LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Page 168 of 4500

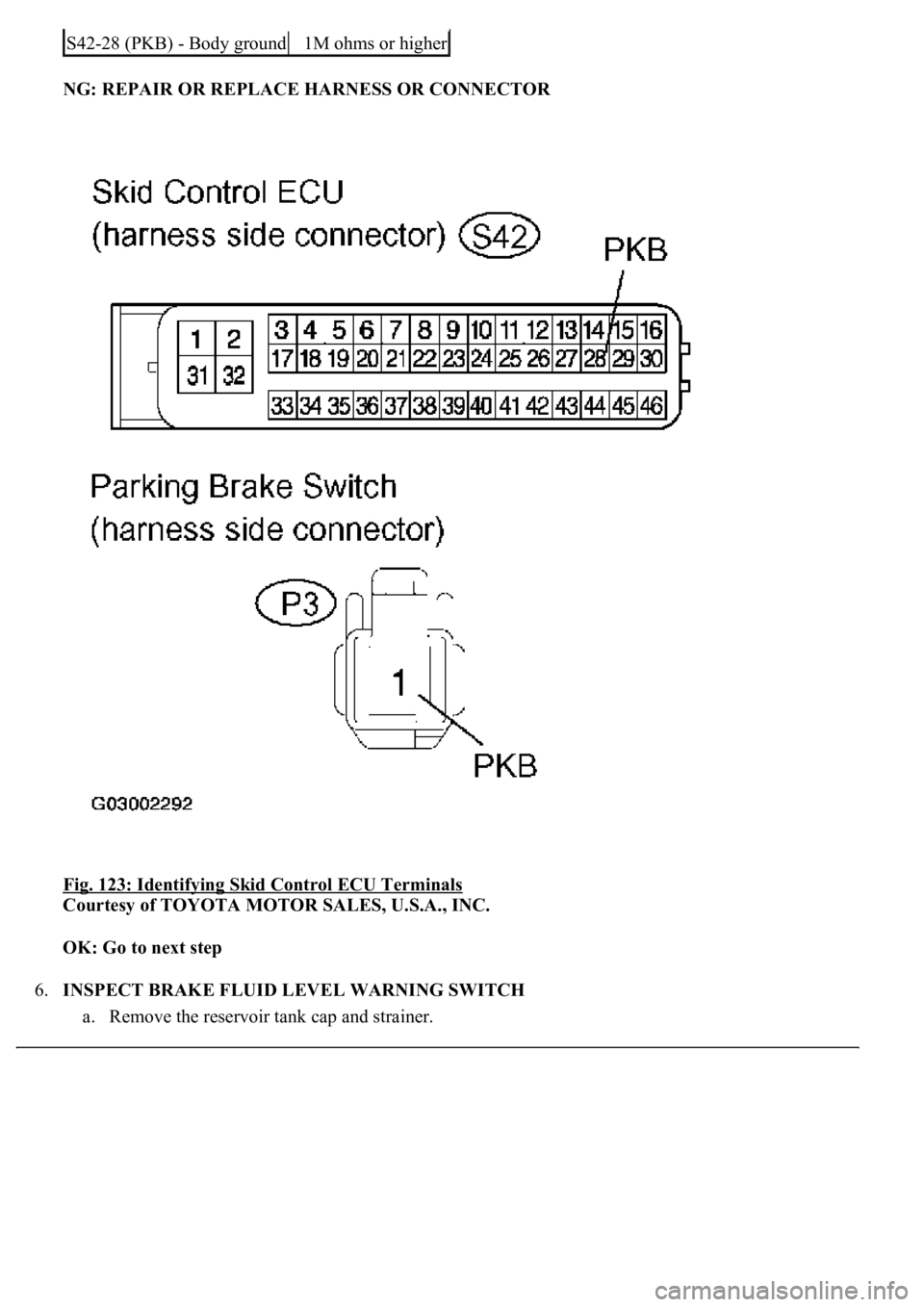

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Fig. 123: Identifying Skid Control ECU Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: Go to next step

6.INSPECT BRAKE FLUID LEVEL WARNING SWITCH

a. Remove the reservoir tank cap and strainer.

