wheel LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2879 of 3229

159

Maintenance

R

In addition, engine se ttings must not be

tampered with. These have been established to

ensure that your vehicle complies with

stringent exhaust em ission regulations.

Incorrect engine settings may adversely affect

exhaust emissions, engi ne performance and

fuel consumption. The y may also cause high

temperatures, which will result in damage to

the catalytic converter and the vehicle.

Road testing dynamometers (rolling

roads)

Because your vehicle is equipped with anti-lock

brakes and four wheel drive, it is essential that

any dynamometer testing is carried out only by

a qualified person, familiar with the

dynamometer testing an d safety procedures

practised by Land Rove r Dealers/Authorised

Repairers.

Safety in the garage

Fuel system

Poisonous fluids

Fluids used in motor vehicles are poisonous

and should not be consumed or brought into

contact with open wounds. These include;

battery acid, antifreeze, brake, clutch and

power steering fluid, petr ol, diesel, engine oil

and windscreen washer additives.

For your own safety, al ways read and obey all

instructions printed on labels and containers.

Used engine oil

Prolonged contact with engine oil may cause

serious skin disorders, including dermatitis

and cancer of the skin. Always wash

thoroughly after contact.

It is illegal to pollute drains, water

courses or soil. Use authorised

waste disposal sites to dispose of

used oil and toxic chemicals.

WARNINGS

If the vehicle has been driven recently,

do not touch exhaust and cooling

system components un til the engine has

cooled.

Never leave the engine running in an

unventilated area - exhaust gases are

poisonous and extremely dangerous.

Do not work beneath the vehicle with

the wheel changing jack as the only

means of support.

Keep your hands and clothing away

from drive belt s and pulleys.

Remove metal wr ist bands and

jewellery, before working in the engine

compartment.

Do not touch electrical leads or

components while the engine is

running, or with the starter switch turned on.

Do not allow tools or metal parts of the

vehicle to make contact with the battery

leads or terminals.

WARNINGS

Under no circumstances should any

part of the fuel system be dismantled or

replaced by anyone other than a suitably

qualified vehicle technician. Failure to comply

with this instruction, may result in fuel spillage

with a consequent serious risk of fire.

Ensure sparks and naked lights are kept

away from the engine compartment.

Wear protective cl othing, including,

where practicable, gloves made from

an impervious material.

