Temperature sensor LEXUS LS430 2003 Factory Manual PDF

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2750 of 4500

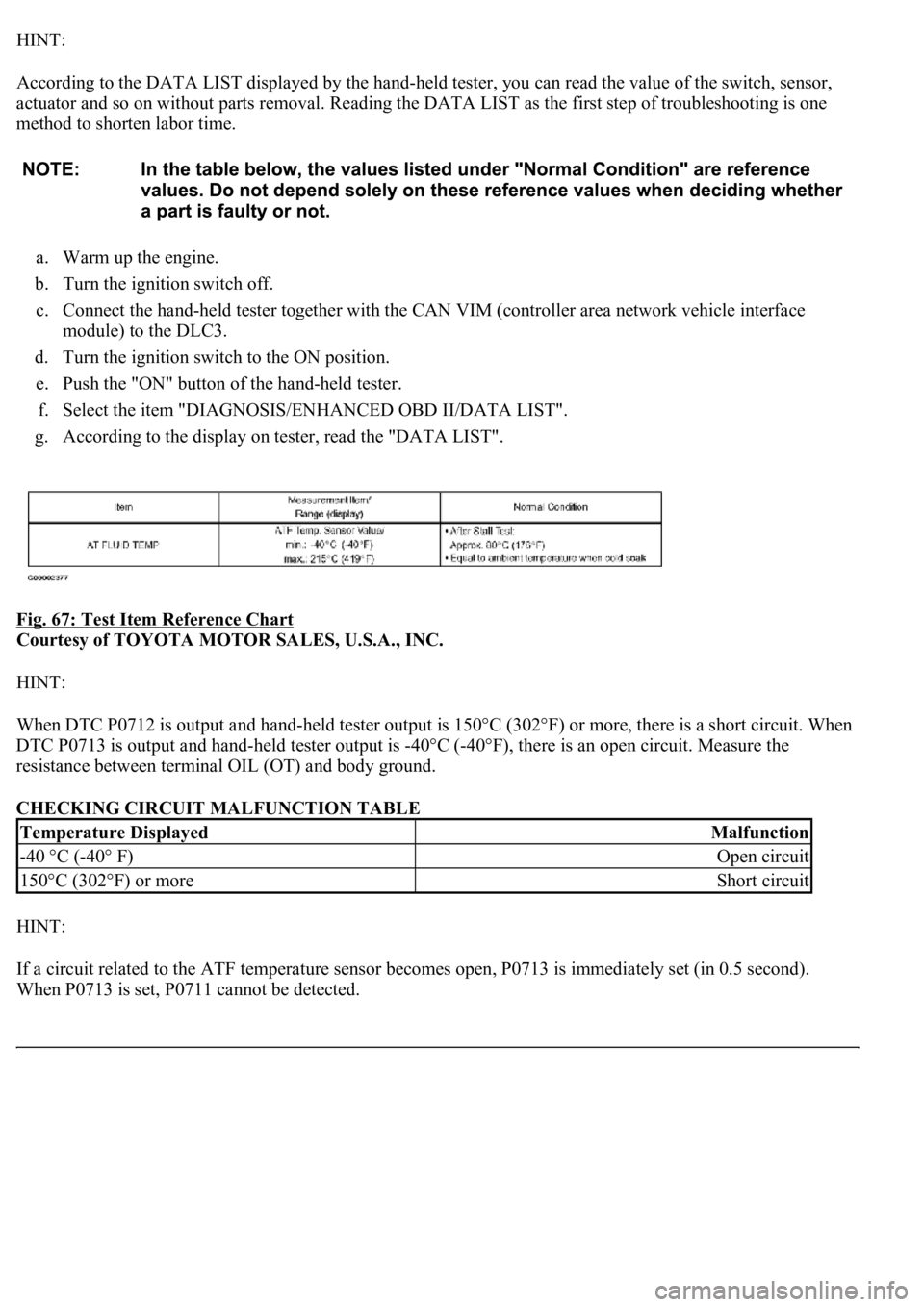

HINT:

According to the DATA LIST displayed by the hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as the first step of troubleshooting is one

method to shorten labor time.

a. Warm up the engine.

b. Turn the ignition switch off.

c. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

d. Turn the ignition switch to the ON position.

e. Push the "ON" button of the hand-held tester.

f. Select the item "DIAGNOSIS/ENHANCED OBD II/DATA LIST".

g. According to the display on tester, read the "DATA LIST".

Fig. 67: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

<003a004b004800510003002700370026000300330013001a001400150003004c0056000300520058005700530058005700030044005100470003004b0044005100470010004b0048004f004700030057004800560057004800550003005200580057005300

5800570003004c00560003001400180013008300260003000b[302°F) or more, there is a short circuit. When

DTC P0713 is output and hand-held tester output is -40°C (-40°F), there is an open circuit. Measure the

resistance between terminal OIL (OT) and body ground.

CHECKING CIRCUIT MALFUNCTION TABLE

HINT:

If a circuit related to the ATF temperature sensor becomes open, P0713 is immediately set (in 0.5 second).

When P0713 is set, P0711 cannot be detected.