S42-28 (PKB) - Body ground1M ohms or higher

Page 1847 of 4500

6.INSPECT LOW OIL PRESSURE WARNING LIGHT

a. Disconnect the connector from the low oil pressure switch.

b. Turn the ignition switch to the ON position.

c. Ground the terminal of the wire harness side connector, then check the low oil pressure warning

light.

OK:

Low oil pressure warning light comes on.

7.INSPECT BRAKE WARNING LIGHT

a. Inspect the parking brake warning light.

1. Disconnect the connector from the parking brake switch

2. Turn the ignition switch to the ON position.

3. Ground the terminal of the wire harness side connector, then check the parking brake

warning light.

OK:

Brake warning light comes on.

b. Inspect the brake fluid level warning light.

1. Disconnect the connector from the brake fluid level warning switch.

2. Turn the ignition switch to the ON position.

3. Connect a terminal to the other terminal of the wire harness side connector, then check the

brake fluid level warning switch.

OK:

Brake warning light comes on.

8.INSPECT BRAKE FLUID LEVEL WARNING SWITCH

a. Remove the reservoir tank cap and strainer.

b. Disconnect the connector.

c. Measure the resistance between the terminals.

Standard:

Float up (switch off): 10 kohms or higher

d. Use a syphon, etc. to take fluid out of the reservoir tank.

e. Measure the resistance between the terminals.

Page 1848 of 4500

Standard:

Float down (switch on): Below 1 ohms

f. Pour the fluid back in the reservoir tank.

9.INSPECT WASHER LEVEL WARNING SWITCH

a. Disconnect the connector from the washer level warning switch.

b. Turn the ignition switch to the ON position.

c. Ground the terminal of the wire harness side connector, then check the washer level warning light.

OK:

Washer level warning light comes on.

10.MAINTENANCE LIQUID RESETTING PROCEDURE

a. Check that the display for ODO/TRIP shows no value (BLANK).

b. Turn the ignition switch off.

c. Pressing the reset switch, turn the ignition switch to the ON (keep pressing at least for 5 seconds).

d. The reset procedure is completed.

HINT:

During reset procedure:

"Mileage Reset" is displayed and the master warning light comes on with a buzzer sound.

Completion of reset procedure:

"Mileage Reset" and the master warning light go off.

If the ignition switch is turned off during reset procedure, reset mode is canceled.

If the reset switch is turned off during the reset procedure, reset mode is canceled and the display

shows the condition prior to the reset procedure.

If "Maint Reqd Soon" is displayed, it goes off 15 seconds after turning the ignition switch to the

ON position.