WARNINGS

Page 2886 of 3229

Maintenance

166

L

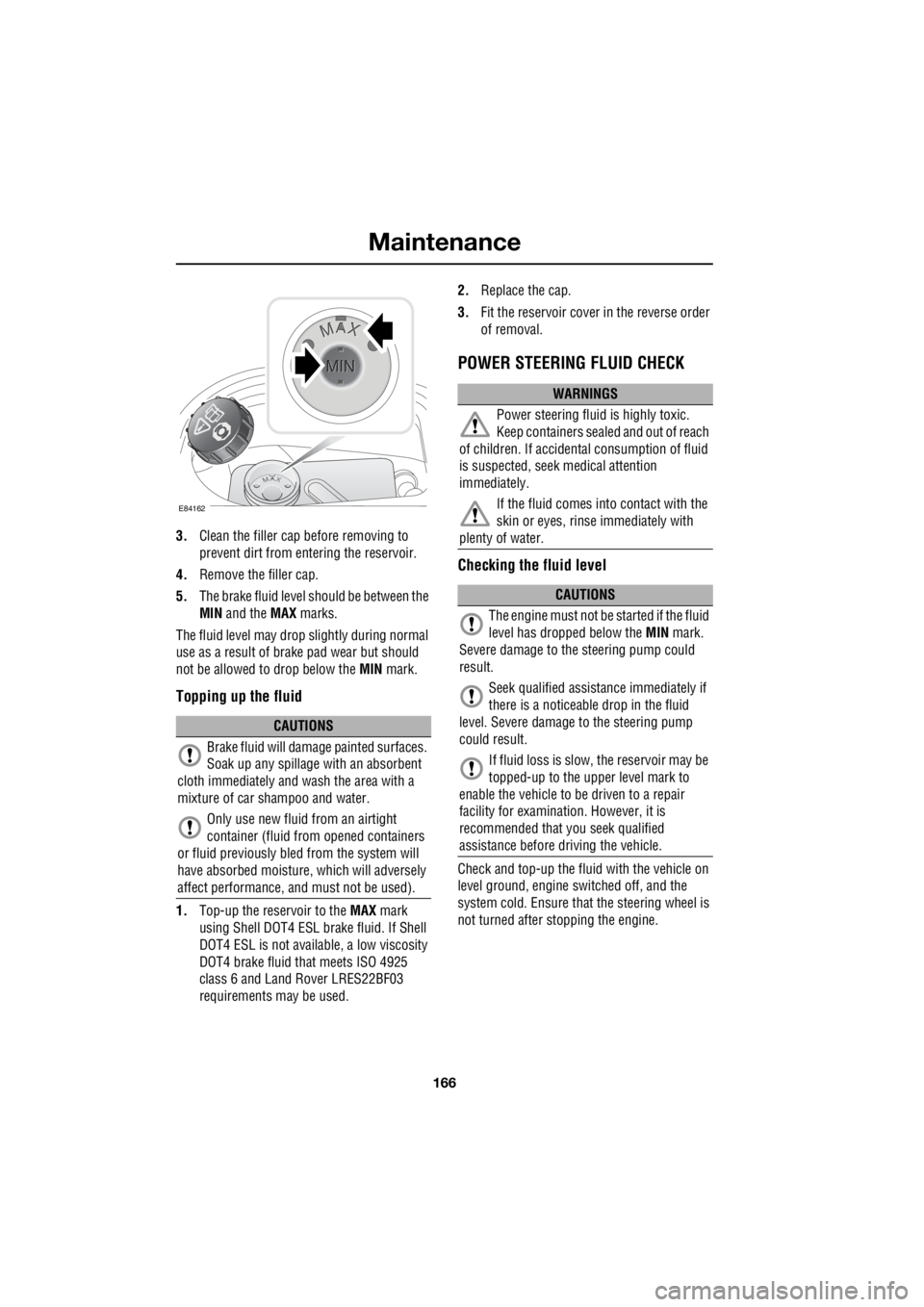

3. Clean the filler cap before removing to

prevent dirt from entering the reservoir.

4. Remove the filler cap.

5. The brake fluid level should be between the

MIN and the MAX marks.

The fluid level may drop slightly during normal

use as a result of brake pad wear but should

not be allowed to drop below the MIN mark.

Topping up the fluid

1.Top-up the reservoir to the MAX mark

using Shell DOT4 ESL brake fluid. If Shell

DOT4 ESL is not availa ble, a low viscosity

DOT4 brake fluid that meets ISO 4925

class 6 and Land Rover LRES22BF03

requirements ma y be used. 2.

Replace the cap.

3. Fit the reservoir cover in the reverse order

of removal.

POWER STEERING FLUID CHECK

Checking the fluid level

Check and top-up the fluid with the vehicle on

level ground, engine switched off, and the

system cold. Ensure that the steering wheel is

not turned after stopping the engine.

CAUTIONS

Brake fluid will damage painted surfaces.

Soak up any spillage with an absorbent

cloth immediately and wash the area with a

mixture of car sh ampoo and water.

Only use new fluid from an airtight

container (fluid from opened containers

or fluid previously bled from the system will

have absorbed moisture, which will adversely

affect performance, and must not be used).

E84162

WARNINGS

Power steering fluid is highly toxic.

Keep containers sealed and out of reach

of children. If accidental consumption of fluid

is suspected, seek medical attention

immediately.

If the fluid comes into contact with the

skin or eyes, rinse immediately with

plenty of water.

CAUTIONS

The engine must not be started if the fluid

level has dropped below the MIN mark.

Severe damage to th e steering pump could

result.

Seek qualified assistance immediately if

there is a noticeable drop in the fluid

level. Severe damage to the steering pump

could result.

If fluid loss is slow, the reservoir may be

topped-up to the uppe r level mark to

enable the vehicle to be driven to a repair

facility for examinatio n. However, it is

recommended that you seek qualified

assistance before driving the vehicle.