Temperature DisplayedMalfunction

-40 °C (-40° F)Open circuit

150°C (302°F) or moreShort circuit

Page 2766 of 4500

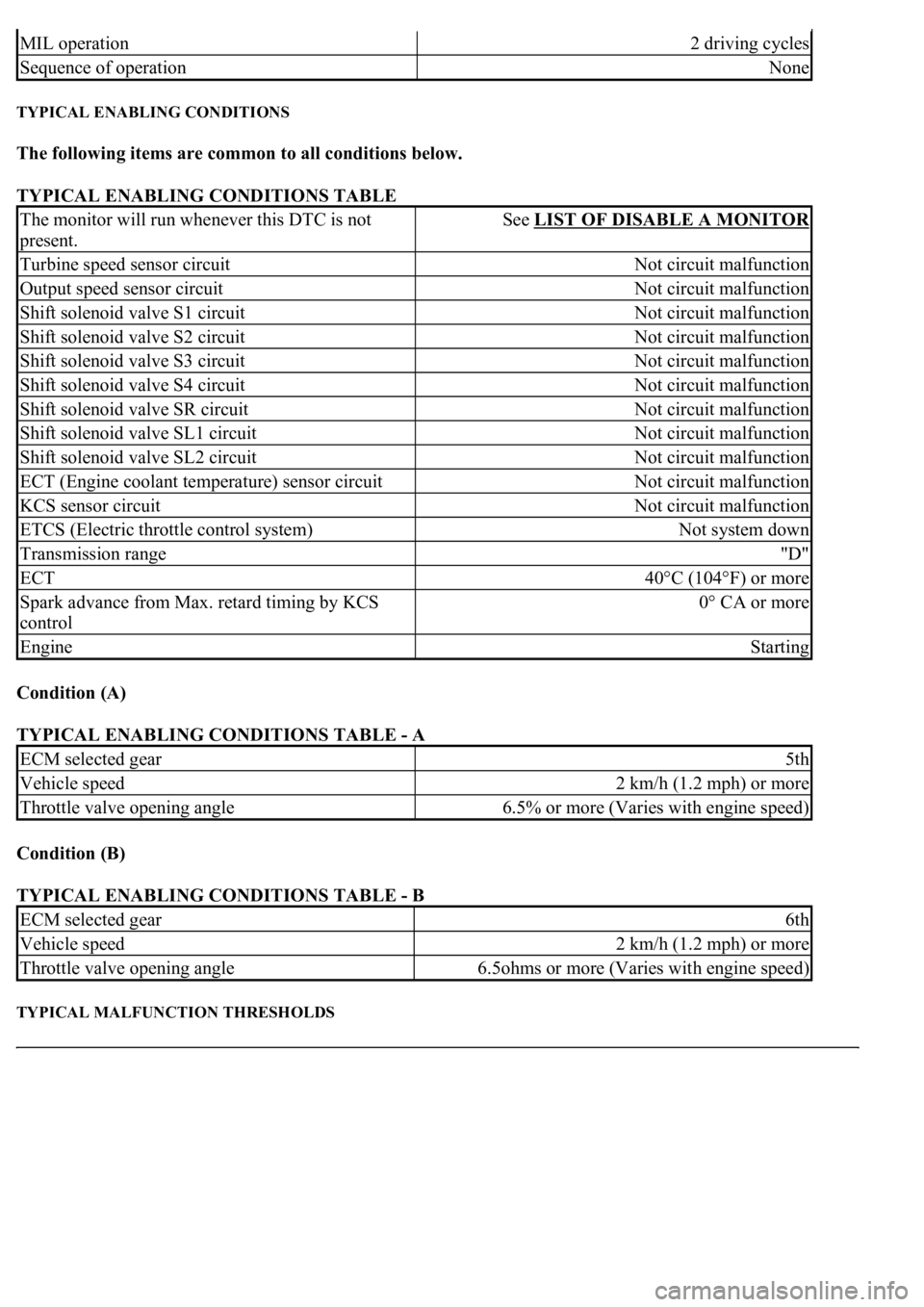

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below.

TYPICAL ENABLING CONDITIONS TABLE

Condition (A)

TYPICAL ENABLING CONDITIONS TABLE - A

Condition (B)

TYPICAL ENABLING CONDITIONS TABLE - B

TYPICAL MALFUNCTION THRESHOLDS

MIL operation2 driving cycles

Sequence of operationNone

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear5th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more (Varies with engine speed)

ECM selected gear6th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5ohms or more (Varies with engine speed)

