torque LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1264 of 4087

CHECK AND REPLACEMENT OF

ENGINE COOLANT

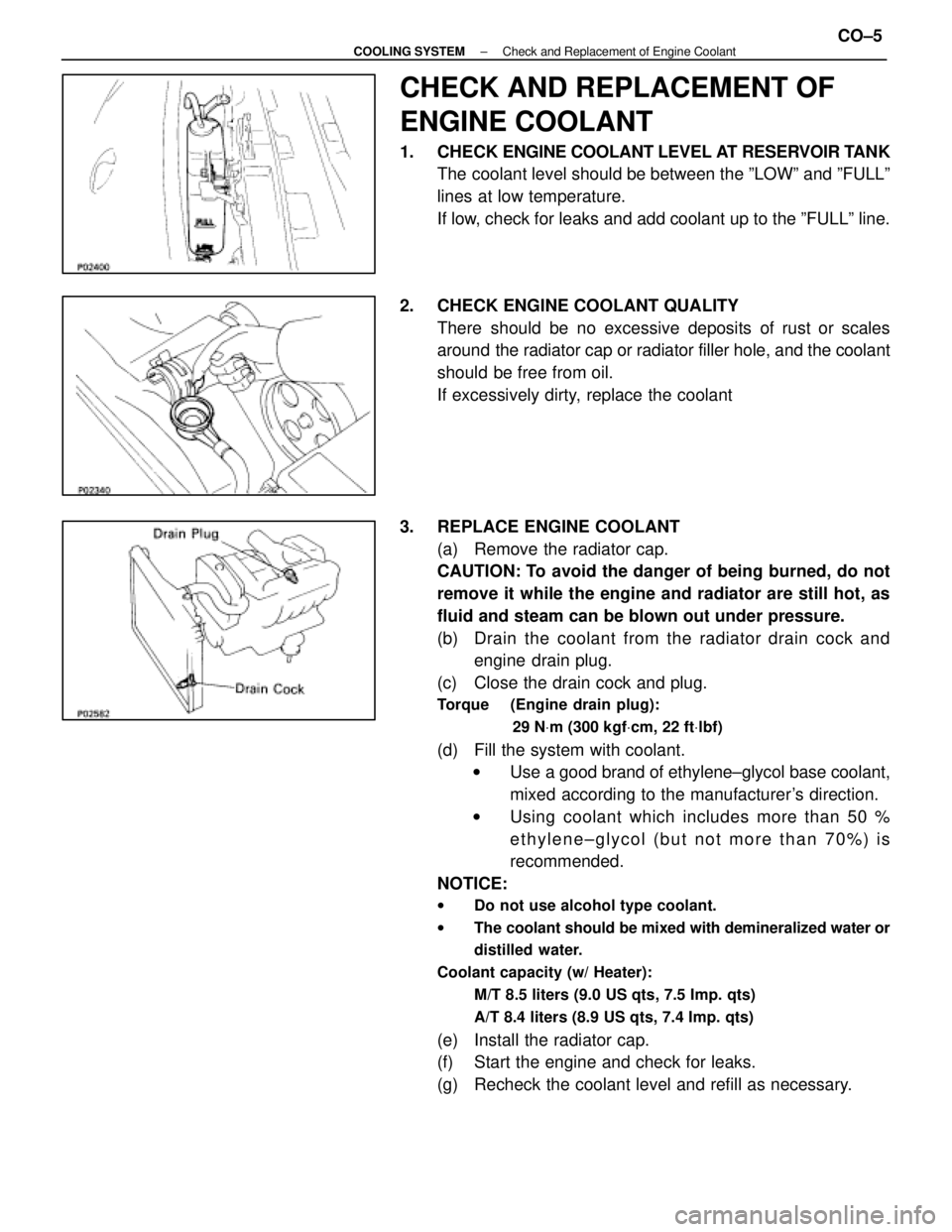

1. CHECK ENGINE COOLANT LEVEL AT RESERVOIR TANK

The coolant level should be between the ºLOWº and ºFULLº

lines at low temperature.

If low, check for leaks and add coolant up to the ºFULLº line.

2. CHECK ENGINE COOLANT QUALITY There should be no excessive deposits of rust or scales

around the radiator cap or radiator filler hole, and the coolant

should be free from oil.

If excessively dirty, replace the coolant

3. REPLACE ENGINE COOLANT (a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not

remove it while the engine and radiator are still hot, as

fluid and steam can be blown out under pressure.

(b) Drain the coolant from the radiator drain cock andengine drain plug.

(c) Close the drain cock and plug.

Torque (Engine drain plug):

29 NVm (300 kgf Vcm, 22 ft Vlbf)

(d) Fill the system with coolant.

w Use a good brand of ethylene±glycol base coolant,

mixed according to the manufacturer's direction.

w Using coolant which includes more than 50 %

ethylene±glycol (but not more than 70%) is

recommended.

NOTICE:

w Do not use alcohol type coolant.

w The coolant should be mixed with demineralized water or

distilled water.

Coolant capacity (w/ Heater): M/T 8.5 liters (9.0 US qts, 7.5 Imp. qts)

A/T 8.4 liters (8.9 US qts, 7.4 Imp. qts)

(e) Install the radiator cap.

(f) Start the engine and check for leaks.

(g) Recheck the coolant level and refill as necessary.

