ens or2 pl aus i bi li ty faultRefer to elect rical circui t diagrams and checkdowns t ream cat al yti c convert er temperat ure sens orci rcuit for short ci rcuit , open ci rcuit

'Reduced Engi nePerformance' mes s agedis played. No effect t odri veabi lit y, regenerati onreduced t o lower level (2)(DTC P054617 al so logged)

Pre-cat alyt ic convertert emperature s ens or circui tvolt age above t hres hol d

Refer to elect rical circui t diagrams and checkpre-cat al yti c convert er temperat ure s ens or ci rcuitfor s hort t o power

'Reduced Engi nePerformance' or 'EngineSyst em Fault ' mes sagedis played. Regenerat ionl ocked out (DTC P244A00

Signal not pl aus i bl e. Different ialpres s ure s ens or hos e l inedefecti ve

Check for correct ins tall ati on and int egrit y ofdifferent ial pres sure s ens or hoses , rect ify asrequired

Page 1689 of 3229

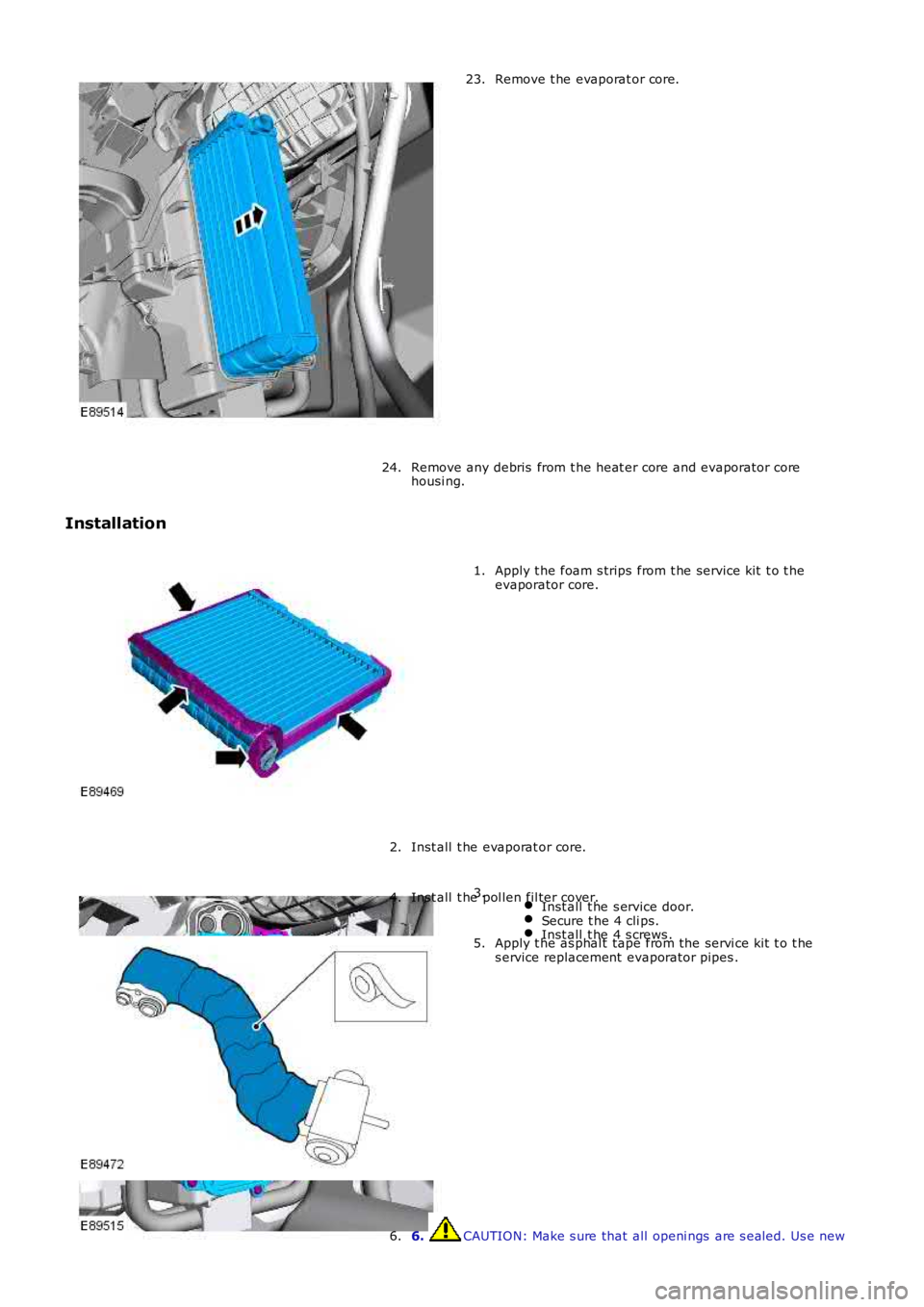

Remove t he evaporat or core.23.

Remove any debris from t he heat er core and evaporator corehousi ng.24.

Installation

Apply t he foam s trips from t he service kit t o t heevaporator core.1.

Inst all t he evaporat or core.2.

Inst all t he s ervice door.Secure t he 4 cli ps.Inst all t he 4 s crews .

3.Inst all t he pol len fil ter cover.4.

Apply t he as phal t tape from the servi ce kit t o t hes ervice replacement evaporator pipes .5.