Page 2778 of 4500

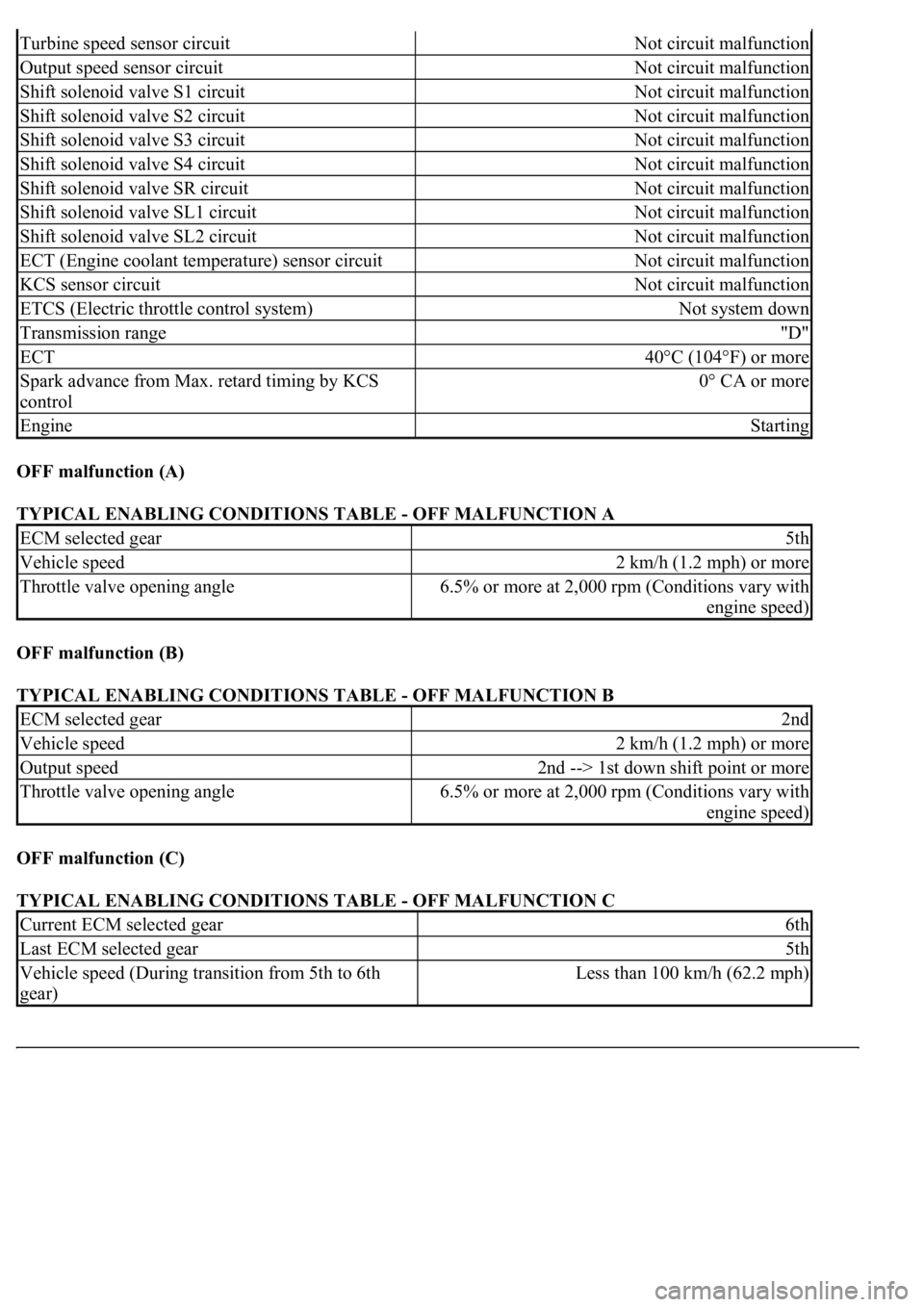

OFF malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION B

OFF malfunction (C)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION C

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear5th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

ECM selected gear2nd

Vehicle speed2 km/h (1.2 mph) or more

Output speed2nd --> 1st down shift point or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

Current ECM selected gear6th

Last ECM selected gear5th

Vehicle speed (During transition from 5th to 6th

gear)Less than 100 km/h (62.2 mph)