Page 1883 of 4500

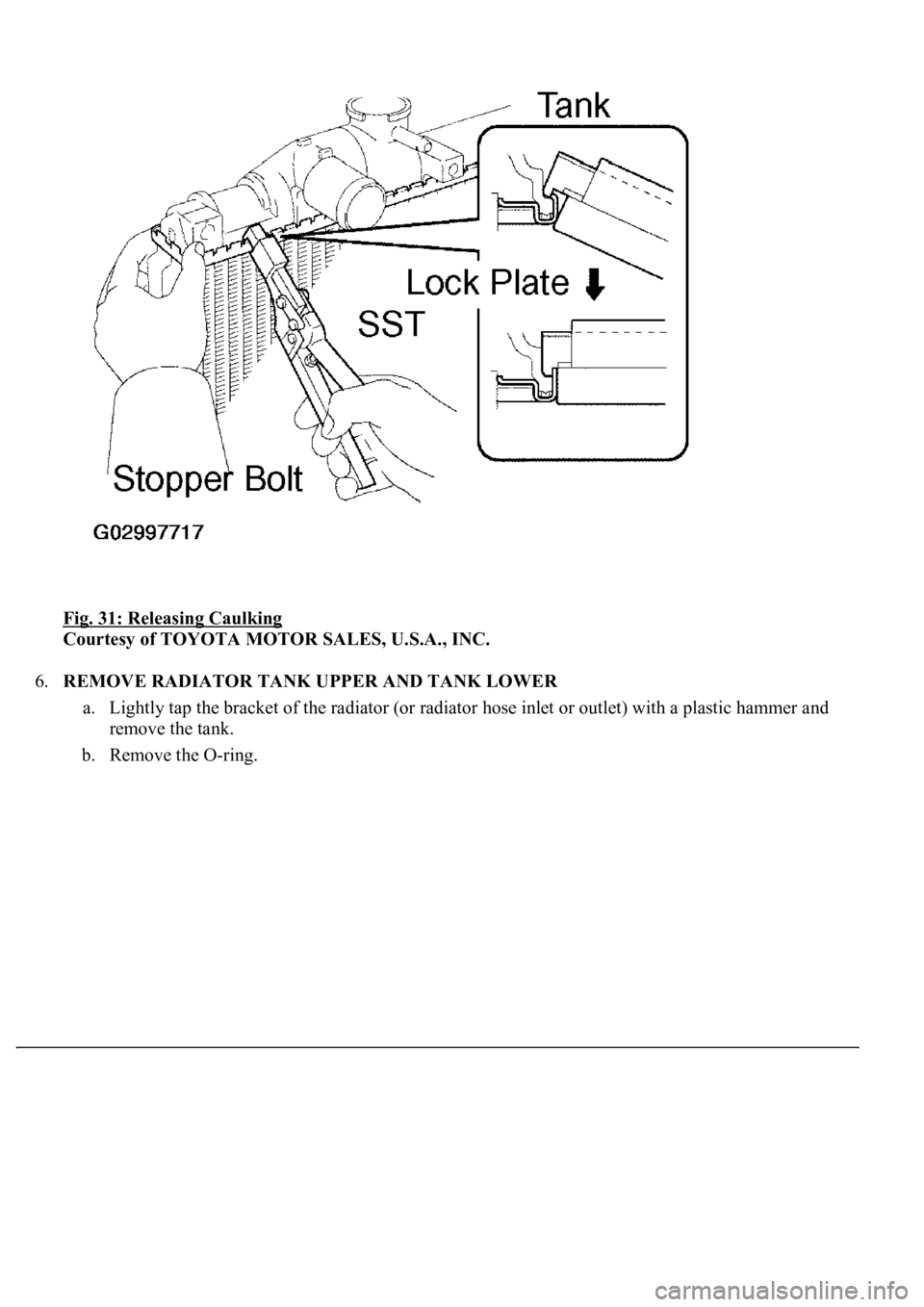

Fig. 31: Releasing Caulking

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

6.REMOVE RADIATOR TANK UPPER AND TANK LOWER

a. Lightly tap the bracket of the radiator (or radiator hose inlet or outlet) with a plastic hammer and

remove the tank.

b. Remove the O-ring.

