engine LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2508 of 3229

• NOTE: The s ame reference point s mus t be chos en on bot h s ides when checking for changed dimens ions (e.g.bores , edges , beads /s wage l ines etc).

All of t he important external body dimens ions are li st ed in Tol erance Checks .For addit ional informat ion, refer t o: Body and Frame (501-26 Body Repai rs - Vehi cl e Speci fi c Informat ion andTolerance Checks , Descripti on and Operat ion).

Measurements wi th a meas uri ng/s trai ghtening jig.A meas uri ng/s traightening ji g is required for accurat e meas urement s of the body. The measuring s yst ems arecat egoris ed by t heir means of operati on:Mechanical meas uring s ys tem.Opti cal meas uri ng s ys t em.

Quick and accurate meas uri ng res ult s can be obtai ned usi ng comput eri sed meas uring s yst ems .

A minimum of t hree int act meas uri ng point s on t he body are requi red for meas urement s of length, wi dth and hei ghtdimens ions .

In s ome cases t his may mean making t he meas uri ng poi nts access ibl e. Al l of thes e meas uring sys tems can be used t omake body meas urements , provided al l t he equipment is avail able.

Planning a repair

The fol lowing decis i ons have t o be made before t he repai rs are s tarted:

Does the vehicl e need to be put on a s traightening ji g, or can it be st rai ght ened by other means ?Does the body need t o be meas ured?Do aggregates l ike engine or axles need t o be removed?• NOTE: It is preferable to repair body part s rat her t han t o renew them, as t his keeps the complet e body-s hel lint act .

W hi ch body parts need t o be renewed?W hi ch body parts can be repai red?

Obtaining spare parts

The avai labil it y of s pare part s oft en determines how eas il y t he body repairs can be carri ed out . The fol lowi ng procedure isrecommended:

Obtai n all t he data for the vehicl e, i ncl udi ng t ype, vehi cl e i dent ificati on number, trim code, engine i dent ificati onlet ters, i nit ial regis t rat ion et c.Es tabli sh all of the metal part s that need t o be renewed.Es tabli sh all of the at tached part s t hat need t o be renewed, including smal l parts li ke ri vet s, cl ips etc.

Straightening repairs

W ARNING: The us e of heat when pull ing t o s traighten body panels , (s uch as s ide members ), i s not recommended.Longi tudinal pulli ng, (hot or col d), is al s o not recommended. A smal l amount of s ide to si de pull is permis s ibl e, (col d).

W hen any t ype of pul li ng or st rai ght ening operat ion i s performed i t is i mport ant to obs erve for any movement i n adjacentpanel s.

A panel must retai n it s s t rength and integrit y, i f there is any doubt the panel mus t be renewed.

Straightening repairs are often required to res tore the body t o i ts origi nal s hape aft er an accident. This can be done wit h:

Ali gnment jigs .Univers al s trai ghtening and meas uri ng ji gs.W el di ng jig s ys tem.

The fol lowing poi nts mus t be foll owed to ens ure that t he repairs are carri ed out profes si onal ly and t hat all t he dimens ionsare correct aft er t he repai rs have been carri ed out.

Struct ure:- The repair s equence depends on the individual repair plan (t aki ng any neces sary dis as sembl y work intoaccount).- Clean t he at tachment areas .- Anchor t he vehi cl e free of s tres s on t he relevant s ys t em.- Support the aggregat es to take s train off the body.- Decide on at l eas t t hree meas uri ng/mounti ng poi nts that are undamaged and as far apart as pos s ible (forbasi c adjus tment ).- Check the di mens i ons of t he meas uri ng/mounti ng poi nts .Straightening:-• NOTE: Check di mensi ons and gaps conti nuous ly during s t raight eni ng.

A body i s always s traightened i n the oppos it e direct ion t o t hat of the i mpact . Always carry out st rai ght eningrepairs wi th the complet e body s hel l as s embled (do not cut out any part s beforehand). Carry out t hes traightening work i n s everal s t ages . This prevents the ris k of over st ret chi ng or of welded joi nts t eari ng out .Duri ng the individual st rai ght ening s t eps , rel ieve t ens i on by s triking wi th an aluminium hammer whi le the part iss ubject ed t o a t ensi le load (in t he area of pre-determined folding poi nt s , dent s , welded joi ns etc.).Speci al feat ures :- Ult ra high s t rength st eel cannot be st rai ght ened due to it s bri tt lenes s and mus t always be repl aced.