Page 2786 of 4500

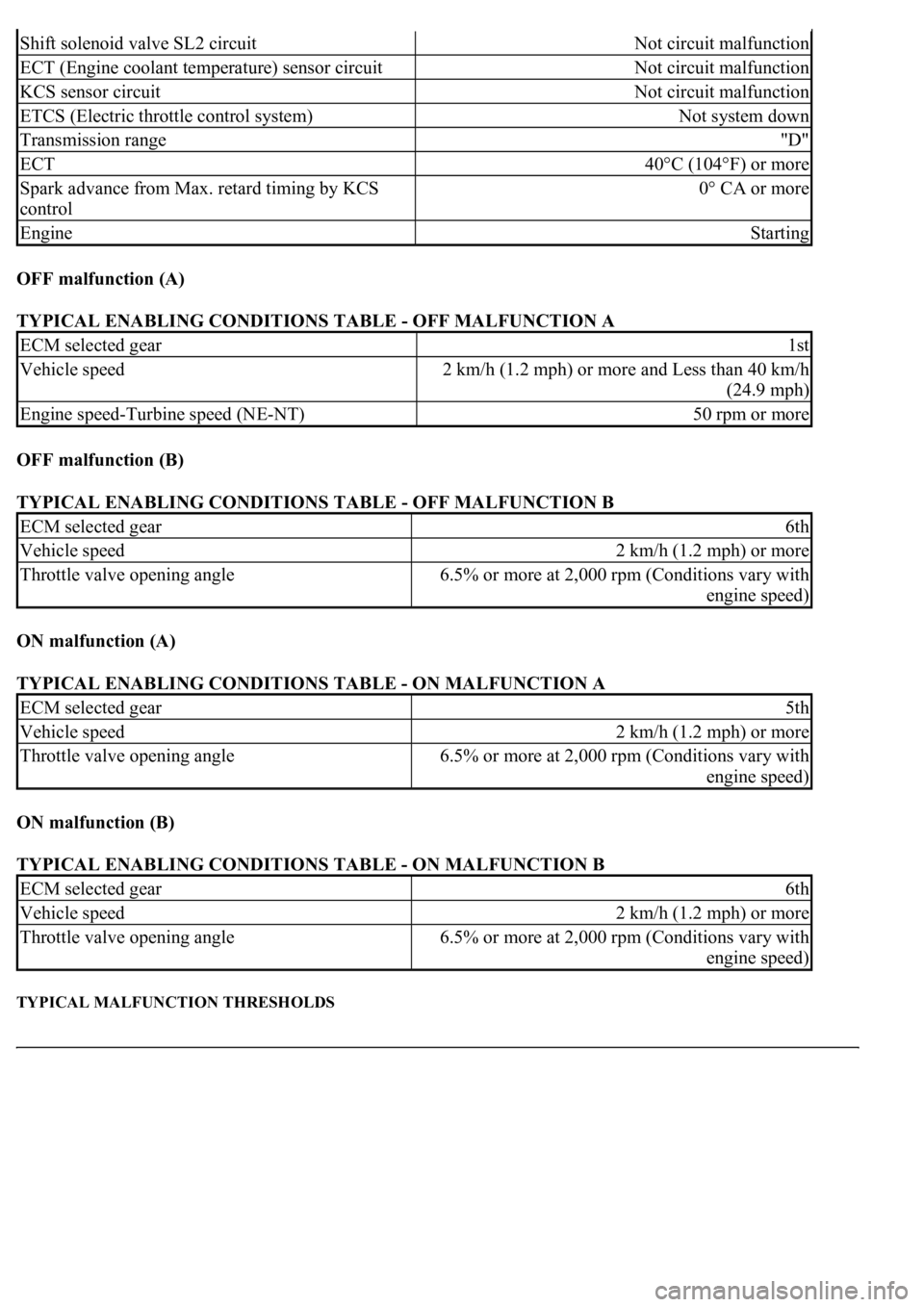

OFF malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION B

ON malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - ON MALFUNCTION A

ON malfunction (B)

TYPICAL ENABLING CONDITIONS TABLE - ON MALFUNCTION B

TYPICAL MALFUNCTION THRESHOLDS

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear1st

Vehicle speed2 km/h (1.2 mph) or more and Less than 40 km/h

(24.9 mph)

Engine speed-Turbine speed (NE-NT)50 rpm or more

ECM selected gear6th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

ECM selected gear5th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

ECM selected gear6th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

Page 2793 of 4500

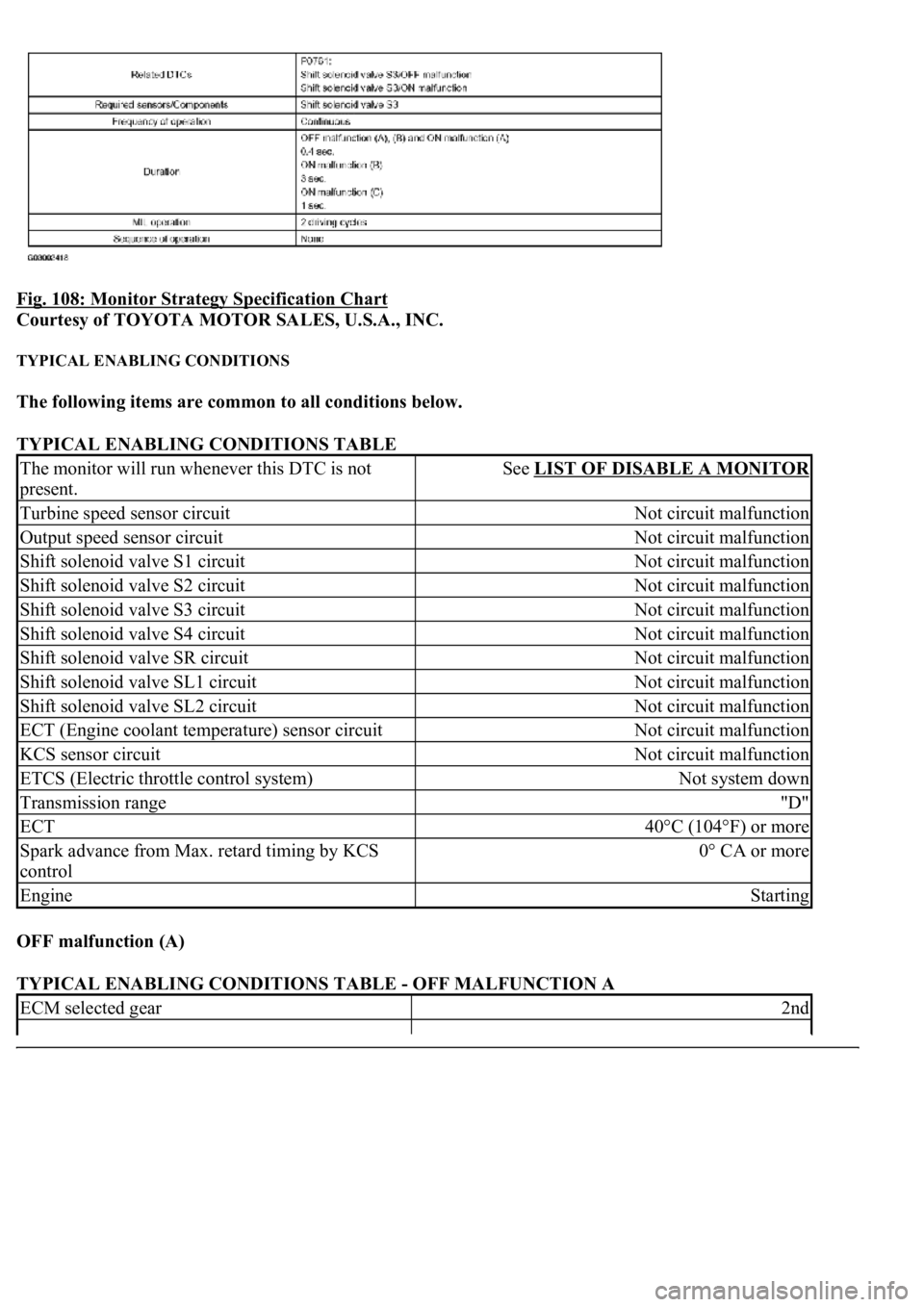

Fig. 108: Monitor Strategy Specification Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below.