±

COOLING SYSTEM Check and Replacement of Engine CoolantCO±5

WhereEverybodyKnowsYourName

Page 1265 of 4087

CHECK AND REPLACEMENT OF

ENGINE COOLANT

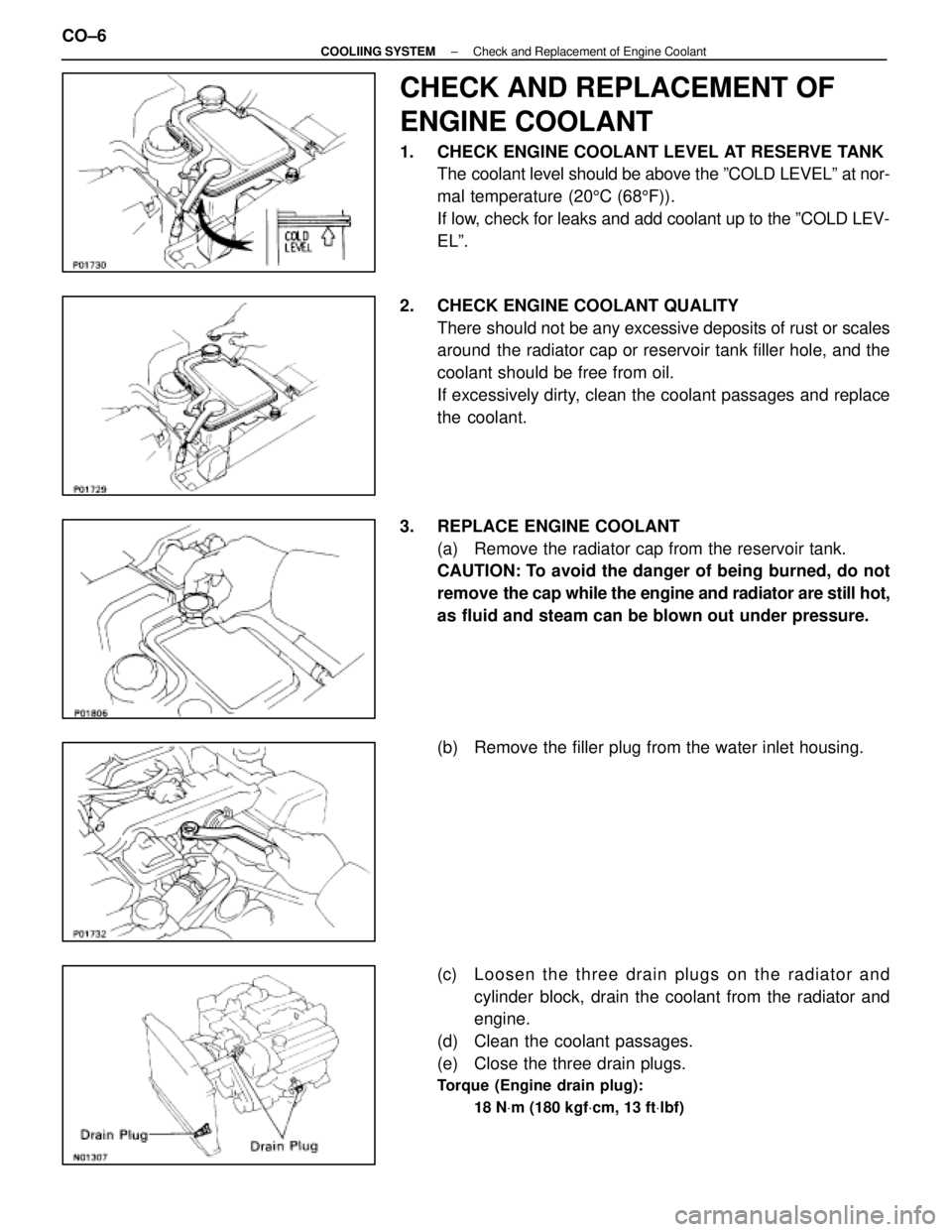

1. CHECK ENGINE COOLANT LEVEL AT RESERVE TANKThe coolant level should be above the ºCOLD LEVELº at nor-

mal temperature (20 5C (68 5F)).

If low, check for leaks and add coolant up to the ºCOLD LEV-

ELº.

2. CHECK ENGINE COOLANT QUALITY There should not be any excessive deposits of rust or scales

around the radiator cap or reservoir tank filler hole, and the

coolant should be free from oil.

If excessively dirty, clean the coolant passages and replace

the coolant.

3. REPLACE ENGINE COOLANT (a) Remove the radiator cap from the reservoir tank.

CAUTION: To avoid the danger of being burned, do not

remove the cap while the engine and radiator are still hot,

as fluid and steam can be blown out under pressure.

(b) Remove the filler plug from the water inlet housing.

(c) Loosen the three drain plugs on the radiator and

cylinder block, drain the coolant from the radiator and

engine.

(d) Clean the coolant passages.

(e) Close the three drain plugs.

Torque (Engine drain plug):

