Control actuator LEXUS LS430 2003 Factory Manual Online

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2630 of 4500

Fuel Lid Opener MotorOn left side of luggage compartment, behind left

rear fenderwell. See Fig. 19

.

Headlight Beam Level Control Actuator LHBehind left headlight. See Fig. 13 .

Headlight Beam Level Control Actuator RHBehind right headlight. See Fig. 13 .

Headlight Cleaner MotorBelow left headlight. See Fig. 13 .

Height Control CompressorOn right front of engine compartment. See Fig. 13 .

Luggage Compartment Door Closer MotorOn center rear of luggage compartment lid. See Fig.

28 .

Power Seat Module (Rear Passenger's RH Seat Slide

Control)Right side of rear seat. See Fig. 32 .

Power Seat Motor (Driver's Seat Cushion Control)Lower left side of driver's seat. See Fig. 31 .

Power Seat Motor (Driver's Seat Front Vertical

Control)Lower left side of driver's seat. See Fig. 31 .

Power Seat Motor (Driver's Seat Lifter Control)Lower right side of driver's seat bottom. See Fig.

31 .

Power Seat Motor (Driver's Seat Lumbar Support

Lower Side Control)Lower right side of driver's seat cushion. See Fig.

31 .

Power Seat Motor (Driver's Seat Lumbar Support

Upper Side Control)Upper right side of driver's seat back. See Fig. 31 .

Power Seat Motor (Driver's Seat Reclining Control)Lower left rear side of driver's seat bottom. See Fig.

31 .

Power Seat Motor (Driver's Seat Slide Control)In lower left side of driver's seat cushion. See Fig.

31 .

Power Seat Motor (Front Passenger's Seat Front

Vertical Control)In lower right side of front passenger's seat bottom.

See Fig. 31

.

Power Seat Motor (Front Passenger's Seat Head

Rest Control)In upper left side of front passenger's seat back. See

Fig. 31

.

Power Seat Motor (Front Passenger's Seat Lifter

Control)In lower left side of front passenger's seat bottom.

See Fig. 31

.

Power Seat Motor (Front Passenger's Seat Lumbar

Support Control)Lower left rear of front passenger seat cushion. See

Fig. 31

.

Power Seat Motor (Front Passenger's Seat Reclining

Control)Lower right side of front passenger's seat. See Fig.

31 .

Power Seat Motor (Front Passenger's Seat Slide

Control)Under passenger's seat cushion. See Fig. 31 .

Power Seat Motor (Rear Passenger's LH Seat Slide

Control)Left side of rear seat. See Fig. 32 .

Power Window Motor Front LHIn left front door. See Fig. 29 .

Power Window Motor Front RHIn right front door. See Fig. 29 .

Power Window Motor Rear LHIn left rear door. See Fig. 29 .

Power Window Motor Rear RHIn right rear door. See Fig. 29 .

Rear Blower MotorCenter rear of vehicle. See Fig. 29 .

Rear Damper Servo MotorRear center of luggage compartment. See Fig. 29 .

Page 2631 of 4500

SENDING UNITS & SENSORS LOCATION

Rear Door W/Motor Lock Assembly LHIn left rear door. See Fig. 29 .

Rear Door W/Motor Lock Assembly RHIn right rear door. See Fig. 29 .

Seat Belt Motor LHBase of left "B" pillar. See Fig. 30 .

Seat Belt Motor RHBase of right "B" pillar. See Fig. 30 .

Seat Climate Fan Motor Rear LH (Seat Back)In left rear seat back. See Fig. 32 .

Seat Climate Fan Motor Rear LH (Seat Cushion)In left rear seat cushion. See Fig. 32 .

Seat Climate Fan Motor Rear RH (Seat Back)In right rear seat back. See Fig. 32 .

Seat Climate Fan Motor Rear RH (Seat Cushion)In right rear seat cushion. See Fig. 32 .

Shoulder Belt Anchor Motor & Position Sensor

(Left)Near center of left "B" pillar. See Fig. 30 .

Shoulder Belt Anchor Motor (Right)Near center of right "B" pillar. See Fig. 30 .

