sensor LEXUS LS430 2003 Factory Service Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 75 of 4500

corresponding to a DTC (see CHECK FOR INTERMITTENT PROBLEMS ).

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

OK: Go to next step

There are no momentary interruption.

HINT:

Perform the above inspection before removing the sensor and connector.

NG: Go to step 5

OK: Go to next step

2.READ VALUE OF HAND-HELD TESTER (REAR SPEED SENSOR)

a. Connect the hand-held tester to the DLC3.

b. Start the engine.

c. Select the DATA LIST mode on the hand-held tester.

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

d. Check that there is no difference between the speed value output from the speed sensor displayed

by the hand-held tester and the speed value displayed on the speedometer when driving the vehicle.

OK: Go to next step

There is almost no difference in the displayed speed value.

HINT:

There is tolerance of 10 % in the speedometer indication.

ItemMeasurement Item / Range (Display)Normal Condition

SPD SEN RRRR speed sensor open detection / OPEN or

NORMALOPEN: Momentary interruption

SPD SEN RLRL speed sensor open detection / OPEN or

NORMALOPEN: Momentary interruption

ItemMeasurement Item / Range (Display)

Normal

Condition

WHEEL SPD RLWheel speed sensor (RL) reading / min.: 0 km/h (0 MPH,

max.: 326 km/h (202 MPH)Actual wheel

speed

WHEEL SPD RRWheel speed sensor (RR) reading / min.: 0 km/h (0 MPH,

max.: 326 km/h (202 MPH)Actual wheel

speed

Page 76 of 4500

NG: Go to step 4

OK: Go to next step

3.INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

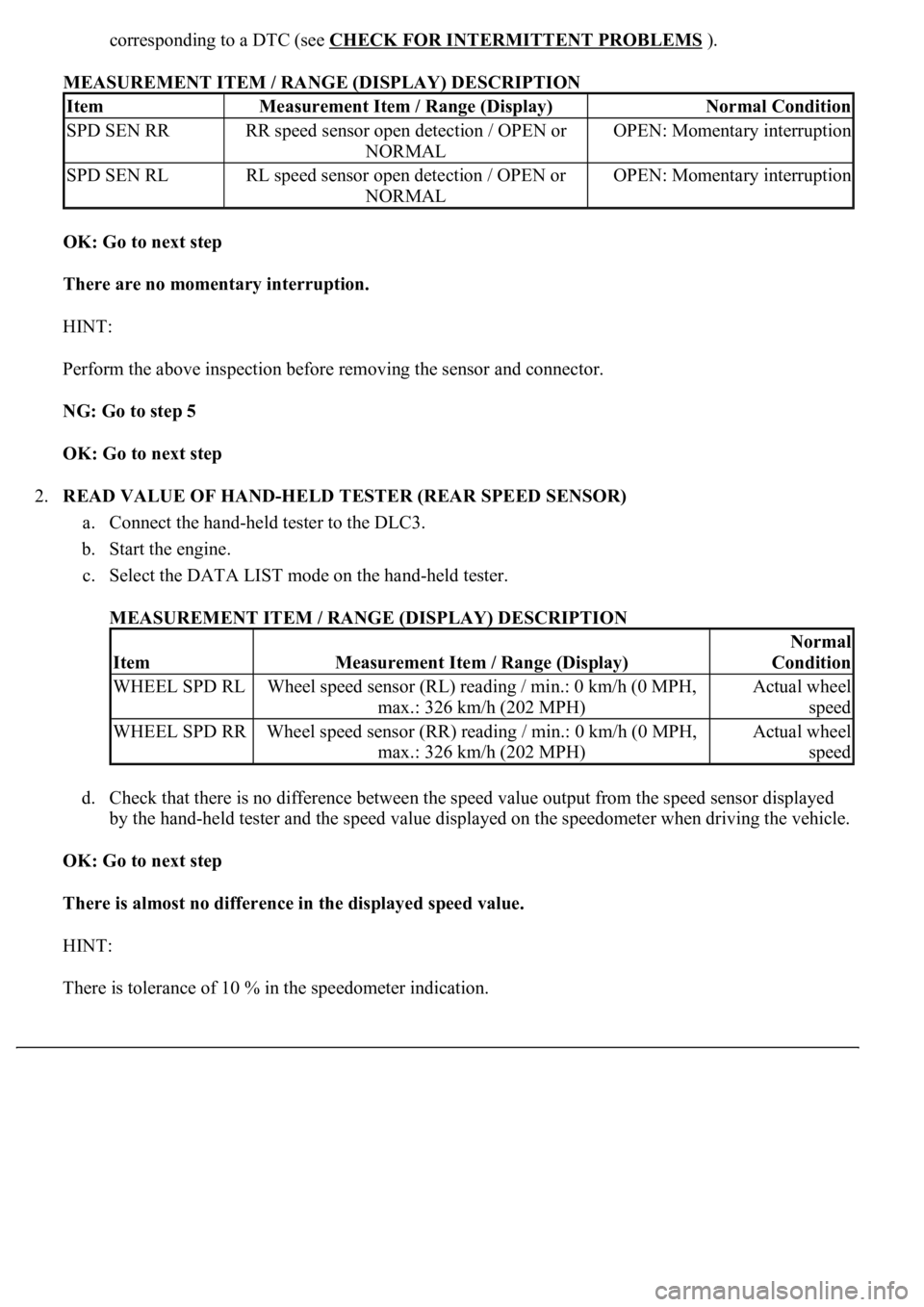

Fig. 55: Normal Signal Waveform

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION USING OSCILLOSCOPE

a. Connect the oscilloscope to terminals RR+ - RR- or RL+ - RL- of the skid control ECU.

b. Drive the vehicle at approximately 19 mph (30 km/h), and check the signal waveform.

OK: Go to next step

A waveform as shown in a figure should be output.

HINT:

As the vehicle speed (wheel revolution speed) increases, a cycle of the waveform narrows and the

Page 77 of 4500

fluctuation in the output voltage becomes greater.

When noise is identified in the waveform on the oscilloscope, error signals are generated due to the

speed sensor rotor's scratches, looseness or foreign matter attached to it.