6. CAUTION: Make s ure that all openi ngs are s ealed. Us e new6.

Page 1698 of 3229

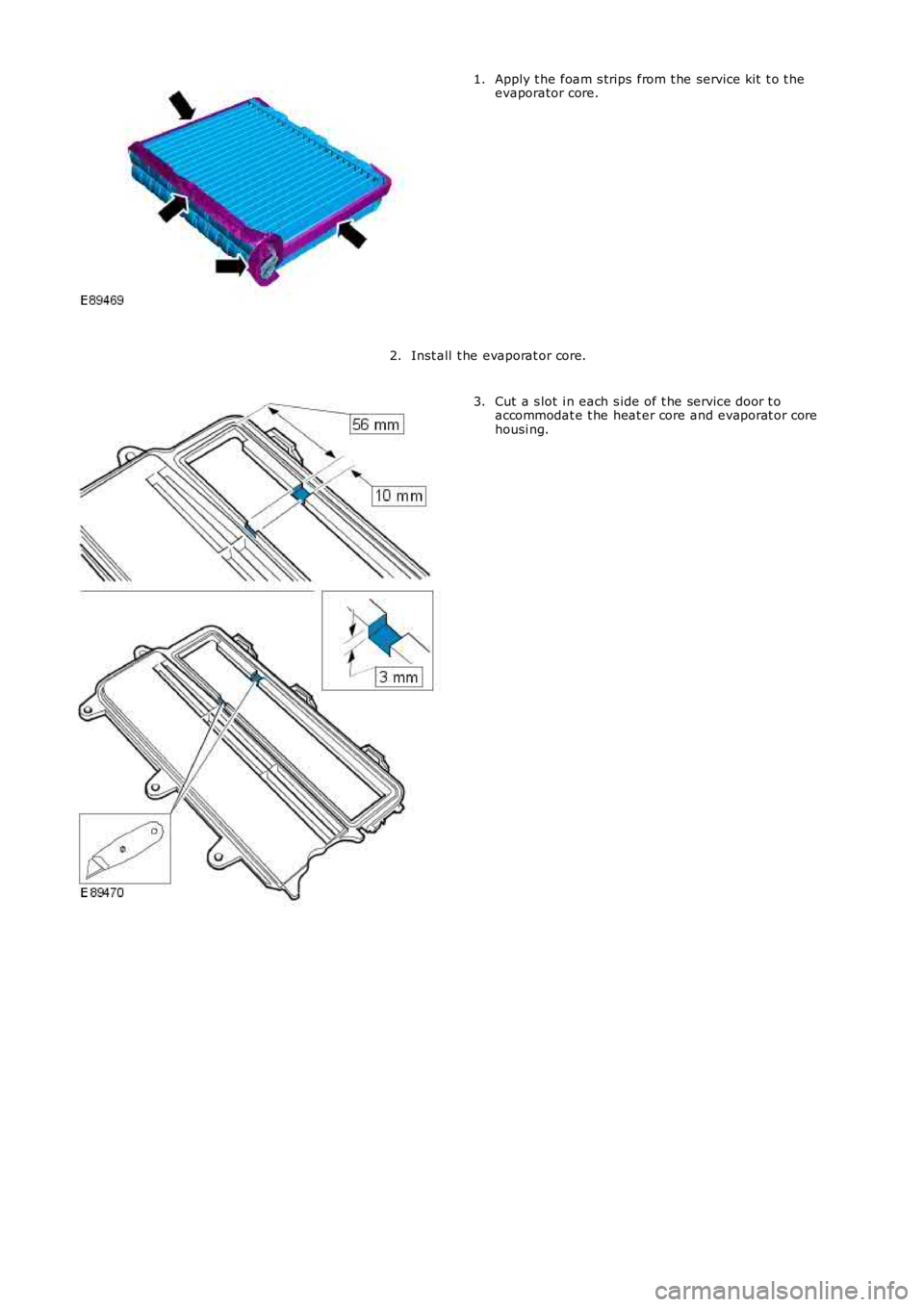

Apply t he foam s trips from t he service kit t o t heevaporator core.1.

Inst all t he evaporat or core.2.

Cut a s lot i n each s ide of t he service door t oaccommodat e t he heat er core and evaporat or corehousi ng.

3.