StarterCenter rear of engine. See Fig. 15 .

Suspension Control Actuator Front LHOn left side of engine compartment. See Fig. 15 .

Suspension Control Actuator Front RHOn right side of engine compartment. See Fig. 15 .

Suspension Control Actuator Rear LHNear base of left "C" pillar. See Fig. 30 .

Suspension Control Actuator Rear RHNear base of right "C" pillar. See Fig. 30 .

Telescopic Motor & Position SensorInside base of steering column. See Fig. 18 .

Tilt Motor & Position SensorInside base of steering column. See Fig. 18 .

Washer MotorOn washer fluid reservoir, below left headlight. See

Fig. 15

.

Water Valve Servo MotorCenter of dash. See Fig. 18 .

ComponentLocation

ABS Speed Sensor Front LHAt left rear of engine compartment. See Fig. 12 .

ABS Speed Sensor & Pad Wear Indicator SW Front

RHRight rear of engine compartment. See Fig. 12 .

ABS Speed Sensor & Pad Wear Indicator SW Rear

RHAt right rear wheel assembly. See Fig. 19 .

ABS Speed Sensor Rear LHAt left rear wheel assembly. See Fig. 19 .

A/C Ambient Temp. SensorBehind left side of bumper fascia. See Fig. 12 .

Acceleration SensorOn left side of luggage compartment, behind left

rear fenderwell. See Fig. 19

.

Accel Position SensorBehind left center of dash. See Fig. 2 .

A/C Pressure SensorOn left front of engine compartment. See Fig. 12 .

A/C Room Temperature SensorBehind left center of dash. See Fig. 2 .

A/C Solar Sensor (Rear)Near center of rear speaker shelf, at base of rear

window. See Fig. 19

.

Airbag Sensor AssemblyFront of center console. See Fig. 2 .

Air Bag Sensor Front LHOn left front of engine compartment. See Fig. 12 .

Page 2670 of 4500

control ECU, PCM

FC idleDeceleration fuel cut

Idle air control valveIdle speed control

VSV for CCV, Canister close valve VSV for

canister controlEvaporative emissions canister vent valve

VSV for EVAP, Vacuum switching valve assembly

No. 1, EVAP VAV, Purge VSVEvaporative emissions canister purge valve

VSV for pressure switching valve, Bypass VSVEvaporative emission pressure switching valve

Vapor pressure sensor, EVAP pressure sensor,

Evaporative emission control system pressure

sensorFuel tank pressure sensor

Charcoal canisterEvaporative emissions canister

ORVR systemOn-boad refueling vapor recovery system

Intake manifold runner controlIntake manifold tuning system

Intake manifold runner valve, IMRV, IACV (runner

valve)Intake manifold tuning valve

Intake control VSVIntake manifold tuning solenoid valve

AFSAir fuel ratio sensor

O2 sensorHeater oxygen sensor

Oxygen sensor pumping current circuitOxygen sensor output signal

Oxygen sensor reference ground circuitOxygen sensor signal ground

Accel position sensorAccelerator pedal position sensor

Throttle actuator control motor, Actuator control

motor, Electronic throttle motor, Throttle control

motorElectronic throttle actuator

Electronic throttle control system, Throttle actuator

control systemElectronic throttle control system

Throttle/pedal position sensor, Throttle/pedal

position switch, Throttle position sensor/switchThrottle position sensor

Turbo press sensorTurbocharger pressure sensor

Turbo VSVTurbocharger pressure control solenoid valve

P/S pressure switchPower-steering pressure switch

VSV for ACMActive control engine mount

Speed sensor, Vehicle speed sensor "A", Speed

sensor for skid control ECUVehicle speed sensor

ATF temperature sensor, Trans, fluid temp, sensor,

ATF temperature sensor "A"Transmission fluid temperature sensor

Electronic controlled automatic transmission, ECTElectronically controlled automatic

Intermediate shaft speed sensor "A"Counter gear speed sensor

Part and system nameDefinition

Output speed sensorOutput shaft speed sensor

<002c00510053005800570003005600530048004800470003005600480051005600520055000f0003002c005100530058005700030057005800550045004c005100480003005600530048004800470003005600480051005600520055000300050024000500

0f0003[

Speed sensor (NT), Turbine speed sensorInput turbine speed sensor

Page 2722 of 4500

b. Fail-safe operation for mechanically malfunction:

HINT:

Fail-safe operation in the event of a mechanical system malfunction.

