engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1122 of 3229

Publi s hed: 11-May-2011

Glow Plug System - Glow Plug System

Des cript ion and Operat ion

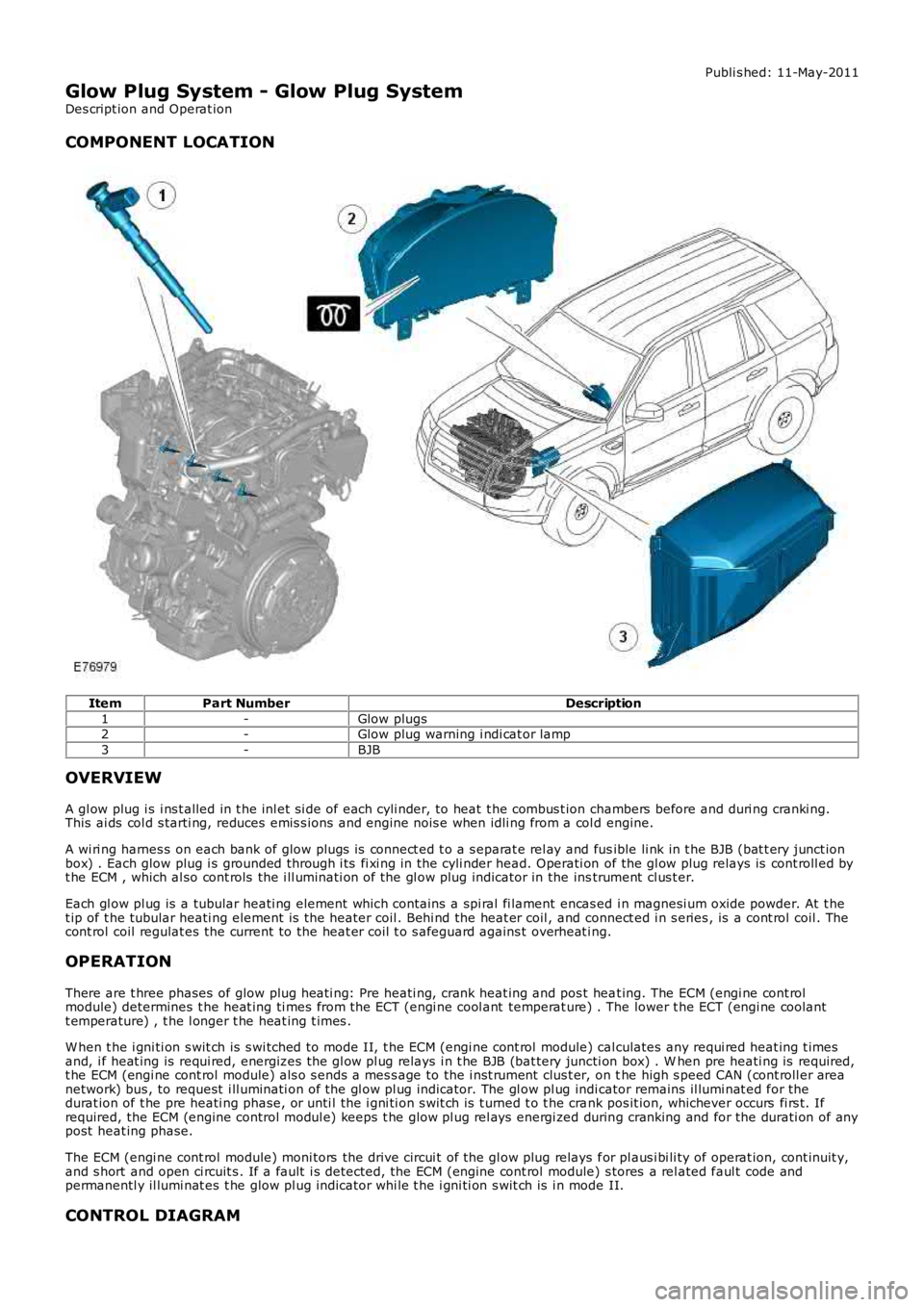

COMPONENT LOCATION

ItemPart NumberDescription

1-Glow plugs2-Glow plug warning i ndi cat or lamp

3-BJB

OVERVIEW

A gl ow plug i s i ns t alled in t he inl et si de of each cyli nder, to heat t he combus t ion chambers before and duri ng cranki ng.This ai ds col d s tarti ng, reduces emis s ions and engine nois e when idli ng from a col d engine.

A wi ri ng harnes s on each bank of glow plugs is connect ed t o a s eparat e rel ay and fusible li nk in t he BJB (bat t ery junct ionbox) . Each glow plug i s grounded through i ts fi xi ng in the cyli nder head. Operati on of the gl ow plug relays is cont roll ed byt he ECM , which al so cont rols the i ll uminati on of the gl ow plug indicator in the instrument cl us t er.

Each gl ow pl ug is a tubular heati ng element which cont ains a spi ral fi lament encas ed i n magnesi um oxide powder. At t het ip of t he tubular heati ng element is the heater coil . Behi nd the heat er coil , and connect ed i n s eries , is a cont rol coil . Thecont rol coil regulat es the current to the heat er coil t o s afeguard agains t overheat ing.

OPERATION

There are t hree phases of glow plug heati ng: Pre heati ng, crank heat ing and pos t heat ing. The ECM (engi ne cont rolmodule) determines t he heat ing ti mes from the ECT (engi ne cool ant temperat ure) . The lower t he ECT (engi ne coolantt emperature) , t he l onger t he heat ing t imes .

W hen t he i gni ti on s wit ch is s wi tched to mode II, t he ECM (engi ne cont rol module) calculates any requi red heat ing t imesand, i f heat ing is requi red, energizes the gl ow pl ug relays i n t he BJB (bat tery juncti on box) . W hen pre heati ng is required,t he ECM (engi ne cont rol module) als o s ends a mes s age to the i nst rument clus t er, on the high s peed CAN (cont roll er areanetwork) bus , to request i ll uminati on of the gl ow pl ug indicator. The gl ow pl ug indicator remains il lumi nat ed for thedurat ion of t he pre heati ng phase, or unti l the i gni ti on s wit ch is t urned t o t he crank pos it ion, whichever occurs fi rs t. Ifrequired, the ECM (engine control modul e) keeps t he glow pl ug rel ays energi zed during cranking and for the durati on of anypost heat ing phase.