18 NVm (180 kgf Vcm, 13 ft Vlbf)

CO±6±

COOLIING SYSTEM Check and Replacement of Engine Coolant

WhereEverybodyKnowsYourName

Page 1266 of 4087

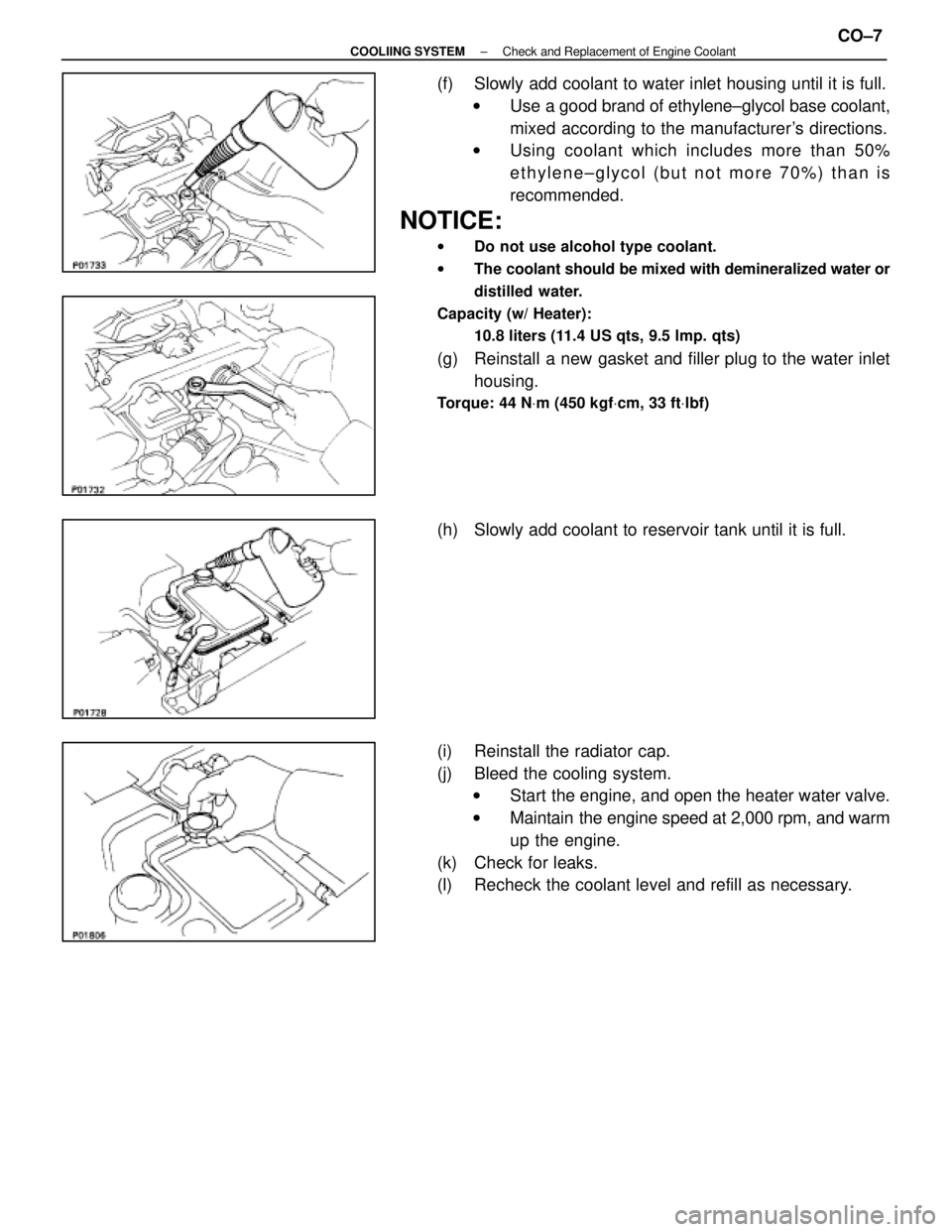

(f) Slowly add coolant to water inlet housing until it is full.w Use a good brand of ethylene±glycol base coolant,

mixed according to the manufacturer's directions.

w Using coolant which includes more than 50%

ethylene±glycol (but not more 70%) than is

recommended.

NOTICE:

w Do not use alcohol type coolant.

w The coolant should be mixed with demineralized water or

distilled water.

Capacity (w/ Heater): 10.8 liters (11.4 US qts, 9.5 lmp. qts)

(g) Reinstall a new gasket and filler plug to the water inlethousing.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(h) Slowly add coolant to reservoir tank until it is full.

(i) Reinstall the radiator cap.

(j) Bleed the cooling system.

w Start the engine, and open the heater water valve.

w Maintain the engine speed at 2,000 rpm, and warm

up the engine.

(k) Check for leaks.

(l) Recheck the coolant level and refill as necessary.

±

COOLIING SYSTEM Check and Replacement of Engine CoolantCO±7

WhereEverybodyKnowsYourName

Page 1269 of 4087

INSTALLATION OF WATER PUMP

(See Components on page CO±8)

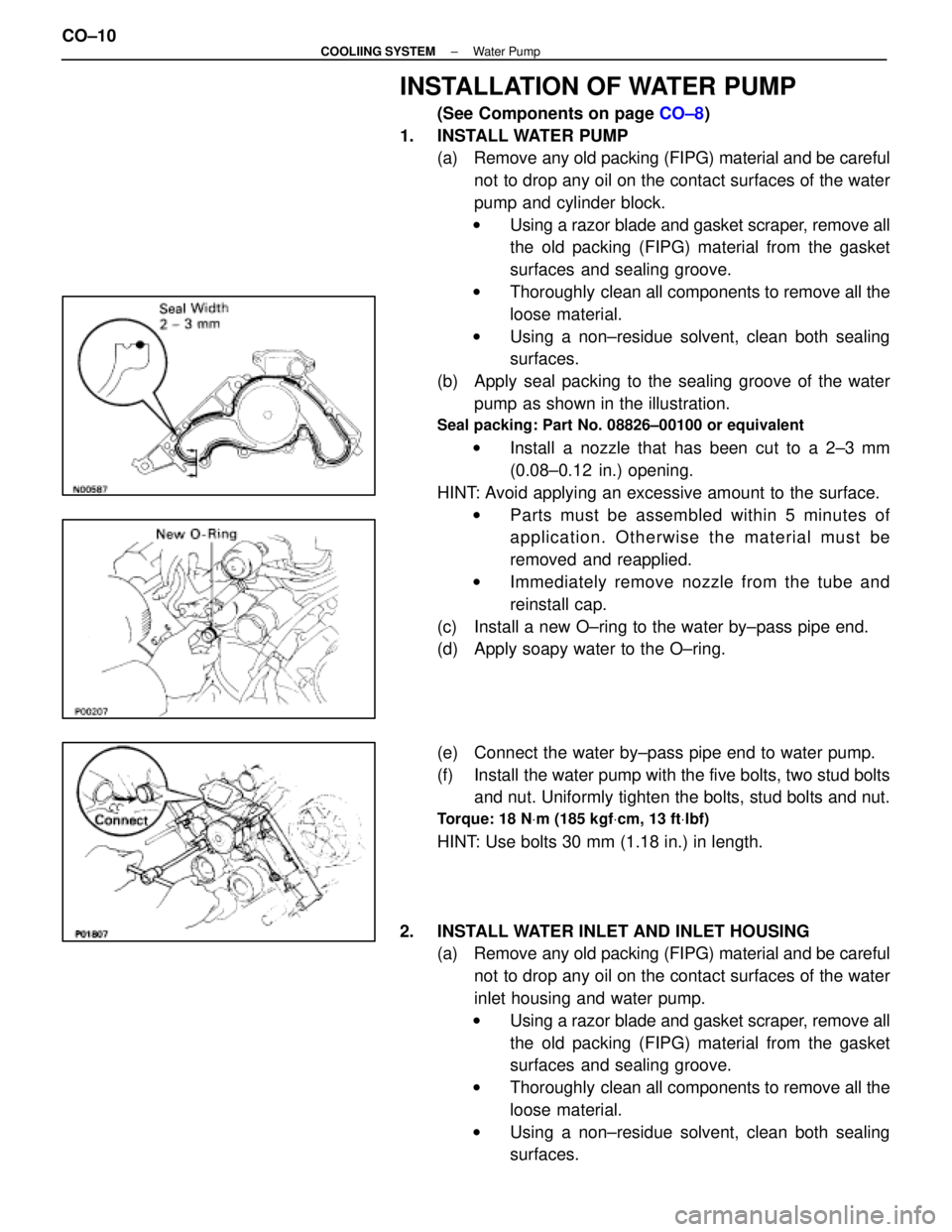

1. INSTALL WATER PUMP (a) Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the water

pump and cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the sealing groove of the water pump as shown in the illustration.