Fail safe function:

The ECM controls the gear position as shown in the table below when malfunctions occur.

Fig. 43: Identifying Mechanical Malfunction Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DATA LIST/ACTIVE TEST

1.DATA LIST

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch,

sensor, actuator and so on without parts removal. Reading the DATA LIST as the first step of

troubleshooting is one method to shorten labor time.

Page 2724 of 4500

Fig. 45: Identifying Data List Reference (2 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2.ACTIVE TEST

HINT:

Performing the ACTIVE TEST using the hand-held tester allows the relay, VSV, actuator and so on to

operate without parts removal. Performing the ACTIVE TEST as the first step of troubleshooting is one

method to shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Select the item "DIAGNOSIS/ENHANCED OBD II/ACTIVE TEST".

g. According to the display on tester, perform the "ACTIVE TEST".

Page 2734 of 4500

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Turn the ignition switch off.

b. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

c. Turn the ignition switch to the ON position.

d. Push the "ON" button of the OBD II scan tool or the hand-held tester.

e. Select the item "DIAGNOSIS/ENHANCED OBD II/DATA LIST".

f. According to the display on tester, read the "DATA LIST".

Fig. 51: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1.INSPECT PARK/NEUTRAL POSITION SWITCH ASSY

a. Disconnect the park/neutral position switch connector.

b. Measure resistance according to the value(s) in the table below when the shift lever is moved to

each position.

Page 2744 of 4500

Fig. 60: DTCs P0710, P0712, P0713 - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