The ECM (engi ne cont rol module) moni tors the drive circui t of the gl ow plug relays for pl aus i bi li ty of operat ion, cont inuit y,and s hort and open ci rcuit s . If a fault i s detected, the ECM (engine cont rol module) s tores a rel ated faul t code andpermanentl y il lumi nat es t he glow pl ug indicator whi le t he i gni ti on s wit ch is i n mode II.

CONTROL DIAGRAM

Page 1124 of 3229

Publi s hed: 11-May-2011

Glow Plug System - Glow Plug System

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the gl ow plug sys tem, refer t o t he rel evant Des cript ion and Operat ion s ecti on in the works hopmanual.REFER to: Gl ow Plug Sys tem (303-07B Glow Pl ug Syst em, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage.2.

Visual InspectionElectrical

Fuse(s )Gl ow plug relayEngine management cont rol rel ayW iri ng harnes sElectrical connect or(s )Gl ow plug(s )Engine control modul e (ECM)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

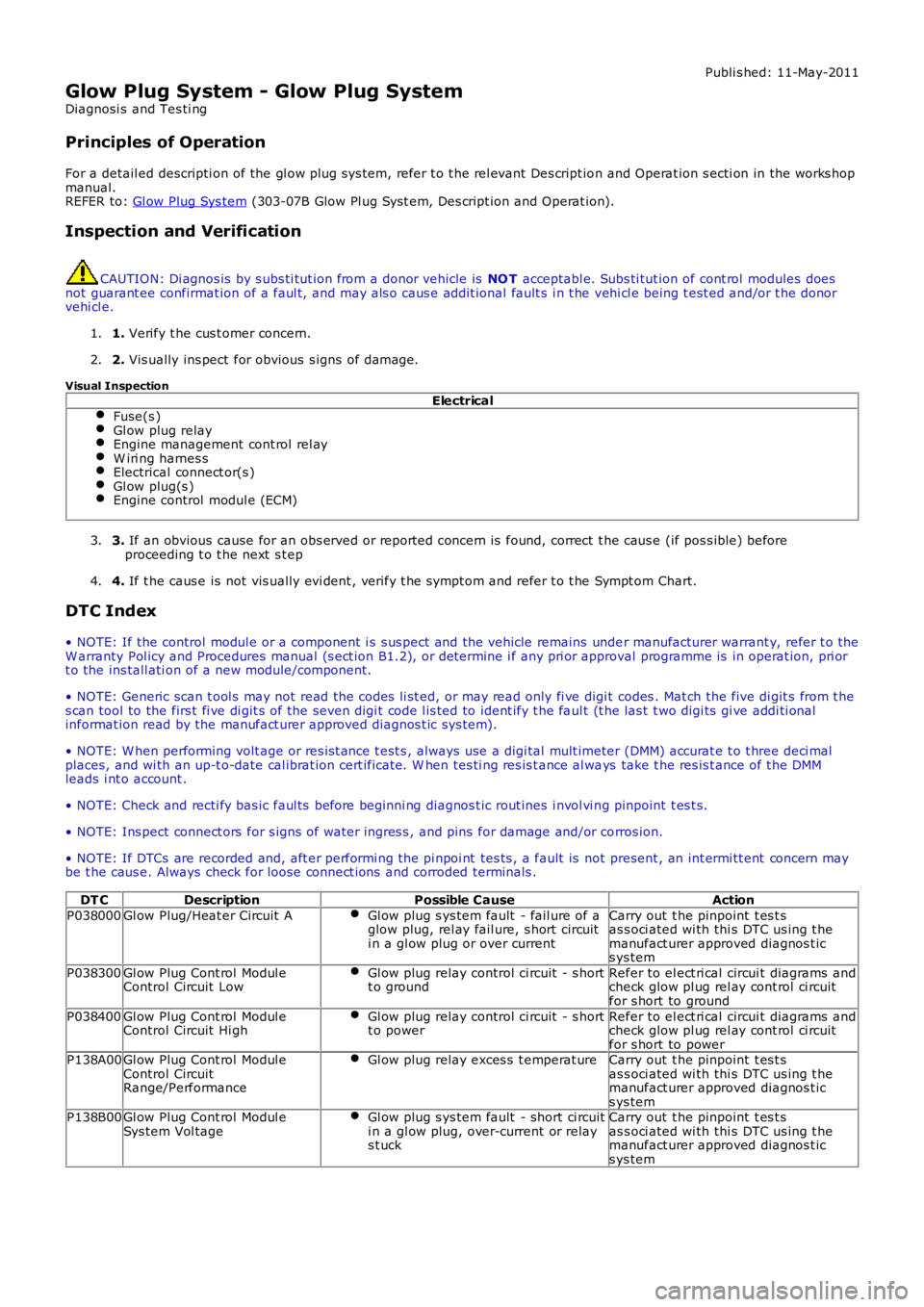

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseAction

P038000Gl ow Plug/Heat er Circuit AGl ow plug s ys tem fault - fail ure of aglow plug, rel ay fail ure, s hort circuiti n a gl ow plug or over current

Carry out t he pinpoint t es t sas s oci ated wi th thi s DTC us ing t hemanufact urer approved diagnos t ics ys tem

P038300Gl ow Plug Cont rol Modul eControl Circuit LowGl ow plug relay control ci rcuit - s hortt o groundRefer to el ect ri cal circui t diagrams andcheck glow pl ug rel ay cont rol ci rcuitfor s hort to ground