Cutting out body parts

Page 2528 of 3229

Publi s hed: 11-May-2011

Body Repairs - Vehicle Specific Information and Tolerance Checks - Body

and Frame

Des cript ion and Operat ion

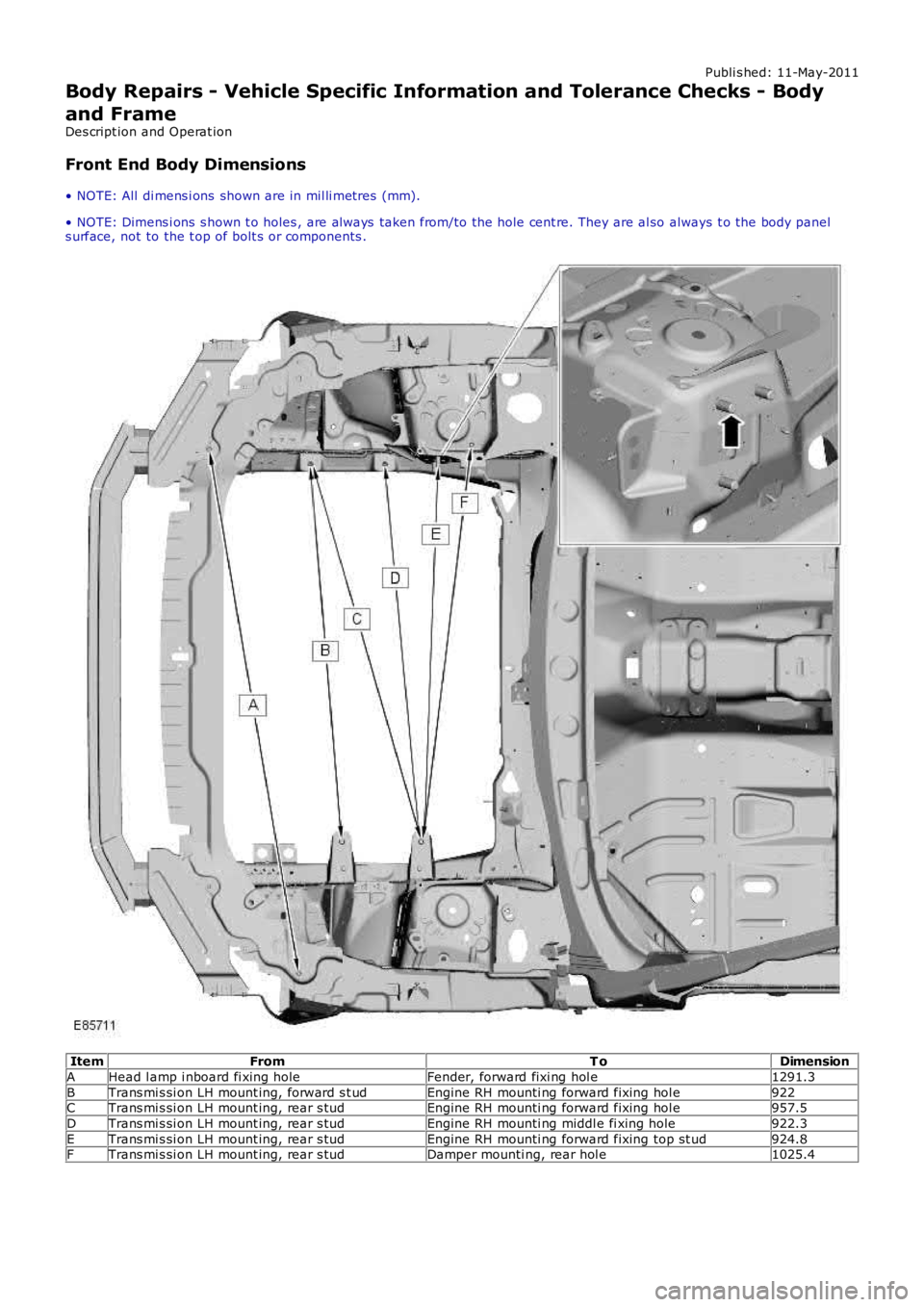

Front End Body Dimensions

• NOTE: All di mens i ons shown are in mil li metres (mm).

• NOTE: Dimens i ons s hown t o holes , are al ways taken from/to the hole cent re. They are al so always t o the body panels urface, not to the t op of bolt s or components .

ItemFromT oDimension

AHead l amp i nboard fi xing holeFender, forward fixi ng hol e1291.3

BTrans mi s si on LH mount ing, forward s t udEngine RH mounti ng forward fixing hol e922CTrans mi s si on LH mount ing, rear s tudEngine RH mounti ng forward fixing hol e957.5

DTrans mi s si on LH mount ing, rear s tudEngine RH mounti ng middl e fi xing hole922.3

ETrans mi s si on LH mount ing, rear s tudEngine RH mounti ng forward fixing top s t ud924.8FTrans mi s si on LH mount ing, rear s tudDamper mounti ng, rear hol e1025.4

