Control actuator LEXUS LS430 2003 Factory Owners Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2787 of 4500

![LEXUS LS430 2003 Factory Owners Manual [OFF malfunction]

Both of the following conditions are met: OFF malfunctions (A) and (B)

OFF malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPIC LEXUS LS430 2003 Factory Owners Manual [OFF malfunction]

Both of the following conditions are met: OFF malfunctions (A) and (B)

OFF malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPIC](/img/36/57050/w960_57050-2786.png)

[OFF malfunction]

Both of the following conditions are met: OFF malfunctions (A) and (B)

OFF malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION B

[ON malfunction]

Both of the following conditions are met: ON malfunctions (A) and (B)

ON malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - ON MALFUNCTION A

ON malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - ON MALFUNCTION B

INSPECTION PROCEDURE

HINT:

Performing the ACTIVE TEST using the hand-held tester allows the relay, VSV, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as the first step of troubleshooting is one method to

shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

Turbine speed/Output speed (NT/NO)1.23 or more and 1.48 or less (This means actual

gear is 3rd)

Turbine speed/Output speed (NT/NO)0.66 or more and 0.80 or less (This means actual

gear is 5th

Turbine speed/Output speed (NT/NO)0.50 or more and 0.64 or less (This means actual

gear is 6th)

Turbine speed/Output speed (NT/NO)0.50 or more and 0.64 or less (This means actual

gear is 6th)

Page 2795 of 4500

![LEXUS LS430 2003 Factory Owners Manual TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION B

[ON malfunction]

One of the following conditions is met: ON LEXUS LS430 2003 Factory Owners Manual TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION B

[ON malfunction]

One of the following conditions is met: ON](/img/36/57050/w960_57050-2794.png)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION B

[ON malfunction]

One of the following conditions is met: ON malfunctions (A), (B) and (C)

ON malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - ON MALFUNCTION A

ON malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - ON MALFUNCTION B

ON malfunction (C)

TYPICAL MALFUNCTION THRESHOLDS TABLE - ON MALFUNCTION C

INSPECTION PROCEDURE

HINT:

Performing the ACTIVE TEST using the hand-held tester allows the relay, VSV, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as the first step of troubleshooting is one method to

shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the han

d-held tester together with the CAN VIM (controller area network vehicle interface

Turbine speed/Output speed (NT/NO)0.93 or more and 1.07 or less (This means actual

gear is 3rd)

Turbine speed/Output speed (NT/NO)0.50 or more and 0.64 or less (This means actual

gear is 6th)

Turbine speed/Output speed (NT/NO)1.23 or more and 1.48 or less (This means actual

gear is 3rd)

Turbine speed - Output speed x 4th gear ratio (NT-

NO x 4th gear ratio)1,000 rpm or more

Turbine speed - Output speed x 5th gear ratio (NT-

NO x 5th gear ratio)1,000 rpm or more

Page 2804 of 4500

OFF malfunction (B)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION B

INSPECTION PROCEDURE

HINT:

Performing the ACTIVE TEST using the hand-held tester allows the relay, VSV, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as the first step of troubleshooting is one method to

shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Clear the DTC.

g. Select the item "DIAGNOSIS/ENHANCED OBD II/ACTIVE TEST/SHIFT".

h. According to the display on tester, perform the "ACTIVE TEST".

HINT:

While driving, the shift position can be forcibly changed with the hand-held tester.

Comparing the shift position commanded by the ACTIVE TEST with the actual shift position enables you to

confirm the problem (see FAIL

-SAFE CHART).

Turbine speed/Output speed (NT/NO)<00130011001c00160003005200550003005000520055004800030044005100470003002f00480056005600030057004b004400510003001400110013001a0003000b0037004b004c0056000300500048004400510056000300440046005700580044004f00

03[

gear is 4th)

Turbine speed/Output speed (NT/NO)<00130011001c00160003005200550003005000520055004800030044005100470003002f00480056005600030057004b004400510003001400110013001a0003000b0037004b004c0056000300500048004400510056000300440046005700580044004f00

03[

gear is 4th)

