LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2711 of 4500

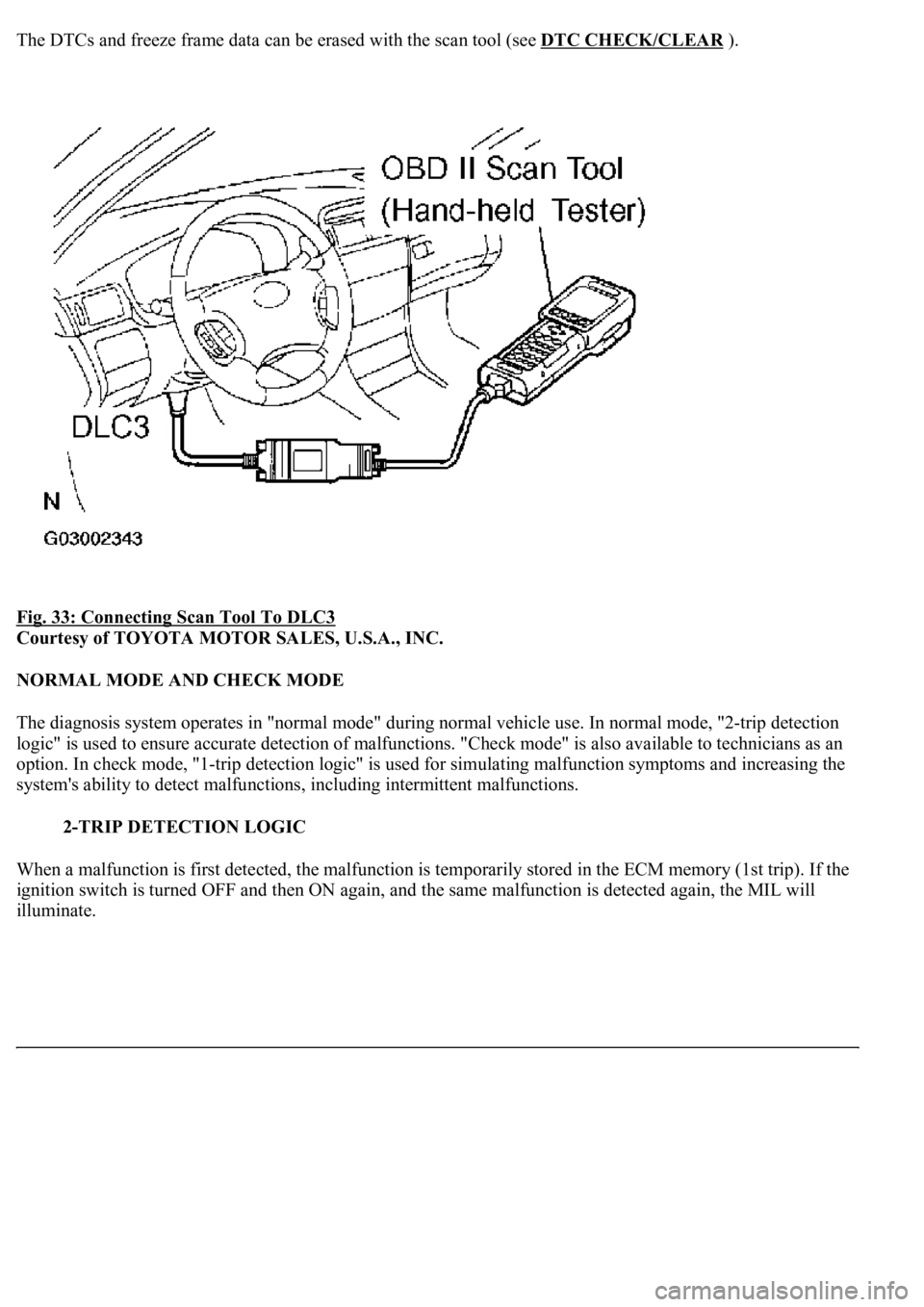

The DTCs and freeze frame data can be erased with the scan tool (see DTC CHECK/CLEAR).

Fig. 33: Connecting Scan Tool To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NORMAL MODE AND CHECK MODE

The diagnosis system operates in "normal mode" during normal vehicle use. In normal mode, "2-trip detection

logic" is used to ensure accurate detection of malfunctions. "Check mode" is also available to technicians as an

option. In check mode, "1-trip detection logic" is used for simulating malfunction symptoms and increasing the

system's ability to detect malfunctions, including intermittent malfunctions.

2-TRIP DETECTION LOGIC

When a malfunction is first detected, the malfunction is temporarily stored in the ECM memory (1st trip). If the

<004c004a0051004c0057004c0052005100030056005a004c00570046004b0003004c005600030057005800550051004800470003003200290029000300440051004700030057004b0048005100030032003100030044004a0044004c0051000f0003004400

51004700030057004b00480003005600440050004800030050[alfunction is detected again, the MIL will

illuminate.