Page 2896 of 3229

Wheels and tyres

176

L

Wheels and tyresGENERAL INFORMATION

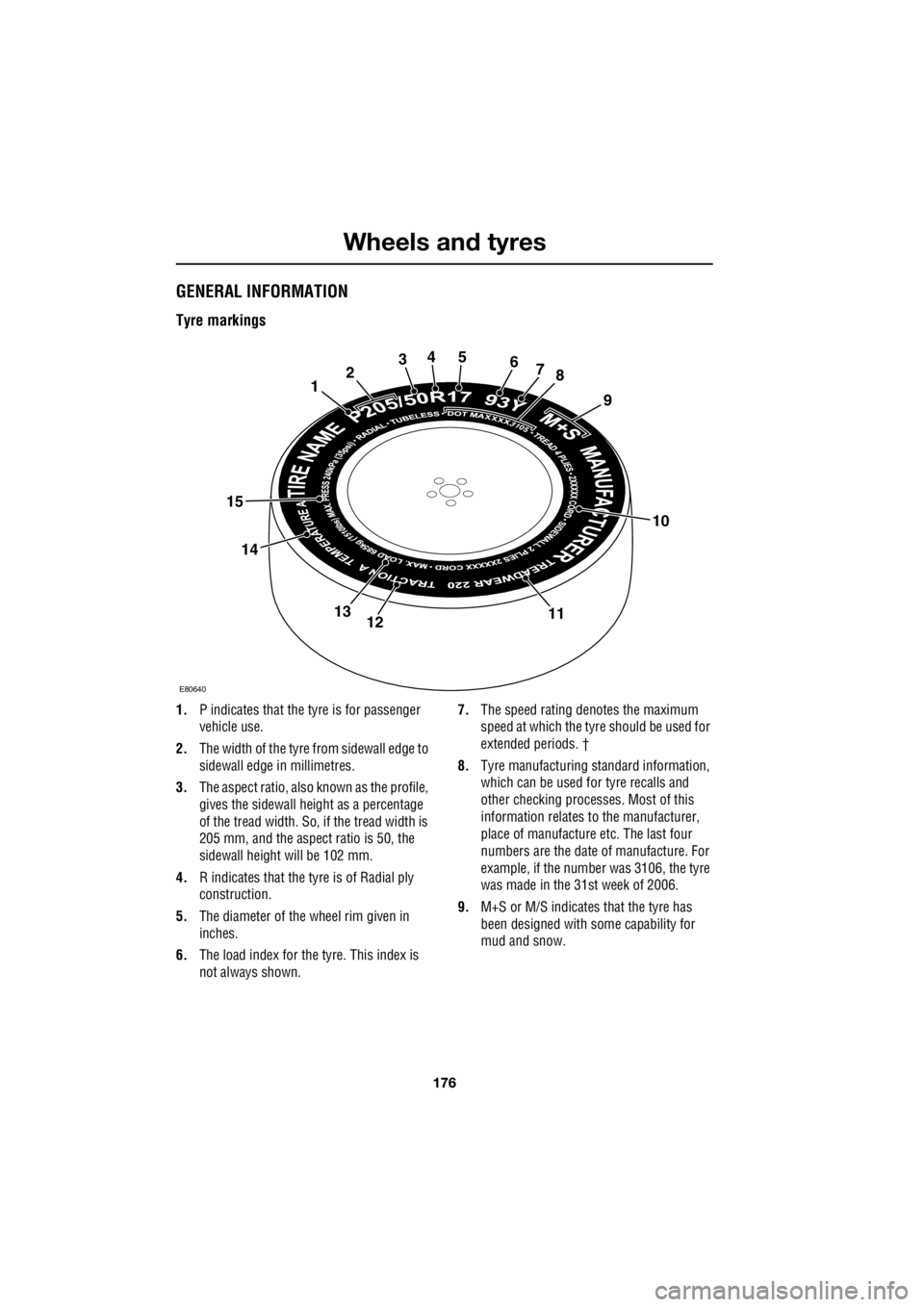

Tyre markings

1. P indicates that the tyre is for passenger

vehicle use.

2. The width of the tyre fr om sidewall edge to

sidewall edge in millimetres.

3. The aspect ratio, also known as the profile,

gives the sidewall height as a percentage

of the tread width. So, if the tread width is

205 mm, and the aspect ratio is 50, the

sidewall height will be 102 mm.

4. R indicates that the ty re is of Radial ply

construction.

5. The diameter of the wheel rim given in

inches.

6. The load index for the tyre. This index is

not always shown. 7.

The speed rating de notes the maximum

speed at which the tyre should be used for

extended periods. †

8. Tyre manufacturing standard information,

which can be used for tyre recalls and

other checking processe s. Most of this

information relates to the manufacturer,

place of manufacture etc. The last four

numbers are the date of manufacture. For

example, if the number was 3106, the tyre

was made in the 31st week of 2006.

9. M+S or M/S indicates that the tyre has

been designed with some capability for

mud and snow.

10

12345678

9

111213

14

15

E80640

Page 2897 of 3229

177

Wheels and tyres

R

10. The number of plies in both the tread area,

and the sidewall area, indicates how many

layers of rubber coat ed material make up

the structure of the tyre. Information is

also provided on the type of materials

used.

11. Wear rate indicator. A tyre rated at 400 for

example, will last twice as long as a tyre

rated at 200.

12. The traction rating grades a tyres

performance when stopping on a wet road

surface. The higher the grade the better the

braking performance. The grades from

highest to lowest are, AA, A, B, and C.

13. The maximum load which can be carried

by the tyre.

14. Heat resistance grading. The tyre's

resistance to heat is grade A, B, or C, with

A indicating the greatest resistance to heat.

This grading is provided for a correctly

inflated tyre, which is being used within its

speed and loading limits.

15. The maximum inflation pressure for the

tyre. This pressure should not be used for

normal driving. See TECHNICAL

SPECIFICATIONS (page 194). † Speed ratings

TYRE CARE

Note:

Tyre condition should be checked after

the vehicle has been used off-road. As soon as

the vehicle returns to a normal, hard, road

surface stop the vehicle and check for damage

to the tyres. Rating Speed kmh (mph)

Q 160 (99)

R 170 (106) S 180 (112)

T 190 (118)

U 200 (124)

H 210 (130)

V 240 (149)

W 270 (168) Y 300 (186)

WARNINGS

Defective tyres are dangerous. Do not

drive the vehicle if a tyre is damaged,

excessively worn, or incorrectly inflated.

Doing so may lead to premature tyre failure.

Avoid contaminating the tyres with

vehicle fluids as they may cause

damage to the tyre.

Avoid spinning the wheels. The forces

released can damage the structure of

the tyre, and cause it to fail. Doing so may lead

to premature tyre failure.

If wheel spin is unavoidable due to a

loss of traction (in deep snow for

example) do not exceed the 50 km/h (30 mph)

point on the speedometer. Doing so may lead

to premature tyre failure.