TYPICAL ENABLING CONDITIONS TABLE

OFF malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION A

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear2nd

Page 2803 of 4500

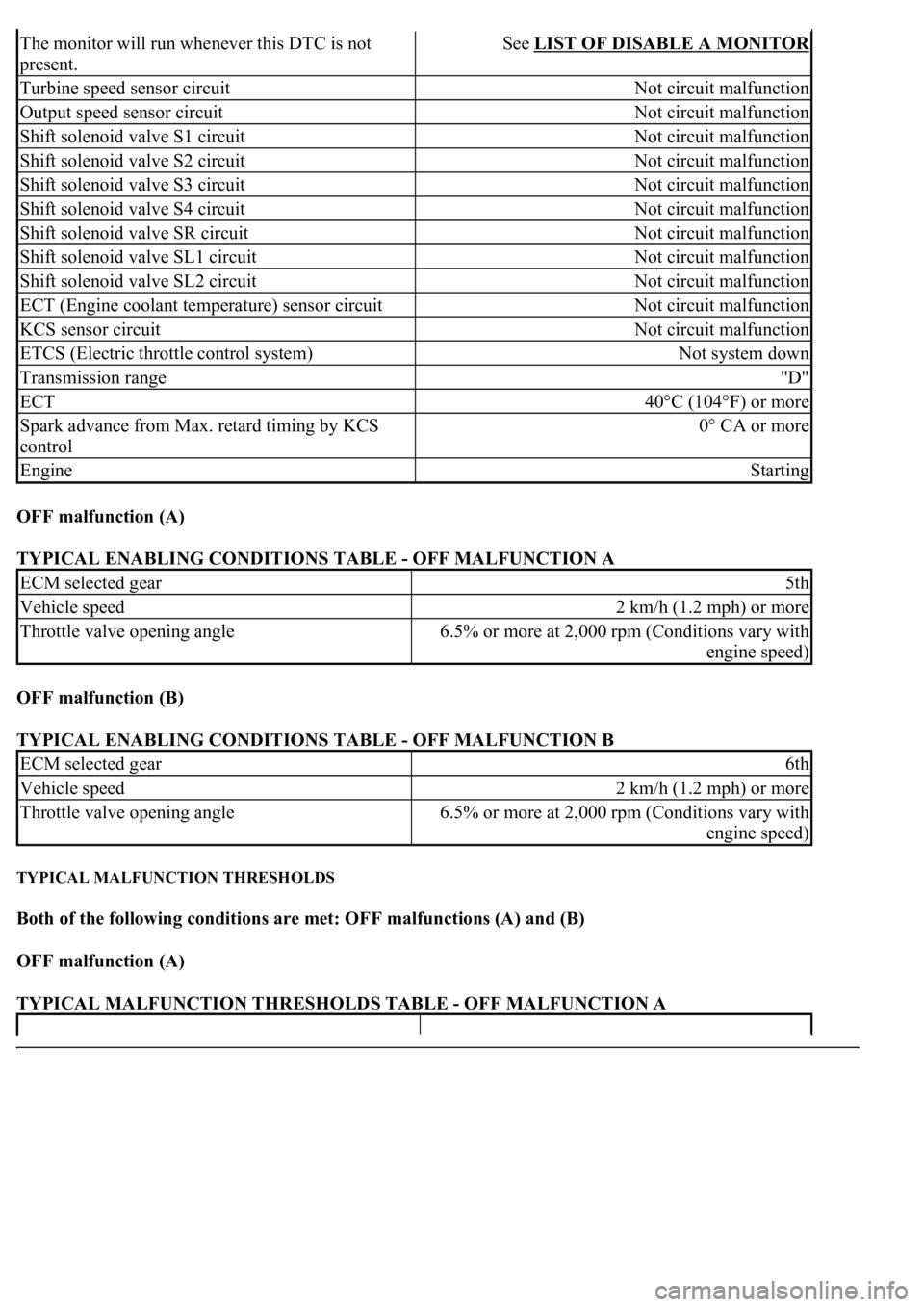

OFF malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION B

TYPICAL MALFUNCTION THRESHOLDS

Both of the following conditions are met: OFF malfunctions (A) and (B)

OFF malfunction (A)

TYPICAL MALFUNCTION THRESHOLDS TABLE - OFF MALFUNCTION A

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear5th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

ECM selected gear6th

Vehicle speed2 km/h (1.2 mph) or more

Throttle valve opening angle6.5% or more at 2,000 rpm (Conditions vary with

engine speed)