Page 1885 of 4500

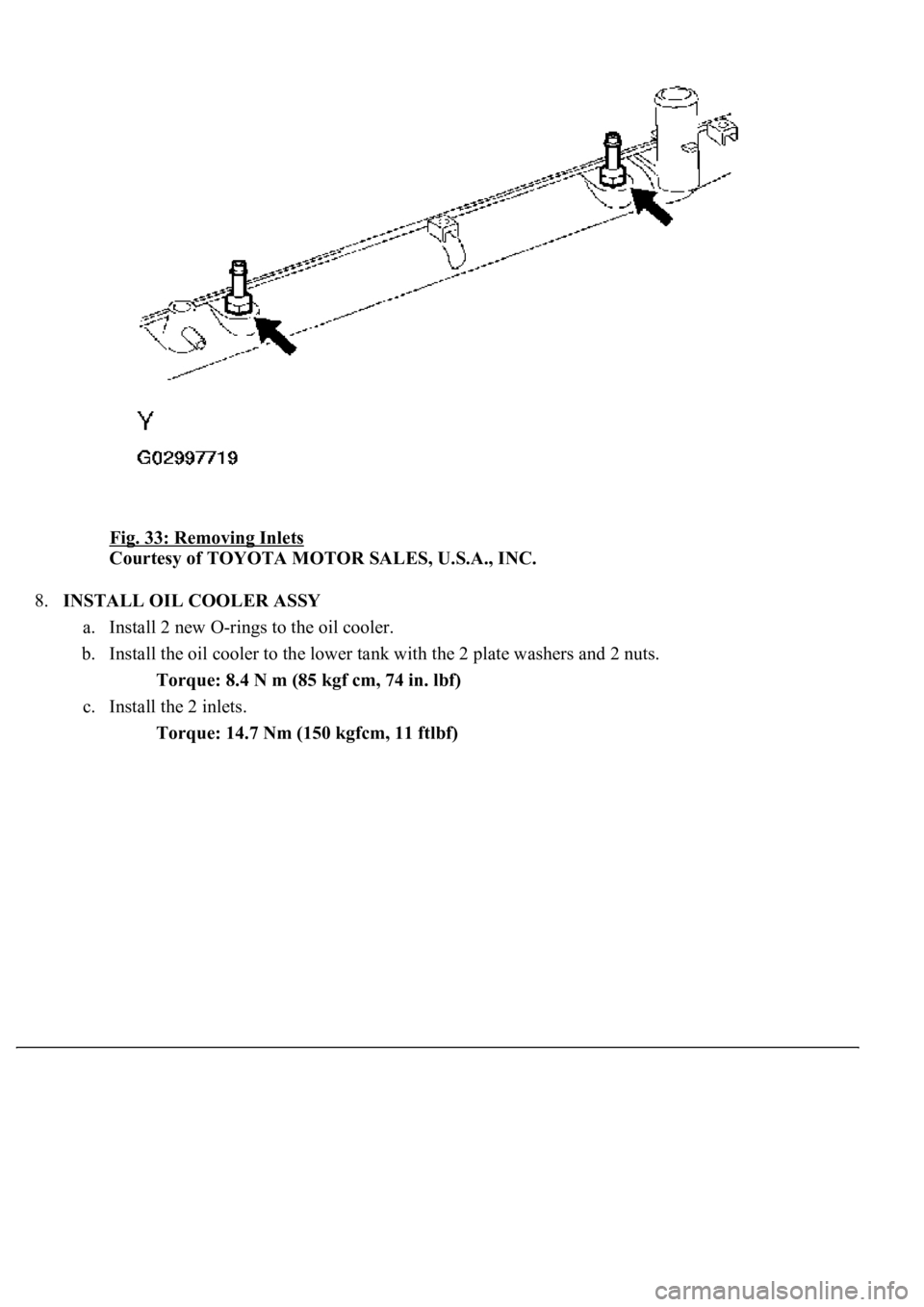

Fig. 33: Removing Inlets

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8.INSTALL OIL COOLER ASSY

a. Install 2 new O-rings to the oil cooler.

b. Install the oil cooler to the lower tank with the 2 plate washers and 2 nuts.

Torque: 8.4 N m (85 kgf cm, 74 in. lbf)

c. Install the 2 inlets.

Torque: 14.7 Nm (150 kgfcm, 11 ftlbf)

Page 1886 of 4500

Fig. 34: Installing New O-Rings To Oil Cooler

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

9.INSPECT LOCK PLATE FOR DAMAGE

Inspect the lock plate for damage.

HINT:

If the sides of the lock plate groove are deformed, reassembly of the tank will be impossible.

Correct any deformations with pliers.

Water leakage will result if the bottom of the lock plate groove is damaged or dented. Repair or

replace if necessar

y.