P038400Gl ow Plug Cont rol Modul eControl Circuit Hi ghGl ow plug relay control ci rcuit - s hortt o powerRefer to el ect ri cal circui t diagrams andcheck glow pl ug rel ay cont rol ci rcuitfor s hort to powerP138A00Gl ow Plug Cont rol Modul eControl CircuitRange/Performance

Gl ow plug relay exces s t emperat ureCarry out t he pinpoint t es t sas s oci ated wi th thi s DTC us ing t hemanufact urer approved diagnos t ics ys temP138B00Gl ow Plug Cont rol Modul eSys tem Vol tageGl ow plug s ys tem fault - short ci rcuiti n a gl ow plug, over-current or relays t uck

Carry out t he pinpoint t es t sas s oci ated wi th thi s DTC us ing t hemanufact urer approved diagnos t ics ys tem

Page 1125 of 3229

Publi s hed: 11-May-2011

Glow Plug System - Glow Plugs

Removal and Inst all ati on

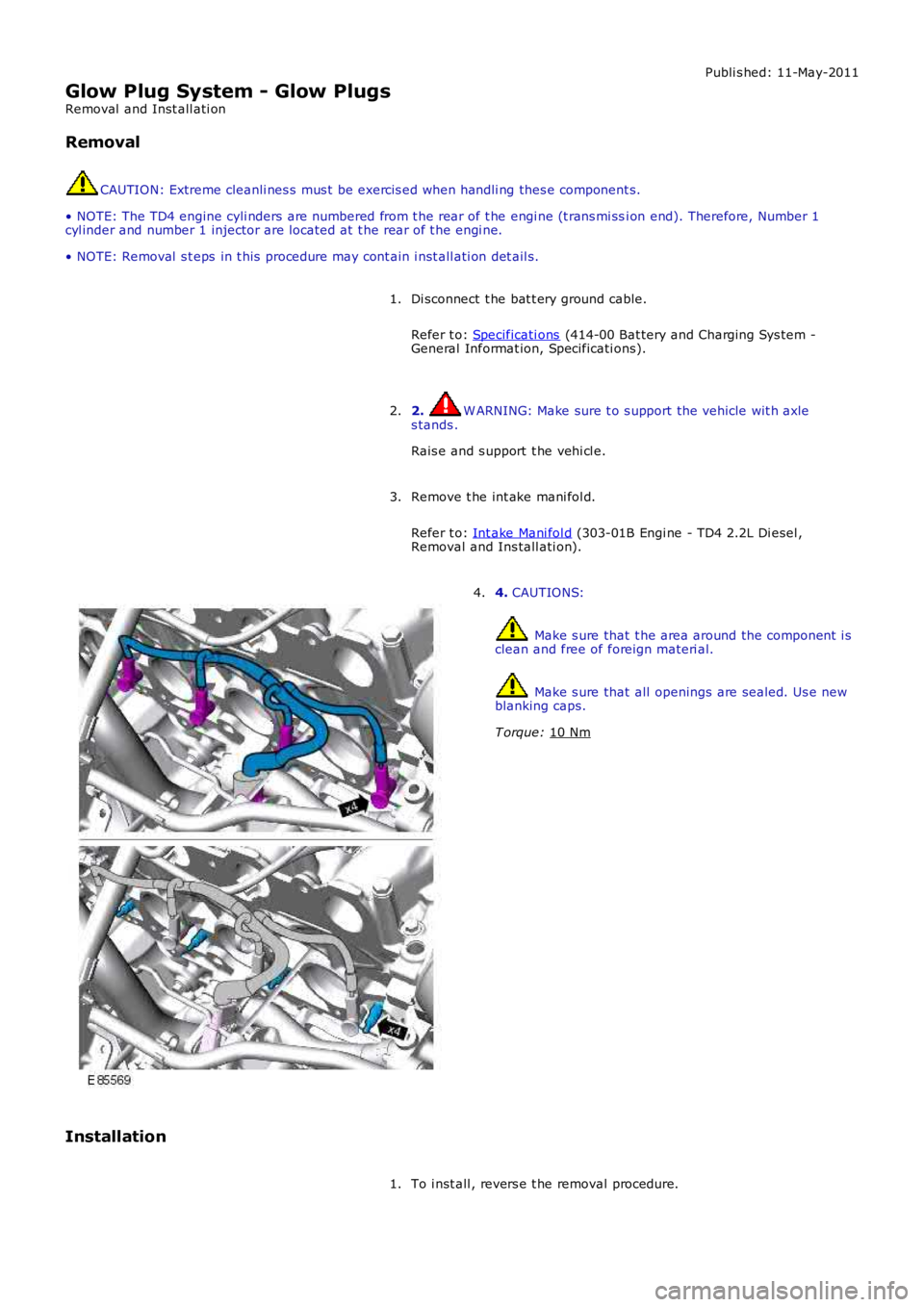

Removal CAUTION: Extreme cleanli nes s mus t be exercis ed when handli ng thes e component s.

• NOTE: The TD4 engine cyli nders are numbered from t he rear of t he engi ne (t rans mi ss i on end). Therefore, Number 1

cyl inder and number 1 injector are located at t he rear of t he engi ne.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -

General Informat ion, Specificati ons).

1.

2. W ARNING: Make sure t o s upport the vehicle wit h axle

s tands .

Rais e and s upport t he vehi cl e.

2.

Remove t he int ake mani fol d.

Refer t o: Int ake Mani fol d (303-01B Engi ne - TD4 2.2L Di esel ,

Removal and Ins tall ati on).

3. 4.

CAUTIONS: Make s ure that t he area around the component i s

clean and free of foreign materi al. Make s ure that all openings are sealed. Us e new

blanking caps.