NG: Go to step 7

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

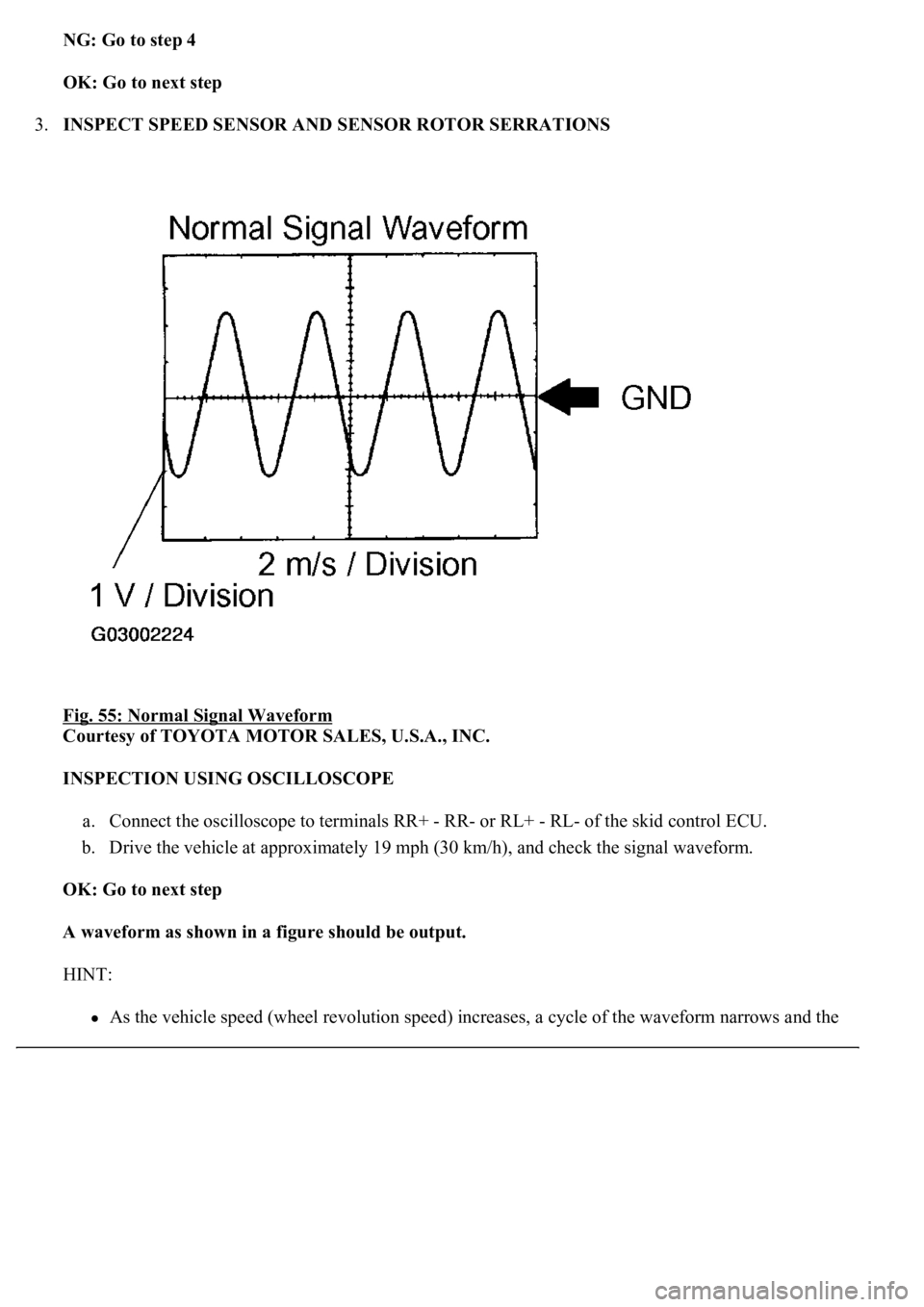

4.INSPECT REAR SPEED SENSOR

Fig. 56: Inspecting Rear Speed Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Remove the rear seat cushion and seatback.

b. Make sure that the speed sensor connector and the wire harness side connector are securely

connected.

c. Disconnect the speed sensor connector.

d. Measure the resistance accordin

g to the value (s) in the table below.

Page 78 of 4500

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

e. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

NG: REPLACE REAR SPEED SENSOR (SEE REPLACEMENT

)

OK: Go to next step

5.CHECK HARNESS AND CONNECTOR (REAR SPEED SENSOR - SKID CONTROL ECU)