Page 2712 of 4500

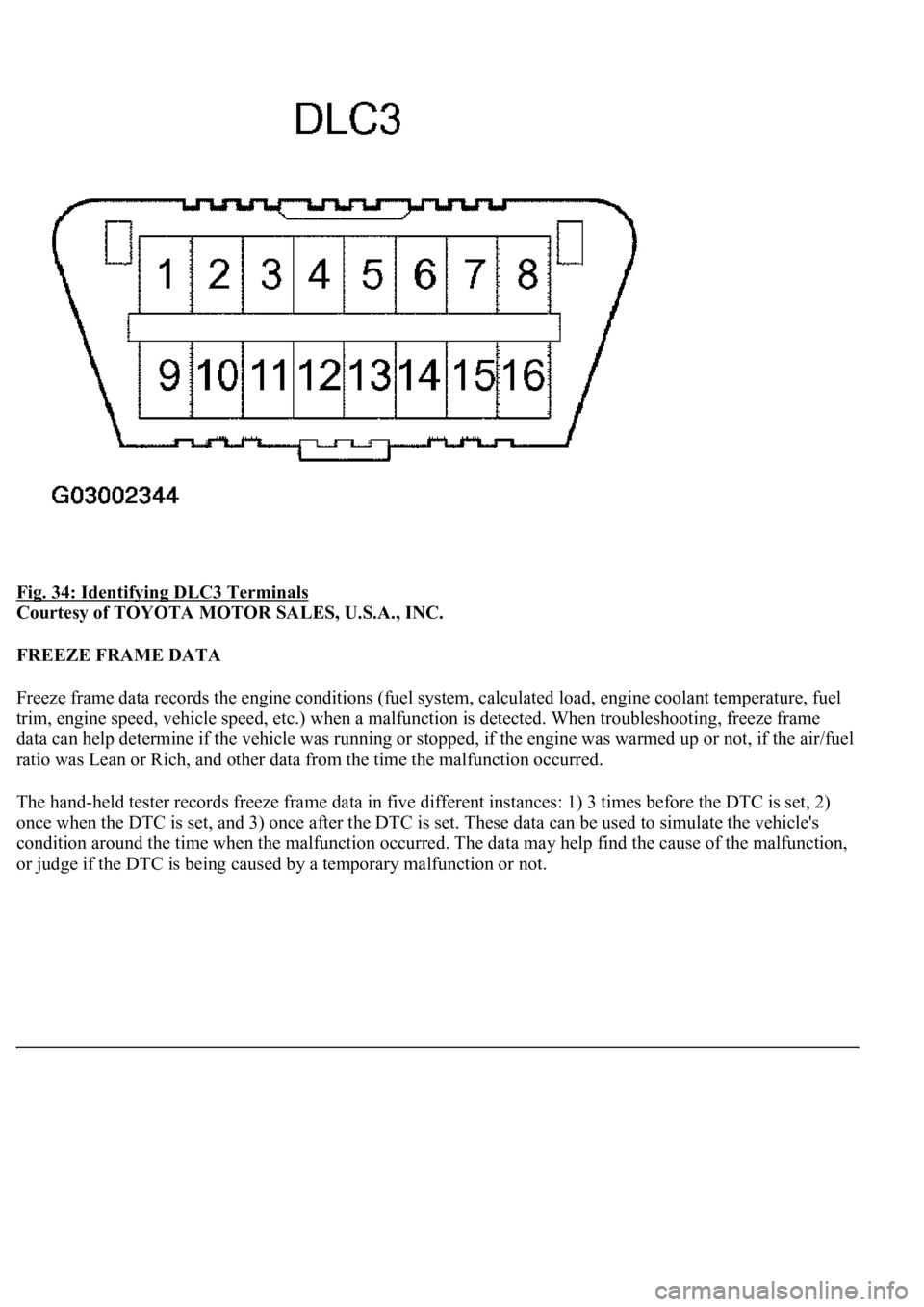

Fig. 34: Identifying DLC3 Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

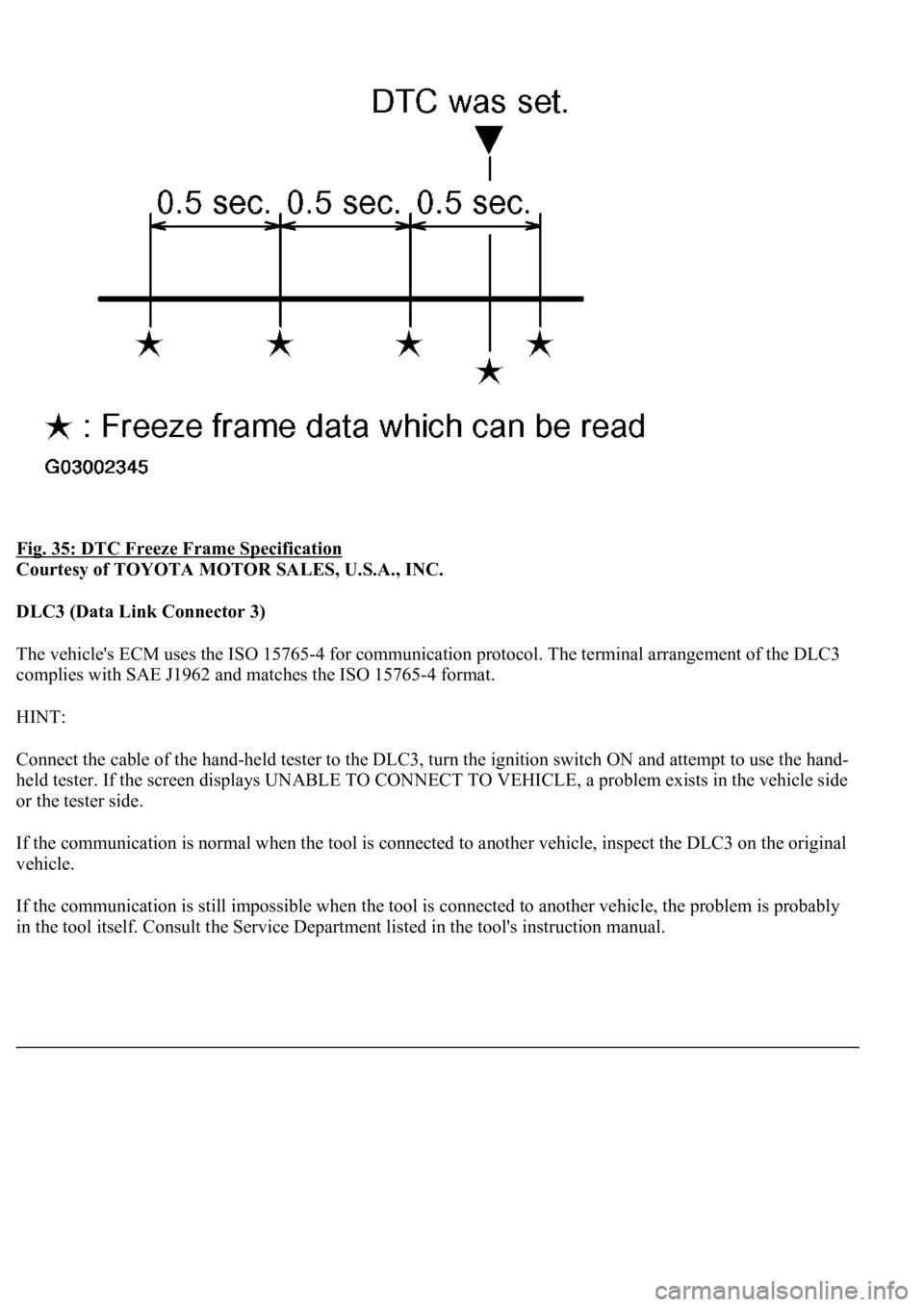

FREEZE FRAME DATA

Freeze frame data records the engine conditions (fuel system, calculated load, engine coolant temperature, fuel

trim, engine speed, vehicle speed, etc.) when a malfunction is detected. When troubleshooting, freeze frame

data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air/fuel

ratio was Lean or Rich, and other data from the time the malfunction occurred.

The hand-held tester records freeze frame data in five different instances: 1) 3 times before the DTC is set, 2)

once when the DTC is set, and 3) once after the DTC is set. These data can be used to simulate the vehicle's

condition around the time when the malfunction occurred. The data may help find the cause of the malfunction,

or

judge if the DTC is being caused by a temporary malfunction or not.

Page 2713 of 4500

Fig. 35: DTC Freeze Frame Specification

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DLC3 (Data Link Connector 3)

The vehicle's ECM uses the ISO 15765-4 for communication protocol. The terminal arrangement of the DLC3

complies with SAE J1962 and matches the ISO 15765-4 format.

HINT:

Connect the cable of the hand-held tester to the DLC3, turn the ignition switch ON and attempt to use the hand-

held tester. If the screen displays UNABLE TO CONNECT TO VEHICLE, a problem exists in the vehicle side

or the tester side.

If the communication is normal when the tool is connected to another vehicle, inspect the DLC3 on the original

vehicle.

If the communication is still impossible when the tool is connected to another vehicle, the problem is probably

in the tool itself. Consult the Service Department listed in the tool's instruction manual.