Page 2541 of 3229

Publi s hed: 11-May-2011

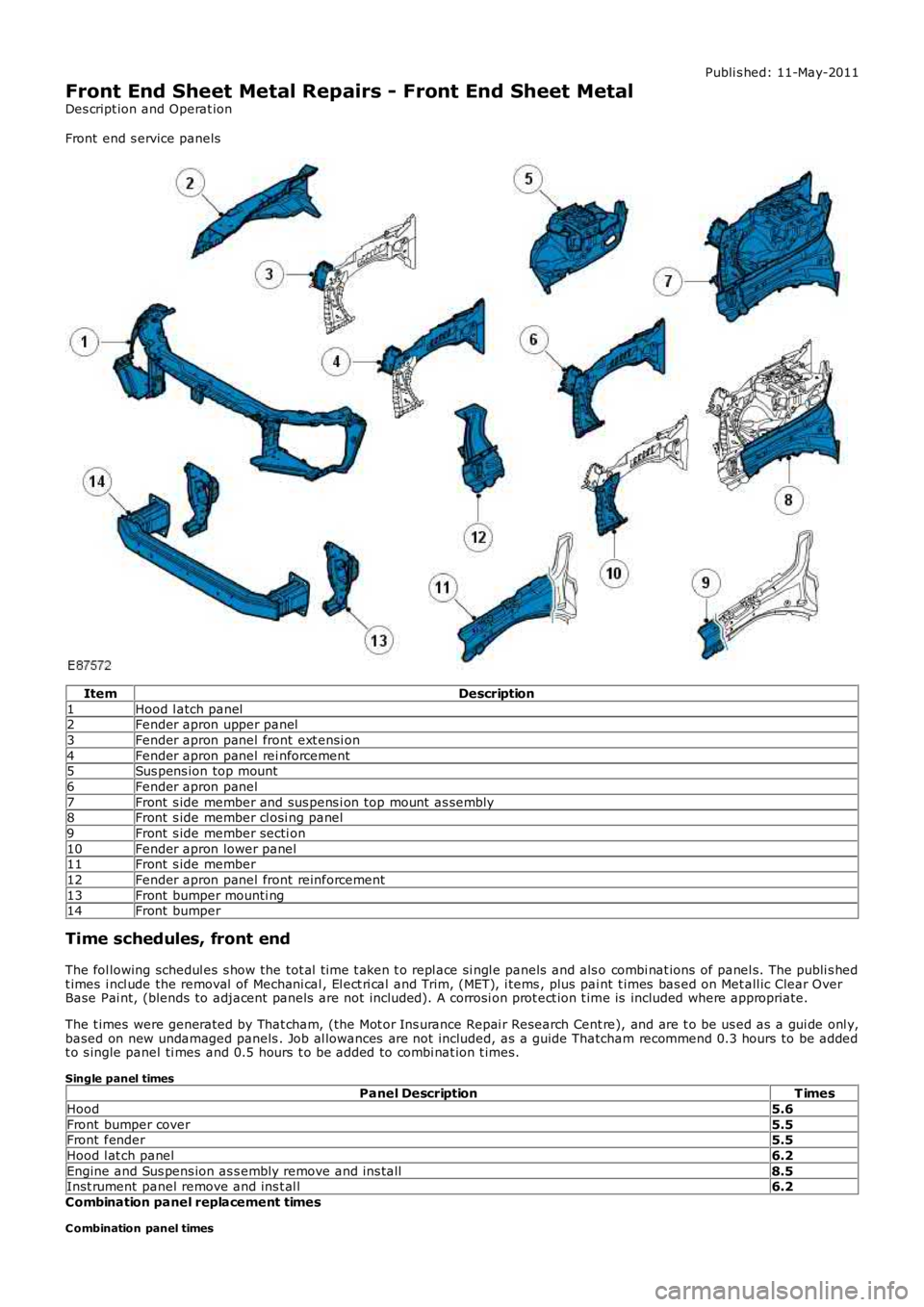

Front End Sheet Metal Repairs - Front End Sheet Metal

Des cript ion and Operat ion

Front end s ervice panels

ItemDescription

1Hood l atch panel2Fender apron upper panel

3Fender apron panel front ext ensi on

4Fender apron panel rei nforcement5Sus pens ion top mount

6Fender apron panel

7Front s ide member and sus pens i on top mount as s embly8Front s ide member cl osi ng panel

9Front s ide member secti on

10Fender apron lower panel11Front s ide member

12Fender apron panel front reinforcement

13Front bumper mounti ng14Front bumper

Time schedules, front end

The fol lowing schedul es s how the tot al t ime t aken t o repl ace si ngl e panels and als o combi nat ions of panel s. The publi s hedt imes i ncl ude the removal of Mechani cal , El ect ri cal and Trim, (MET), i tems , plus paint t imes bas ed on Met all ic Clear OverBase Pai nt, (blends to adjacent panels are not included). A corrosi on prot ect ion t ime is included where appropriate.

The t imes were generated by That cham, (the Mot or Ins urance Repai r Research Cent re), and are t o be us ed as a gui de onl y,based on new undamaged panels . Job al lowances are not included, as a guide Thatcham recommend 0.3 hours to be addedt o s ingle panel ti mes and 0.5 hours t o be added to combi nat ion t imes.

Single panel timesPanel DescriptionT imes

Hood5.6

Front bumper cover5.5Front fender5.5

Hood l at ch panel6.2

Engine and Sus pens ion as s embly remove and ins tal l8.5Inst rument panel remove and ins t al l6.2