Seal packing: Part No. 08826±00100 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Install a new O±ring to the water by±pass pipe end.

(d) Apply soapy water to the O±ring.

(e) Connect the water by±pass pipe end to water pump.

(f) Install the water pump with the five bolts, two stud bolts and nut. Uniformly tighten the bolts, stud bolts and nut.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 30 mm (1.18 in.) in length.

2. INSTALL WATER INLET AND INLET HOUSING (a) Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the water

inlet housing and water pump.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

CO±10

±

COOLIING SYSTEM Water Pump

WhereEverybodyKnowsYourName

Page 1270 of 4087

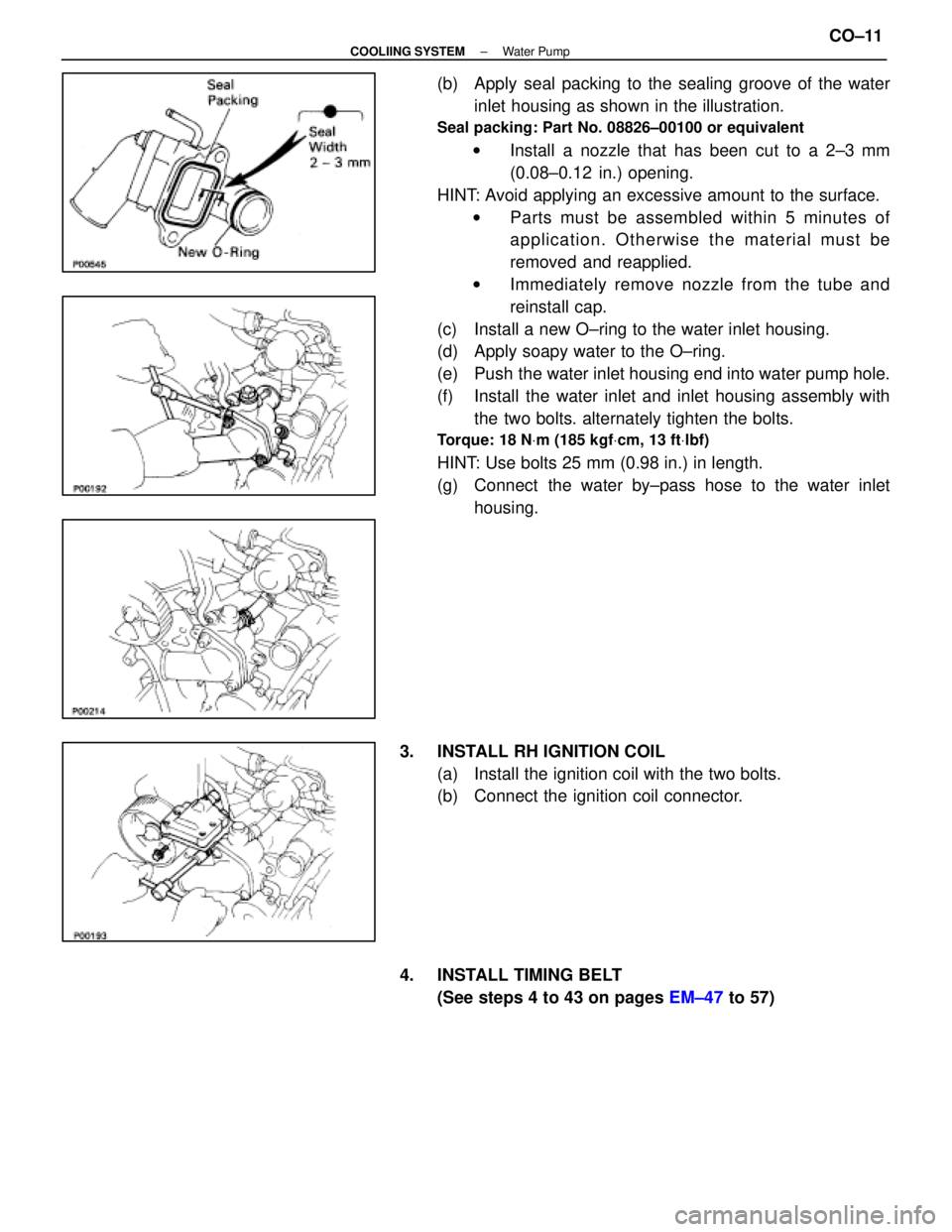

(b) Apply seal packing to the sealing groove of the waterinlet housing as shown in the illustration.

Seal packing: Part No. 08826±00100 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Install a new O±ring to the water inlet housing.

(d) Apply soapy water to the O±ring.

(e) Push the water inlet housing end into water pump hole.

(f) Install the water inlet and inlet housing assembly with the two bolts. alternately tighten the bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 25 mm (0.98 in.) in length.

(g) Connect the water by±pass hose to the water inlet

housing.

3. INSTALL RH IGNITION COIL (a) Install the ignition coil with the two bolts.

(b) Connect the ignition coil connector.