Page 2714 of 4500

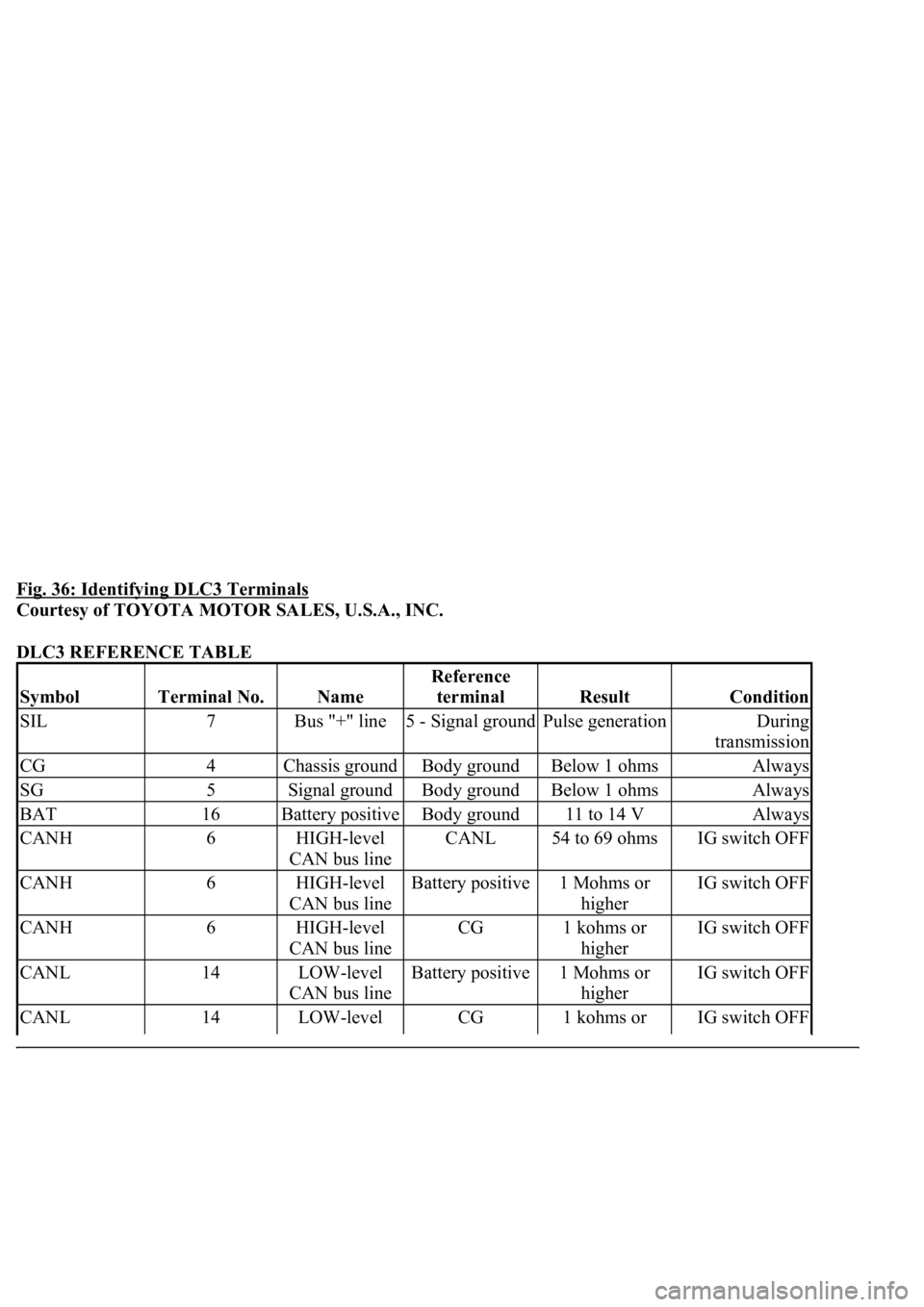

Fig. 36: Identifying DLC3 Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DLC3 REFERENCE TABLE

SymbolTerminal No.Name

Reference

terminal

ResultCondition

SIL7Bus "+" line5 - Signal groundPulse generationDuring

transmission

CG4Chassis groundBody groundBelow 1 ohmsAlways

SG5Signal groundBody groundBelow 1 ohmsAlways

BAT16Battery positiveBody ground11 to 14 VAlways

CANH6HIGH-level

CAN bus lineCANL54 to 69 ohmsIG switch OFF

CANH6HIGH-level

CAN bus lineBattery positive1 Mohms or

higherIG switch OFF

CANH6HIGH-level

CAN bus lineCG1 kohms or

higherIG switch OFF

CANL14LOW-level

CAN bus lineBattery positive1 Mohms or

higherIG switch OFF

CANL14LOW-level CG1 kohms or IG switch OFF

Page 2715 of 4500

CHECK BATTERY VOLTAGE

Battery voltage: 11 to 14 V

If voltage is below 11 V, replace the battery before proceeding.

CHECK MIL

a. Check that the MIL illuminates when turning the ignition switch ON.

If the MIL does not illuminate, there is a problem in the MIL circuit (refer to MIL CIRCUIT

)

b. When the engine is started, the MIL should turn off.

ALL READINESS

For this vehicle, using the hand-held tester allows readiness codes corresponding to all DTCs to be read. When

diagnosis (normal or malfunctioning) has been complete, readiness codes are set. Enter the following menus:

ENHANCED OBD II/ MONITOR STATUS on the hand-held tester.

DTC CHECK/CLEAR

1.CHECK DTC

DTCs which are stored in the ECM can be displayed with the hand-held tester or generic OBD II scan-

tool.

These scan tools can display pending DTCs and current DTCs. Some DTC aren't stored if the ECM

doesn't detect a malfunction during consecutive driving. However, the detected malfunction during once

driving is stored as pending DTC.