Page 2859 of 4500

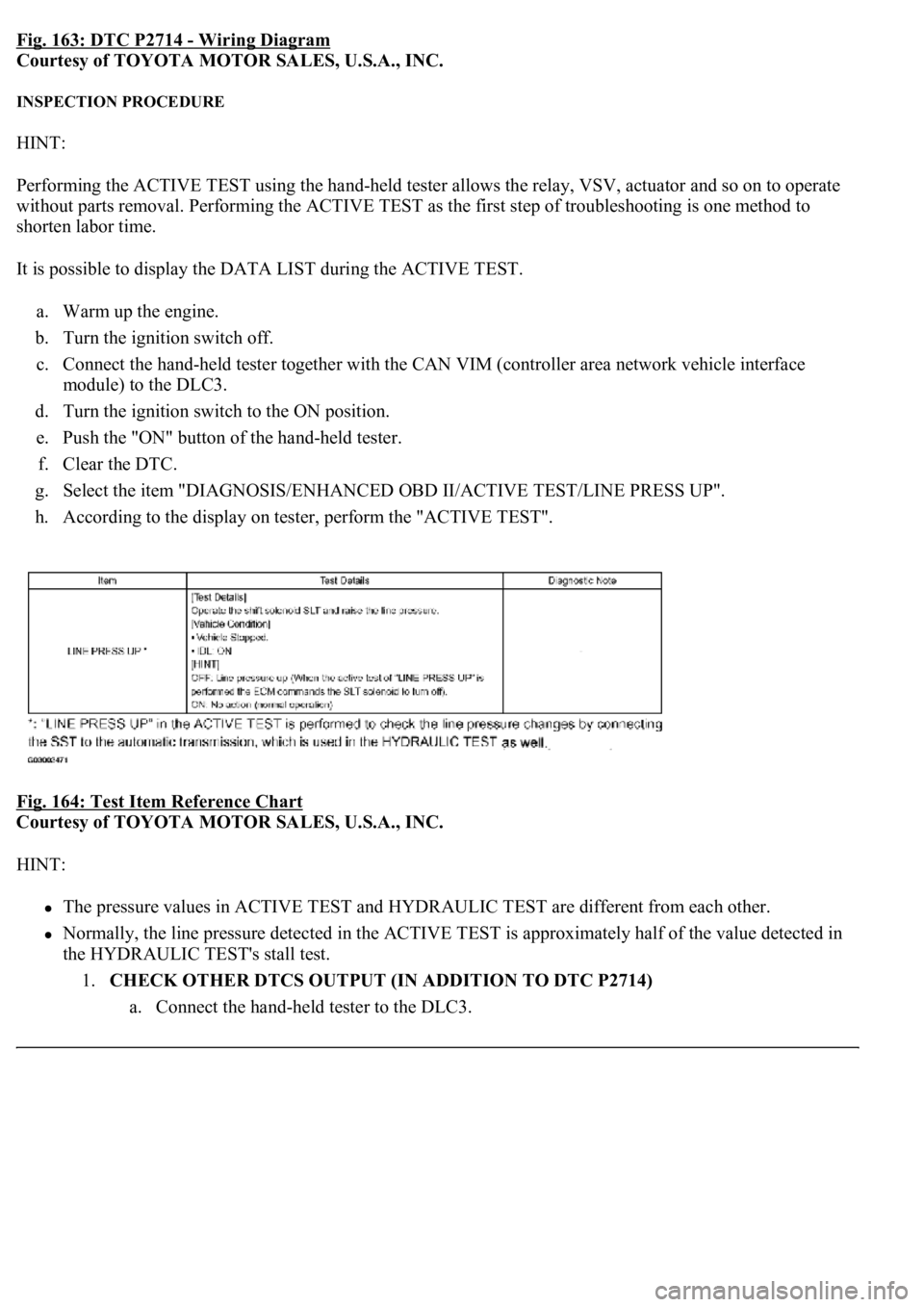

Fig. 163: DTC P2714 - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

HINT:

Performing the ACTIVE TEST using the hand-held tester allows the relay, VSV, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as the first step of troubleshooting is one method to

shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Clear the DTC.

g. Select the item "DIAGNOSIS/ENHANCED OBD II/ACTIVE TEST/LINE PRESS UP".

h. According to the display on tester, perform the "ACTIVE TEST".

Fig. 164: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

The pressure values in ACTIVE TEST and HYDRAULIC TEST are different from each other.

Normally, the line pressure detected in the ACTIVE TEST is approximately half of the value detected in

the HYDRAULIC TEST's stall test.

1.CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P2714)

a. Connect the han

d-held tester to the DLC3.