Combination panel replacement times

C ombination panel times

Page 2542 of 3229

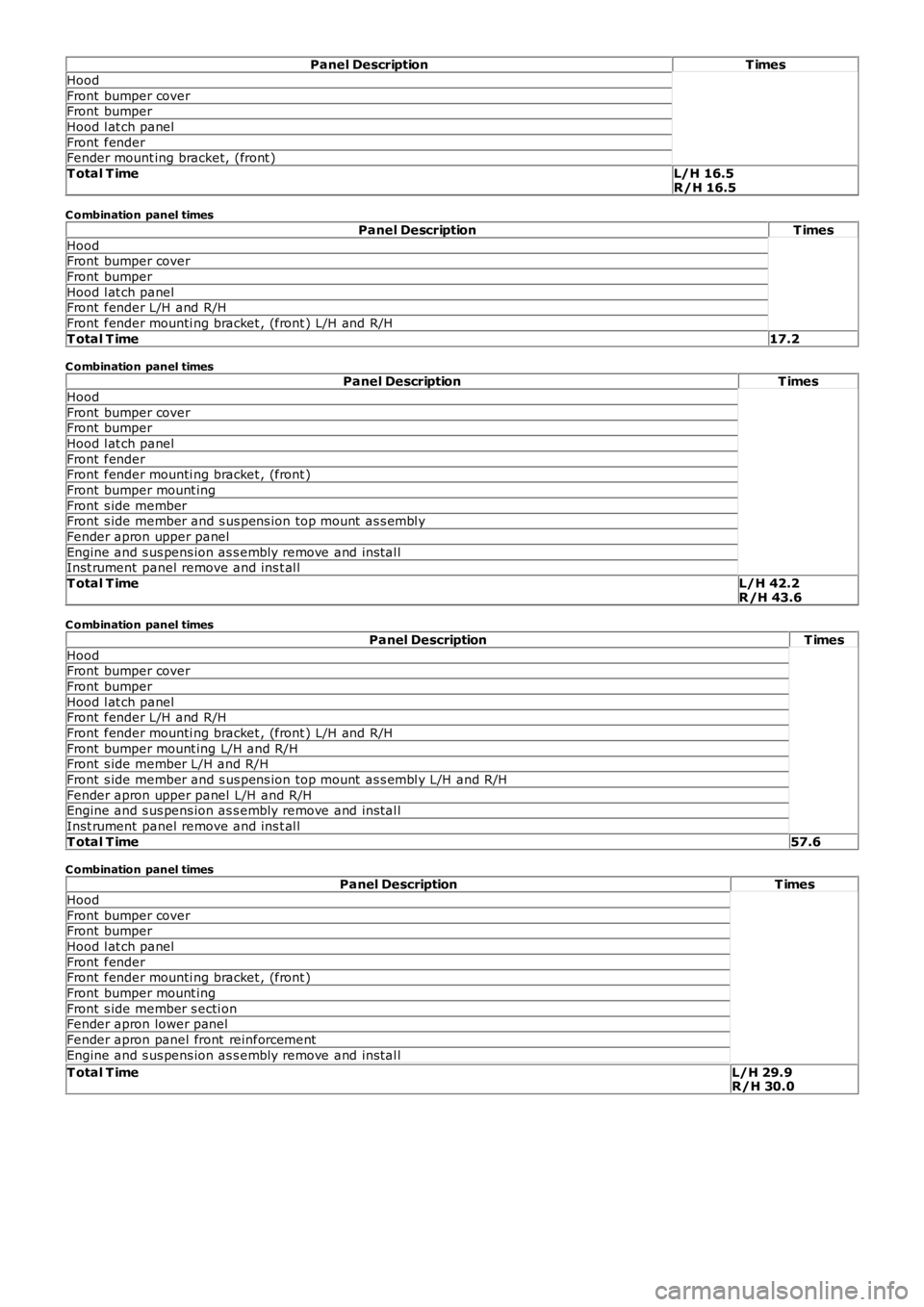

Panel DescriptionT imes

Hood

Front bumper coverFront bumper

Hood l at ch panel

Front fenderFender mount ing bracket, (front )

T otal T imeL/H 16.5R/H 16.5

C ombination panel times

Panel DescriptionT imes

HoodFront bumper cover

Front bumper

Hood l at ch panelFront fender L/H and R/H

Front fender mounti ng bracket , (front ) L/H and R/H

T otal T ime17.2

C ombination panel timesPanel DescriptionT imes

Hood

Front bumper coverFront bumper

Hood l at ch panel

Front fenderFront fender mounti ng bracket , (front )

Front bumper mount ing

Front s ide memberFront s ide member and s us pens ion top mount as s embl y

Fender apron upper panel

Engine and s us pens ion as s embly remove and ins tal lInst rument panel remove and ins t al l

T otal T imeL/H 42.2R /H 43.6

C ombination panel times

Panel DescriptionT imes

HoodFront bumper cover

Front bumper

Hood l at ch panelFront fender L/H and R/H

Front fender mounti ng bracket , (front ) L/H and R/H

Front bumper mount ing L/H and R/HFront s ide member L/H and R/H

Front s ide member and s us pens ion top mount as s embl y L/H and R/H

Fender apron upper panel L/H and R/HEngine and s us pens ion as s embly remove and ins tal l

Inst rument panel remove and ins t al l

T otal T ime57.6

C ombination panel timesPanel DescriptionT imes

Hood

Front bumper coverFront bumper

Hood l at ch panel

Front fenderFront fender mounti ng bracket , (front )

Front bumper mount ing

Front s ide member s ecti onFender apron lower panel

Fender apron panel front reinforcement

Engine and s us pens ion as s embly remove and ins tal l

T otal T imeL/H 29.9R/H 30.0

Page 2550 of 3229

Publi s hed: 11-May-2011

Front End Sheet Metal Repairs - Front Side Member

Removal and Inst all ati on

• NOTE: The front s ide member i s s erviced as a s eparate weld on panel. This procedure is to fit a long s ect ion cut from thes ervice panel, dis carding t he rear part .

• NOTE: The s ervice panel is not ful ly wel ded.

• NOTE: The s ect ion must be made at leas t 20mm forward of the l aser wel d.

1. The front s i de member is replaced in conjuncti on wit h:

Front bumper cover

Front bumper

Hood lat ch panel

Both front fenders

Front bumper mount ing

Front s ide member clos ing panel

Fender apron panel front reinforcement

Fender apron l ower panel

• NOTE: It is al so neces sary t o remove t he engine and s us pens ion as an as s embly.

2. For addit ional informati on rel at ing to this repair procedurepleas e s ee t he foll owing:For addi ti onal informat ion, refer t o: Body and Frame (501-26Body Repai rs - Vehi cl e Speci fic Informat ion and ToleranceChecks , Descripti on and Operat ion) /Standard W orks hop Practi ces (100-00 General Informat ion,Des cript ion and Operat ion).

3. Remove the front s ide member clos ing panel.For addi ti onal informat ion, refer t o: Front Side Member Cl os i ngPanel (501-27 Front End Sheet Met al Repai rs , Removal andIns t allat ion).

