torque LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1404 of 4087

(n) Connect the No. 1 high±tension cord to the cord clamp on the

front high±tension cord clamp.

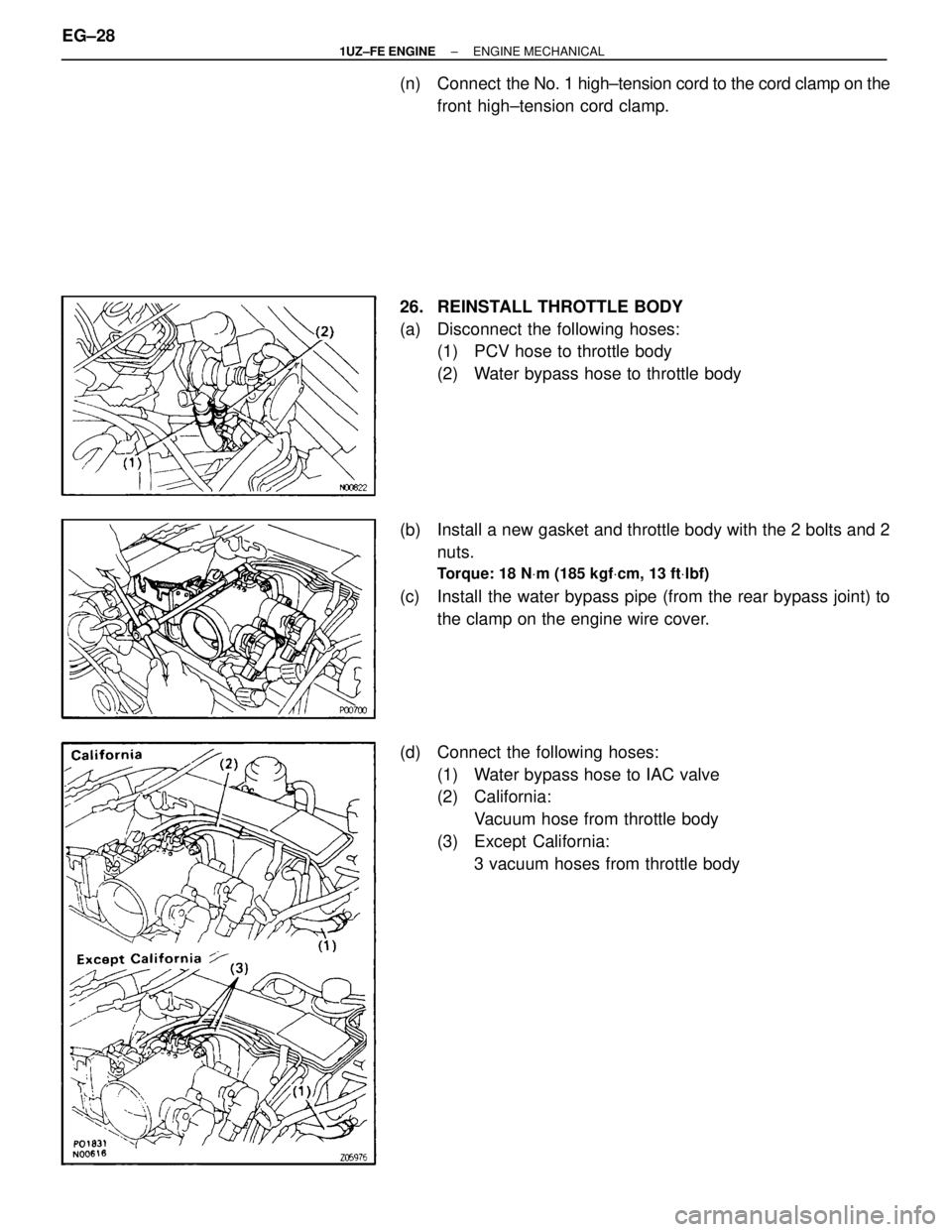

26. REINSTALL THROTTLE BODY

(a) Disconnect the following hoses: (1) PCV hose to throttle body

(2) Water bypass hose to throttle body

(b) Install a new gasket and throttle body with the 2 bolts and 2 nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(c) Install the water bypass pipe (from the rear bypass joint) to

the clamp on the engine wire cover.

(d) Connect the following hoses: (1) Water bypass hose to IAC valve

(2) California:Vacuum hose from throttle body

(3) Except California: 3 vacuum hoses from throttle body

EG±28

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1406 of 4087

31. RECONNECT FUEL INLET HOSE TO LH DELIVERY PIPE

(a) Temporarily connect the fuel inlet hose to the delivery pipewith 2 new gaskets and pulsation damper.

(b) Using SST, tighten the pulsation damper.