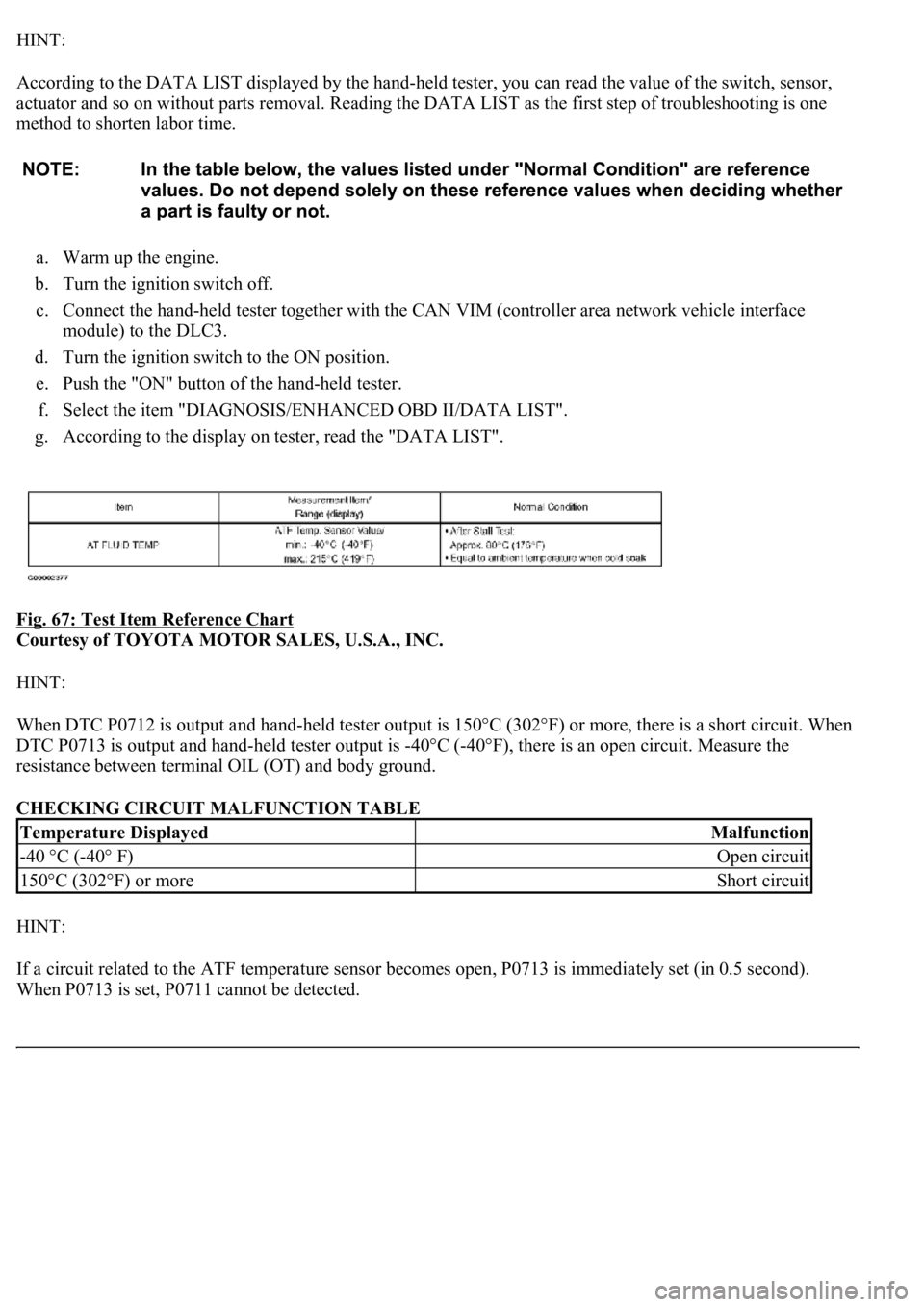

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Select the item "DIAGNOSIS/ENHANCED OBD II/DATA LIST".

g. According to the display on tester, read the "DATA LIST".

Page 2750 of 4500

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Select the item "DIAGNOSIS/ENHANCED OBD II/DATA LIST".

g. According to the display on tester, read the "DATA LIST".

Fig. 67: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

<003a004b004800510003002700370026000300330013001a001400150003004c0056000300520058005700530058005700030044005100470003004b0044005100470010004b0048004f004700030057004800560057004800550003005200580057005300

5800570003004c00560003001400180013008300260003000b[302°F) or more, there is a short circuit. When

DTC P0713 is output and hand-held tester output is -40°C (-40°F), there is an open circuit. Measure the

resistance between terminal OIL (OT) and body ground.

CHECKING CIRCUIT MALFUNCTION TABLE

HINT:

If a circuit related to the ATF temperature sensor becomes open, P0713 is immediately set (in 0.5 second).

When P0713 is set, P0711 cannot be detected.

Temperature DisplayedMalfunction

-40 °C (-40° F)Open circuit

150°C (302°F) or moreShort circuit

Page 2755 of 4500

Fig. 71: DTC P0717 - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Select the item "DIAGNOSIS/ENHANCED OBD II/DATA LIST".

g. According to the display on tester, read the "DATA LIST".

Fig. 72: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

Page 2760 of 4500

TYPICAL ENABLING CONDITIONS

The stop light switch remains on during GO and STOP 10 times.

GO and STOP is defined as follows;

TYPICAL ENABLING CONDITIONS TABLE

TYPICAL MALFUNCTION THRESHOLDS

TYPICAL MALFUNCTION THRESHOLDS TABLE

WIRING DIAGRAM

See DTC P0504, P0571: BRAKE SWITCH "A"/"B" CORRELATION, BRAKE SWITCH "A"

CIRCUIT .

INSPECTION PROCEDURE

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Turn the ignition switch off.

b. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

Related DTCsP0724: Stop light switch/Range check/Rationality

Required sensors/ComponentsStop light switch

Frequency of operationContinuous

DurationGO and STOP 5 times

MIL operation2 driving cycles

Sequence of operationNone

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

GO: (Vehicle speed is 30 km/h (18.63 mph) or

more)Once

STOP: (Vehicle speed is Less than 3 km/h (1.86

mph))Once

StarterOFF

Battery voltage8 V or more

Ignition switchON

Brake switchRemain ON during GO and STOP 5 times.