Page 2898 of 3229

Wheels and tyres

178

L

All of the vehicle's tyres (including the spare)

should be checked regularly for damage, wear

and distortion. If you ar e in any doubt about the

condition of a tyre, have it checked immediately

by a tyre repair centre, or your Land Rover

Dealer/Authorised repairer.

Tyre wear

Good driving practise w ill improve the mileage

you obtain from your tyres, and avoid

unnecessary damage.

• Always ensure that the tyre pressures are

correctly adjusted.

• Always observe the posted speed limits,

and advisory speeds for bends.

• Avoid pulling away quickly, or hard

acceleration.

• Avoid making fast turns or braking

sharply.

• Wherever possible, avoid potholes, or

obstacles on the road.

• Do not drive up kerbs, or rub the tyres

against them when parking.

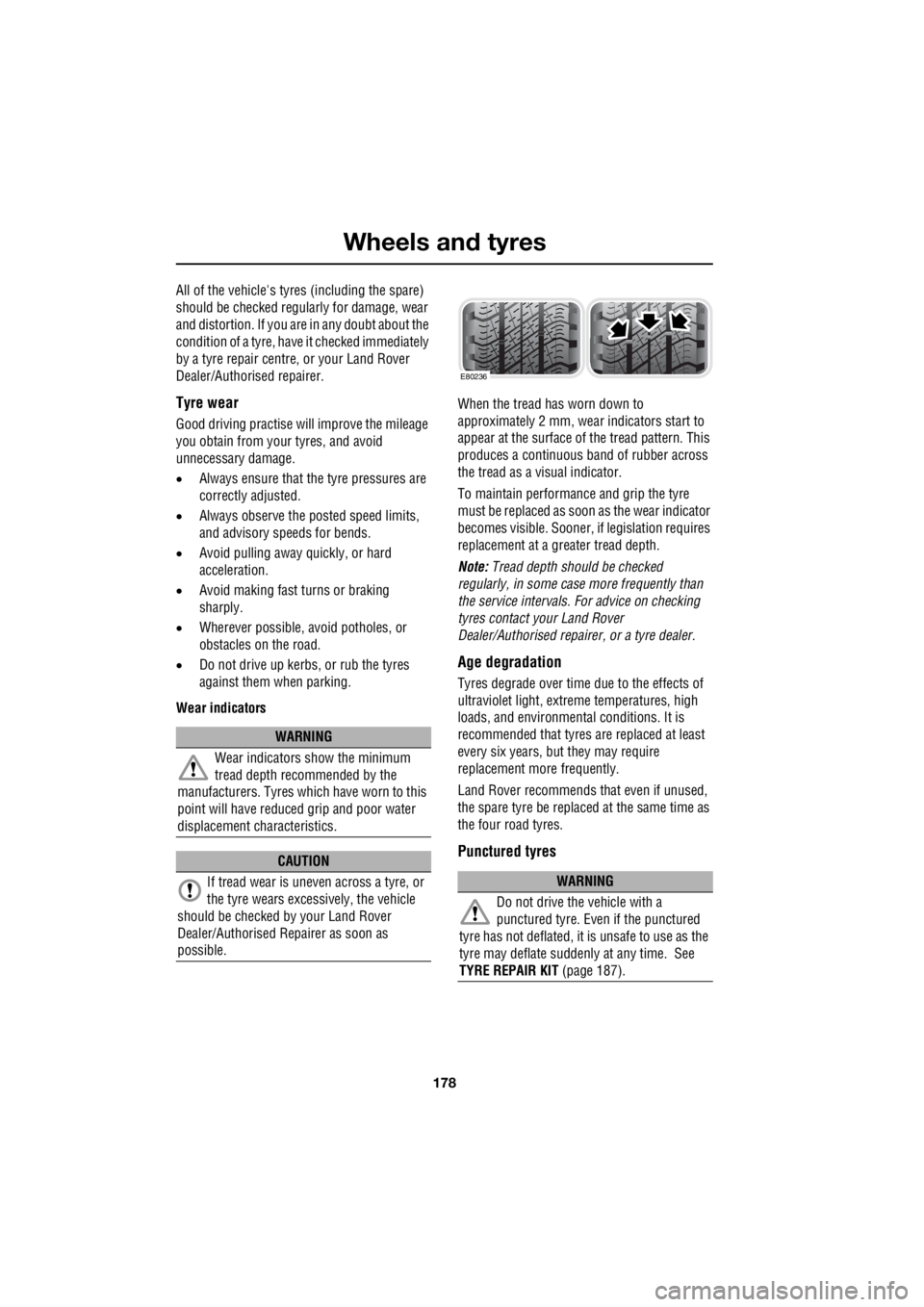

Wear indicators When the tread has worn down to

approximately 2 mm, wear indicators start to

appear at the surface of the tread pattern. This

produces a continuous ba nd of rubber across

the tread as a visual indicator.

To maintain performance and grip the tyre

must be replaced as s oon as the wear indicator

becomes visible. Sooner, if legislation requires

replacement at a greater tread depth.

Note: Tread depth should be checked

regularly, in some case more frequently than

the service intervals. For advice on checking

tyres contact your Land Rover

Dealer/Authorised repairer, or a tyre dealer.