4. Remove the radi ator cool ing pack.For addi ti onal informat ion, refer t o: Radiator (303-03A Engi neCooling - I6 3.2L Petrol, Removal and Ins tall ati on).

5. Remove the engine and front s uspens ion as an as s embly.

6. Rel eas e and lay as ide t he brake pipe.

7. LH Side: Release the bat tery juncti on box and posi ti on asi de.

8. LH Side: Remove the ai r int ake pi pe.

9. LH Side: Release and lay as ide t he brake pi pe at the si demember.

10. LH Side: Remove the ant i-Lock brake s ys tem (ABS) Module.For addi ti onal informat ion, refer t o: Anti -Lock Brake Syst em(ABS) Module (206-09A Ant i-Lock Control, Removal andIns t allat ion).

11. RH Side: Remove the winds hi eld was her res ervoir.For addi ti onal informat ion, refer t o: W i nds hiel d W as herRes ervoi r (501-16 W i pers and W as hers , Removal andIns t allat ion).

12. RH Side: Remove the engi ne mount ing bracket .For addi ti onal informat ion, refer t o: Engi ne Mount RH (303-01BEngine - TD4 2.2L Dies el, Removal and Ins tall ati on).

13. RH Side: Remove the fender apron brake pipes .

14. RH Side: Remove the fender apron A/C pipe.

15. Rel eas e and l ay as ide t he ins ulat ing mat eri al at t hebulkhead.

16. Rel eas e and l ay as ide t he wiring harnes s .

Page 2554 of 3229

Publi s hed: 11-May-2011

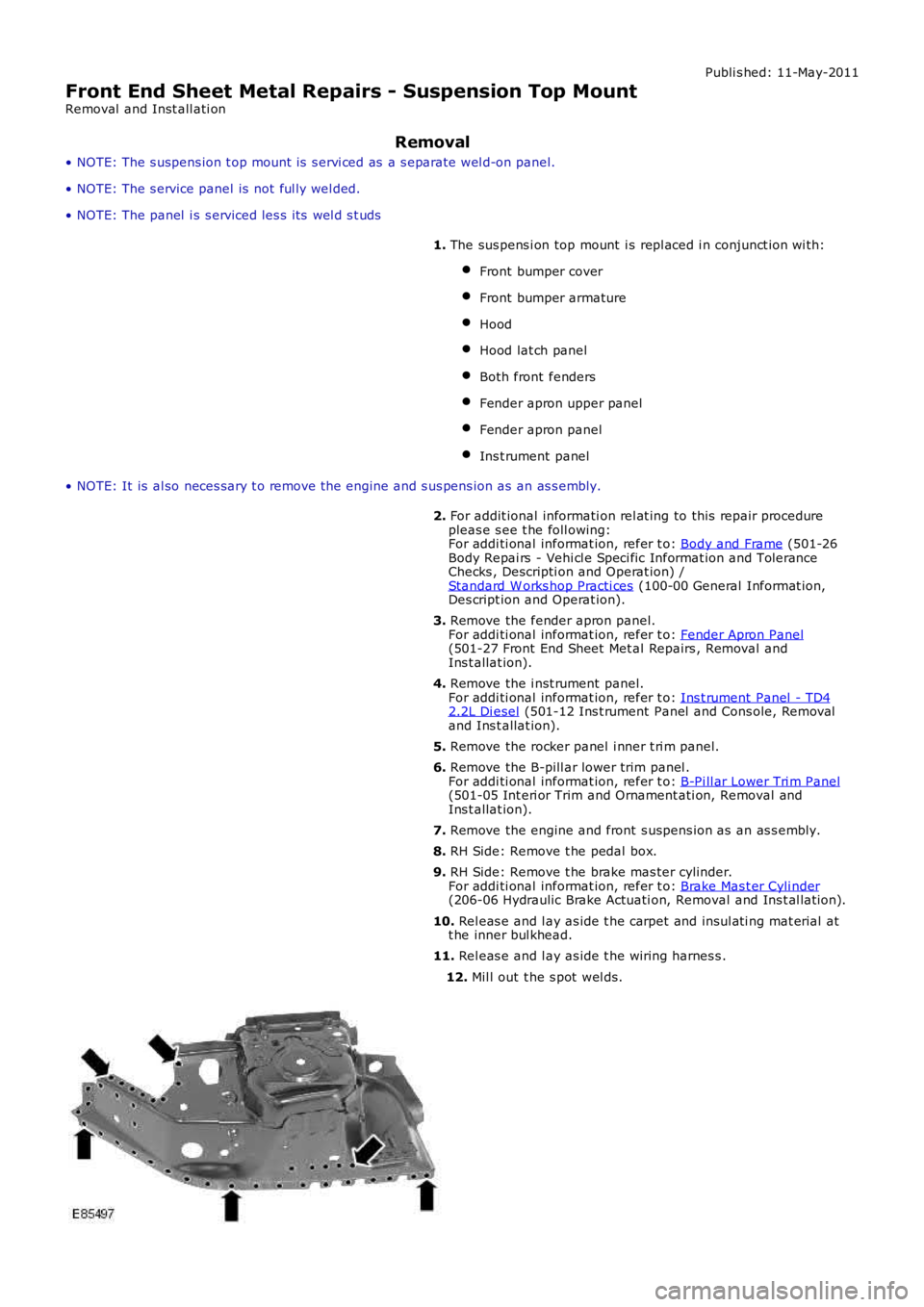

Front End Sheet Metal Repairs - Suspension Top Mount

Removal and Inst all ati on

Removal

• NOTE: The s uspens ion t op mount is s ervi ced as a s eparate wel d-on panel.