Page 2820 of 4500

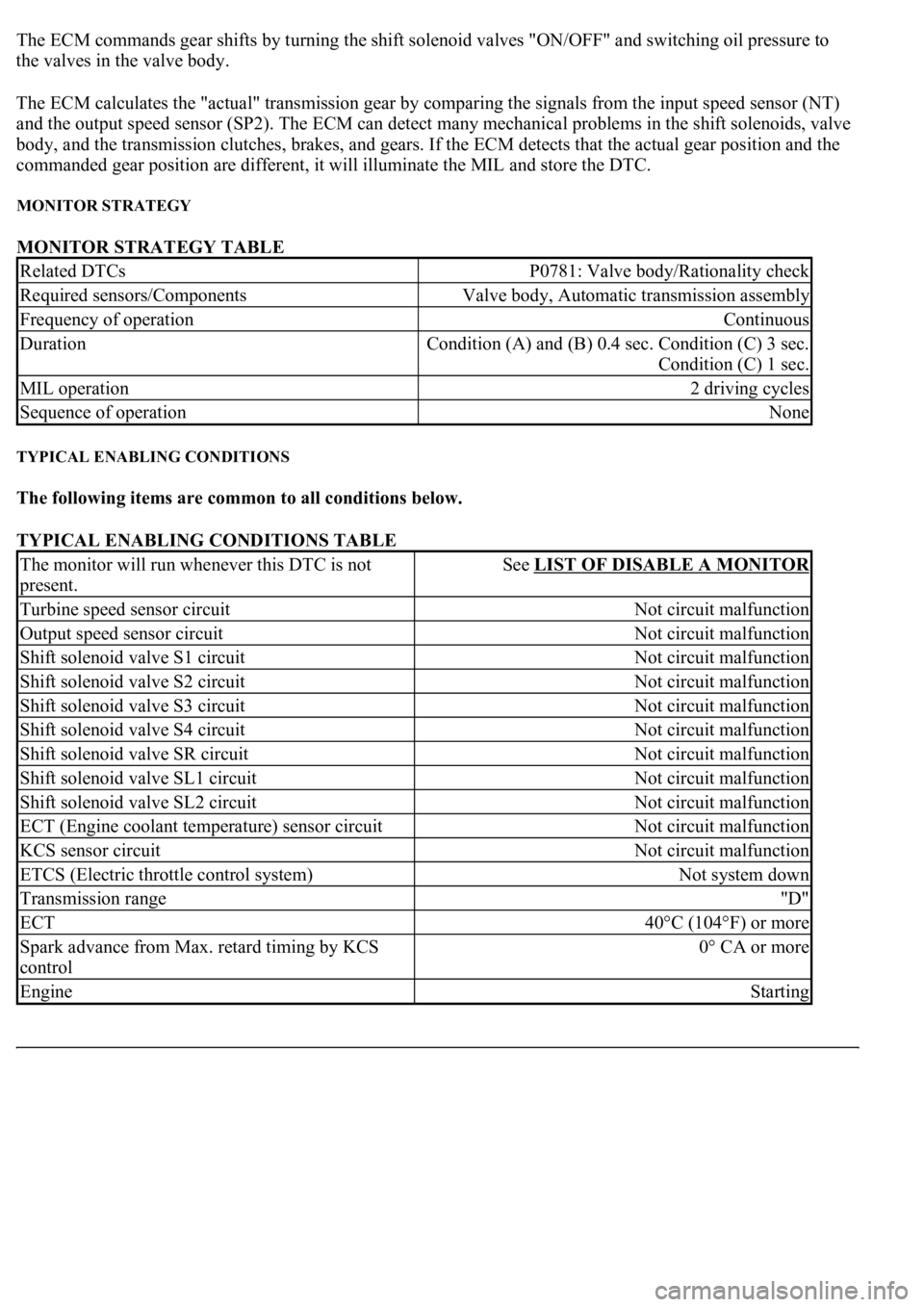

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF" and switching oil pressure to

the valves in the valve body.

The ECM calculates the "actual" transmission gear by comparing the signals from the input speed sensor (NT)

and the output speed sensor (SP2). The ECM can detect many mechanical problems in the shift solenoids, valve

body, and the transmission clutches, brakes, and gears. If the ECM detects that the actual gear position and the

commanded gear position are different, it will illuminate the MIL and store the DTC.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below.

TYPICAL ENABLING CONDITIONS TABLE

Related DTCsP0781: Valve body/Rationality check

Required sensors/ComponentsValve body, Automatic transmission assembly

Frequency of operationContinuous

Duration<0026005200510047004c0057004c005200510003000b0024000c00030044005100470003000b0025000c00030013001100170003005600480046001100030026005200510047004c0057004c005200510003000b0026000c00030016000300560048004600

110003[

Condition (C) 1 sec.