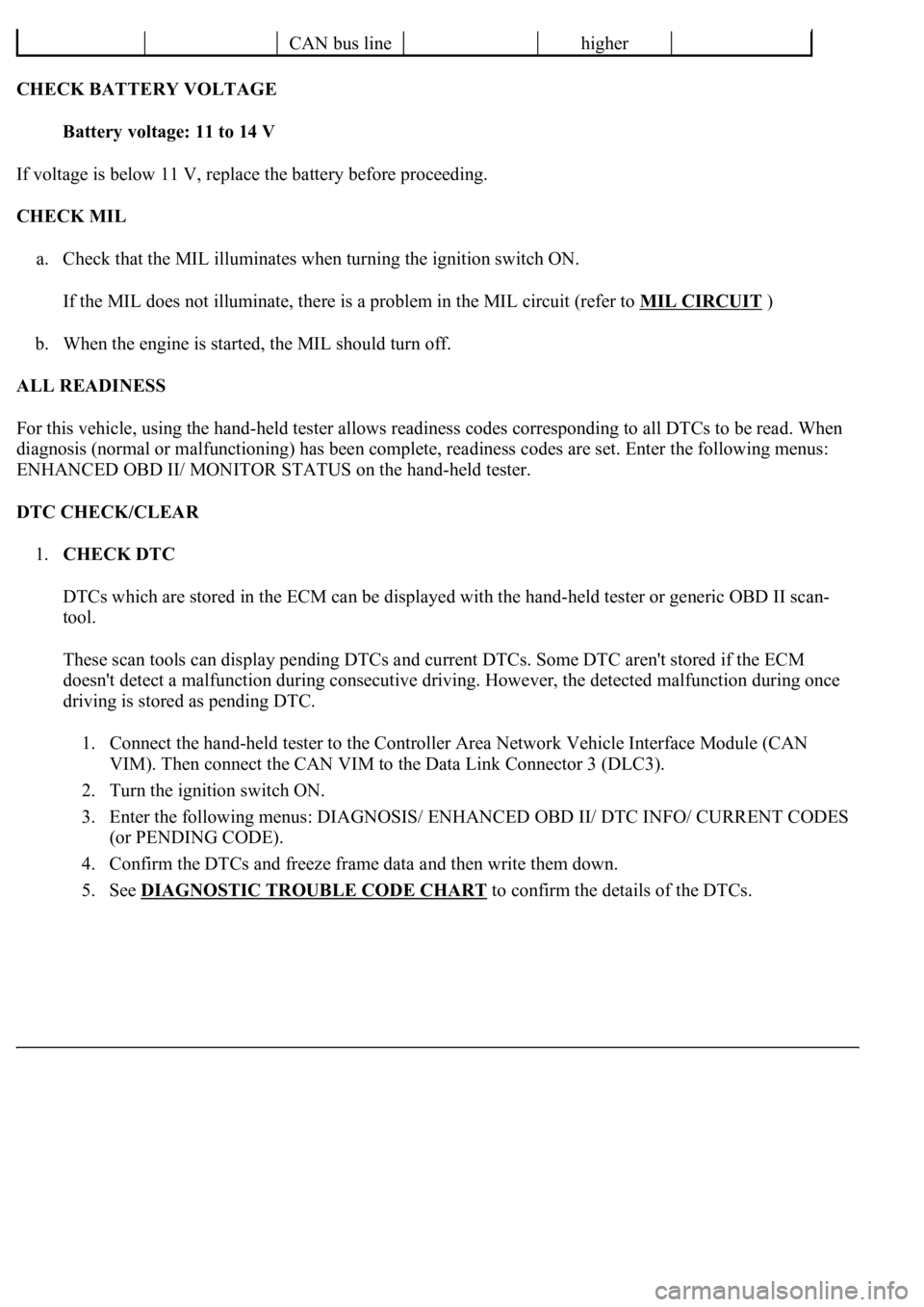

1. Connect the hand-held tester to the Controller Area Network Vehicle Interface Module (CAN

VIM). Then connect the CAN VIM to the Data Link Connector 3 (DLC3).

2. Turn the ignition switch ON.

3. Enter the following menus: DIAGNOSIS/ ENHANCED OBD II/ DTC INFO/ CURRENT CODES

(or PENDING CODE).

4. Confirm the DTCs and freeze frame data and then write them down.

5. See DIAGNOSTIC TROUBLE CODE CHART

to confirm the details of the DTCs.

CAN bus linehigher

Page 2716 of 4500

Fig. 37: Connecting Hand Held Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Turn the ignition switch OFF after the symptom is simulated once. Then repeat the simulation process

again. When the problem has been simulated twice, the MIL illuminates and the DTCs are recorded in the

ECM.

2.CLEAR DTC

a. Connect the hand-held tester to the CAN VIM. Then connect the CAN VIM to the DLC3.

b. Turn the ignition switch ON.

c. Enter the following menus: DIAGNOSIS/ ENHANCED OBD II/ DTC INFO/ CLEAR CODES and

press YES.