Page 1887 of 4500

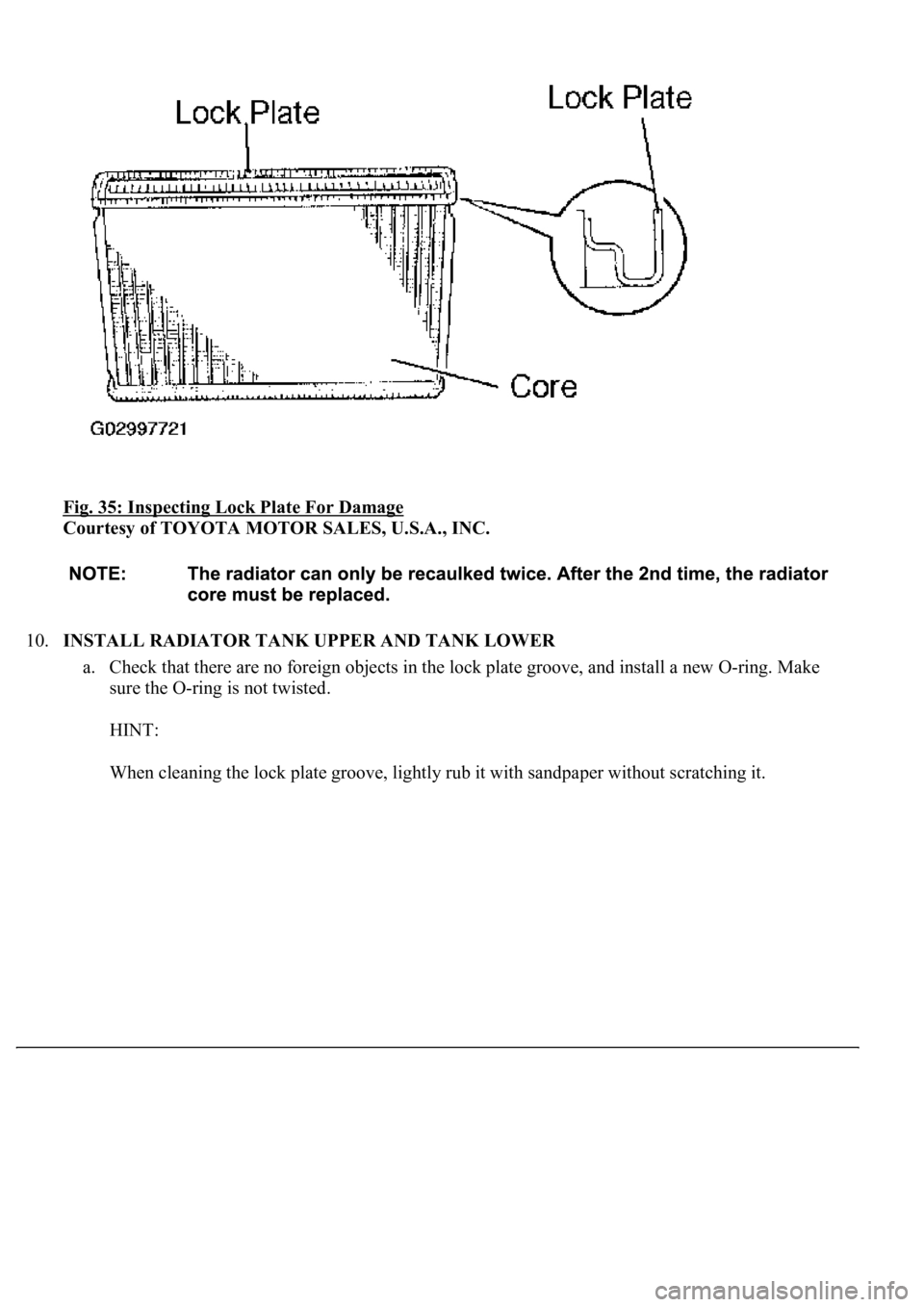

Fig. 35: Inspecting Lock Plate For Damage

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

10.INSTALL RADIATOR TANK UPPER AND TANK LOWER

a. Check that there are no foreign objects in the lock plate groove, and install a new O-ring. Make

sure the O-ring is not twisted.

HINT:

When cleanin

g the lock plate groove, lightly rub it with sandpaper without scratching it.