4. INSTALL TIMING BELT (See steps 4 to 43 on pages EM±47 to 57)

±

COOLIING SYSTEM Water PumpCO±11

WhereEverybodyKnowsYourName

Page 1272 of 4087

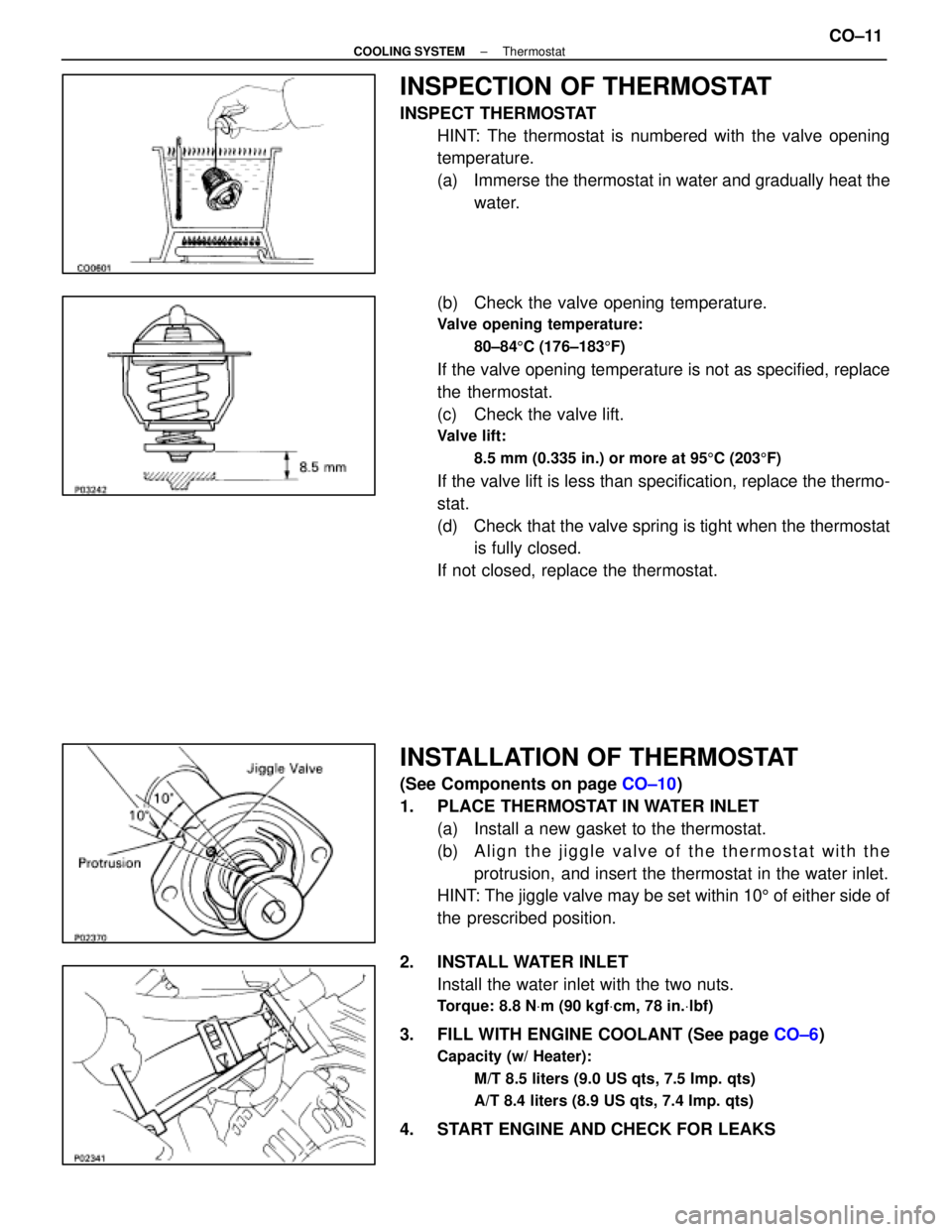

INSPECTION OF THERMOSTAT

INSPECT THERMOSTATHINT: The thermostat is numbered with the valve opening

temperature.

(a) Immerse the thermostat in water and gradually heat thewater.

(b) Check the valve opening temperature.

Valve opening temperature: 80±84 5C (176±183 5F)

If the valve opening temperature is not as specified, replace

the thermostat.

(c) Check the valve lift.

Valve lift:

8.5 mm (0.335 in.) or more at 95 5C (203 5F)

If the valve lift is less than specification, replace the thermo-

stat.

(d) Check that the valve spring is tight when the thermostat

is fully closed.

If not closed, replace the thermostat.

INSTALLATION OF THERMOSTAT

(See Components on page CO±10)

1. PLACE THERMOSTAT IN WATER INLET (a) Install a new gasket to the thermostat.

(b) A l i g n t h e j i g g l e v a l v e o f t h e t h e r m o s t a t w i t h t h eprotrusion, and insert the thermostat in the water inlet.

HINT: The jiggle valve may be set within 10 5 of either side of

the prescribed position.

2. INSTALL WATER INLET Install the water inlet with the two nuts.

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

3. FILL WITH ENGINE COOLANT (See page CO±6)

Capacity (w/ Heater):

M/T 8.5 liters (9.0 US qts, 7.5 Imp. qts)

A/T 8.4 liters (8.9 US qts, 7.4 Imp. qts)