SST 09631±22020

Torque:

39 NVm (400 kgf Vcm, 29 ft Vlbf)

33 N Vm (340 kgf Vcm, 24 ft Vlbf) for SST

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.).

32. RECONNECT FUEL RETURN HOSE TO FUEL RETURN PIPE

33. RECONNECT PCV HOSE TO LH CYLINDER HEAD

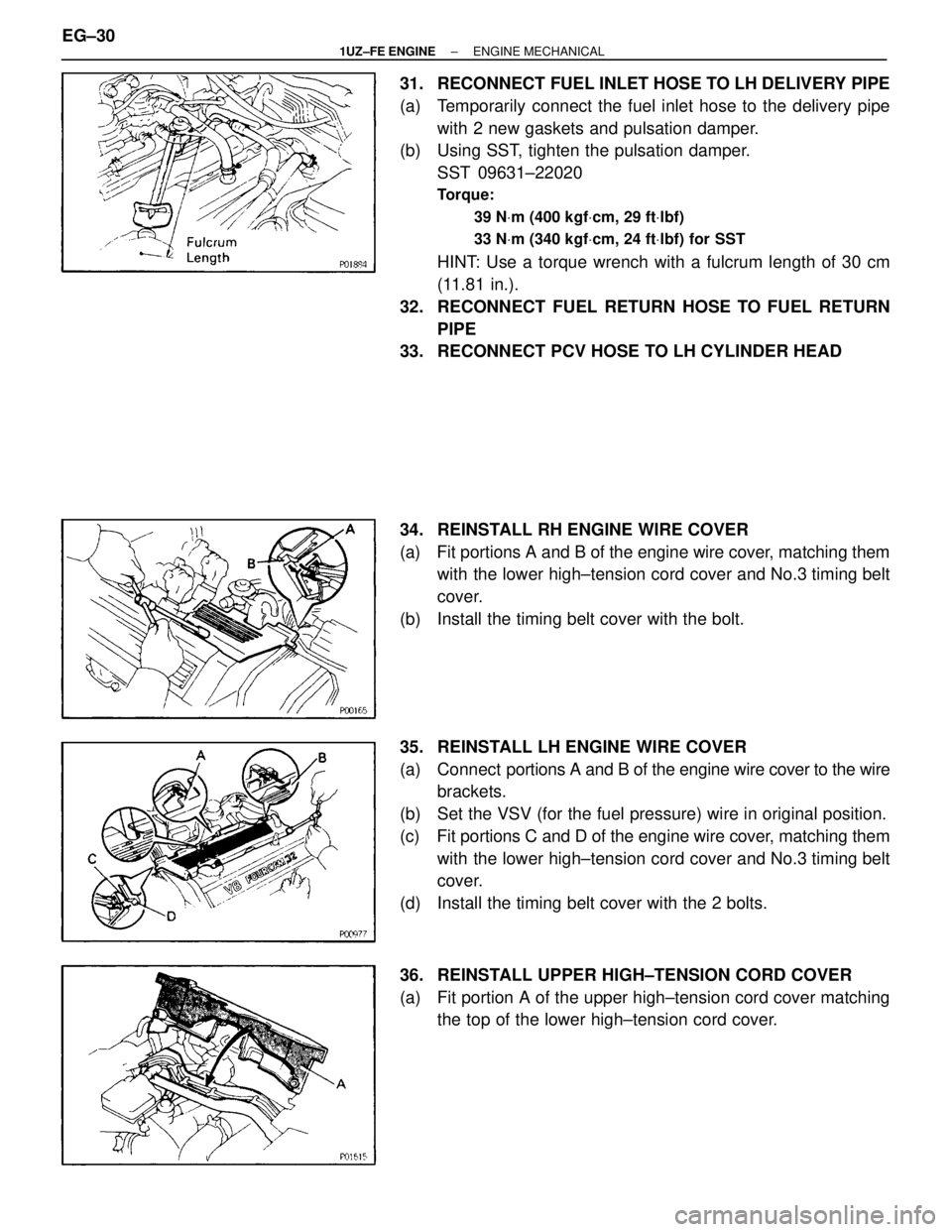

34. REINSTALL RH ENGINE WIRE COVER

(a) Fit portions A and B of the engine wire cover, matching them with the lower high±tension cord cover and No.3 timing belt

cover.

(b) Install the timing belt cover with the bolt.

35. REINSTALL LH ENGINE WIRE COVER

(a) Connect portions A and B of the engine wire cover to the wire

brackets.

(b) Set the VSV (for the fuel pressure) wire in original position.

(c) Fit portions C and D of the engine wire cover, matching them with the lower high±tension cord cover and No.3 timing belt

cover.

(d) Install the timing belt cover with the 2 bolts.

36. REINSTALL UPPER HIGH±TENSION CORD COVER

(a) Fit portion A of the upper high±tension cord cover matching the top of the lower high±tension cord cover.