Page 1888 of 4500

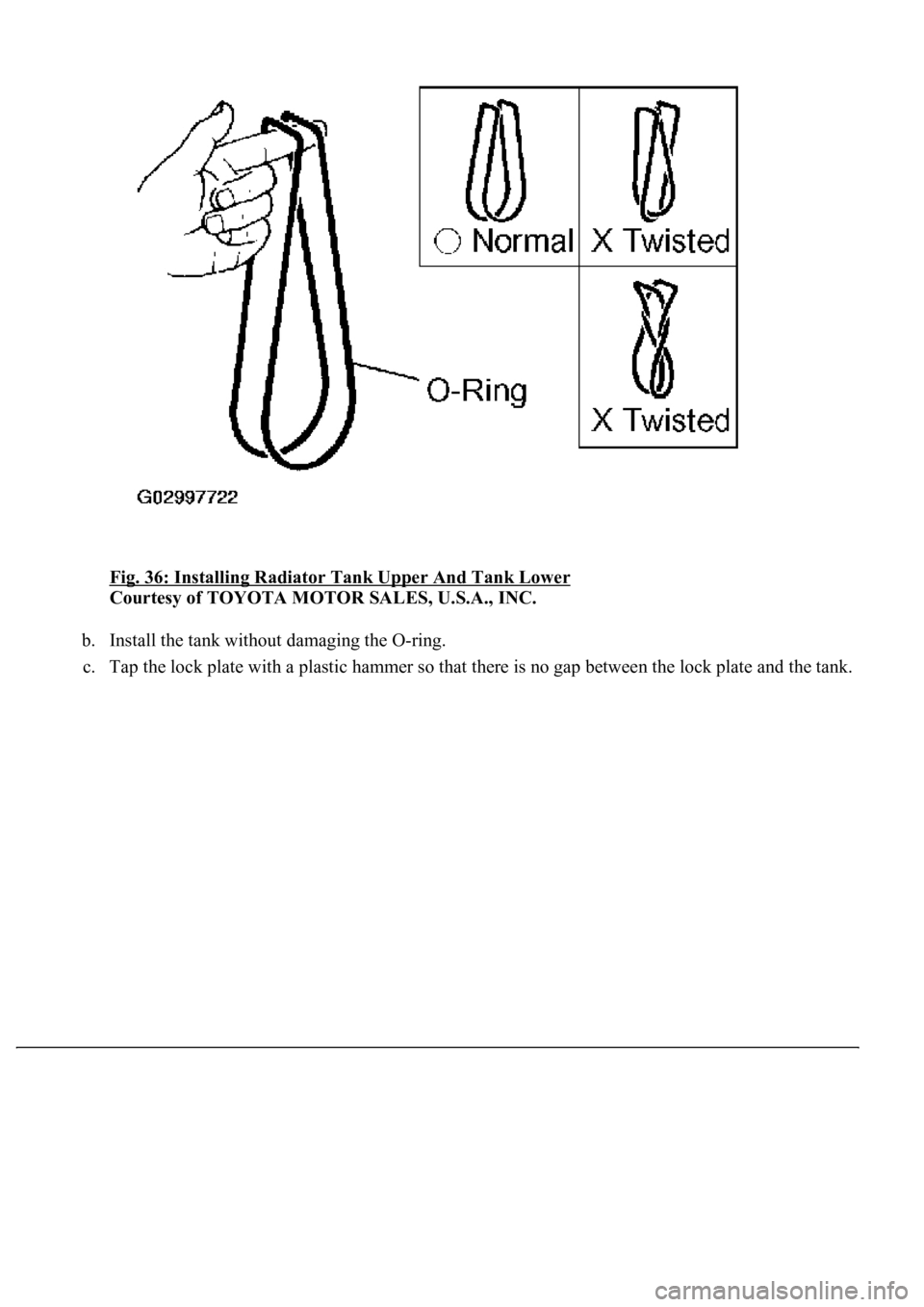

Fig. 36: Installing Radiator Tank Upper And Tank Lower

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

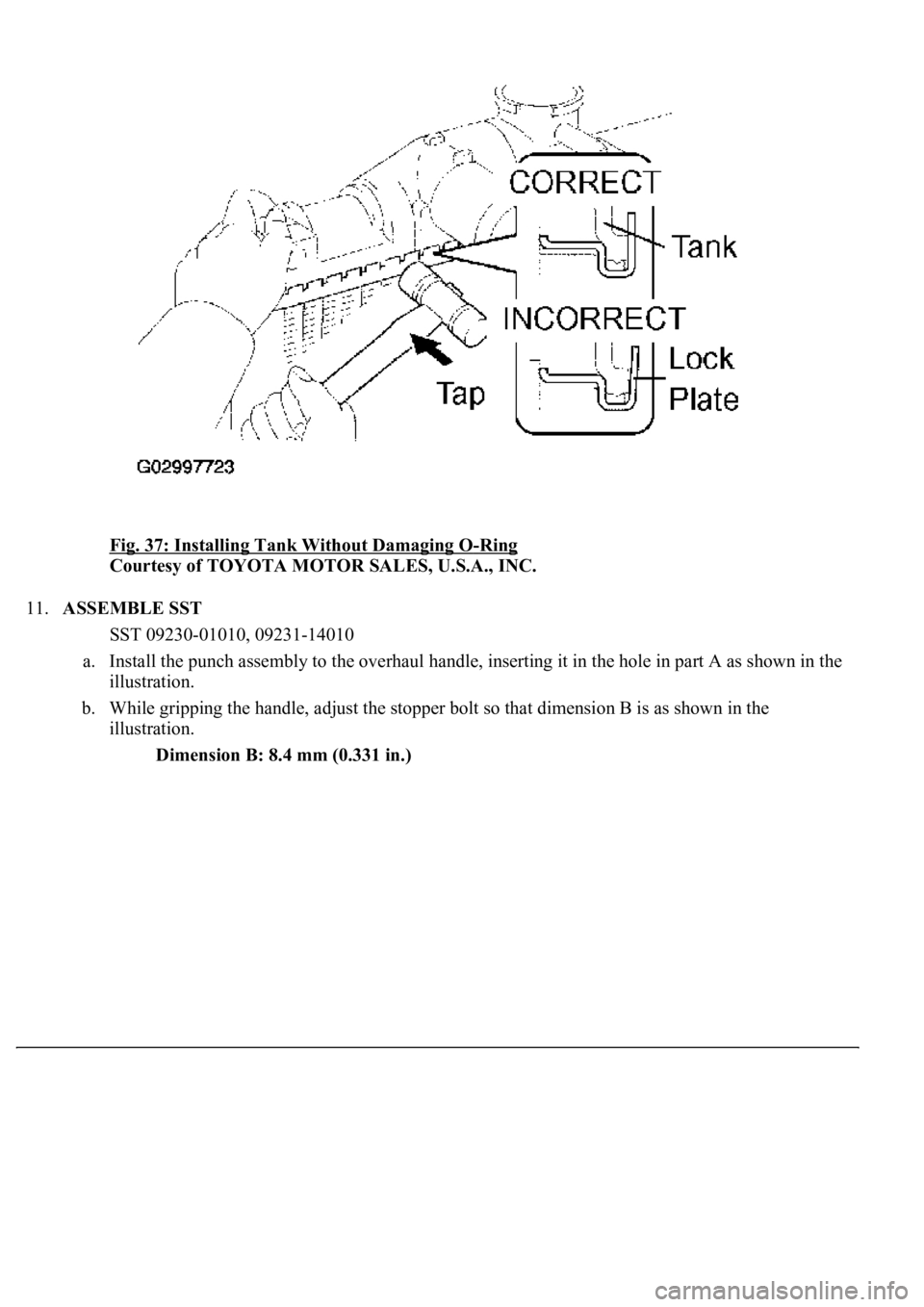

b. Install the tank without damaging the O-ring.

c. Tap the lock plate with a plastic hammer so that there is no

gap between the lock plate and the tank.

Page 1889 of 4500

Fig. 37: Installing Tank Without Damaging O-Ring

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

11.ASSEMBLE SST

SST 09230-01010, 09231-14010

a. Install the punch assembly to the overhaul handle, inserting it in the hole in part A as shown in the

illustration.

b. While gripping the handle, adjust the stopper bolt so that dimension B is as shown in the

illustration.

Dimension B: 8.4 mm (0.331 in.)