4. START ENGINE AND CHECK FOR LEAKS

±

COOLING SYSTEM ThermostatCO±11

WhereEverybodyKnowsYourName

Page 1274 of 4087

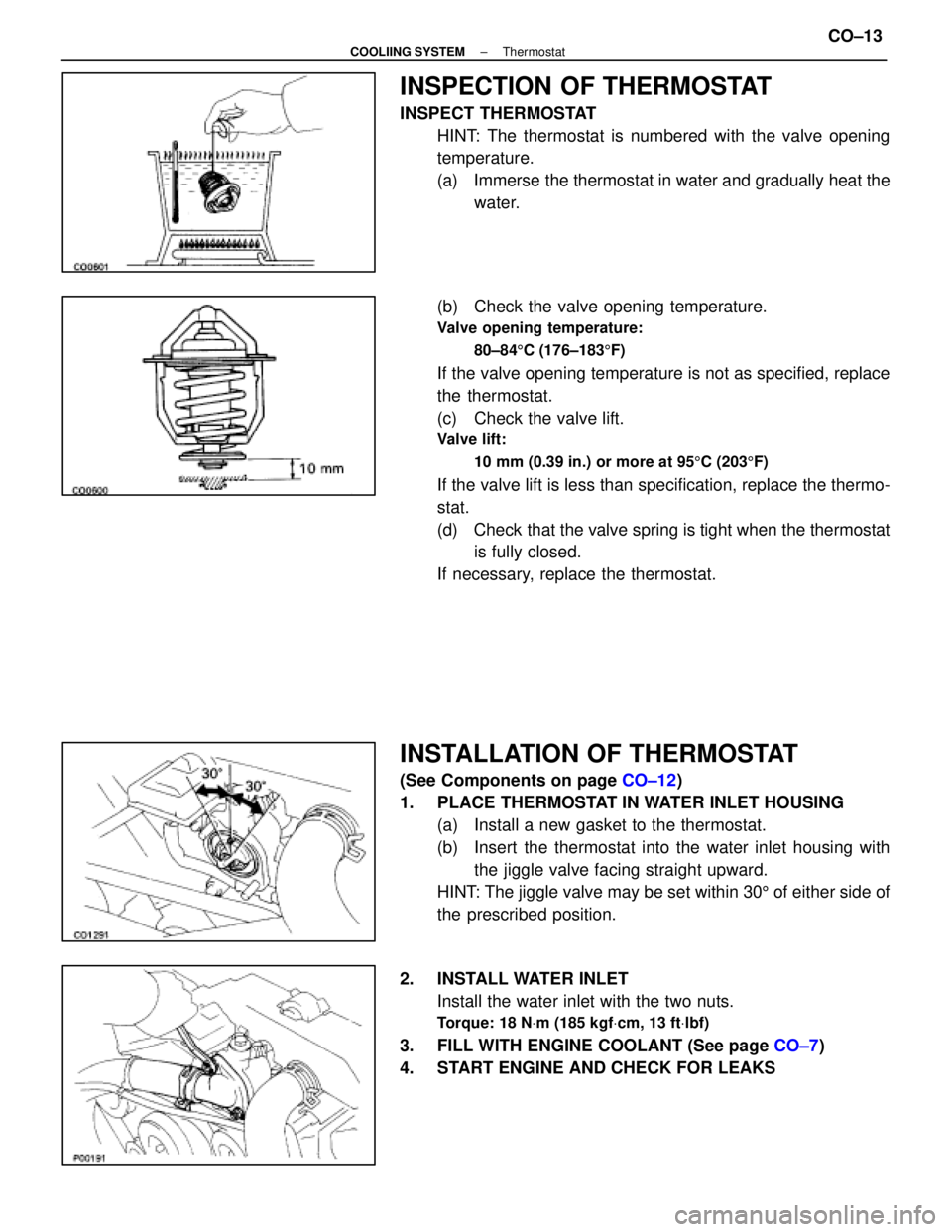

INSPECTION OF THERMOSTAT

INSPECT THERMOSTATHINT: The thermostat is numbered with the valve opening

temperature.

(a) Immerse the thermostat in water and gradually heat thewater.

(b) Check the valve opening temperature.

Valve opening temperature: 80±84 5C (176±183 5F)

If the valve opening temperature is not as specified, replace

the thermostat.

(c) Check the valve lift.

Valve lift:

10 mm (0.39 in.) or more at 95 5C (203 5F)

If the valve lift is less than specification, replace the thermo-

stat.

(d) Check that the valve spring is tight when the thermostat

is fully closed.

If necessary, replace the thermostat.

INSTALLATION OF THERMOSTAT

(See Components on page CO±12)

1. PLACE THERMOSTAT IN WATER INLET HOUSING (a) Install a new gasket to the thermostat.

(b) Insert the thermostat into the water inlet housing withthe jiggle valve facing straight upward.

HINT: The jiggle valve may be set within 30 5 of either side of

the prescribed position.