CHECK MODE PROCEDURE

DESCRIPTION

Page 2717 of 4500

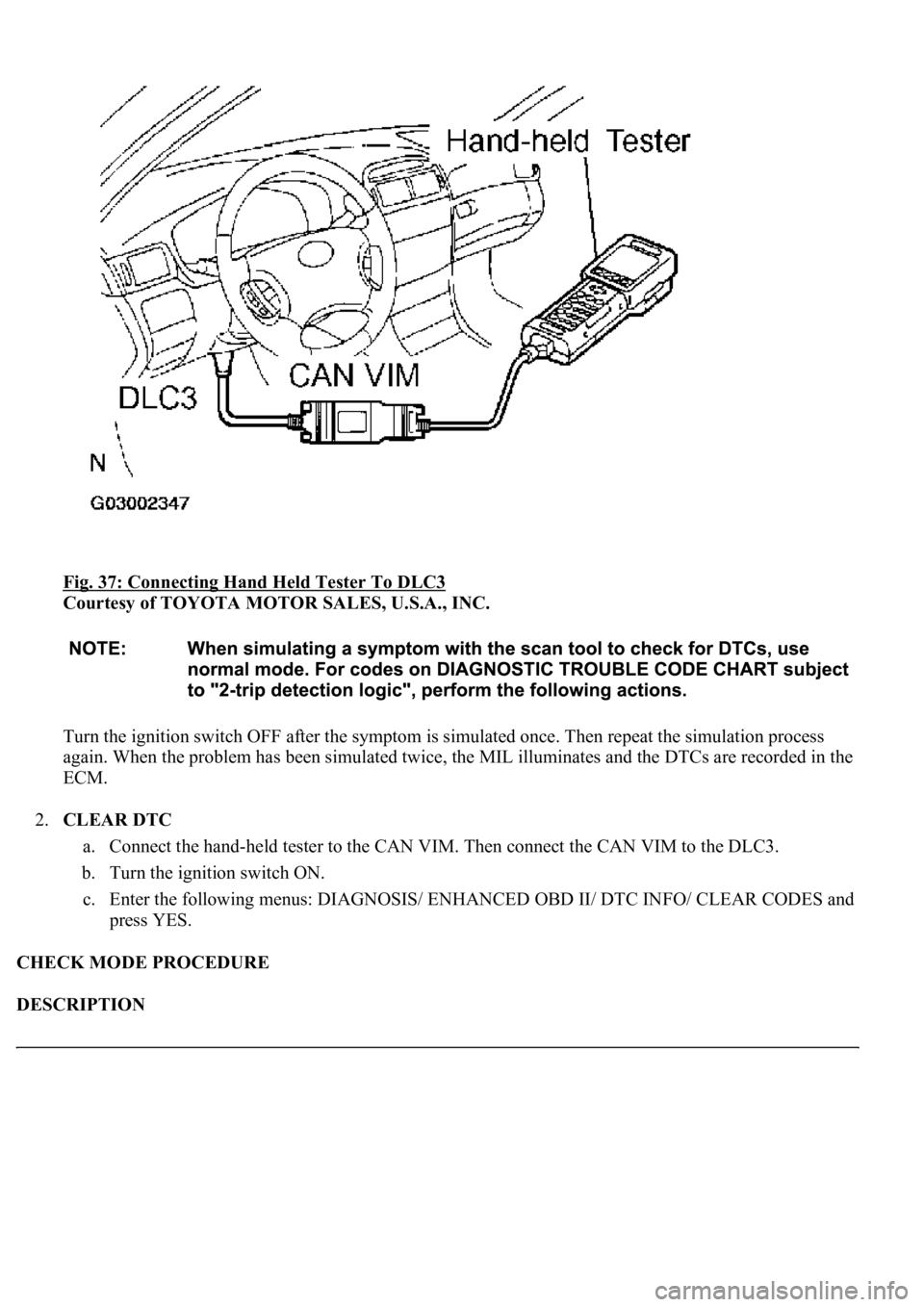

Check mode has a higher sensitivity to malfunctions and can detect malfunctions that normal mode cannot

detect. Check mode can also detect all the malfunctions that normal mode can detect. In check mode, DTCs are

detected with 1-tirp detection logic.

CHECK MODE PROCEDURE

a. Make sure that the items below are true:

1. Battery positive voltage 11 V or more

2. Throttle valve fully closed

3. Transmission in the P or N position

4. A/C switched OFF

b. Turn the ignition switch OFF.

c. Connect the hand-held tester together with the Controller Area Network Vehicle Interface Module (CAN

VIM) to the DLC3.

d. Turn the ignition switch ON.

e. Enter the following menus: DIAGNOSIS/ ENHANCED OBD II/CHECK MODE.