Age degradation

Tyres degrade over time due to the effects of

ultraviolet light, extreme temperatures, high

loads, and environmen tal conditions. It is

recommended that tyres are replaced at least

every six years, but they may require

replacement more frequently.

Land Rover recommends that even if unused,

the spare tyre be replaced at the same time as

the four road tyres.

Punctured tyres

WARNING

Wear indicators show the minimum

tread depth recommended by the

manufacturers. Tyres whic h have worn to this

point will have reduced grip and poor water

displacement characteristics.

CAUTION

If tread wear is uneve n across a tyre, or

the tyre wears excessively, the vehicle

should be checked by your Land Rover

Dealer/Authorised Repairer as soon as

possible.

WARNING

Do not drive the vehicle with a

punctured tyre. Even if the punctured

tyre has not deflated, it is unsafe to use as the

tyre may deflat e suddenly at an y time. See

TYRE REPAIR KIT (page 187).

E80236

Page 2899 of 3229

179

Wheels and tyres

R

Tyre checks

Not all punctures result in the tyre deflating

immediately. Therefore, it is important to check

the tyres for damage and foreign objects,

regularly.

When driving, if a sudden vibration, or change

to the vehicle's handling is noticed, reduce

speed immediately. Do not brake hard, or make

any sudden manoeuvres or direction changes.

Drive slowly to an area off of the main highway

and stop the vehicle.

Note: Driving the vehicle to a safe area may

cause damage to the punctured tyre, but

occupant safety is far more important.

Inspect the tyres for signs of punctures,

damage, or under inflat ion. If any damage or

deformity is detected, the tyre should be

replaced. If a spare tyre is not available, then

the vehicle should be recovered to a tyre repair

centre, or Land Rover Dealer/Approved

repairer.

Note: The tyres should be checked

immediately after any off -road use, and prior to

using the vehicle on a public highway.

Replacement tyres

Ideally, tyres should be re placed in sets of four.

If this is not po ssible, replace the tyres in pairs

(front and rear). When tyres are replaced, the

wheels should always be re-balanced, and

alignment checked.

The correct tyre specific ation for your vehicle

can be found on the tyre information label.

WARNINGS

Do not fit cross-ply tyres.

Do not fit tubed tyres.

Do not swap tyres around the vehicle.

Tyres bed in to the specific

characteristics of each wheel position.

Swapping them around may affect the

vehicle's handli ng and traction.

Always fit replacement tyres of the

same type, and wher ever possible of

the same make and tread pattern.

Replacement wheels should be genuine

Land Rover parts. This will maintain the

designed driving charac teristics both on and

off road.

If the use of tyres not recommended by

Land Rover is unavoidable, ensure that

you read, and fully comply with the tyre

manufacturers instructi ons. Failure to do so

may lead to tyre failure due to incorrect fitment

or use.