T orque: 10 Nm 4.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1126 of 3229

Publi s hed: 11-May-2011

Engine Emission Control - I6 3.2L Petrol -

Torque SpecificationsDescriptionNmlb-ft

Crankcas e vent oil s eparator retaini ng bol ts107

Exhaus t gas recircul ati on (EGR) cooler to exhaus t manifol d bolt s2518

Page 1127 of 3229

Publi s hed: 11-May-2011

Engine Emission Control - I6 3.2L Petrol - Engine Emission Control3.2L

Des cript ion and Operat ion

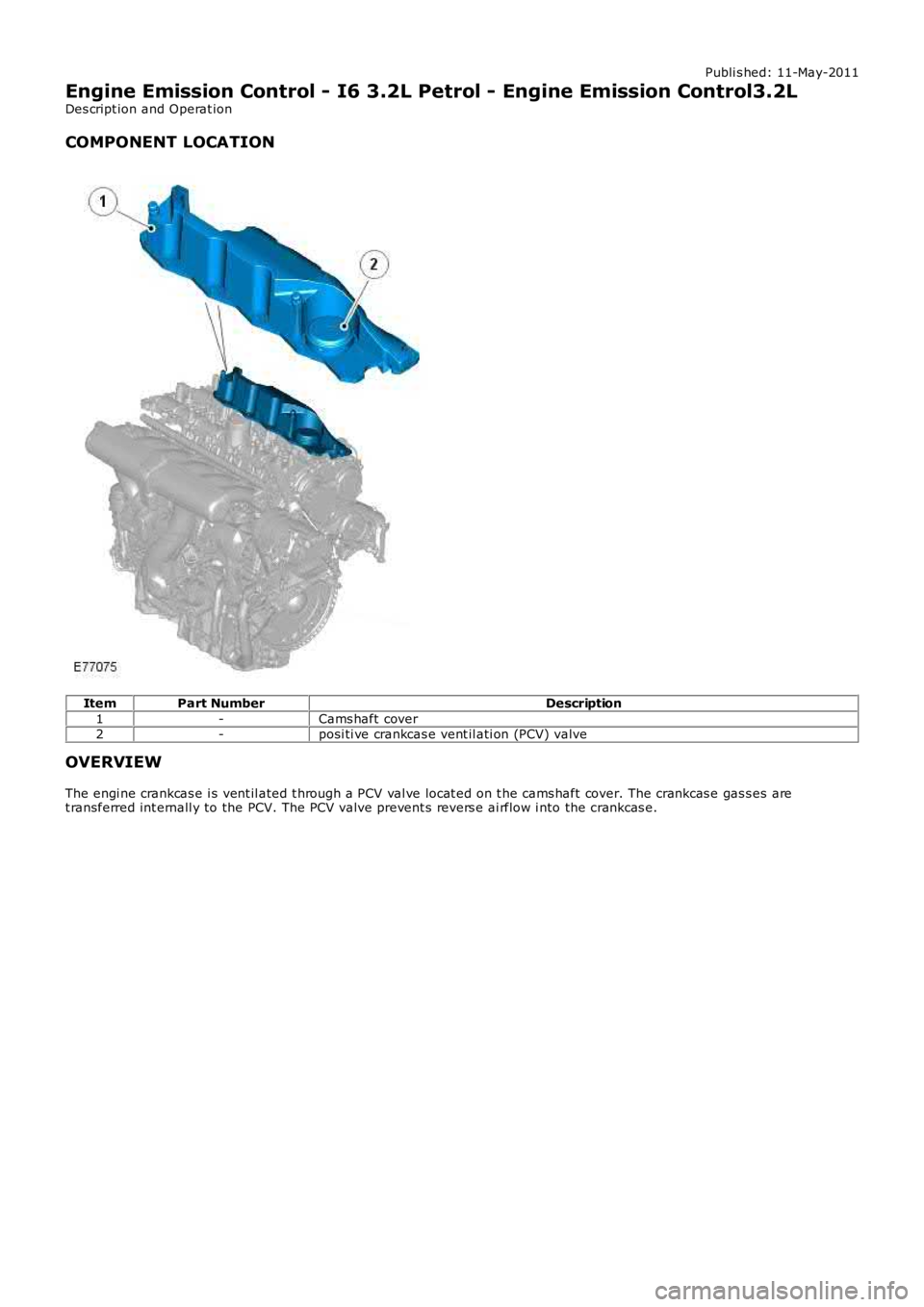

COMPONENT LOCATION

ItemPart NumberDescription

1-Cams haft cover2-posi ti ve crankcas e vent il ati on (PCV) valve

OVERVIEW

The engi ne crankcas e i s vent il ated t hrough a PCV val ve locat ed on t he cams haft cover. The crankcas e gas s es aret ransferred int ernall y to the PCV. The PCV valve prevent s revers e ai rflow i nto the crankcas e.