Fig. 38: Connecting Hand

-Held Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 2718 of 4500

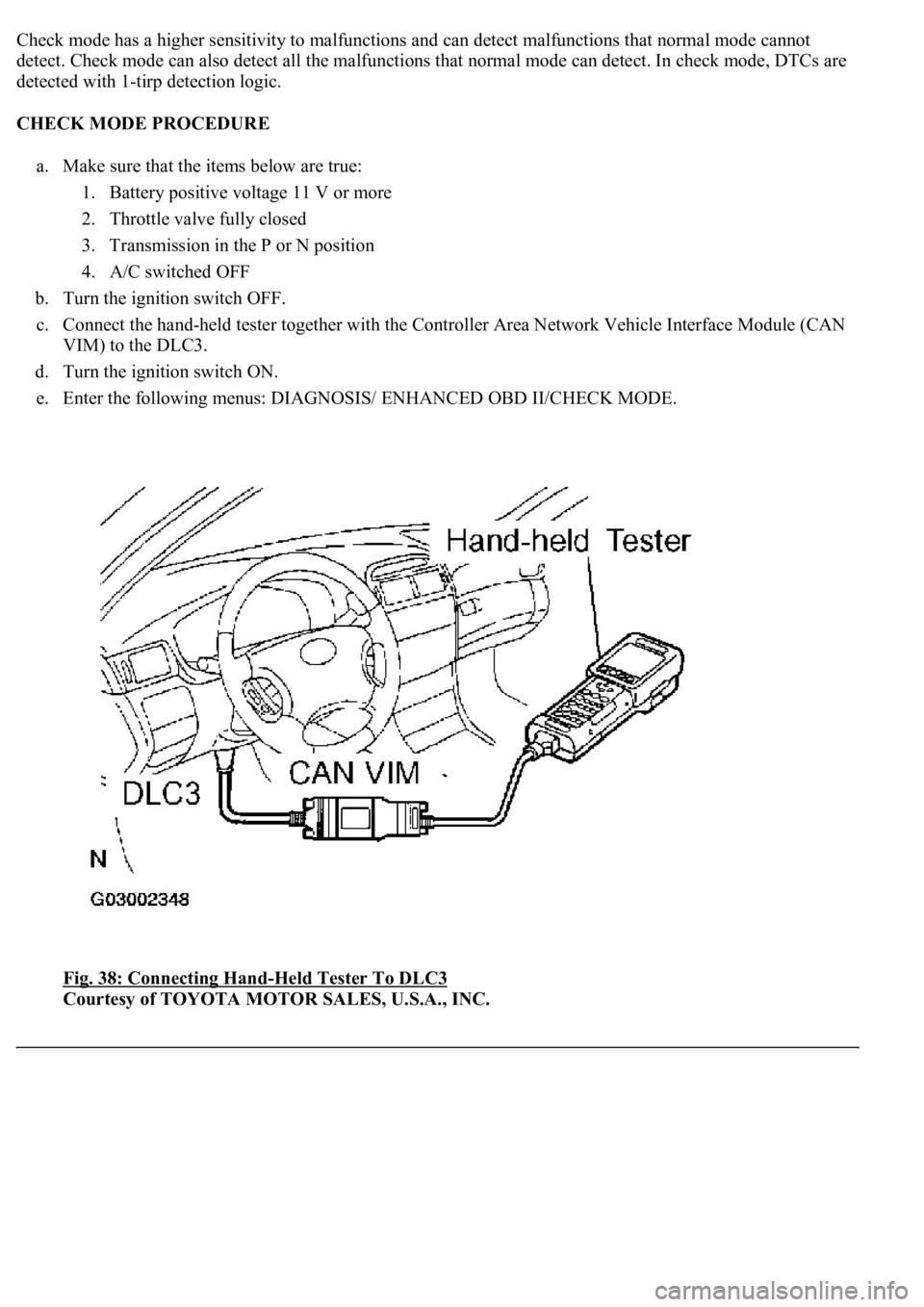

f. Change the ECM to check mode. Make sure the MIL flashes as shown in the illustration.

g. Start the engine. The MIL should turn off after the engine starts.

h. Perform "MONITOR DRIVE PATTERN" for the ECT test (see MONITOR DRIVE PATTERN

).

(Or, simulate the conditions of the malfunction described by the customer).

i. After simulating the malfunction conditions, use the hand-held tester diagnosis selector to check the DTC

and freeze frame data.

Fig. 39: Identifying MIL Blinking Pattern

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

FAIL-SAFE CHART

1.FAIL-SAFE

Page 2719 of 4500

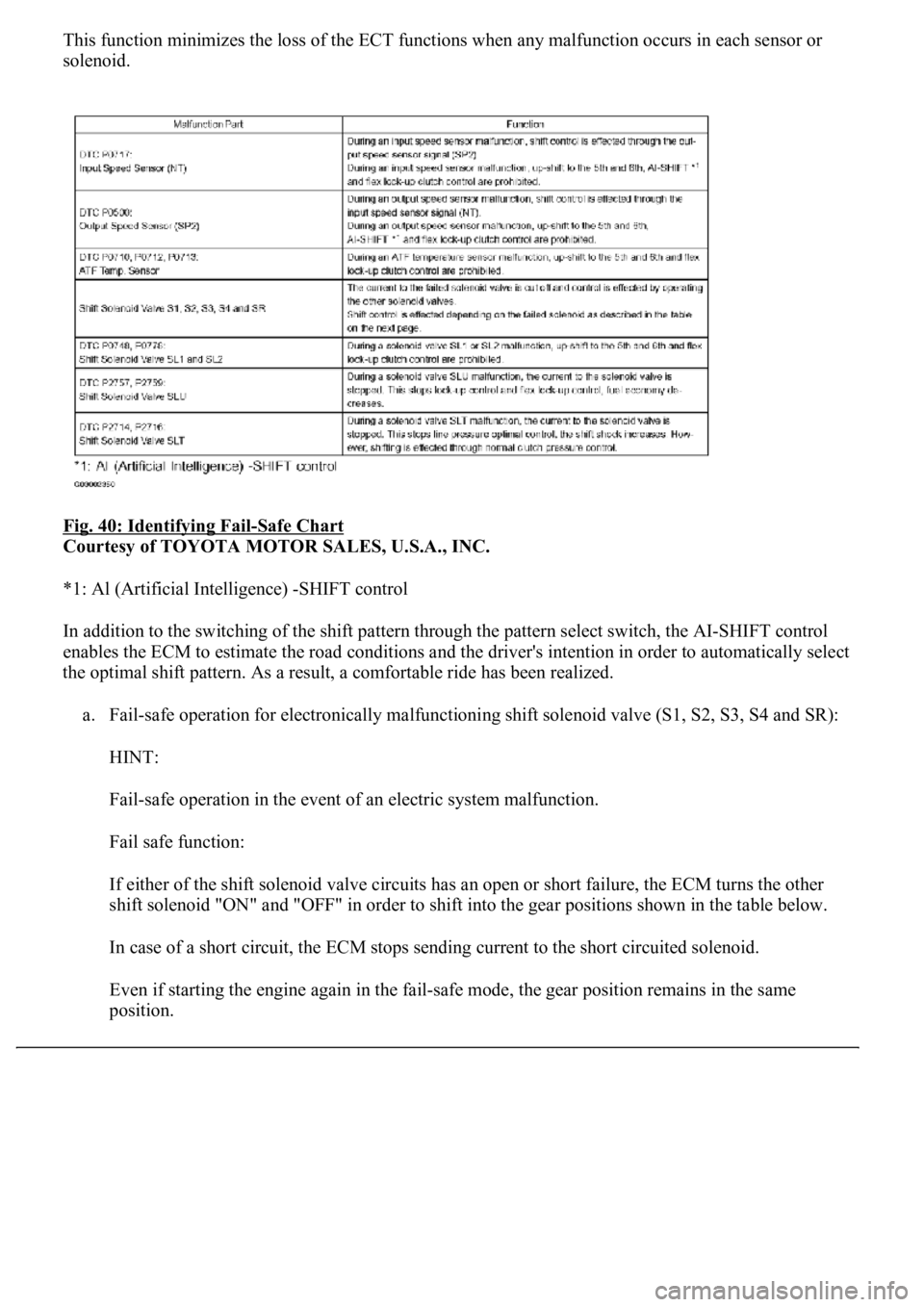

This function minimizes the loss of the ECT functions when any malfunction occurs in each sensor or

solenoid.