2. INSTALL WATER INLET Install the water inlet with the two nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

3. FILL WITH ENGINE COOLANT (See page CO±7)

4. START ENGINE AND CHECK FOR LEAKS

±

COOLIING SYSTEM ThermostatCO±13

WhereEverybodyKnowsYourName

Page 1279 of 4087

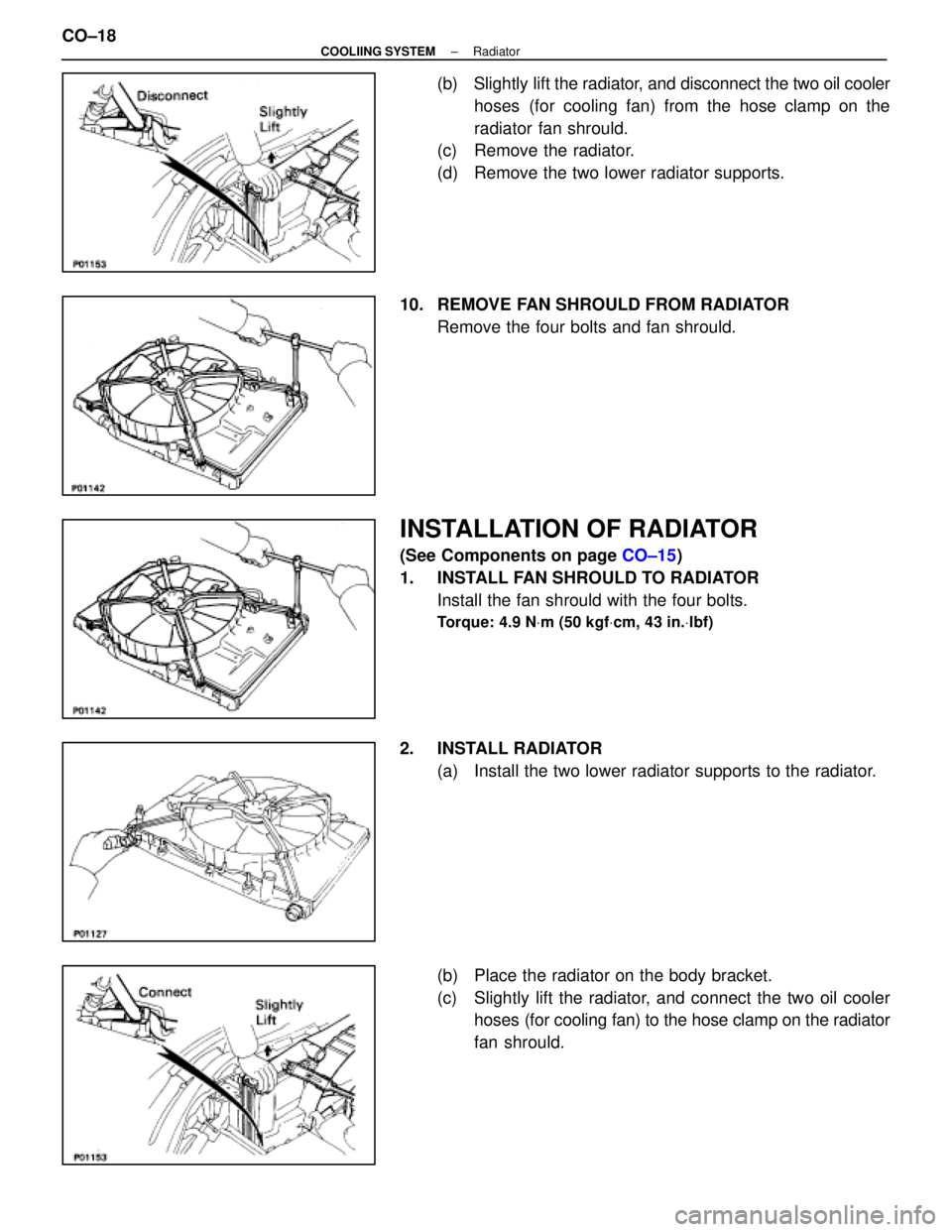

(b) Slightly lift the radiator, and disconnect the two oil cooler

hoses (for cooling fan) from the hose clamp on the

radiator fan shrould.

(c) Remove the radiator.

(d) Remove the two lower radiator supports.

10. REMOVE FAN SHROULD FROM RADIATOR Remove the four bolts and fan shrould.

INSTALLATION OF RADIATOR

(See Components on page CO±15)

1. INSTALL FAN SHROULD TO RADIATOR Install the fan shrould with the four bolts.

Torque: 4.9 N Vm (50 kgf Vcm, 43 in. Vlbf)

2. INSTALL RADIATOR

(a) Install the two lower radiator supports to the radiator.

(b) Place the radiator on the body bracket.

(c) Slightly lift the radiator, and connect the two oil coolerhoses (for cooling fan) to the hose clamp on the radiator

fan shrould.

CO±18

±

COOLIING SYSTEM Radiator

WhereEverybodyKnowsYourName

Page 1280 of 4087

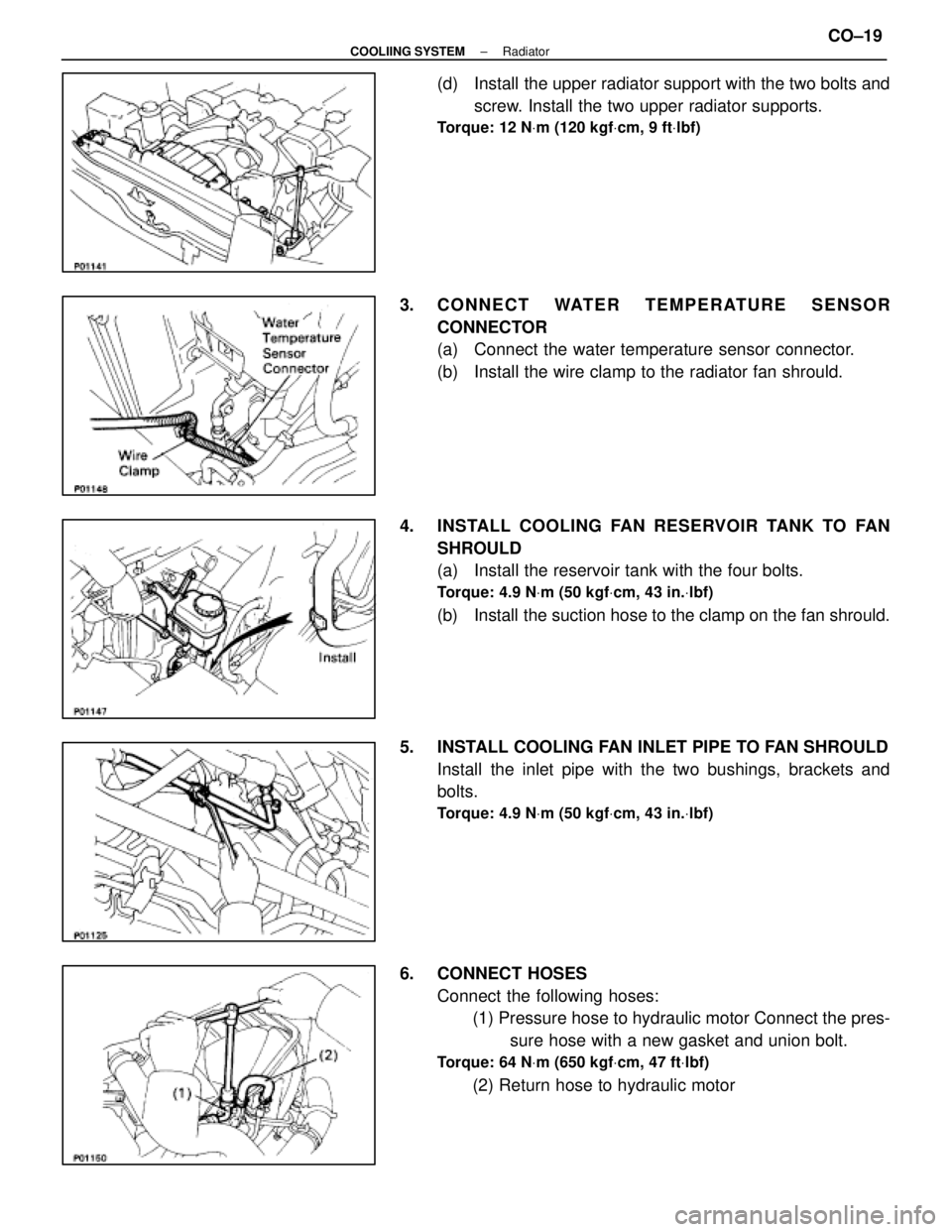

(d) Install the upper radiator support with the two bolts andscrew. Install the two upper radiator supports.