Page 1128 of 3229

Publi s hed: 11-May-2011

Engine Emission Control - I6 3.2L Petrol - Engine Emission Control

Diagnosi s and Tes ti ng

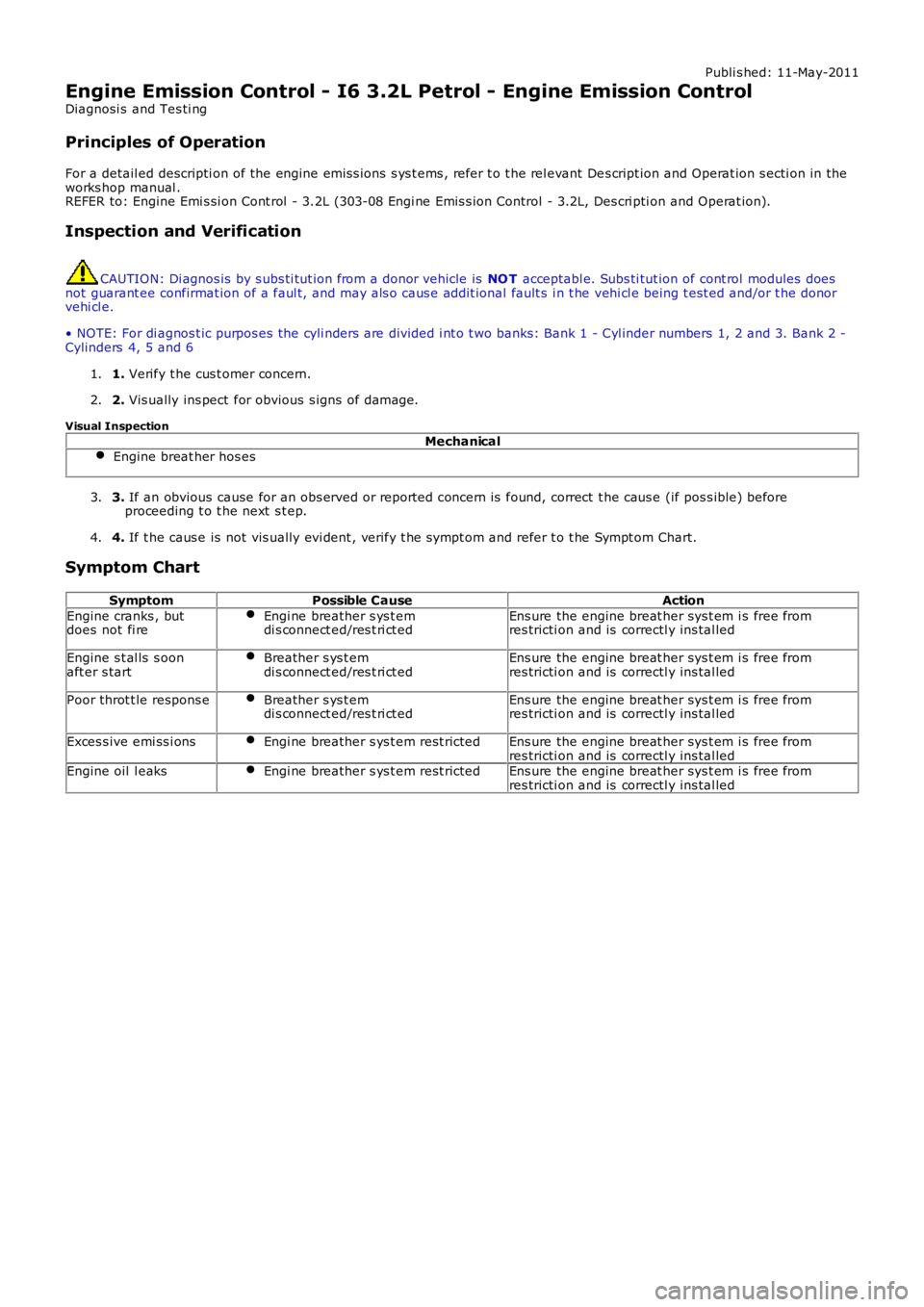

Principles of Operation

For a detail ed descripti on of the engine emis s ions s ys t ems , refer t o t he rel evant Des cript ion and Operat ion s ecti on in theworks hop manual .REFER to: Engine Emi s si on Cont rol - 3.2L (303-08 Engi ne Emis s ion Control - 3.2L, Descri pti on and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: For di agnos t ic purpos es the cyli nders are divided i nt o t wo banks: Bank 1 - Cyl inder numbers 1, 2 and 3. Bank 2 -Cylinders 4, 5 and 6

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage.2.

Visual Inspection

MechanicalEngine breat her hos es

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

Symptom Chart

SymptomPossible CauseAction

Engine cranks , butdoes not fi reEngi ne breather s ys t emdi s connect ed/res t ri ct edEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Engine s t al ls s oonaft er s tartBreather s ys t emdi s connect ed/res t ri ct edEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Poor throt t le respons eBreather s ys t emdi s connect ed/res t ri ct edEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Exces s ive emi ss i onsEngi ne breather s ys t em rest rictedEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledEngine oil l eaksEngi ne breather s ys t em rest rictedEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Page 1129 of 3229