• NOTE: The s ervice panel is not ful ly wel ded.

• NOTE: The panel i s s erviced les s i ts wel d s t uds

1. The sus pens i on top mount i s repl aced i n conjunct ion wi th:

Front bumper cover

Front bumper armature

Hood

Hood lat ch panel

Both front fenders

Fender apron upper panel

Fender apron panel

Ins t rument panel

• NOTE: It is al so neces sary t o remove t he engine and s us pens ion as an as s embly.

2. For addit ional informati on rel at ing to this repair procedurepleas e s ee t he foll owing:For addi ti onal informat ion, refer t o: Body and Frame (501-26Body Repai rs - Vehi cl e Speci fic Informat ion and ToleranceChecks , Descripti on and Operat ion) /Standard W orks hop Practi ces (100-00 General Informat ion,Des cript ion and Operat ion).

3. Remove the fender apron panel.For addi ti onal informat ion, refer t o: Fender Apron Panel(501-27 Front End Sheet Met al Repairs , Removal andIns t allat ion).

4. Remove the i nst rument panel.For addi ti onal informat ion, refer t o: Ins t rument Panel - TD42.2L Di esel (501-12 Ins t rument Panel and Cons ole, Removaland Ins t allat ion).

5. Remove the rocker panel i nner t ri m panel.

6. Remove the B-pill ar lower trim panel .For addi ti onal informat ion, refer t o: B-Pi ll ar Lower Tri m Panel(501-05 Int eri or Trim and Ornament ati on, Removal andIns t allat ion).

7. Remove the engine and front s uspens ion as an as s embly.

8. RH Side: Remove t he pedal box.

9. RH Side: Remove t he brake mas ter cylinder.For addi ti onal informat ion, refer t o: Brake Mas t er Cyli nder(206-06 Hydraulic Brake Actuati on, Removal and Ins t al lat ion).

10. Rel eas e and l ay as ide t he carpet and ins ul ati ng mat erial att he inner bul khead.

11. Rel eas e and l ay as ide t he wiring harnes s .

12. Mil l out t he s pot wel ds.

Page 2557 of 3229

Publ is hed: 11-May-2011

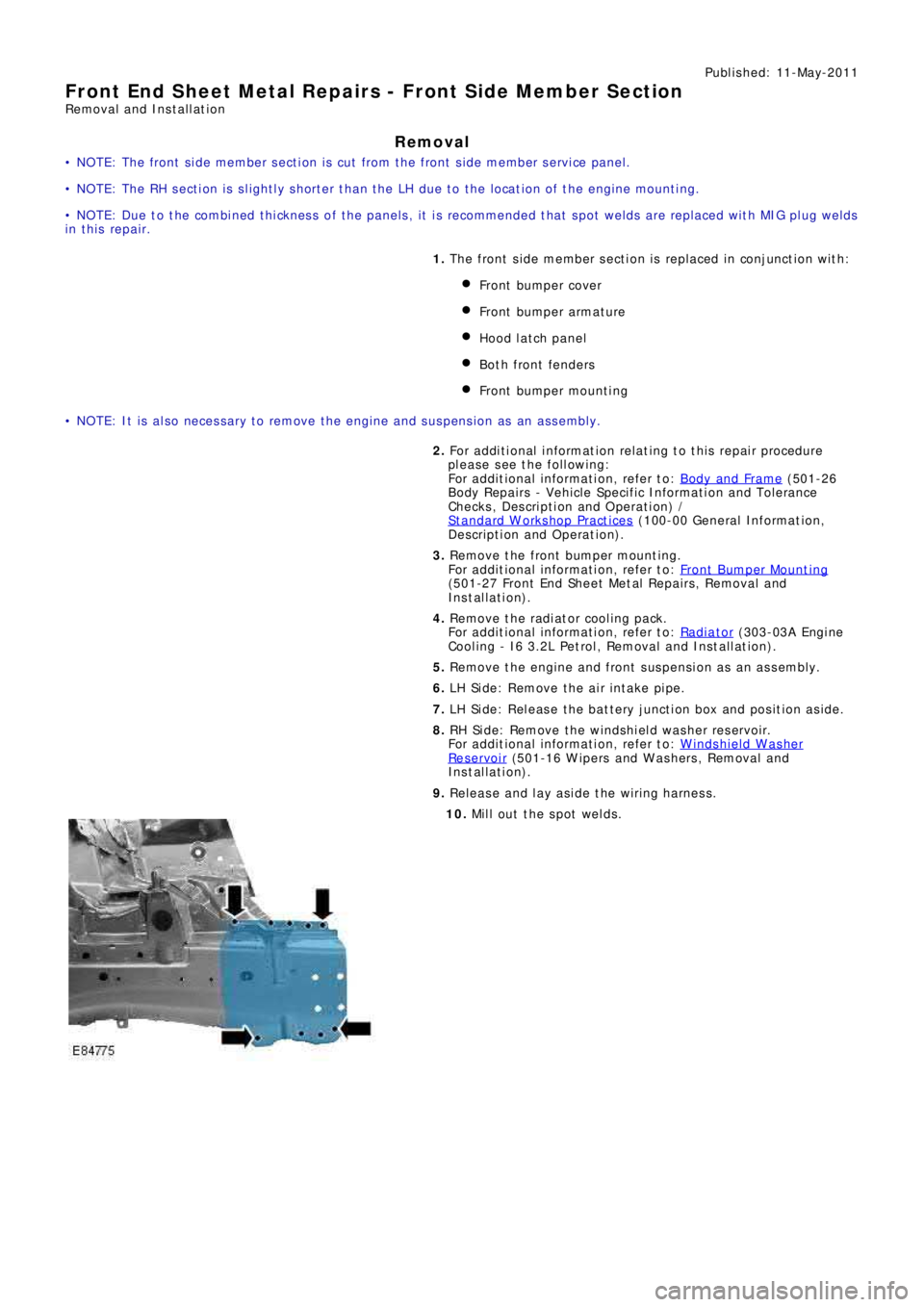

Front End Sheet Metal Repairs - Front Side Member Section

Removal and Installation

Removal

• NOTE: The front side member section is cut from the front side member service panel.