Page 2943 of 4500

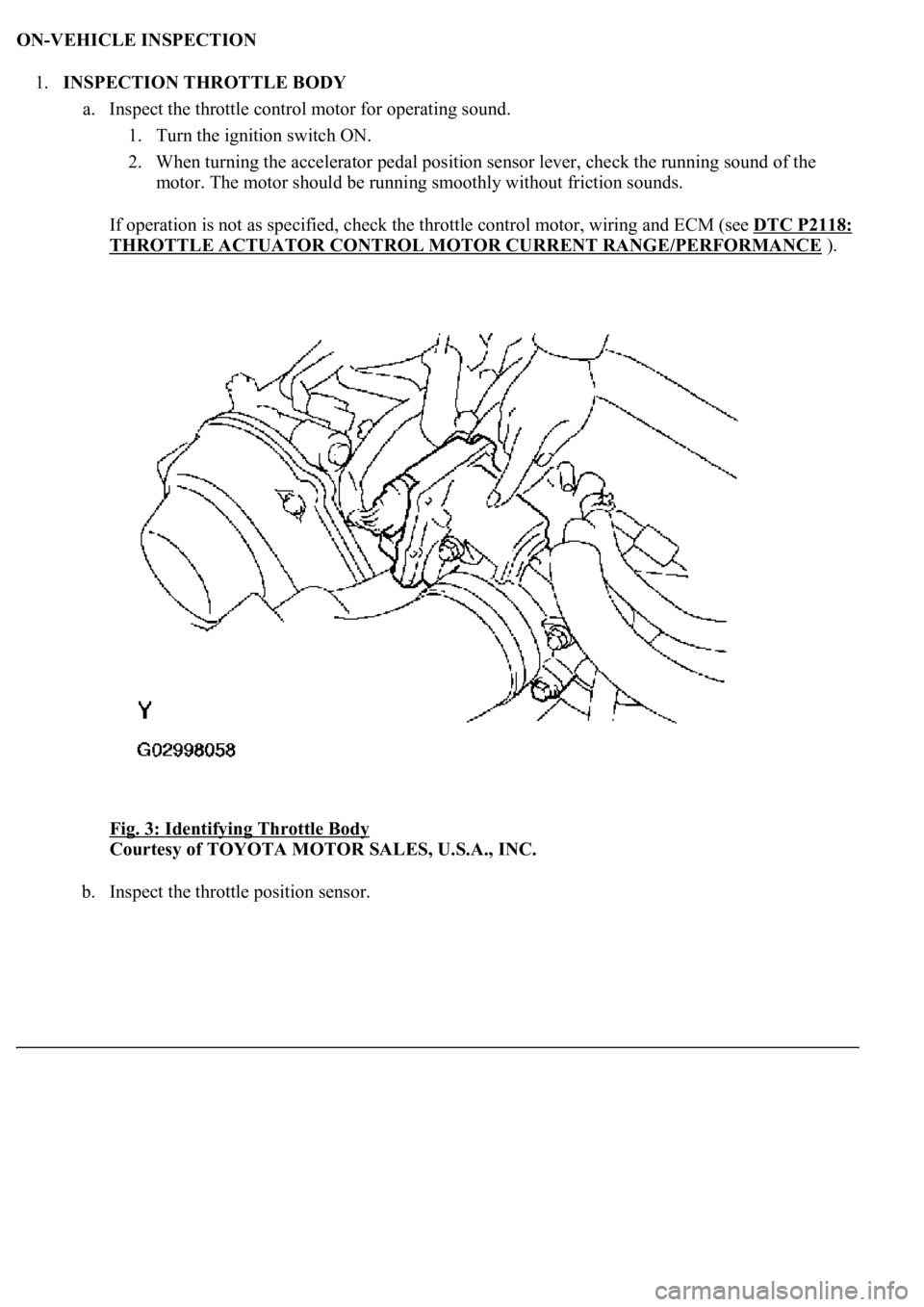

ON-VEHICLE INSPECTION

1.INSPECTION THROTTLE BODY

a. Inspect the throttle control motor for operating sound.

1. Turn the ignition switch ON.

2. When turning the accelerator pedal position sensor lever, check the running sound of the

motor. The motor should be running smoothly without friction sounds.

If operation is not as specified, check the throttle control motor, wiring and ECM (see DTC P2118:

THROTTLE ACTUATOR CONTROL MOTOR CURRENT RANGE/PERFORMANCE ).

Fig. 3: Identifying Throttle Body

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Inspect the throttle position sensor.