WARNINGS

Page 2900 of 3229

Wheels and tyres

180

L

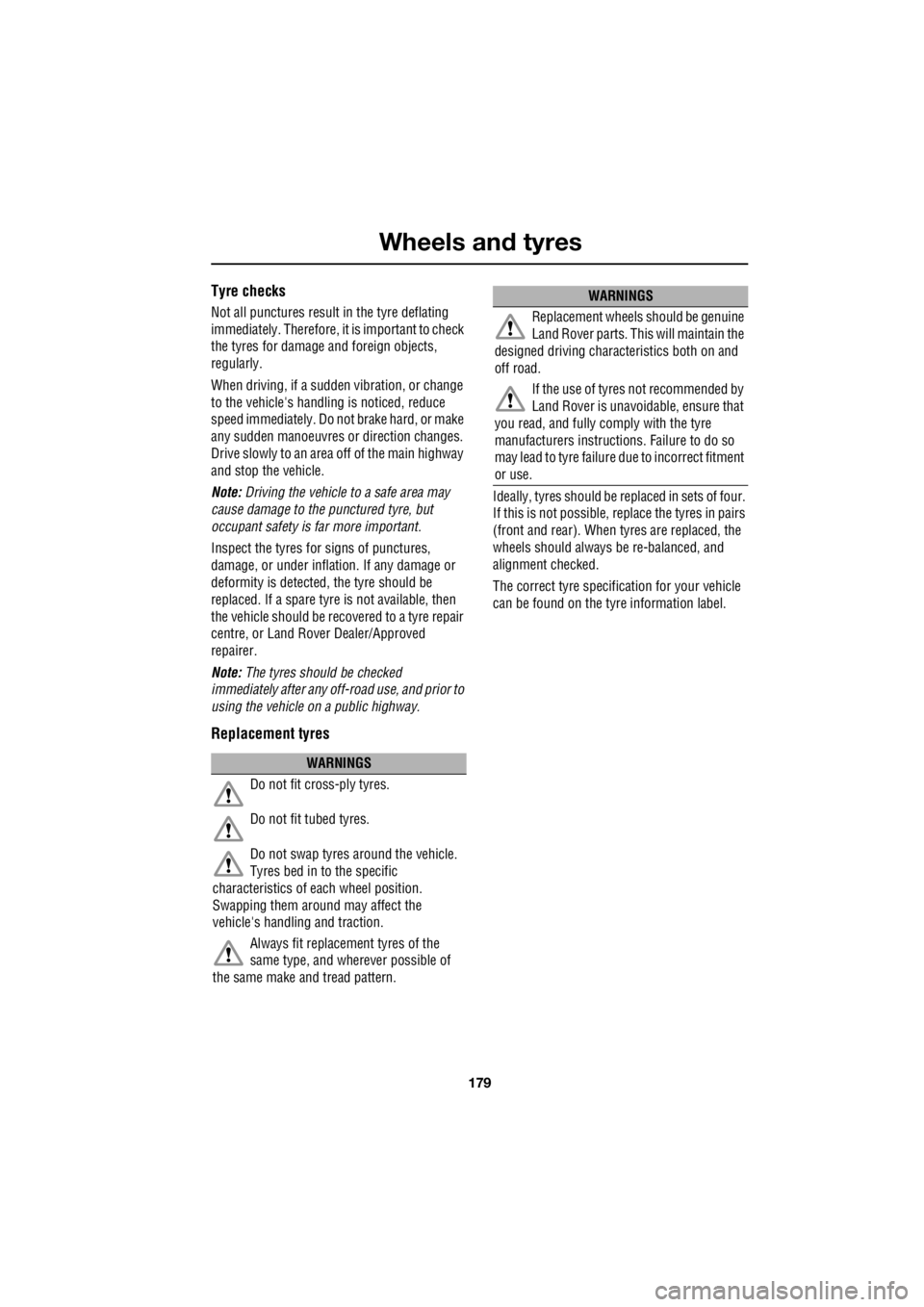

Directional tyres

Directional tyres are designed to operate

correctly when rotati ng forwards (when the

vehicle is travelling forwards).