Publi s hed: 11-May-2011

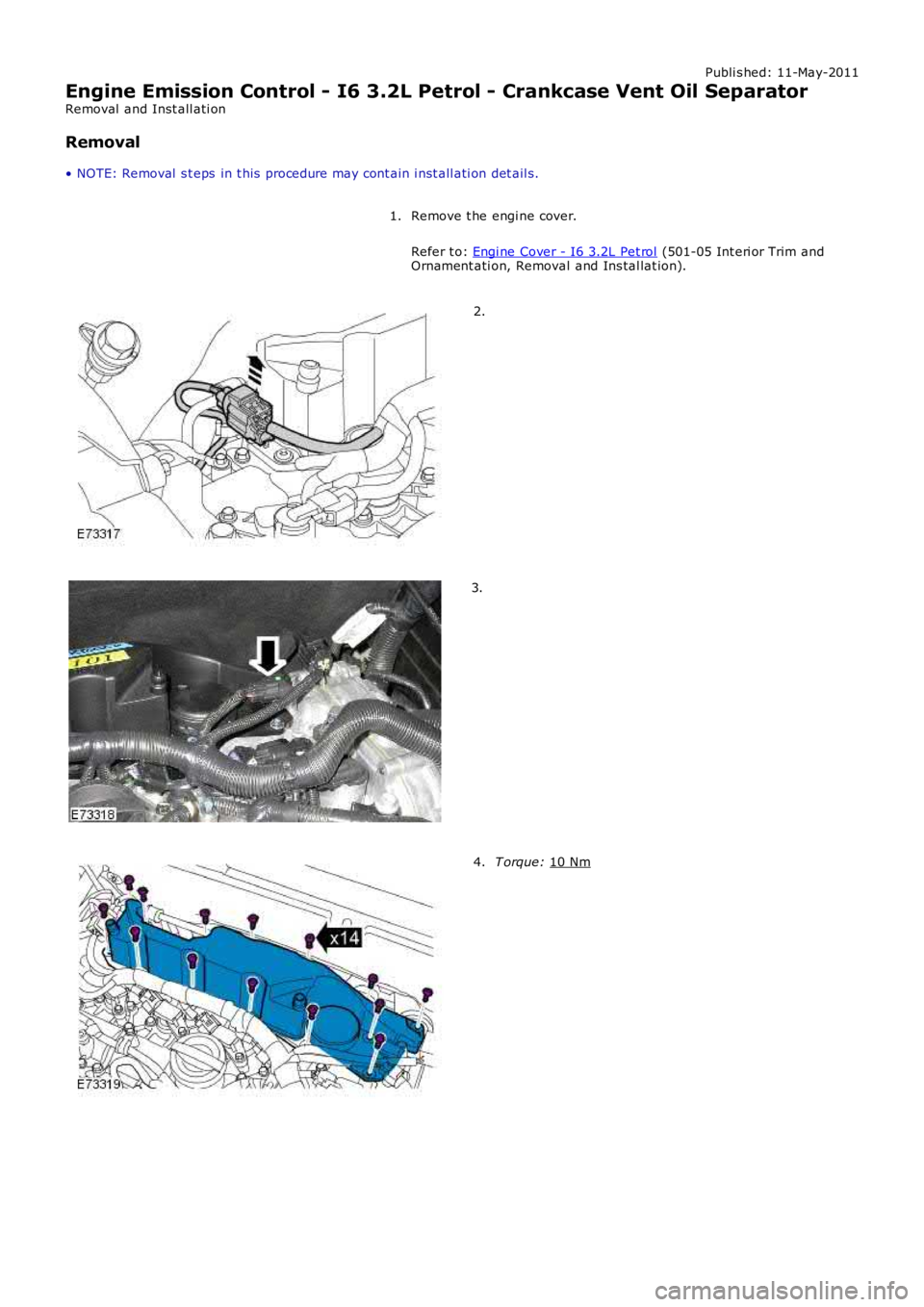

Engine Emission Control - I6 3.2L Petrol - Crankcase Vent Oil Separator

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - I6 3.2L Pet rol (501-05 Int eri or Trim and

Ornament ati on, Removal and Ins tal lat ion).

1. 2.

3.

T orque:

10 Nm 4.

Page 1131 of 3229

Publi s hed: 11-May-2011

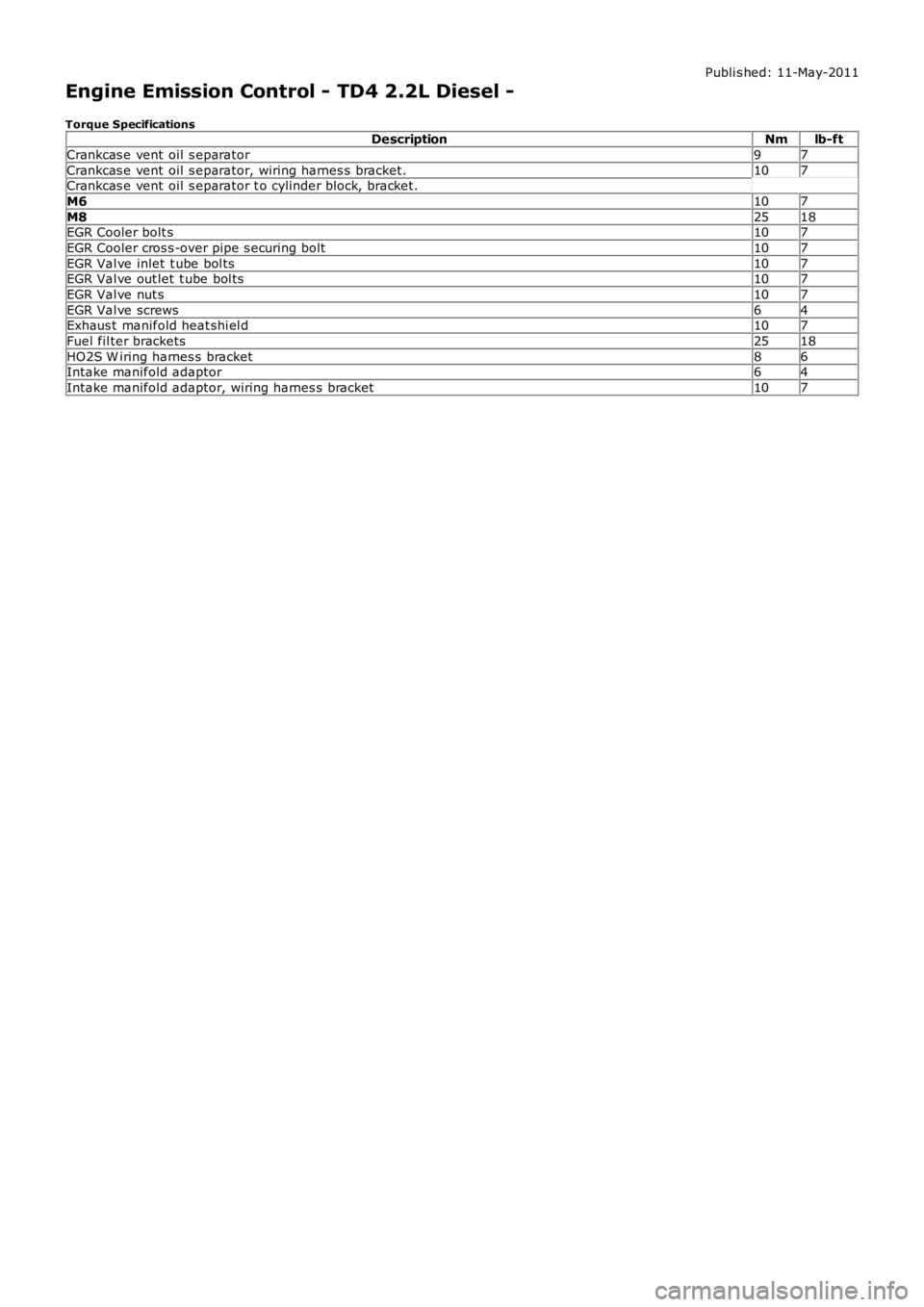

Engine Emission Control - TD4 2.2L Diesel -

Torque SpecificationsDescriptionNmlb-ft

Crankcas e vent oil s eparator97

Crankcas e vent oil s eparator, wiring harnes s bracket.107Crankcas e vent oil s eparator t o cylinder block, bracket.