Page 3198 of 4500

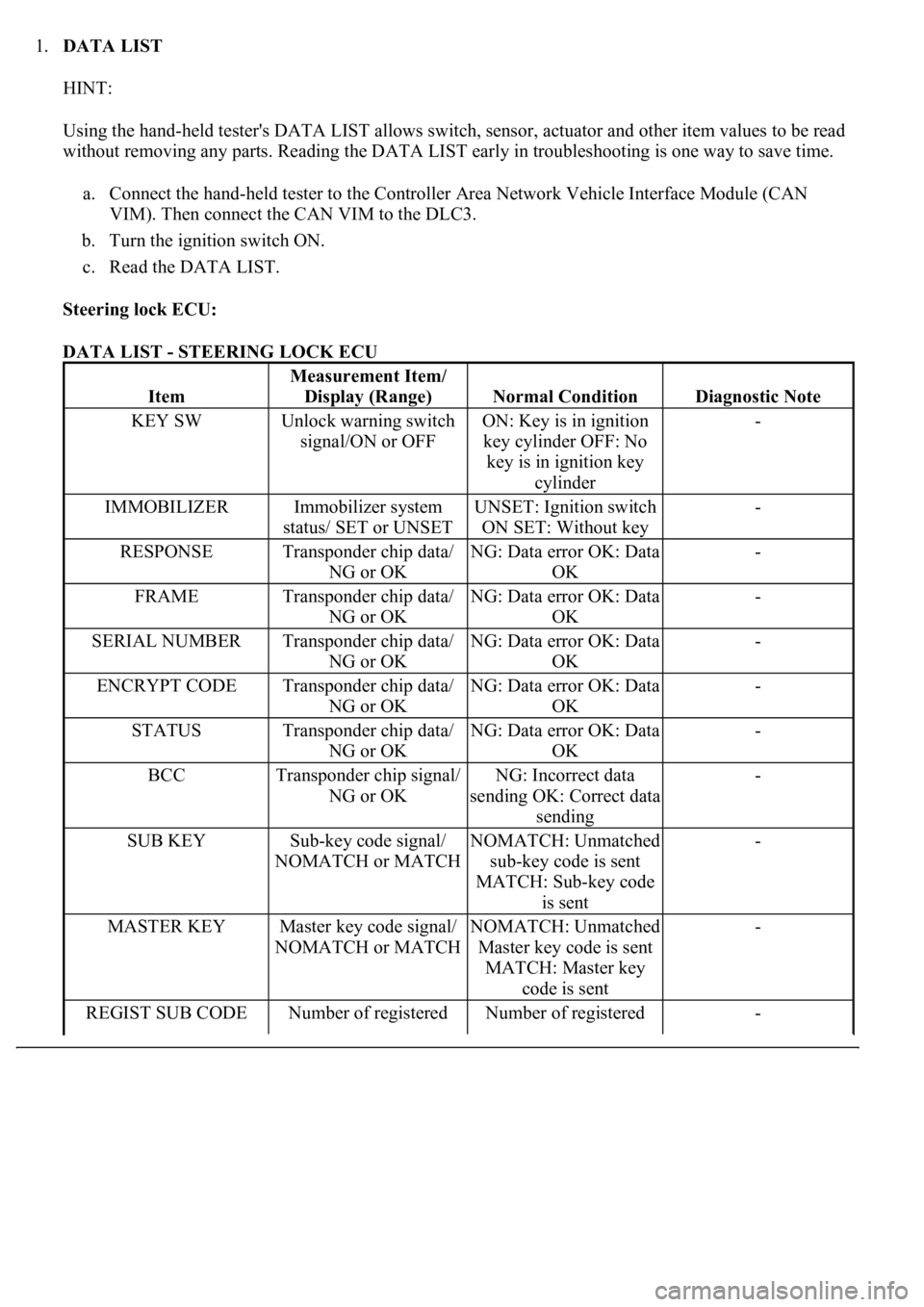

1.DATA LIST

HINT:

Using the hand-held tester's DATA LIST allows switch, sensor, actuator and other item values to be read

without removing any parts. Reading the DATA LIST early in troubleshooting is one way to save time.

a. Connect the hand-held tester to the Controller Area Network Vehicle Interface Module (CAN

VIM). Then connect the CAN VIM to the DLC3.

b. Turn the ignition switch ON.

c. Read the DATA LIST.

Steering lock ECU:

DATA LIST - STEERING LOCK ECU

Item

Measurement Item/

Display (Range)