Fig. 40: Identifying Fail

-Safe Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

*1: Al (Artificial Intelligence) -SHIFT control

In addition to the switching of the shift pattern through the pattern select switch, the AI-SHIFT control

enables the ECM to estimate the road conditions and the driver's intention in order to automatically select

the optimal shift pattern. As a result, a comfortable ride has been realized.

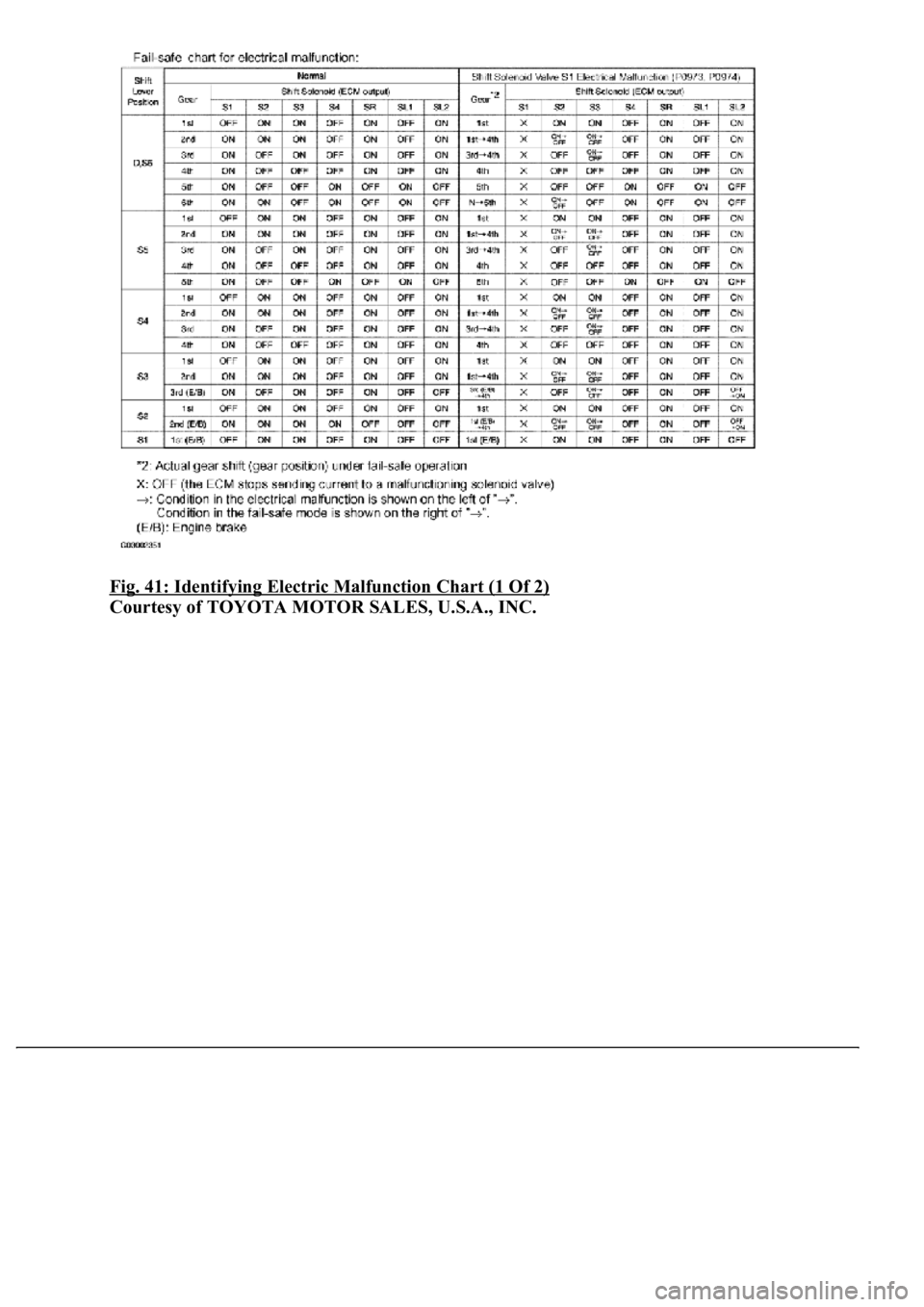

a. Fail-safe operation for electronically malfunctioning shift solenoid valve (S1, S2, S3, S4 and SR):

HINT:

Fail-safe operation in the event of an electric system malfunction.

Fail safe function:

If either of the shift solenoid valve circuits has an open or short failure, the ECM turns the other

shift solenoid "ON" and "OFF" in order to shift into the gear positions shown in the table below.

In case of a short circuit, the ECM stops sending current to the short circuited solenoid.

Even if starting the engine again in the fail-safe mode, the gear position remains in the same

position.

Page 2720 of 4500

Fig. 41: Identifying Electric Malfunction Chart (1 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.