Page 1895 of 4500

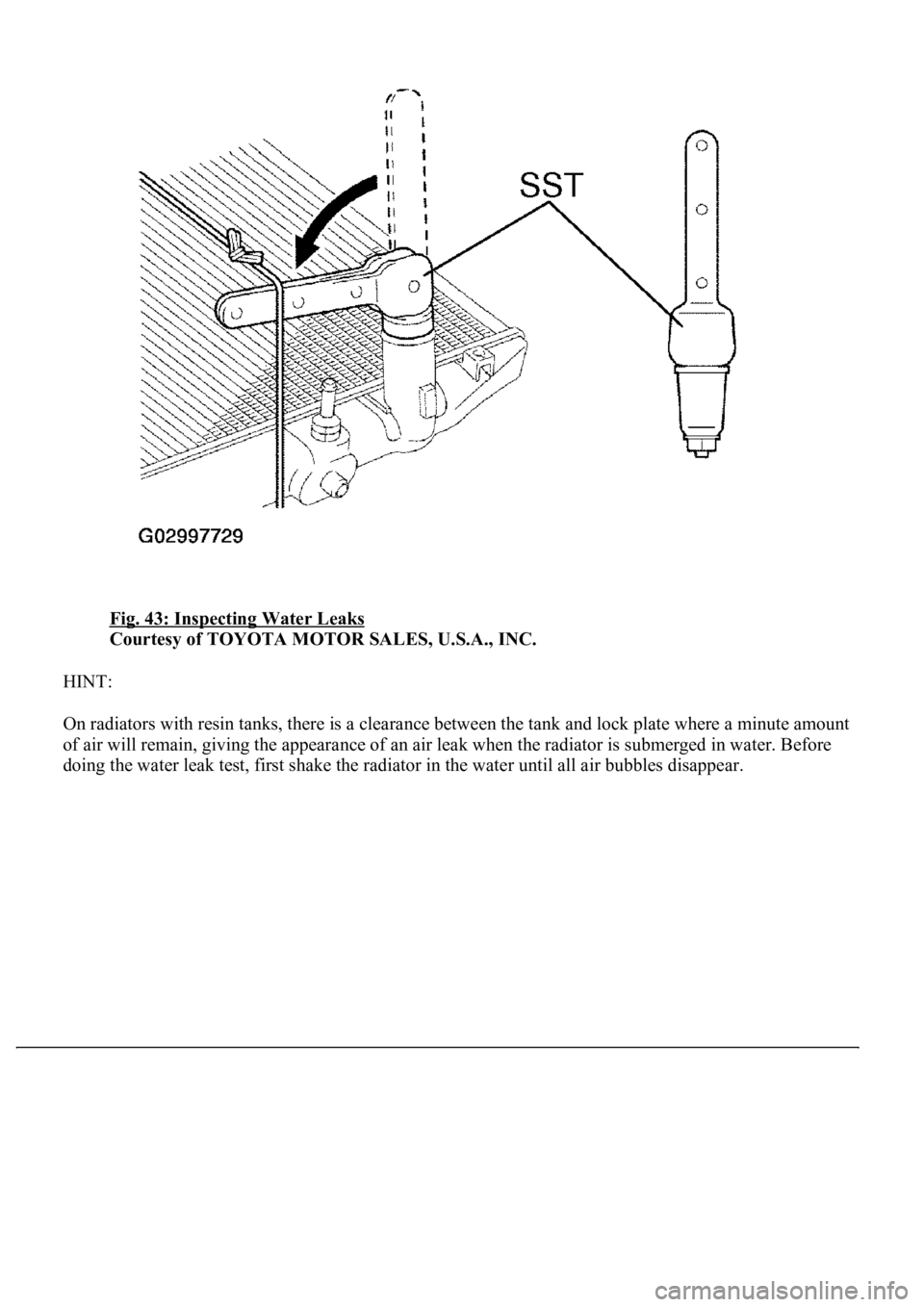

Fig. 43: Inspecting Water Leaks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

On radiators with resin tanks, there is a clearance between the tank and lock plate where a minute amount

of air will remain, giving the appearance of an air leak when the radiator is submerged in water. Before

doin

g the water leak test, first shake the radiator in the water until all air bubbles disappear.