Normal ConditionDiagnostic Note

KEY SWUnlock warning switch

signal/ON or OFFON: Key is in ignition

key cylinder OFF: No

key is in ignition key

cylinder-

IMMOBILIZERImmobilizer system

status/ SET or UNSETUNSET: Ignition switch

ON SET: Without key-

RESPONSETransponder chip data/

NG or OKNG: Data error OK: Data

OK-

FRAMETransponder chip data/

NG or OKNG: Data error OK: Data

OK-

SERIAL NUMBERTransponder chip data/

NG or OKNG: Data error OK: Data

OK-

ENCRYPT CODETransponder chip data/

NG or OKNG: Data error OK: Data

OK-

STATUSTransponder chip data/

NG or OKNG: Data error OK: Data

OK-

BCCTransponder chip signal/

NG or OKNG: Incorrect data

sending OK: Correct data

sending-

SUB KEYSub-key code signal/

NOMATCH or MATCHNOMATCH: Unmatched

sub-key code is sent

MATCH: Sub-key code

is sent-

MASTER KEYMaster key code signal/

NOMATCH or MATCHNOMATCH: Unmatched

Master key code is sent

MATCH: Master key

code is sent-

REGIST SUB CODENumber of registered Number of registered -

Page 3253 of 4500

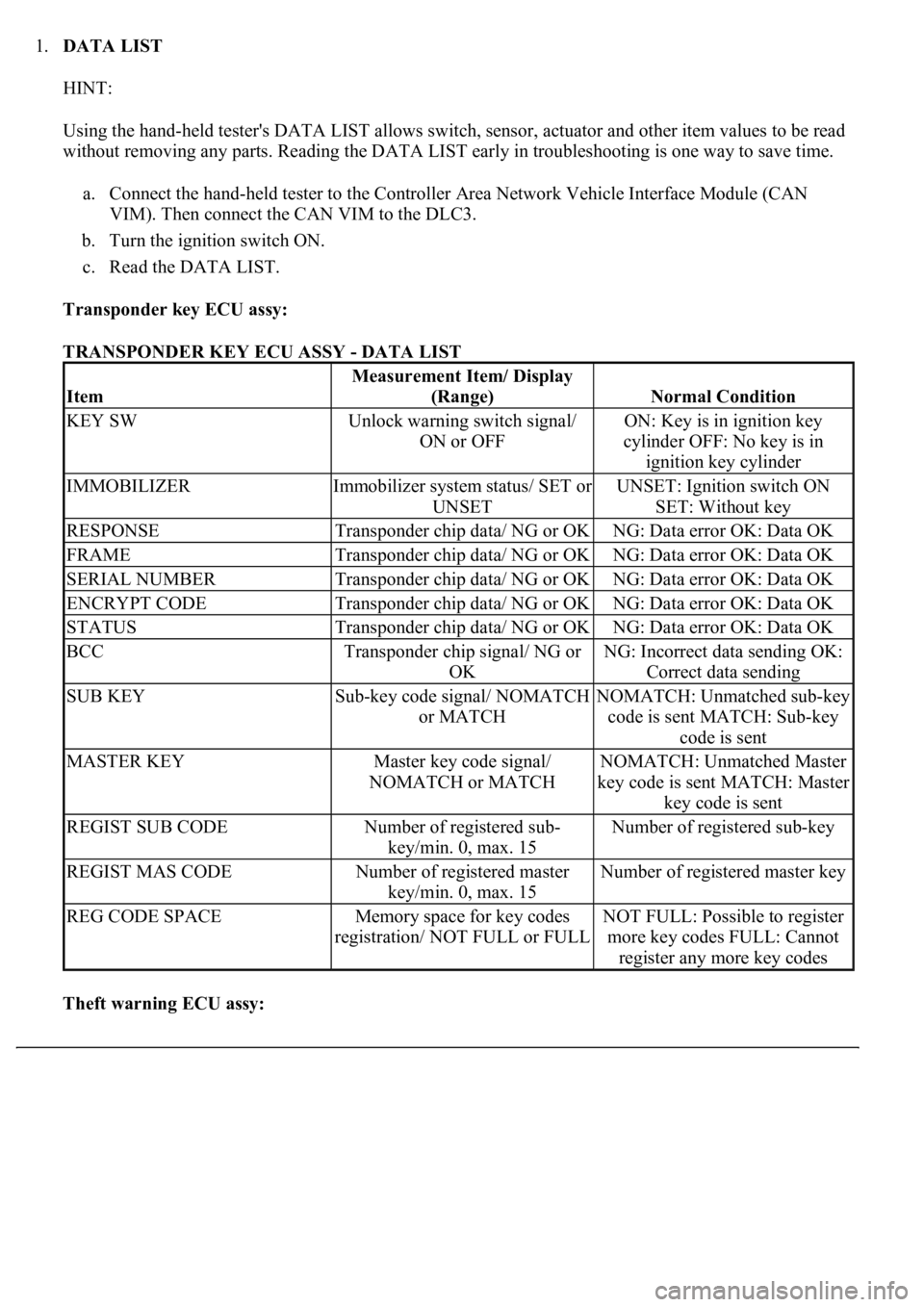

1.DATA LIST

HINT:

Using the hand-held tester's DATA LIST allows switch, sensor, actuator and other item values to be read

without removing any parts. Reading the DATA LIST early in troubleshooting is one way to save time.

a. Connect the hand-held tester to the Controller Area Network Vehicle Interface Module (CAN

VIM). Then connect the CAN VIM to the DLC3.

b. Turn the ignition switch ON.

c. Read the DATA LIST.