Typical direction indicators

Tyre pressures

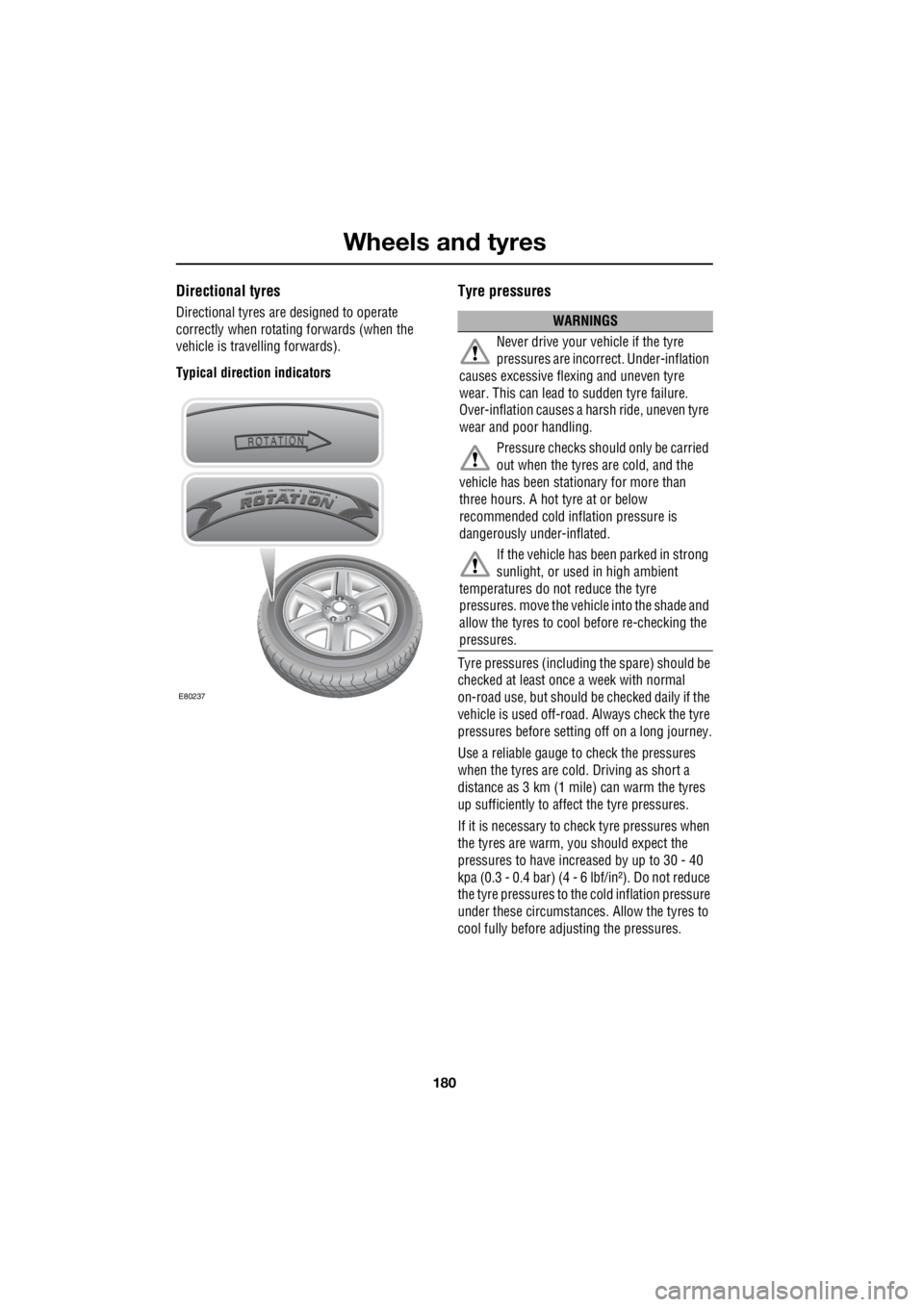

Tyre pressures (including the spare) should be

checked at least once a week with normal

on-road use, but should be checked daily if the

vehicle is used off-road. Always check the tyre

pressures before setti ng off on a long journey.

Use a reliable gauge to check the pressures

when the tyres are cold. Driving as short a

distance as 3 km (1 mile) can warm the tyres

up sufficiently to affect the tyre pressures.

If it is necessary to check tyre pressures when

the tyres are warm, you should expect the

pressures to have incr eased by up to 30 - 40

kpa (0.3 - 0.4 bar) (4 - 6 lbf/in²). Do not reduce

the tyre pressures to the cold inflation pressure

under these circumstances. Allow the tyres to

cool fully before ad justing the pressures.

E80237

WARNINGS

Never drive your vehicle if the tyre

pressures are incorrect. Under-inflation

causes excessive flex ing and uneven tyre

wear. This can lead to sudden tyre failure.

Over-inflation causes a ha rsh ride, uneven tyre

wear and poor handling.

Pressure checks shoul d only be carried

out when the tyres are cold, and the

vehicle has been stationary for more than

three hours. A hot tyre at or below

recommended cold inflation pressure is

dangerously under-inflated.

If the vehicle has been parked in strong

sunlight, or used in high ambient

temperatures do not reduce the tyre

pressures. move the vehicle into the shade and

allow the tyres to cool before re-checking the

pressures.

Page 2901 of 3229

181

Wheels and tyres

R

Checking the tyre pressures

1. Tyre information label position on a

left-hand drive vehicle.

2. Tyre information label position on a

right-hand drive vehicle.

The following procedure should be used to

check and adjust the tyres pressures.

1. Remove the valve cap.

2. Firmly attach a tyre pressure gauge/inflator

to the valve.

3. Read the tyre pressure from the gauge,

and add air if required.

4. If air is added to the tyre, remove the gauge

and re-attach it be fore reading the

pressure. Failure to do so may result in an

inaccurate reading. 5.

If the tyre pressure is too high, remove the

gauge and allow air out of the tyre by

pressing the centre of the valve. Refit the

gauge to the valve and check the pressure.

6. Repeat the process a dding or removing air

as required until the co rrect tyre pressure

is reached.

7. Refit the valve cap.

Note: It is an offence in certain countries to

drive a vehicle with incorrect tyre pressures.

Note: It is the driver's responsibility to ensure

that the tyre pressures are correct.

Tyre valves

Keep the valve caps screwed down firmly to

prevent water or dirt entering the valve. Check

the valves for leaks when checking the tyre

pressures.

WARNING

Tyre pressures should be checked

regularly using an accurate pressure

gauge, when the tyres are cold. Failure to

properly maintain your tyre pressures could

increase the risk of tyre failure resulting in loss

of vehicle control and personal injury.

E83967

Page 2902 of 3229

Wheels and tyres

182

L

Pressure compensation for ambient

temperature changes

If the ambient temperature drops, the tyre

pressures will decrease, which may cause

under inflation. This should be borne in mind

when travelling to, or through, areas of lower

temperature.

Under inflation causes th e tyre side wall height

to reduce, which in turn results in uneven tyre

wear, and a risk of tyre failure.

Tyre pressures may be adjusted before setting

off on a journey to, or through, areas of low

temperature. Alternatively, the tyre pressures

can be adjusted when low temperature areas

are reached.

Note: If the tyre pressures are to be adjusted in

the lower temperature area, the vehicle should

be left standing for at least one hour prior to

adjustment.

Tyre pressures should be increased by 0.14

bar/14 kPa (2 lbf/in²) for each 10 °C (20 °F)

temperature decrease.

Flat spots

If the vehicle is stationary for a long period

when the ambient temperature is high, the

tyres may form flat spots. When the vehicle is

driven these flat spots will cause a vibration

which will steadily disappear as the tyres warm

up and regain their original shape.

In order to minimise fl at spotting, the tyre

pressures can be increased.

Tyre pressures should be increased by 0.14

bar/14 kPa (2 lbf/in²) for each 10 °C (20 °F)

temperature increase above 20 °C (68 °F).

Long term storage

Flat spotting can be minimised during long

term storage by increasing the tyre pressures

to the maximum indicated on the tyre sidewall.

Note: The tyre pressures s hould be reduced to

the correct pressure before the vehicle is

driven.

E80321

E80322

Page 2903 of 3229

183

Wheels and tyres

R

USING WINTER TYRES

If winter tyres are fitted to the vehicle, the tyre

manufacturers instructions should be

followed. Pay particular attention to

instructions regarding the maximum speed

that the vehicle can be driven, and the correct

pressures for the tyres.