Page 1792 of 3229

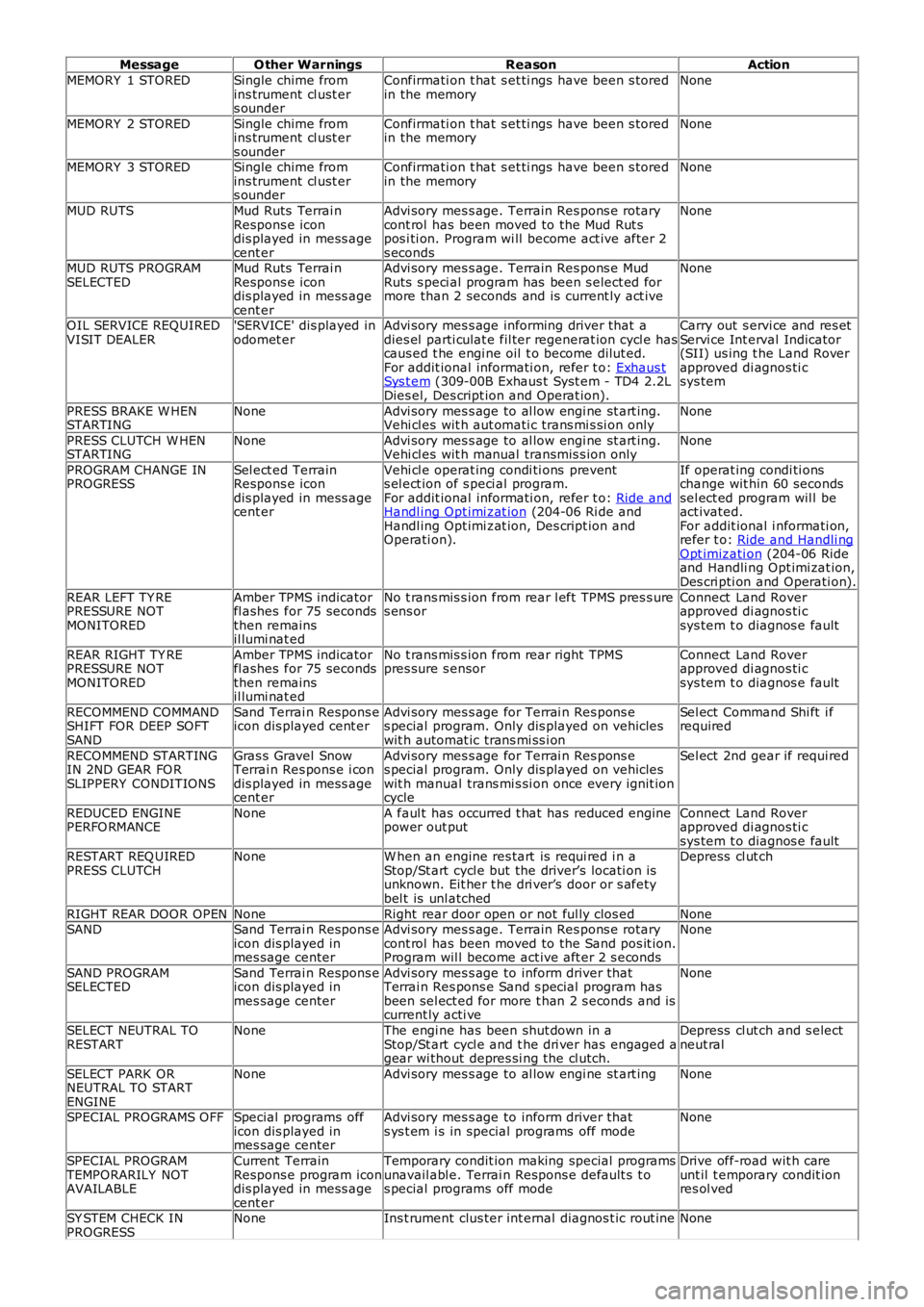

MessageO ther WarningsReasonAction

MEMORY 1 STOREDSingle chime fromins trument cl ust ers ounder

Confirmati on t hat s et ti ngs have been s toredin the memoryNone

MEMORY 2 STOREDSingle chime fromins trument cl ust ers ounder

Confirmati on t hat s et ti ngs have been s toredin the memoryNone

MEMORY 3 STOREDSingle chime fromins trument cl ust ers ounder

Confirmati on t hat s et ti ngs have been s toredin the memoryNone

MUD RUTSMud Ruts Terrai nRespons e icondis played in mess agecent er

Advi sory mes s age. Terrain Res pons e rotarycont rol has been moved to the Mud Rut spos i ti on. Program wi ll become act ive after 2s econds

None

MUD RUTS PROGRAMSELECTEDMud Ruts Terrai nRespons e icondis played in mess agecent er

Advi sory mes s age. Terrain Res pons e MudRuts s peci al program has been s elect ed formore than 2 seconds and is current ly act ive

None

OIL SERVICE REQUIREDVISIT DEALER'SERVICE' dis played inodomet erAdvi sory mes s age informing driver that adies el parti culat e fil ter regenerat ion cycl e hascaus