Torque: 12 N Vm (120 kgf Vcm, 9 ft Vlbf)

3. CONNECT WATER TEMPERATURE SENSOR

CONNECTOR

(a) Connect the water temperature sensor connector.

(b) Install the wire clamp to the radiator fan shrould.

4. INSTALL COOLING FAN RESERVOIR TANK TO FAN SHROULD

(a) Install the reservoir tank with the four bolts.

Torque: 4.9 N Vm (50 kgf Vcm, 43 in. Vlbf)

(b) Install the suction hose to the clamp on the fan shrould.

5. INSTALL COOLING FAN INLET PIPE TO FAN SHROULD Install the inlet pipe with the two bushings, brackets and

bolts.

Torque: 4.9 N Vm (50 kgf Vcm, 43 in. Vlbf)

6. CONNECT HOSES

Connect the following hoses:(1) Pressure hose to hydraulic motor Connect the pres-

sure hose with a new gasket and union bolt.

Torque: 64 N Vm (650 kgf Vcm, 47 ft Vlbf)

(2) Return hose to hydraulic motor

±

COOLIING SYSTEM RadiatorCO±19

WhereEverybodyKnowsYourName

Page 1281 of 4087

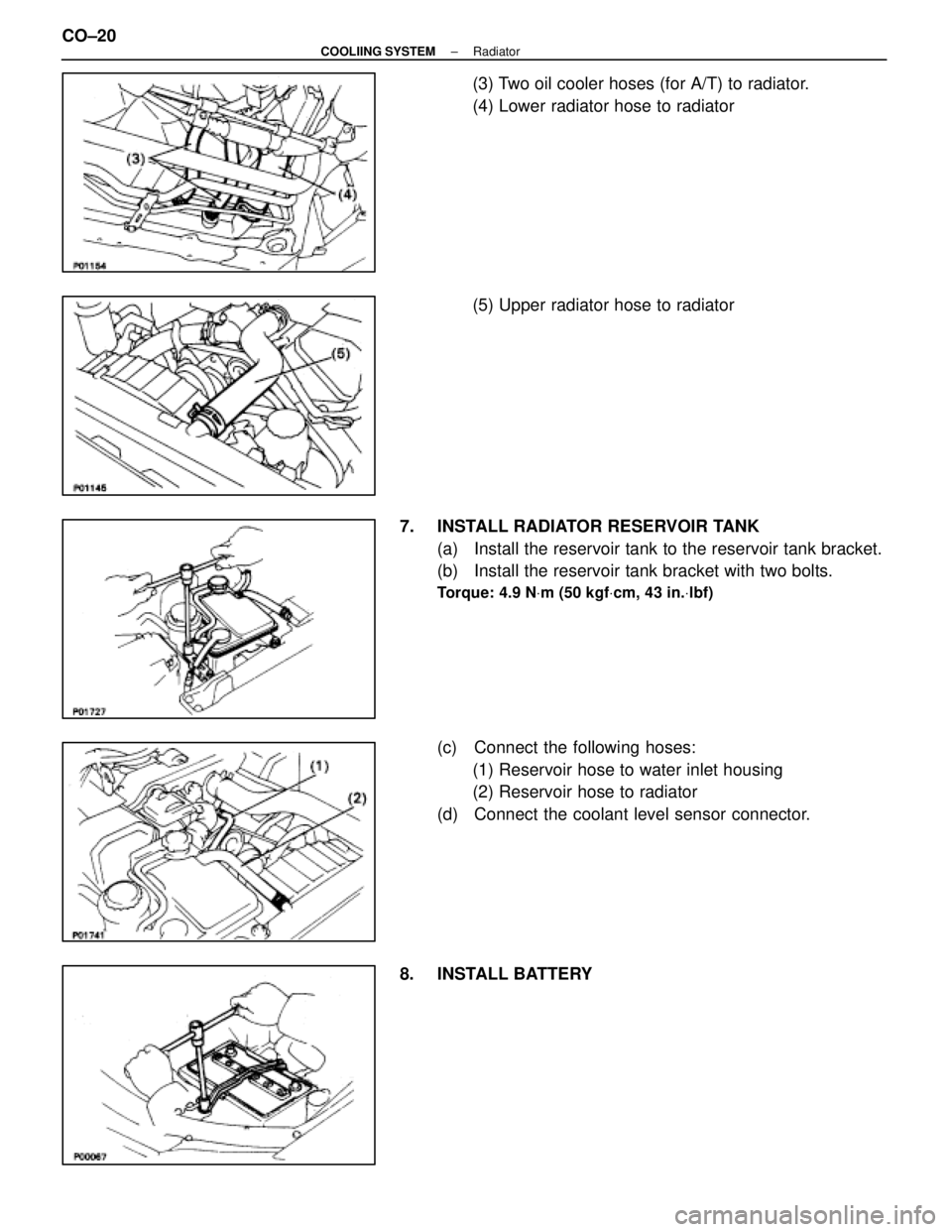

(3) Two oil cooler hoses (for A/T) to radiator.

(4) Lower radiator hose to radiator

(5) Upper radiator hose to radiator

7. INSTALL RADIATOR RESERVOIR TANK (a) Install the reservoir tank to the reservoir tank bracket.

(b) Install the reservoir tank bracket with two bolts.

Torque: 4.9 N Vm (50 kgf Vcm, 43 in. Vlbf)

(c) Connect the following hoses:

(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(d) Connect the coolant level sensor connector.

8. INSTALL BATTERY

CO±20

±

COOLIING SYSTEM Radiator

WhereEverybodyKnowsYourName