Transponder key ECU assy:

TRANSPONDER KEY ECU ASSY - DATA LIST

Theft warning ECU assy:

Item

Measurement Item/ Display

(Range)

Normal Condition

KEY SWUnlock warning switch signal/

ON or OFFON: Key is in ignition key

cylinder OFF: No key is in

ignition key cylinder

IMMOBILIZERImmobilizer system status/ SET or

UNSETUNSET: Ignition switch ON

SET: Without key

RESPONSETransponder chip data/ NG or OKNG: Data error OK: Data OK

FRAMETransponder chip data/ NG or OKNG: Data error OK: Data OK

SERIAL NUMBERTransponder chip data/ NG or OKNG: Data error OK: Data OK

ENCRYPT CODETransponder chip data/ NG or OKNG: Data error OK: Data OK

STATUSTransponder chip data/ NG or OKNG: Data error OK: Data OK

BCCTransponder chip signal/ NG or

OKNG: Incorrect data sending OK:

Correct data sending

SUB KEYSub-key code signal/ NOMATCH

or MATCHNOMATCH: Unmatched sub-key

code is sent MATCH: Sub-key

code is sent

MASTER KEYMaster key code signal/

NOMATCH or MATCHNOMATCH: Unmatched Master

key code is sent MATCH: Master

key code is sent

REGIST SUB CODENumber of registered sub-

key/min. 0, max. 15Number of registered sub-key

REGIST MAS CODENumber of registered master

key/min. 0, max. 15Number of registered master key

REG CODE SPACEMemory space for key codes

registration/ NOT FULL or FULLNOT FULL: Possible to register

more key codes FULL: Cannot

register any more key codes

Page 4009 of 4500

REPLACEMENT

HINT:

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1.REMOVE FRONT WHEELS

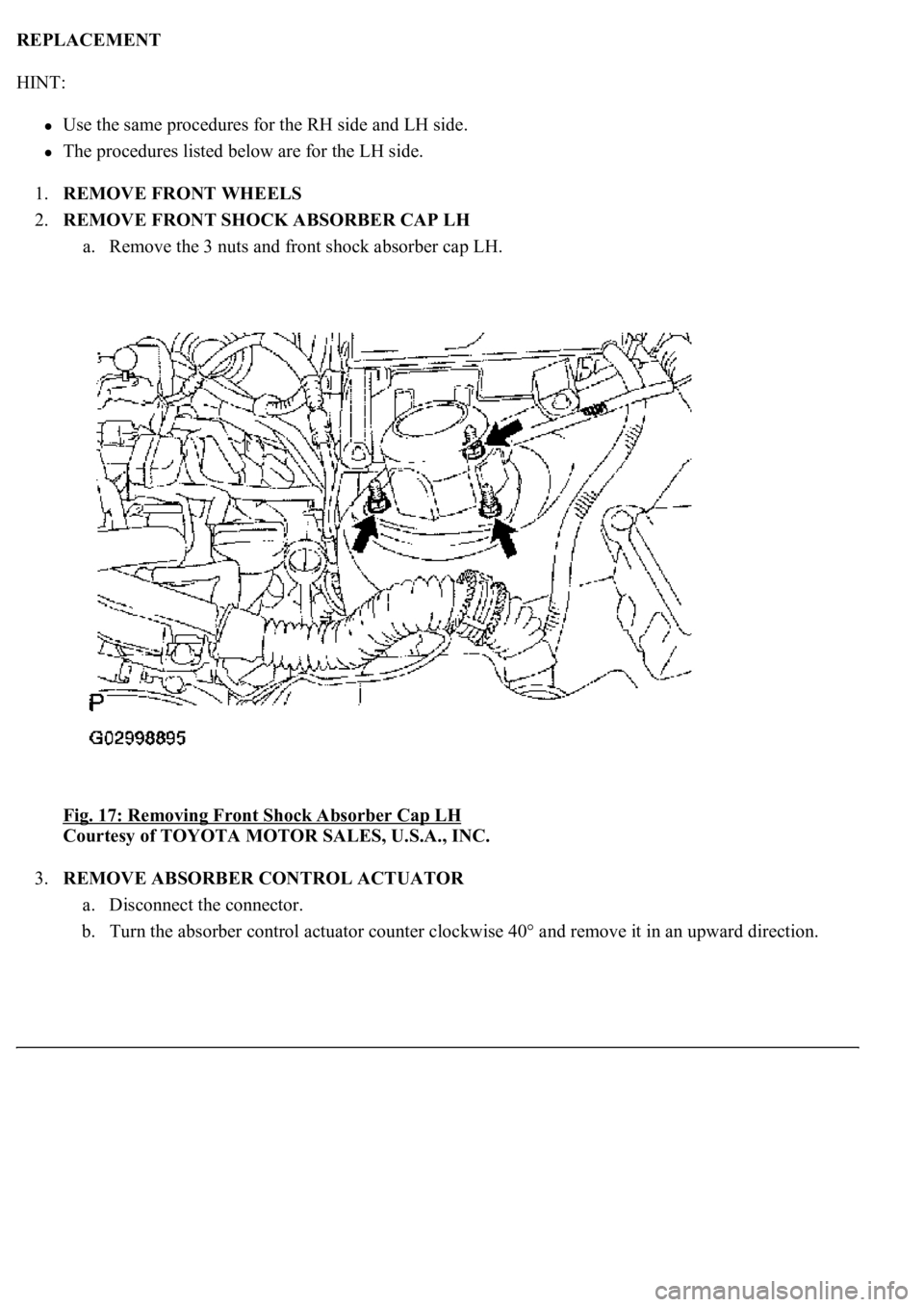

2.REMOVE FRONT SHOCK ABSORBER CAP LH

a. Remove the 3 nuts and front shock absorber cap LH.

Fig. 17: Removing Front Shock Absorber Cap LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

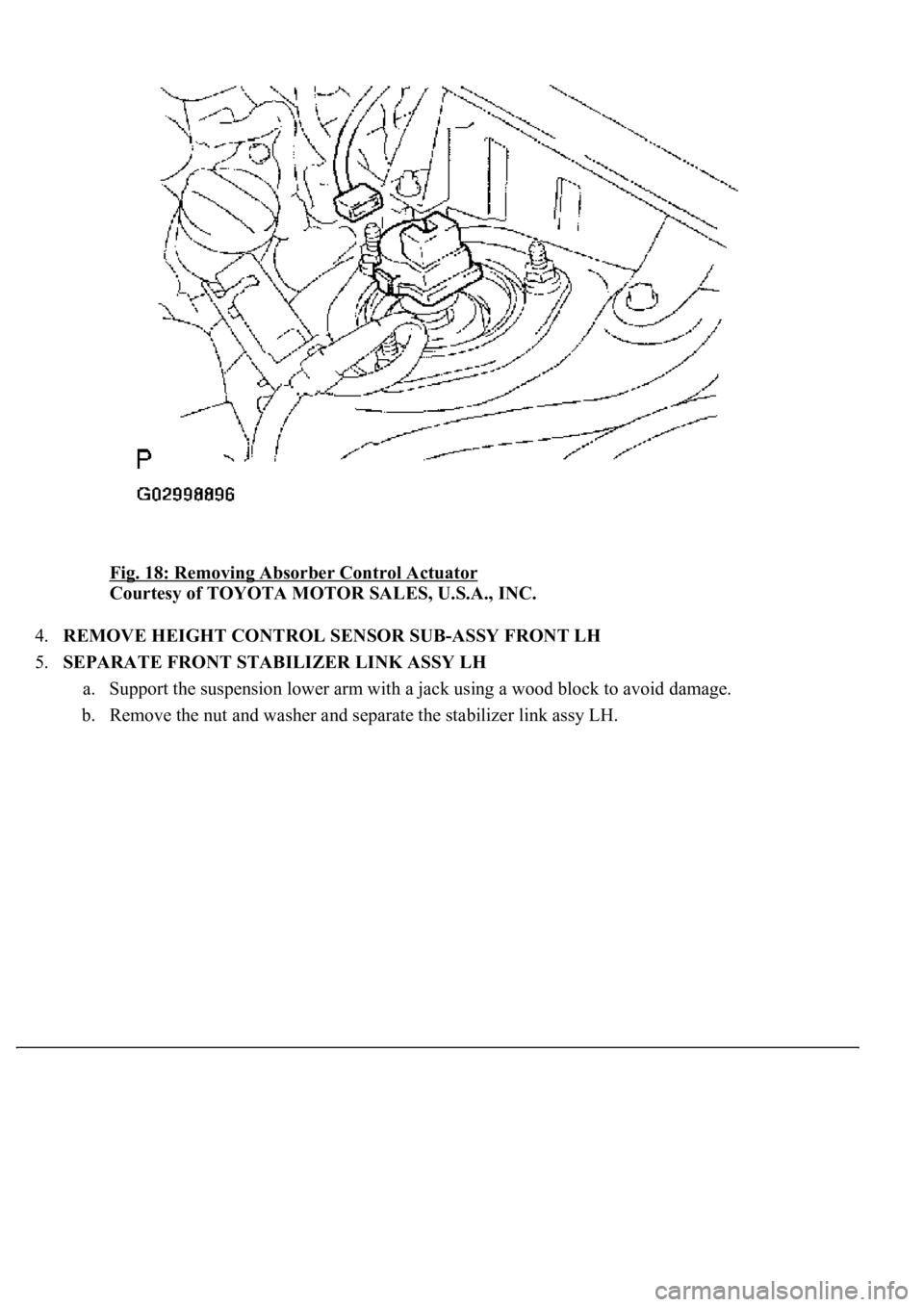

3.REMOVE ABSORBER CONTROL ACTUATOR

a. Disconnect the connector.

b. Turn the absorber control actuator counter clockwise 40° and remove it in an upward direction.