ed t he engi ne oil t o become dilut ed.For addit ional informati on, refer t o: Exhaus tSys t em (309-00B Exhaus t Syst em - TD4 2.2LDies el, Des cript ion and Operat ion).

Carry out s ervi ce and res etServi ce Int erval Indicator(SII) us ing t he Land Roverapproved di agnos ti csys tem

PRESS BRAKE W HENSTARTINGNoneAdvi sory mes s age to al low engi ne st art ing.Vehi cl es wit h aut omati c trans mi s si on onlyNone

PRESS CLUTCH W HENSTARTINGNoneAdvi sory mes s age to al low engi ne st art ing.Vehi cl es wit h manual transmis s ion onlyNone

PROGRAM CHANGE INPROGRESSSel ect ed TerrainRespons e icondis played in mess agecent er

Vehi cl e operat ing condi ti ons prevents el ect ion of s peci al program.For addit ional informati on, refer t o: Ride andHandl ing Opt imi zat ion (204-06 Ri de andHandl ing Opt imi zat ion, Des cript ion andOperati on).

If operat ing condi ti onschange wit hin 60 secondssel ect ed program wil l beact ivated.For addit ional i nformati on,refer t o: Ride and Handli ngOpt imizati on (204-06 Rideand Handli ng Opt imi zat ion,Des cri pti on and Operati on).