• NOTE: The RH section is slightly shorter than the LH due to the location of the engine mounting.

• NOTE: Due to the combined thickness of the panels, it is recommended that spot welds are replaced with MIG plug welds

in this repair.

1. The front s ide member s ect ion is replaced in conjunct ion wit h:

Front bumper cover

Front bumpe r a rma t ure

Hood lat ch panel

Both front fenders

Front bumpe r mount i ng

• NOTE: It is also necessary to remove the engine and suspension as an assembly.

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he f ront bumpe r mount i ng.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Bumper Mount ing

(501-27 Front End Sheet Met al Re pai rs , Removal and

Installation).

4. Remove the radiator cooling pack.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Radiator

(303-03A Engi ne

Cooling - I6 3.2L Petrol, Removal and Installation).

5. Remove the engine and front suspension as an assembly.

6. LH Side: Remove the air intake pipe.

7. LH Side: Release the battery junction box and position aside.

8. RH Side: Remove the windshield washer reservoir.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Washer

Res ervoi r (501-16 W i pers and W as hers , Removal and

Installation).

9. Release and lay aside the wiring harness.

10. Mill out the spot welds.

Page 2560 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Panel

Removal and Installation

Removal

• NOTE: The fender apron panel is serviced as a separate weld-on panel. It is an assembly of the fender apron panel

reinforcement, fender apron lower panel and fender apron panel front extension.

• NOTE: The panel is serviced less its weld studs

1. The fender apron panel is replaced in conjunction with:

Front bumper cover

Hood lat ch panel

Both front fenders

Fender apron upper panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the fender apron upper panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Fender Apron Upper Panel

(501-27 Front End Sheet Met al Re pai rs , Removal and

Installation).

4. L H Si d e : Re mo ve t he a i r cl e a ne r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Air Cleaner

(303-12A

I nt a ke A i r Di s t ri b ut i o n a nd Fi l t e ri ng - I 6 3. 2L P e t ro l , Re mo va l

and Installation).

5. LH Side: Remove the air intake pipe.

6. LH Side: Remove the bat tery t ray.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Battery Tray

(414-01

Battery, Mounting and Cables, Removal and Installation).

7. LH Side: Remove the engine lower support insulator.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Lower Support

Insulator (303-01A Engi ne - I6 3.2L Pet rol, Removal and

Installation).

8. LH Side: Release the battery junction box and position aside.

9. RH Side: Drain the cooling system.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Cooling Sys tem Draining,

Filling and Bleeding (303-03A Engine Cooling - I6 3.2L Petrol,

General Procedures ).

10. RH Side: Evacuate the A/C system.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Air Conditioning (A/C)

System Recovery, Evacuation and Charging (412-00 Cl i mat e

Co nt ro l Sys t e m - Ge ne ra l I nf o rma t i o n, Ge ne ra l P ro ce d ure s ).

11. RH Si d e : Re mo ve t he p o we r s t e e ri ng re s e rvo i r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : P o we r St e e ri ng Fl ui d

Res ervoi r (211-02 Power St eeri ng, Removal and Ins t al lat i on).

12. RH Side: Release the coolant expansion tank and position

aside.

13. RH Side: Remove the engine mounting bracket.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Mount RH

(303-01A

Engine - I6 3.2L Petrol, Removal and Installation).

14. RH Side: Remove the windshield washer reservoir.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Washer

Res ervoi r (501-16 W i pers and W as hers , Removal and

Installation).

15. RH Side: Remove the fender apron A/C pipes.

16. Remove the shock absorber and spring assembly.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Sho ck A b s o rb e r a nd Sp ri ng

Assembly (204-01 Front Sus pens i on, Removal and

Installation).

17. Release and lay aside the wiring harness.

Page 2564 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Panel Reinforcement

Removal and Installation

Removal

• NOTE: The fender apron panel reinforcement has to be unpicked from the fender apron panel service panel, it is not

available separately.

• NOTE: The RH panel is serviced less its weld studs 1. T he f e nd e r a p ro n p a ne l re i nf o rce me nt i s re p l a ce d i n

conjunct ion wit h:

Front bumper cover

Hood lat ch panel

Both front fenders

Fender apron upper panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the fender apron upper panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Fender Apron Upper Panel

(501-27 Front End Sheet Met al Re pai rs , Removal and

Installation).

4. Remove the front shock absorber.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Shock Abs orber

(204-01 Front Suspension, Removal and Installation).

5. LH Side: Remove the engine support insulator.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Upper Support

Insulator (303-01B Engi ne - TD4 2.2L Di es el, Removal and

Installation).

6. LH Side: Remove the bat tery t ray.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Battery Tray

(414-01

Battery, Mounting and Cables, Removal and Installation).