Tester ConnectionSpecified Condition

(A31-1) - (A31-2)0.6 to 1.8 kohms

Tester ConnectionSpecified Condition

(A30-1) - (A30-2)0.6 to 1.8 kohms

Tester ConnectionSpecified Condition

(A31-1) - Body ground1 Mohms or higher

(A31-2) - Body ground1 Mohms or higher

Tester ConnectionSpecified Condition

(A30-1) - Body ground1 Mohms or higher

(A30-2) - Body ground1 Mohms or higher

Page 79 of 4500

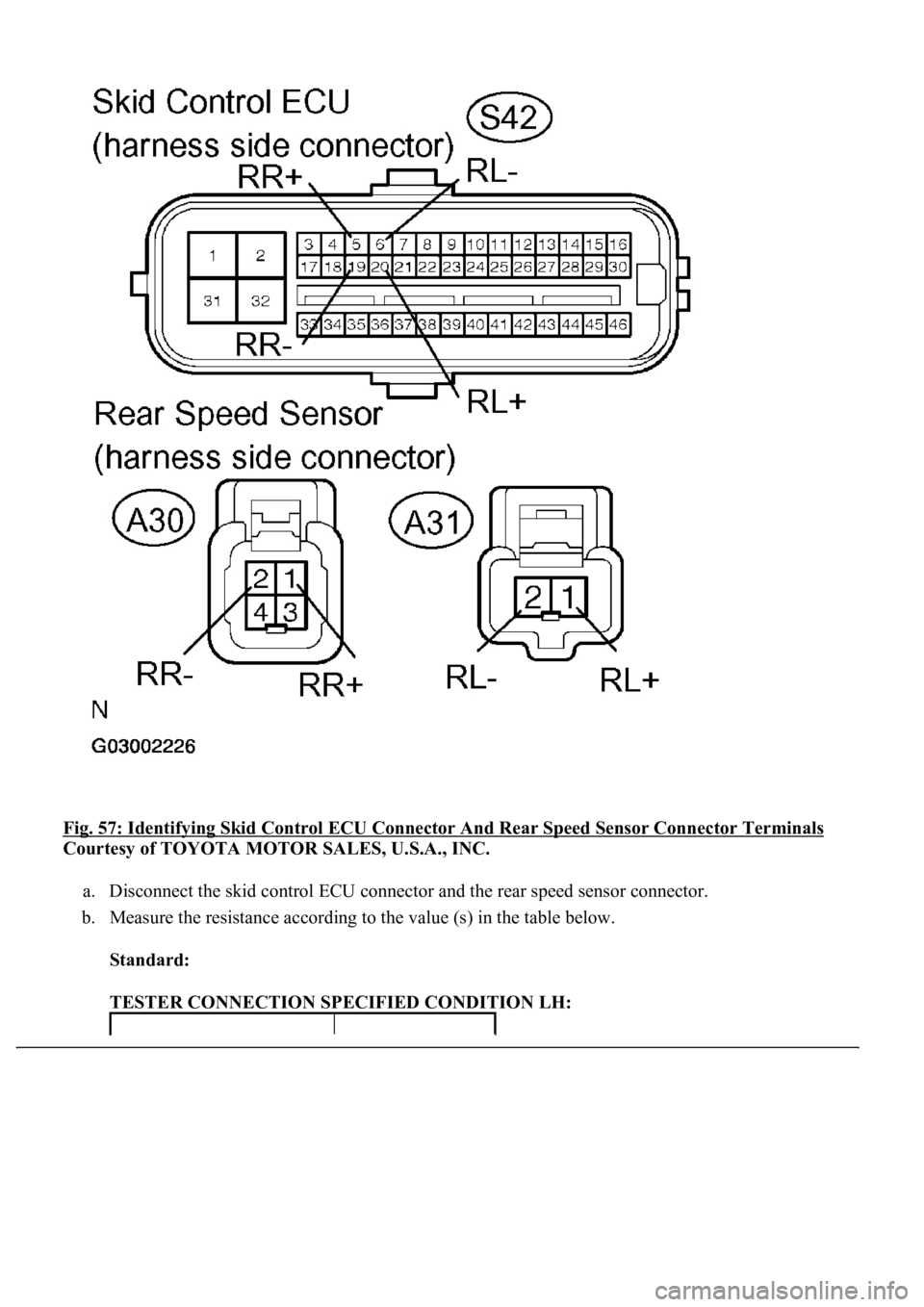

Fig. 57: Identifying Skid Control ECU Connector And Rear Speed Sensor Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Disconnect the skid control ECU connector and the rear speed sensor connector.

b. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

Page 80 of 4500

TESTER CONNECTION SPECIFIED CONDITION RH:

c. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION LH:

TESTER CONNECTION SPECIFIED CONDITION RH:

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: Go to next step

6.INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

Tester ConnectionSpecified Condition

S42-20 (RL+) - A31-1 (RL+)Below 1 ohms

S42-6 (RL-) - A31-2 (RL-)Below 1 ohms

Tester ConnectionSpecified Condition

S42-5 (RR+) - A30-1 (RR+)Below 1 ohms

S42-19 (RR-) - A30-2 (RR-)Below 1 ohms

Tester ConnectionSpecified Condition

S42-20 (RL+) - Body ground1 Mohms or higher

S42-6 (RL-) - Body ground1 Mohms or higher

Tester ConnectionSpecified Condition

S42-5 (RR+) - Body ground1 Mohms or higher

S42-19 (RR-) - Body ground1 Mohms or higher

Page 81 of 4500

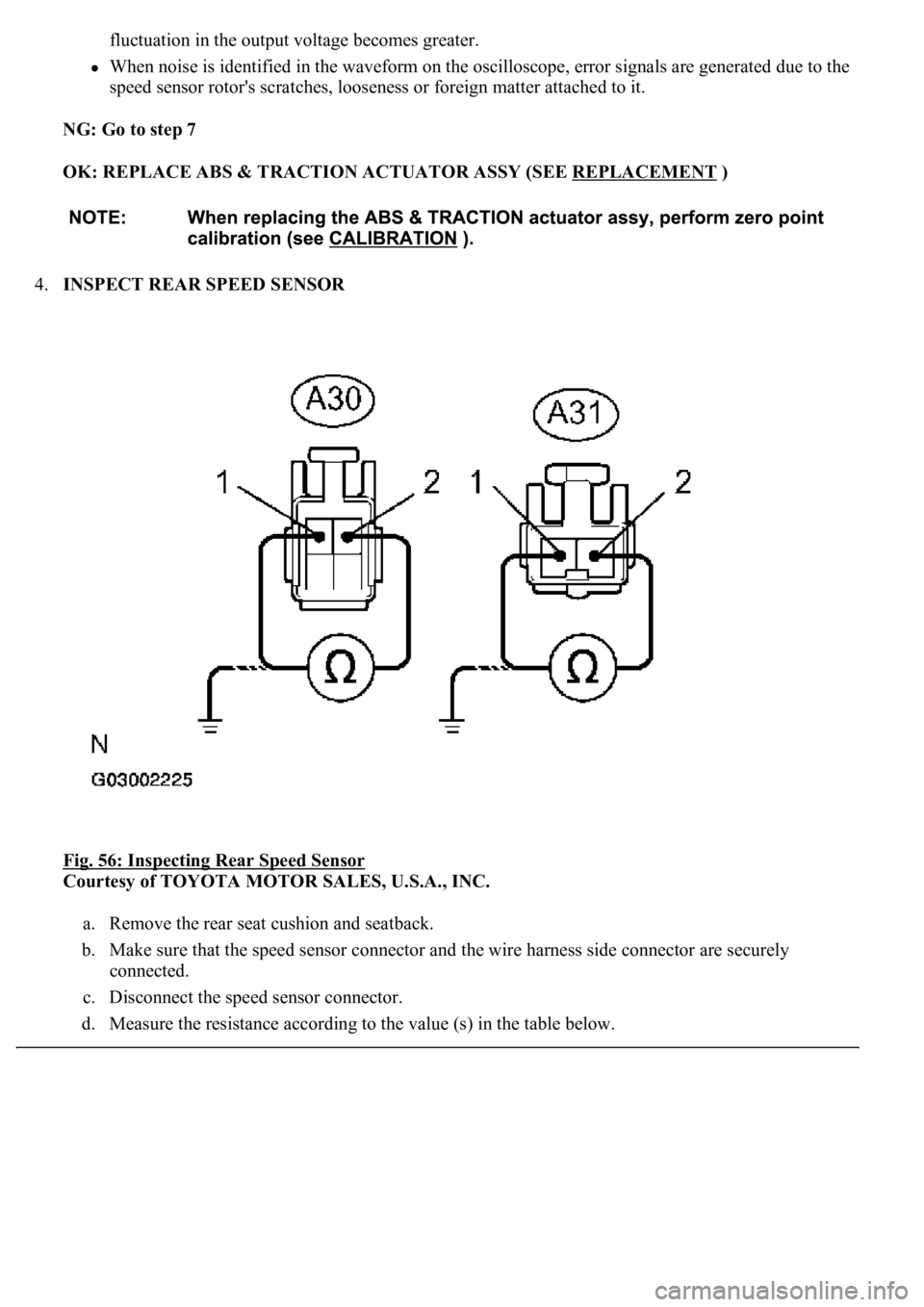

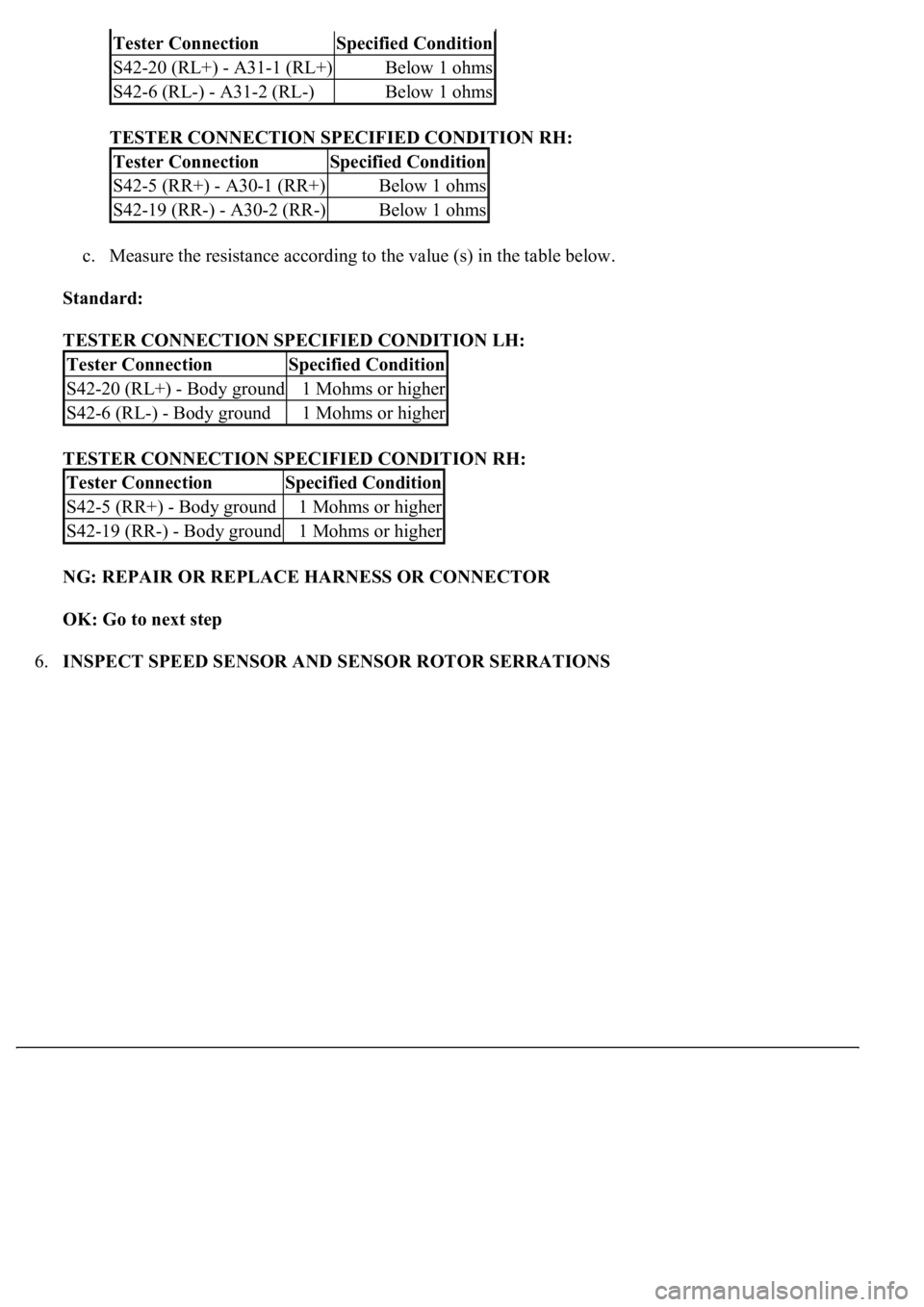

Fig. 58: Normal Signal Waveform

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION USING OSCILLOSCOPE

a. Connect the oscilloscope to terminals RR+ - RR- or RL+ - RL- of the skid control ECU.

b. Drive the vehicle at approximately 19 mph (30 km/h), and check the signal waveform.

OK: Go to next step

A waveform as shown in a figure should be output.

HINT:

As the vehicle speed (wheel revolution speed) increases, a cycle of the waveform narrows and the

fluctuation in the output voltage becomes greater.

When noise is identified in the waveform on the oscilloscope, error signals are generated due to the

speed sensor rotor's scratches, looseness or foreign matter attached to it.

NG: Go to step 7

Page 82 of 4500

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT )

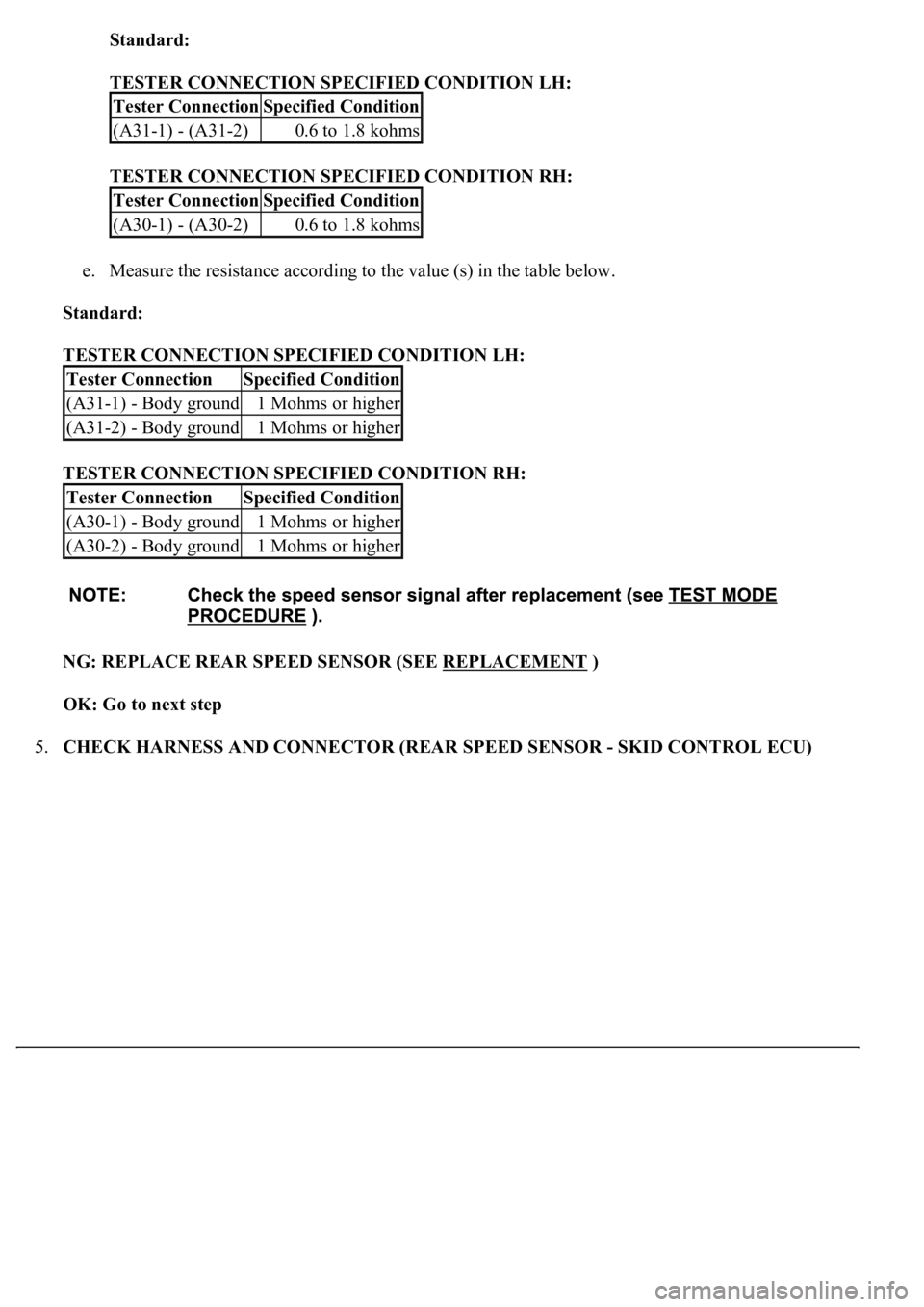

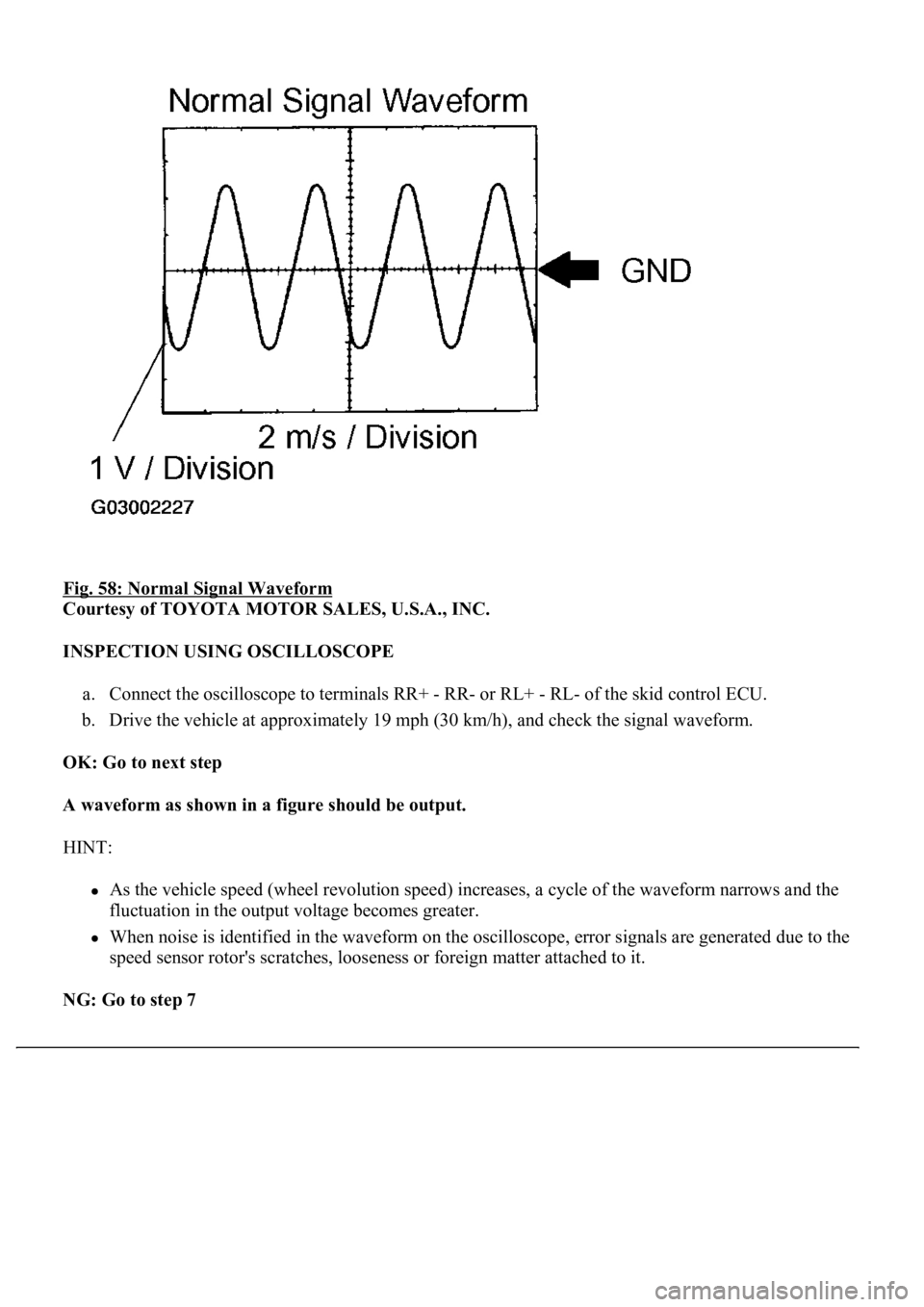

7.INSPECT REAR SPEED SENSOR INSTALLATION

Fig. 59: Inspecting Rear Speed Sensor Gap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Check the sensor installation.

OK: Go to next step

There is no clearance between the sensor and rear axle carrier.

The installation bolt is tightened properly.

Torque: 8.0 N.m (82 kgf.cm, 71 in..lbf)

Page 83 of 4500

NG: REPLACE REAR SPEED SENSOR

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

<0037004b004c0056000300560052004f004800510052004c00470003005700580055005100560003005200510003005a004b0048005100030056004c004a00510044004f0056000300440055004800030055004800460048004c0059004800470003004900

550052005000030057004b0048000300280026003800030044[nd controls the pressure acting on the wheel

c

ylinders to control the braking force.

Page 102 of 4500

HINT:

It is suspect that the DTCs output was caused by the poor connection on the connector terminal.

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

If trouble occurs in the engine control system, the ECM transmits the abnormality to the skid control ECU. The

skid control ECU sets this DTC and the skid control ECU prohibits TRAC and VSC control.

DTC DETECTING CONDITION DESCRIPTION

INSPECTION PROCEDURE

1.CHECK HARNESS AND CONNECTOR (MOMENTARY INTERRUPTION)

a. Using the hand-held tester, check for any momentary interruption in the wire harness and connector

corresponding to a DTC (see CHECK FOR INTERMITTENT PROBLEMS

).

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

OK: Go to next step

There are no momentary interruptions.

HINT:

Perform the above inspection before removing the sensor and connector.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - SKID CONTROL ECU)

OK: Go to next step

2.CHECK DTC FOR ENGINE

a. Check if the normal code is recorded for en

gine control system.

DTC No.DTC Detecting ConditionTrouble Area

C1201/51At the engine speed of 500 RPM, a trouble signal in the engine

control system continues for 5 secs, or more.Engine control

system

ItemMeasurement Item / Range (Display)Normal Condition

EFI COMEFI communication open detectionOPEN: Momentary interruption