REAR LEFT TY REPRESSURE NOTMONITORED

Amber TPMS indicatorfl ashes for 75 secondsthen remainsil lumi nat ed

No t rans mis s ion from rear l eft TPMS pres s ures ens orConnect Land Roverapproved di agnos ti csys tem t o diagnos e fault

REAR RIGHT TY REPRESSURE NOTMONITORED

Amber TPMS indicatorfl ashes for 75 secondsthen remainsil lumi nat ed

No t rans mis s ion from rear right TPMSpres sure s ensorConnect Land Roverapproved di agnos ti csys tem t o diagnos e fault

RECOMMEND COMMANDSHIFT FOR DEEP SOFTSAND

Sand Terrai n Respons eicon dis played cent erAdvi sory mes s age for Terrai n Res pons es pecial program. Only dis played on vehicleswit h automat ic trans mi ss i on

Sel ect Command Shi ft i frequired

RECOMMEND STARTINGIN 2ND GEAR FO RSLIPPERY CONDITIONS

Gras s Gravel SnowTerrai n Res pons e i condis played in mess agecent er

Advi sory mes s age for Terrai n Res pons es pecial program. Only dis played on vehicleswit h manual trans mi s si on once every ignit ioncycle

Sel ect 2nd gear if requi red

REDUCED ENGINEPERFO RMANCENoneA faul t has occurred t hat has reduced enginepower out putConnect Land Roverapproved di agnos ti csys tem t o diagnos e faultRESTART REQ UIREDPRESS CLUTCHNoneW hen an engine res tart is requi red i n aStop/St art cycl e but the driver’s locati on isunknown. Eit her t he dri ver’s door or s afetybel t is unl atched

Depress cl ut ch

RIGHT REAR DOOR OPENNoneRight rear door open or not ful ly clos edNoneSANDSand Terrai n Respons eicon dis played inmes sage center

Advi sory mes s age. Terrain Res pons e rotarycont rol has been moved to the Sand pos it ion.Program wil l become act ive aft er 2 s econds

None

SAND PROGRAMSELECTEDSand Terrai n Respons eicon dis played inmes sage center

Advi sory mes s age to inform driver thatTerrai n Res pons e Sand s pecial program hasbeen sel ect ed for more t han 2 s econds and iscurrent ly acti ve

None

SELECT NEUTRAL TORESTARTNoneThe engi ne has been shut down in aStop/St art cycl e and t he dri ver has engaged agear wi thout depres si ng the cl utch.

Depress cl ut ch and s electneut ral

SELECT PARK ORNEUTRAL TO STARTENGINE

NoneAdvi sory mes s age to al low engi ne st art ingNone

SPECIAL PROGRAMS OFFSpecial programs officon dis played inmes sage center

Advi sory mes s age to inform driver thats ys t em i s in special programs off modeNone

SPECIAL PROGRAMTEMPORARILY NOTAVAILABLE

Current TerrainRespons e program icondis played in mess agecent er

Temporary condit ion making special programsunavail abl e. Terrai n Respons e default s t os pecial programs off mode

Drive off-road wit h careunt il t emporary condit ionres ol ved

SY STEM CHECK INPROGRESSNoneIns t rument clus ter int ernal diagnos t ic rout ineNone

Page 1795 of 3229

The current vehicle operat ing mode, s hown in parenthes is above, i s dis played in the odomet er for 5 s econds when t hevehi cl e first ent ers power mode 6.

• NOTE: 'Nor' is only di s pl ayed in t he Odometer when t he vehicle operat ing mode is changed t o normal from any of theother vehi cle operat ing modes . Under al l ot her condit ions , 'Nor' is not di spl ayed.

The vehi cl e operat ing mode can be changed us i ng the Land Rover approved di agnos ti c sys t em.

Gear Position

The gear pos it ion i ndicat or s hows the current aut omati c t ransmis s ion s elector l ever posi ti on. During normal operat ion thedis play wi ll s how P (park), R (revers e), N (neutral) and D (drive). W hen the t rans mis s ion is operat ed in 'CommandShi ft ™'mode, the odomet er di spl ays the current ly sel ect ed manual gear; 1, 2, 3, 4, 5 or 6.

In the event of eit her a CAN bus fai lure, or if t he TCM det ect s a t rans mi ss i on overheat s it uati on, t he odometer wi ll dis playt he let ter 'E' in the s ame area of t he dis play as t he 'CommandShift™' s elected gear informat ion.

Supplemental Restrain System Warning Indicator

If the i nst rument clus ter det ect s the Supplement al Res t raint Sys tem (SRS) warni ng indicator has fai led, t he mes sage 'SrS'wil l be dis played in the odomet er and a DTC s tored. The DTC can be ret rieved from the ins trument cl us t er us i ng the LandRover approved diagnost ic sys tem.