M6107

M82518EGR Cooler bolt s107

EGR Cooler cros s -over pipe s ecuring bolt107

EGR Val ve inlet t ube bol ts107EGR Val ve out let t ube bol ts107

EGR Val ve nut s107

EGR Val ve screws64Exhaus t manifold heat shi el d107

Fuel fil ter brackets2518

HO2S W iring harnes s bracket86Intake manifold adaptor64

Intake manifold adaptor, wiring harnes s bracket107

Page 1132 of 3229

Publ is hed: 10-Jun-2011

Engine Emission Control - TD4 2.2L Diesel - Engine Emission Control

Des cript ion and Operat ion

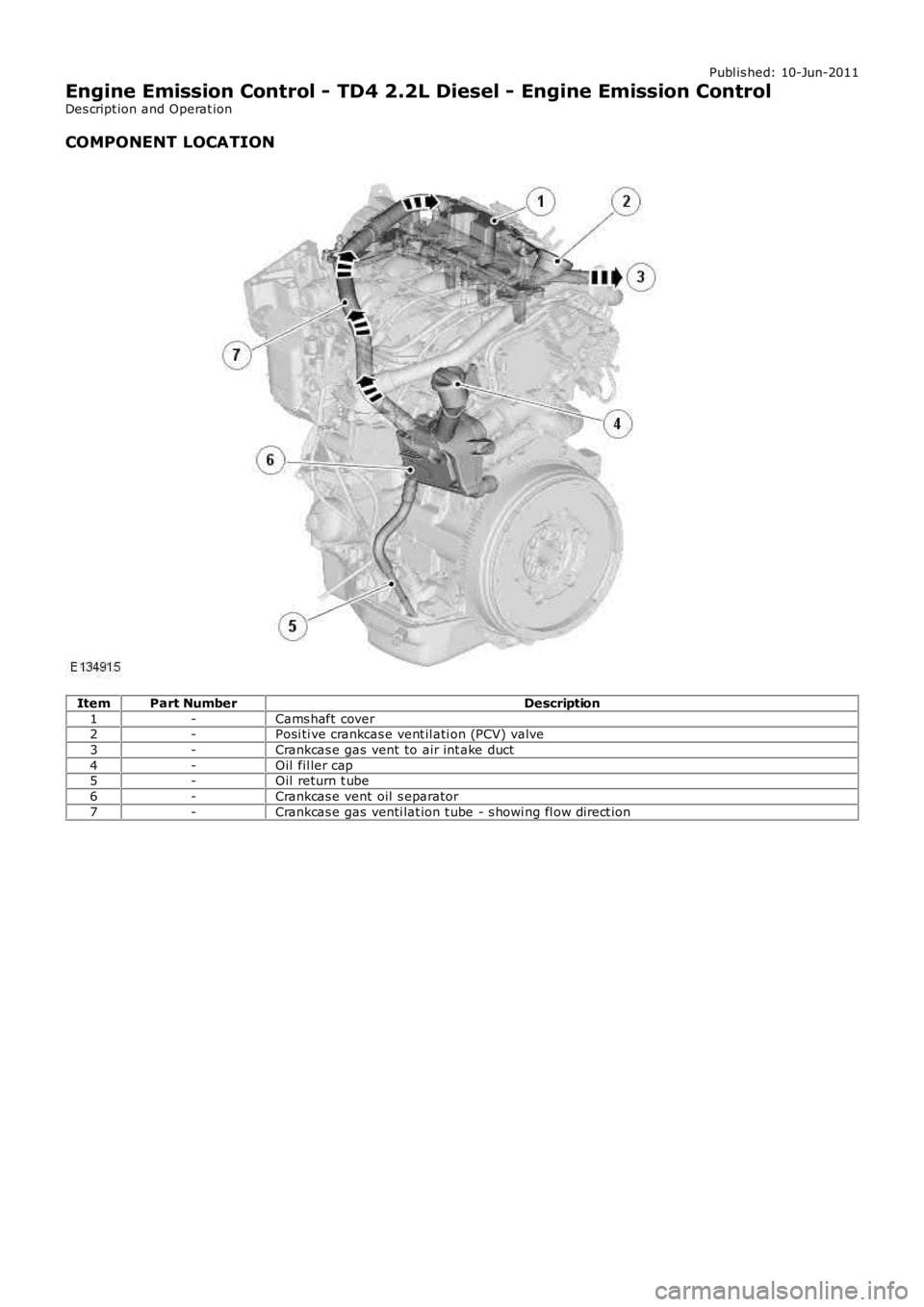

COMPONENT LOCATION

ItemPart NumberDescription

1-Cams haft cover2-Posi ti ve crankcas e vent il ati on (PCV) valve

3-Crankcas e gas vent to air int ake duct

4-Oil fil ler cap5-Oil return t ube

6-Crankcas e vent oil s eparator

7-Crankcas e gas venti lat ion t ube - s howi ng fl ow direct ion

Page 1133 of 3229

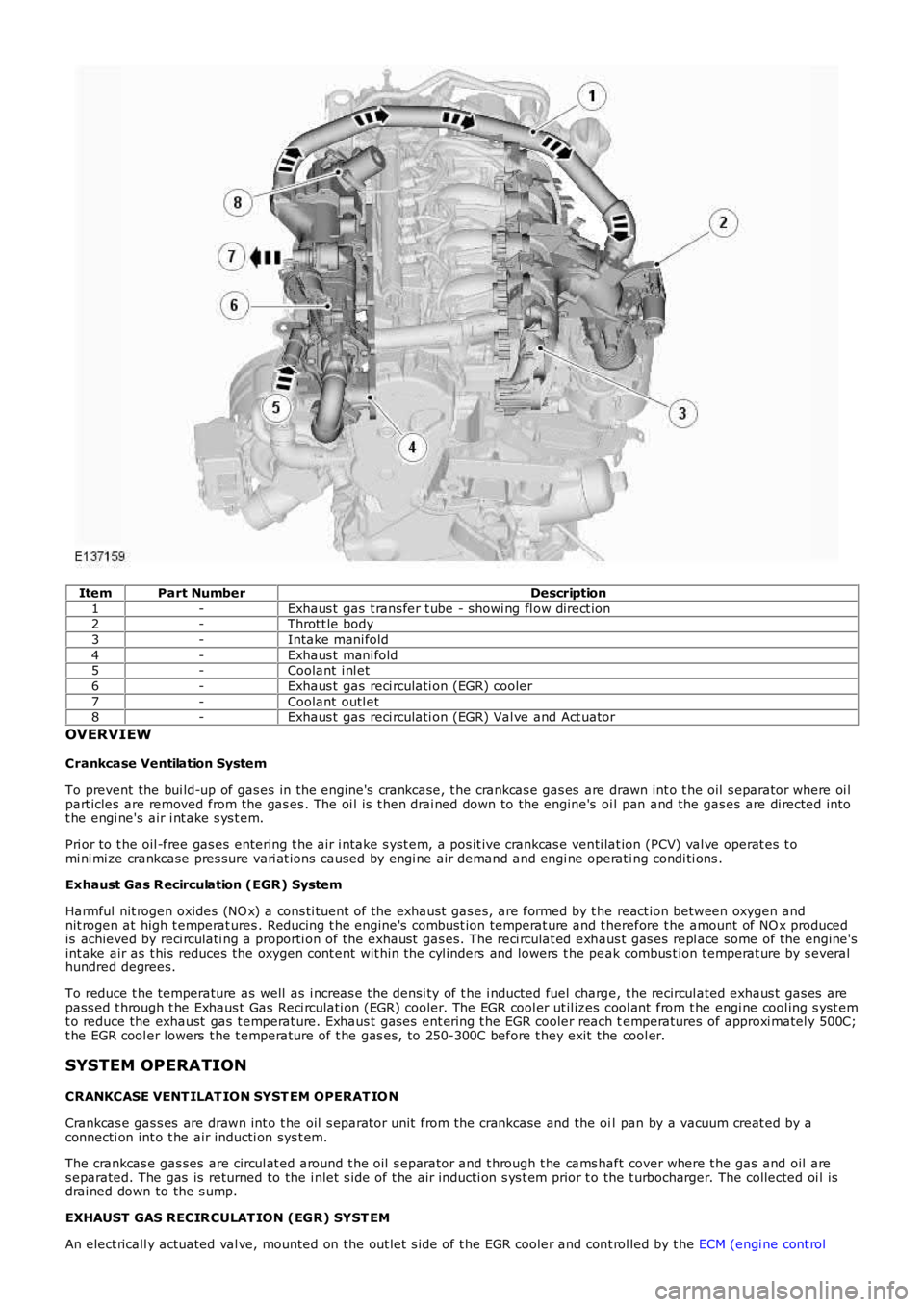

ItemPart NumberDescription

1-Exhaus t gas t rans fer t ube - showi ng fl ow direct ion2-Throt t le body

3-Intake mani fold

4-Exhaus t mani fold5-Coolant i nl et

6-Exhaus t gas reci rculati on (EGR) cooler

7-Coolant outl et8-Exhaus t gas reci rculati on (EGR) Val ve and Act uator

OVERVIEW

Crankcase Ventilation System

To prevent the bui ld-up of gas es in the engine's crankcase, t he crankcas e gas es are drawn int o t he oil s eparator where oi lpart icles are removed from the gas es . The oi l is t hen drai ned down to the engine's oi l pan and the gas es are di rected intot he engi ne's air i nt ake s ys t em.

Pri or to t he oil -free gas es entering t he air i ntake s yst em, a pos it ive crankcas e venti lat ion (PCV) val ve operat es t omi ni mi ze crankcase pres sure vari at ions caused by engi ne air demand and engi ne operati ng condi ti ons .