7. LH Side: Remove the air intake pipe.

8. LH Side: Release the battery junction box and position aside.

9. RH Side: Remove the windshield washer reservoir.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Washer

Res ervoi r (501-16 W i pers and W as hers , Removal and

Installation).

10. RH Side: Remove the engine mounting bracket.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Mount RH

(303-01B

Engine - TD4 2.2L Diesel, Removal and Installation).

11. RH Side: Release the coolant expansion tank and lay it

aside.

12. RH Side: Evacuate the A/C system.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Air Conditioning (A/C)

System Recovery, Evacuation and Charging (412-00 Cl i mat e

Co nt ro l Sys t e m - Ge ne ra l I nf o rma t i o n, Ge ne ra l P ro ce d ure s ).

13. RH Side: Remove the fender apron A/C pipes.

14. RH Side: Release and lay aside the insulating material at the

bulkhead.

15. Release and lay aside the wiring harness.

Page 2574 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Front Side Member Closing Panel

Removal and Installation

Removal

• NOTE: The front side member closing panel must be unpicked from the front side member and suspension top mount

assembly, it is not serviced separately.

• NOTE: The panel is serviced less its weld studs

1. The front side member closing panel is replaced in conjunction

with:

Front bumper cover

Front bumper

Hood lat ch panel

Both front fenders

Front bumpe r mount i ng

Fender apron l ower panel

Fender apron panel front reinforcement

Front s i de me mbe r

• NOTE: It is also necessary to remove the engine and suspension as an assembly.

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he f ront s i de me mbe r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Side Member

(501-27

Front End Sheet Metal Repairs, Removal and Installation).

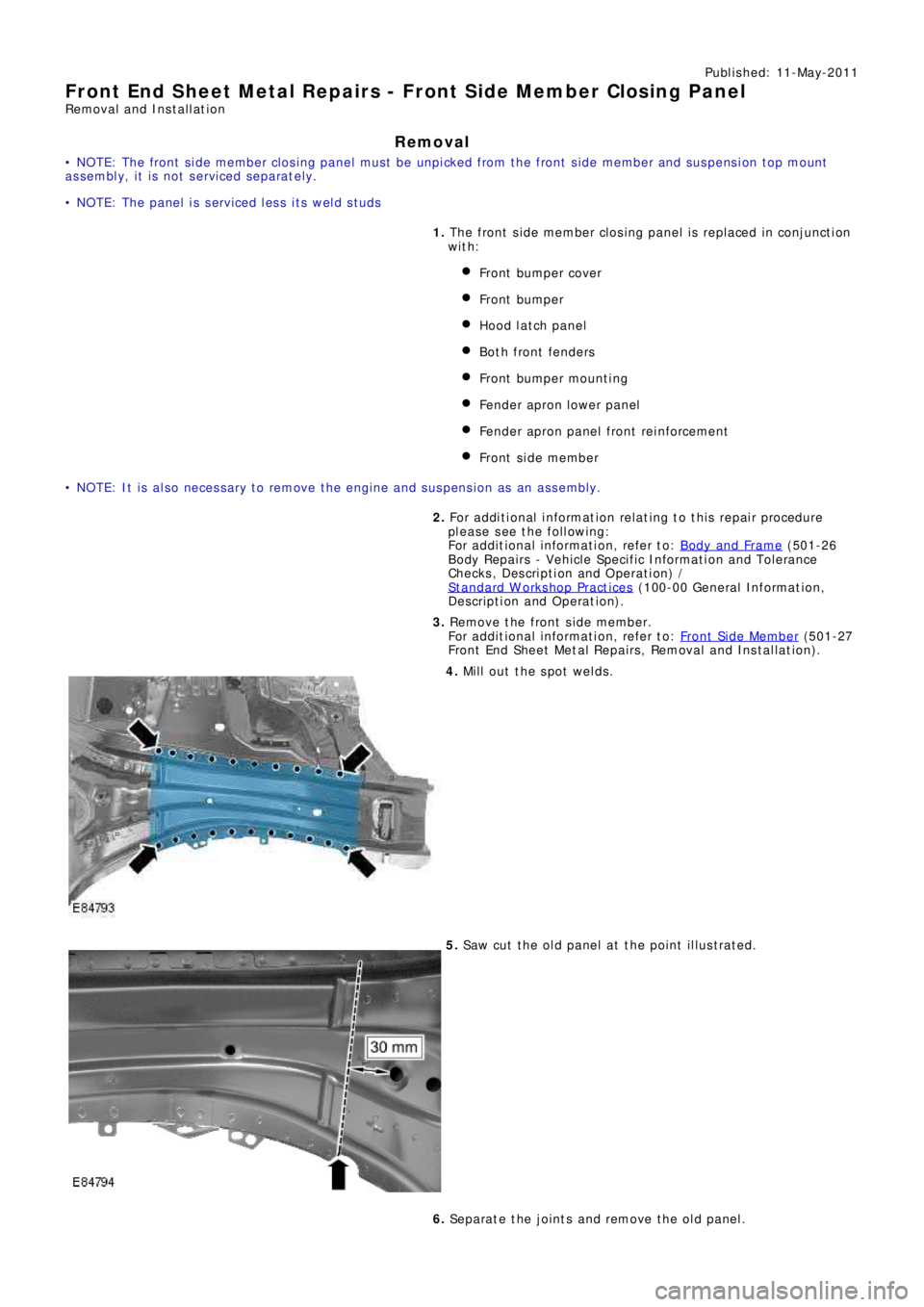

4. Mill out the spot welds.

5. Saw cut the old panel at the point illustrated.

6. Separate the joints and remove the old panel.