Service Interval Indicator

The Service Interval Indi cat or (SII) i nforms t he driver when t he next vehicle servi ce is due. The ins t rument clus ter monit orst he dis tance t he vehi cl e has travel ed and t he ti me el aps ed s ince t he las t s ervice.

If vehicle dis tance is the t rigger for the SII, 'SERVICE' will be di s pl ayed in t he odometer accompanied by a dis tancequal ifier (ei ther 'MILES' or 'KM' dependi ng on t he ins trument cl ust er s pecificati on). A di st ance counter wi ll als o be di s pl ayedin the t op Ri ght Hand (RH) corner of t he odometer. If t he point at which a servi ce is requi red is pas sed, t he count er wi lldis play a negat ive value. W hen acti vat ed, t he SII is di spl ayed for 5 s econds when t he vehi cl e enters power mode 6.

If ti me i s the trigger for the SII, 'SERVICE' wil l be di s pl ayed in t he odometer accompanied by a clock symbol . A count er willals o be di spl ayed i n t he t op RH corner of the odomet er. If t he point at which a s ervice is required is pas s ed, t he count erwil l dis play a negati ve val ue. Agai n, when act ivated t he SII is dis played for 5 s econds when t he vehi cl e enters power mode6.

If bot h t he dis tance and t ime triggers are acti vat ed, t he SII wil l di s pl ay the di s tance informat ion for 5 s econds, foll owedby t he ti me i nformati on for 5 s econds .

W hen a service has been carri ed out , t he SII wi ll need t o be re-s et. This can be done us ing t he Land Rover approveddiagnost ic s ys tem or foll owing a manual re-s et procedure. The manual re-s et mode is ent ered by carrying out the foll owingrout ine:

Pres s and hold the t ri p res et butt on wi th the vehicle st ati onary and in a power mode les s t han 6.W hi le holdi ng the trip res et but ton, enter t he vehi cl e int o power mode 6.Releas e the trip res et but ton wit hi n 10 s econds of entering power mode 6.

If the manual re-set mode has been s ucces s full y entered 'dISt ' or 'DATE' wi ll be di spl ayed i n t he odomet er, dependi ng onwhich t ri gger has been acti vat ed.

To clear the 'dISt ' trigger pres s, and hold the t rip reset but ton for more than 5 s econds wit hi n 10 s econds of entering t hemanual re-s et mode. If s ucces s ful, 'RESET' wil l be dis played in the odometer for 5 seconds. If t he dat e t ri gger has notbeen act ivated 'END' wil l t hen be dis played i n t he odomet er.

• NOTE: The dis t ance t ri gger wi ll not res et if t he dis t ance t he vehi cle has t raveled i s les s t han 20% of t he next s ervi ceint erval val ue.

If the dat e trigger has been act ivated, 'DATE' wil l be dis played in t he odometer. To clear the t ri gger, pres s and hold t het rip res et but t on for more t han 5 s econds wit hin 10 s econds of 'DATE' being di s pl ayed. If succes s ful , 'RESET' wi ll bedis played wit hin the odomet er for 5 s econds fol lowed by 'END'. The odomet er wil l now exit re-s et mode.

AMBIENT AIR TEMPERATURE

The ins t rument clus ter can dis play t he ambient air t emperature readi ng in ei ther degrees Cels ius or Fahrenhei t. Theambient air t emperat ure s ignal ori gi nat es i n the ambient air t emperature s ens or. The s ens or i s a Negati ve TemperatureCoefficient (NTC) t hermi st or, and i s mounted i n t he LH door mirror. A t emperature value i s cal cul ated by t he ECM andbroadcas t over the hi gh speed CAN bus to t he i ns t rument clus ter.

If the t emperat ure value fall s bel ow 4ºC (39ºF) t he mes sage center wi ll flas h the low ambi ent ai r temperat ure icon 5t imes . Thi s i s accompanied by a chime from the i nst rument clus t er s ounder. The low ambient air t emperature icon wi ll berepeated if t he ambient air t emperature ri s es above 6ºC (43ºF) t hen drops below 4ºC (39ºF) again or a new ignit ion cycleis st art ed.