Page 4010 of 4500

Fig. 18: Removing Absorber Control Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4.REMOVE HEIGHT CONTROL SENSOR SUB-ASSY FRONT LH

5.SEPARATE FRONT STABILIZER LINK ASSY LH

a. Support the suspension lower arm with a jack using a wood block to avoid damage.

b. Remove the nut and washer and separate the stabilizer link assy LH.

Page 4019 of 4500

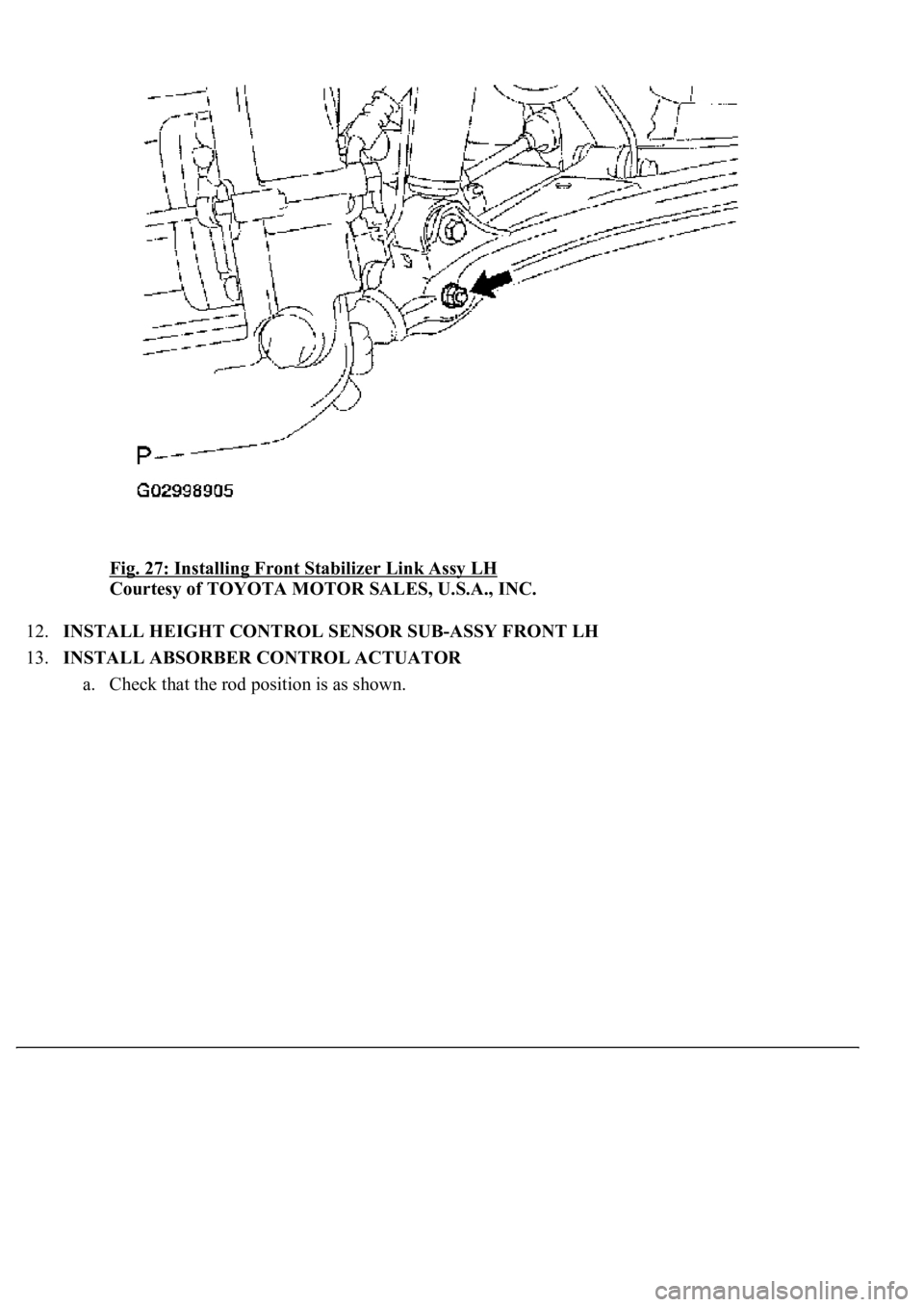

Fig. 27: Installing Front Stabilizer Link Assy LH

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

12.INSTALL HEIGHT CONTROL SENSOR SUB-ASSY FRONT LH

13.INSTALL ABSORBER CONTROL ACTUATOR

a. Check that the rod position is as shown.