MIL operation2 driving cycles

Sequence of operationNone

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

Page 2870 of 4500

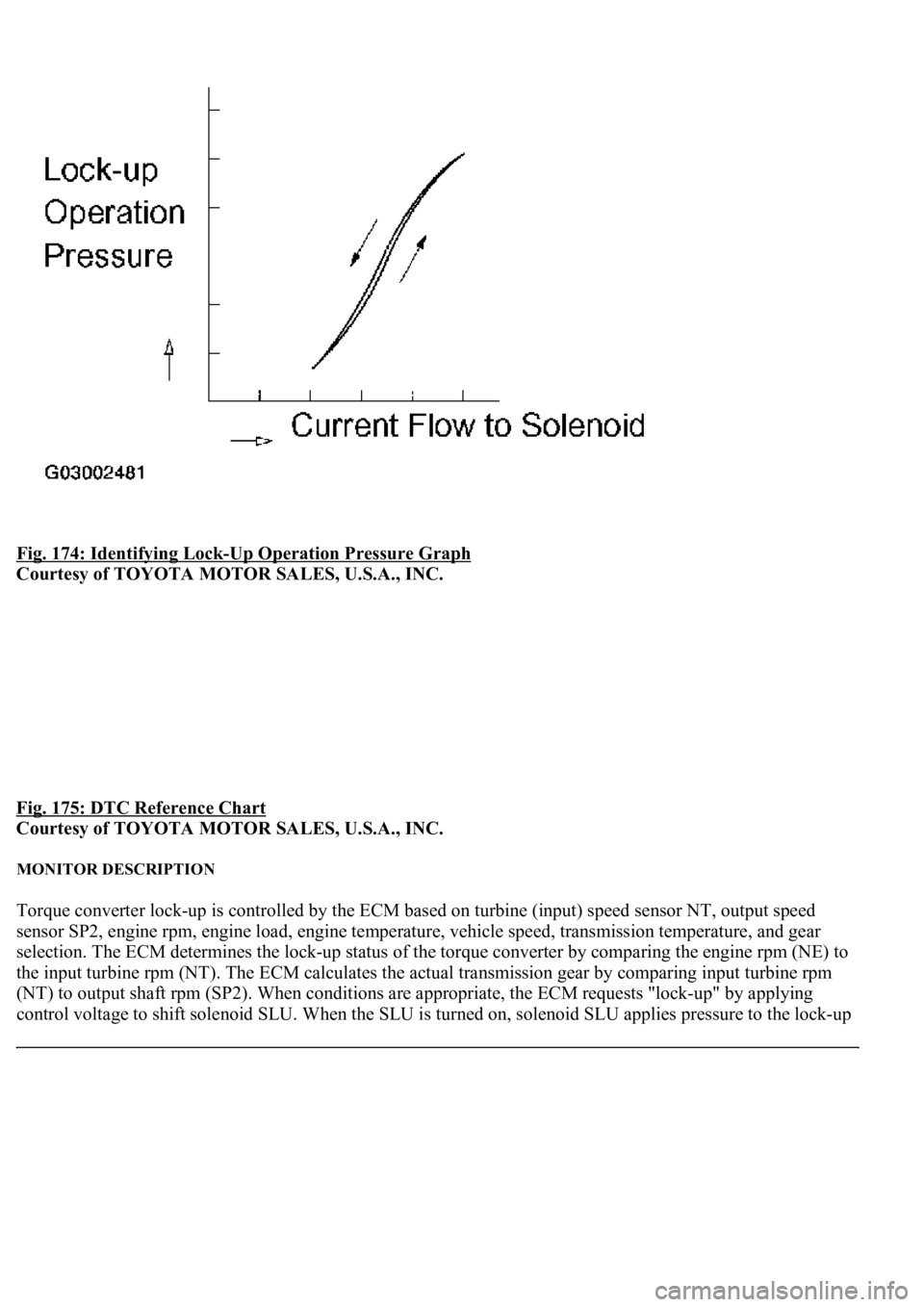

Fig. 174: Identifying Lock-Up Operation Pressure Graph

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 175: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on turbine (input) speed sensor NT, output speed

sensor SP2, engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and gear

selection. The ECM determines the lock-up status of the torque converter by comparing the engine rpm (NE) to

the input turbine rpm (NT). The ECM calculates the actual transmission gear by comparing input turbine rpm

(NT) to output shaft rpm (SP2). When conditions are appropriate, the ECM requests "lock-up" by applying

control volta

ge to shift solenoid SLU. When the SLU is turned on, solenoid SLU applies pressure to the lock-up

Page 2872 of 4500

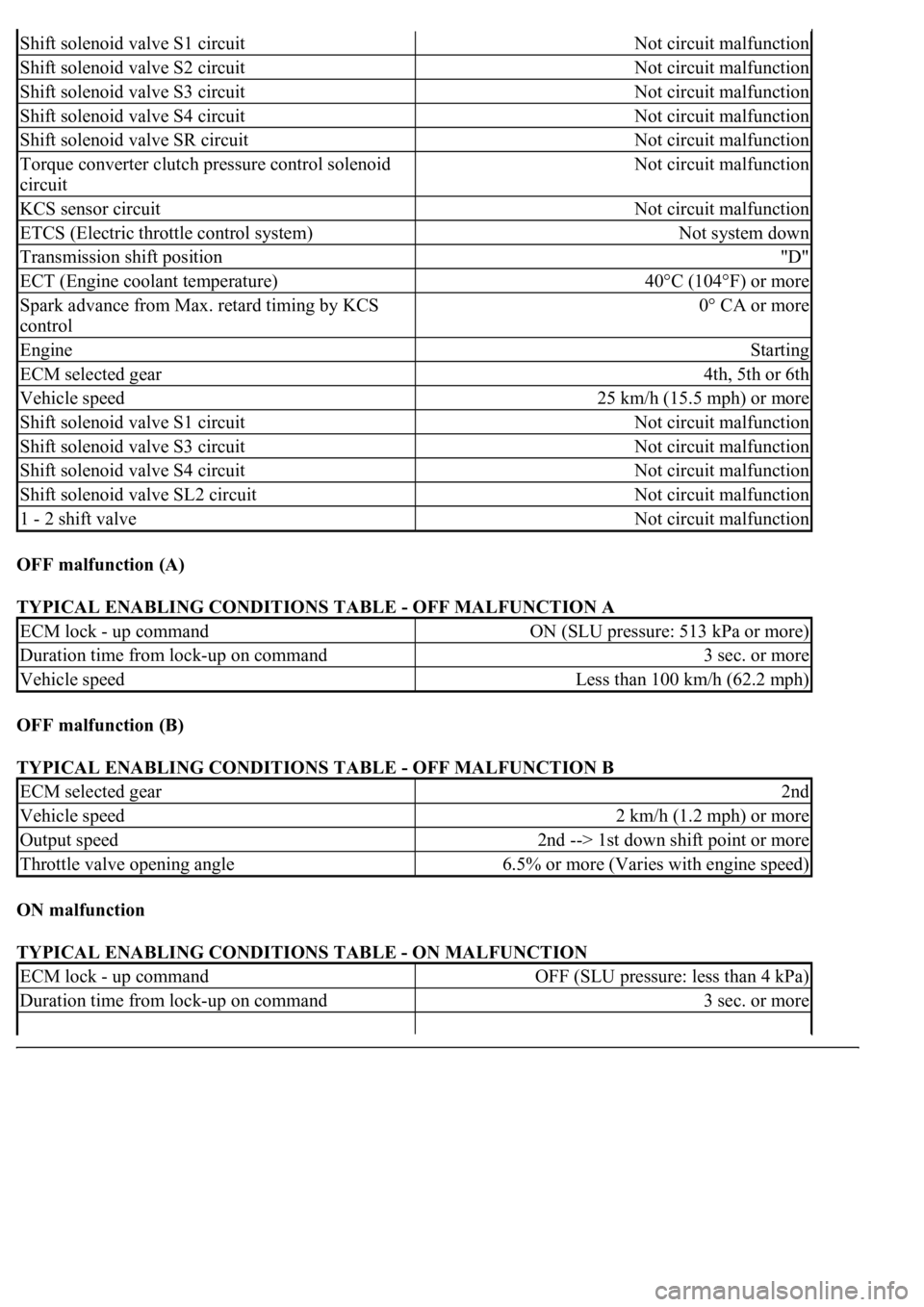

OFF malfunction (A)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION A

OFF malfunction (B)