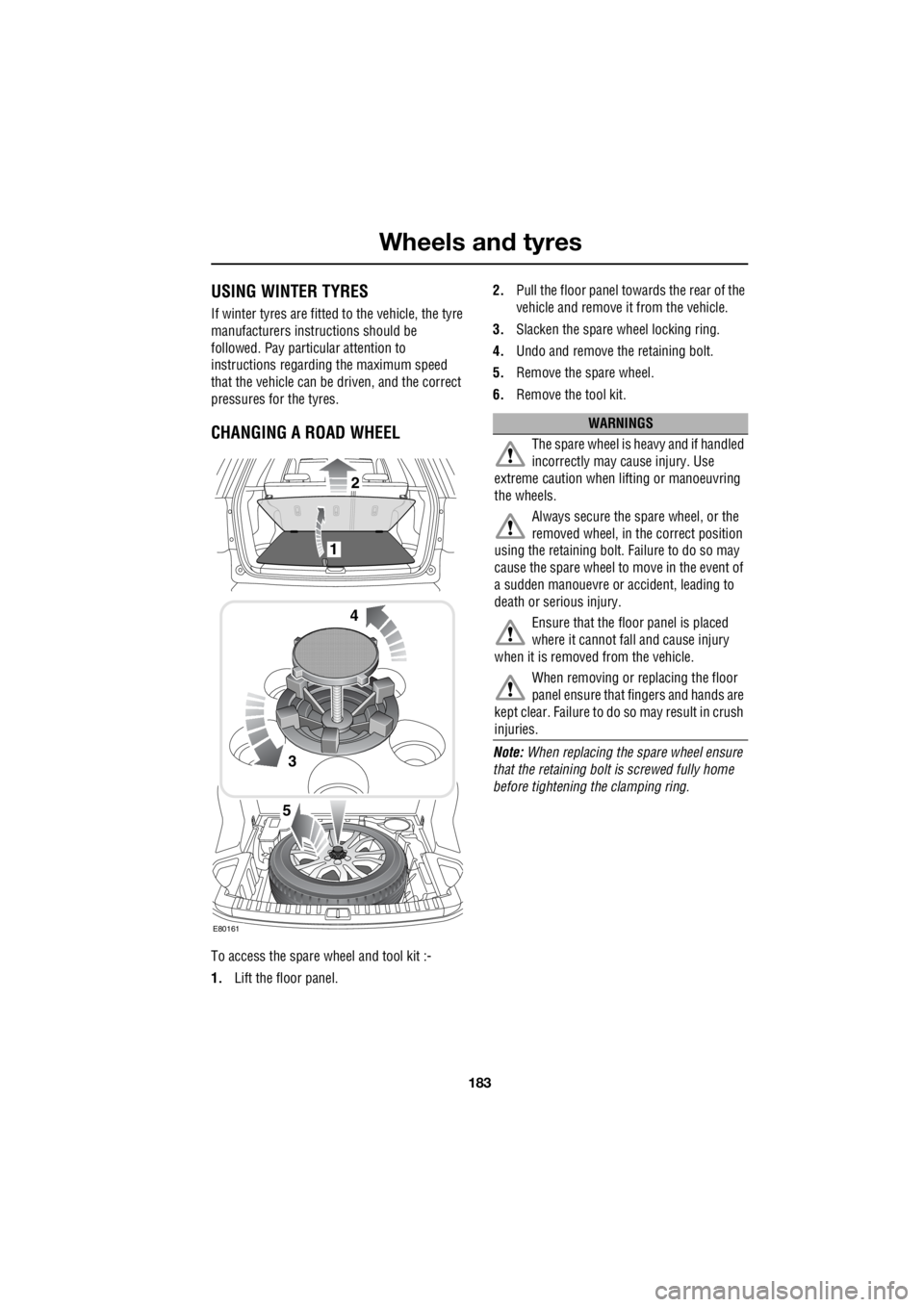

CHANGING A ROAD WHEEL

To access the spare wheel and tool kit :-

1. Lift the floor panel. 2.

Pull the floor panel towards the rear of the

vehicle and remove it from the vehicle.

3. Slacken the spare wheel locking ring.

4. Undo and remove the retaining bolt.

5. Remove the spare wheel.

6. Remove the tool kit.

Note: When replacing the spare wheel ensure

that the retaining bolt is screwed fully home

before tightening the clamping ring.

3

4

1

2

5

E80161

WARNINGS

The spare wheel is heavy and if handled

incorrectly may cause injury. Use

extreme caution when lifting or manoeuvring

the wheels.

Always secure the spare wheel, or the

removed wheel, in the correct position

using the retaining bolt. Failure to do so may

cause the spare wheel to move in the event of

a sudden manouevre or accident, leading to

death or serious injury.

Ensure that the floo r panel is placed

where it cannot fall and cause injury

when it is removed from the vehicle.

When removing or replacing the floor

panel ensure that fingers and hands are

kept clear. Failure to do so may result in crush

injuries.