Exhaust Gas R ecirculation (EGR) System

Harmful nit rogen oxides (NO x) a cons ti tuent of the exhaust gas es, are formed by t he react ion between oxygen andnit rogen at high t emperat ures . Reducing t he engine's combust ion temperat ure and t herefore t he amount of NO x producedis achieved by reci rculati ng a proporti on of the exhaust gas es. The reci rculat ed exhaus t gas es repl ace some of the engine'sint ake air as t hi s reduces the oxygen cont ent wit hin t he cyl inders and lowers t he peak combus t ion t emperat ure by s everalhundred degrees.

To reduce t he temperature as well as i ncreas e t he densi ty of t he i nducted fuel charge, t he recircul ated exhaus t gas es arepass ed t hrough t he Exhaus t Gas Reci rculati on (EGR) cooler. The EGR cool er ut il izes cool ant from t he engi ne cool ing s yst emt o reduce the exhaust gas t emperat ure. Exhaus t gas es ent ering t he EGR cooler reach temperatures of approxi matel y 500C;t he EGR cool er lowers t he t emperature of t he gas es , to 250-300C before t hey exit t he cool er.

SYSTEM OPERATION

CRANKCASE VENT ILAT ION SYST EM OPERAT IO N

Crankcas e gas s es are drawn int o t he oil s eparator unit from the crankcase and the oil pan by a vacuum creat ed by aconnecti on int o t he air inducti on sys t em.

The crankcas e gas ses are circul at ed around t he oil s eparator and t hrough t he cams haft cover where t he gas and oil ares eparated. The gas is returned to the i nlet s ide of t he air inducti on s ys t em prior to the t urbocharger. The collected oi l isdrai ned down to the s ump.

EXHAUST GAS RECIR CULAT ION (EGR) SYST EM

An elect ricall y actuated val ve, mounted on the out let s ide of t he EGR cooler and cont rol led by t he ECM (engi ne cont rol