TYPICAL ENABLING CONDITIONS TABLE - OFF MALFUNCTION B

ON malfunction

TYPICAL ENABLING CONDITIONS TABLE - ON MALFUNCTION

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Torque converter clutch pressure control solenoid

circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission shift position"D"

ECT (Engine coolant temperature)40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

ECM selected gear4th, 5th or 6th

Vehicle speed25 km/h (15.5 mph) or more

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

1 - 2 shift valveNot circuit malfunction

ECM lock - up commandON (SLU pressure: 513 kPa or more)

Duration time from lock-up on command3 sec. or more

Vehicle speedLess than 100 km/h (62.2 mph)

ECM selected gear2nd

Vehicle speed2 km/h (1.2 mph) or more

Output speed2nd --> 1st down shift point or more

Throttle valve opening angle6.5% or more (Varies with engine speed)

ECM lock - up commandOFF (SLU pressure: less than 4 kPa)

Duration time from lock-up on command3 sec. or more

Page 2950 of 4500

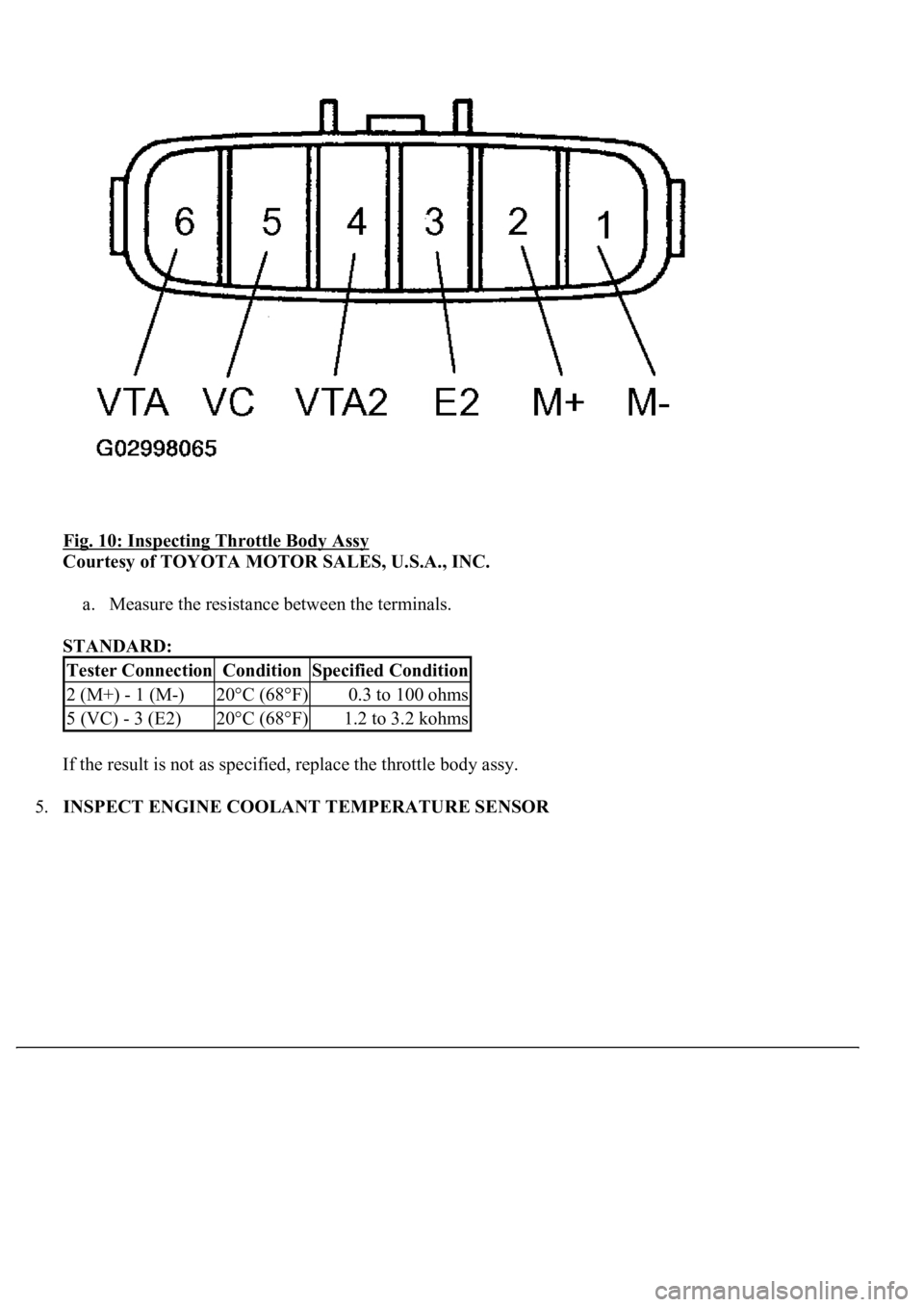

Fig. 10: Inspecting Throttle Body Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Measure the resistance between the terminals.

STANDARD:

If the result is not as specified, replace the throttle body assy.

5.INSPECT ENGINE COOLANT TEMPERATURE SENSOR

Tester ConnectionConditionSpecified Condition

2 (M+) - 1 (M-)20°C (68°F)0.3 to 100 ohms

5 (VC) - 3 (E2)20°C (68°F)1.2 to 3.2 kohms