EG±30

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1416 of 4087

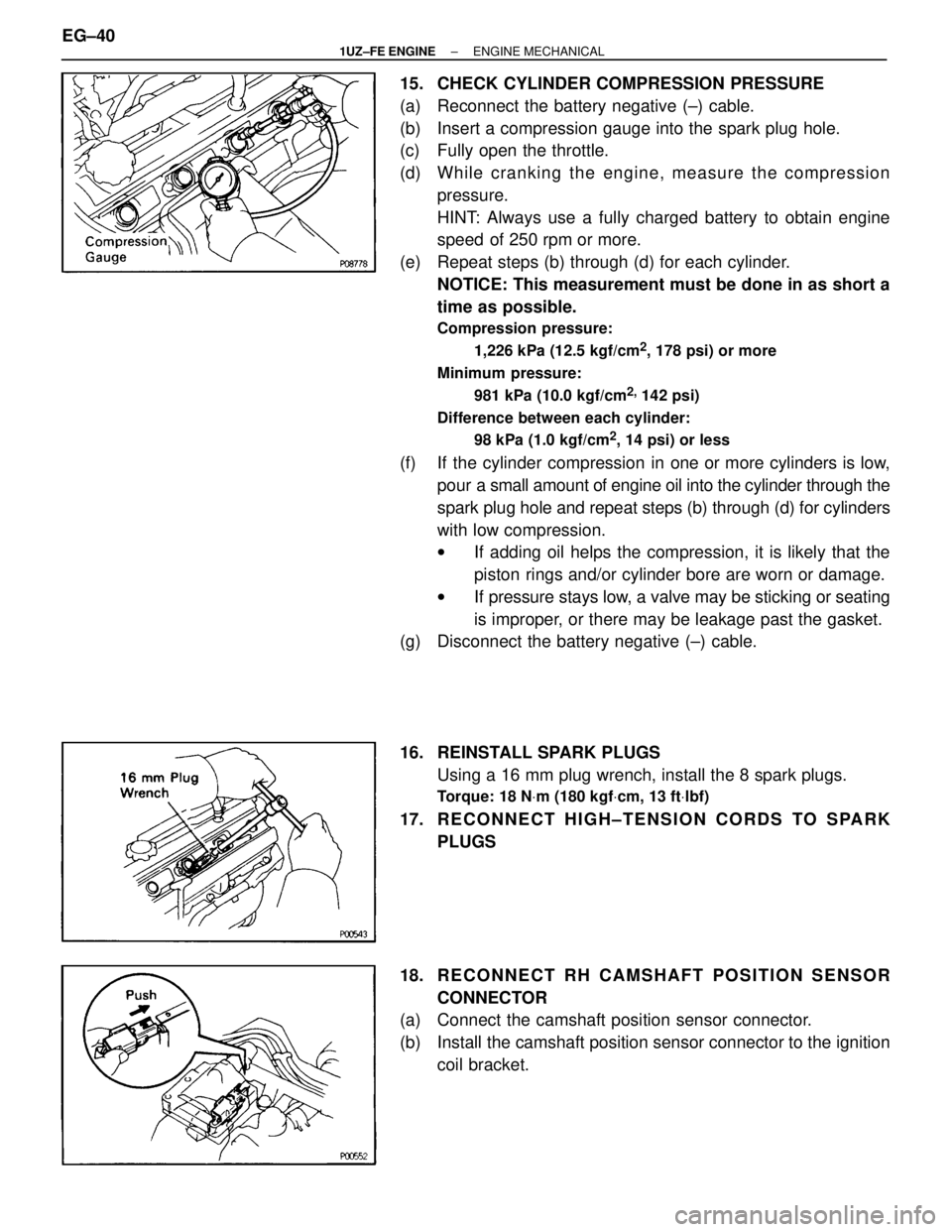

15. CHECK CYLINDER COMPRESSION PRESSURE

(a) Reconnect the battery negative (±) cable.

(b) Insert a compression gauge into the spark plug hole.

(c) Fully open the throttle.

(d) Wh ile cra n kin g th e en g in e , me a su re th e co mp re ssio npressure.

HINT: Always use a fully charged battery to obtain engine

speed of 250 rpm or more.

(e) Repeat steps (b) through (d) for each cylinder. NOTICE: This measurement must be done in as short a

time as possible.

Compression pressure:

1,226 kPa (12.5 kgf/cm

2, 178 psi) or more

Minimum pressure: 981 kPa (10.0 kgf/cm

2, 142 psi)

Difference between each cylinder: 98 kPa (1.0 kgf/cm

2, 14 psi) or less

(f) If the cylinder compression in one or more cylinders is low,pour a sm all amount of engine oil into the cylinder through the

spark plug hole and repeat steps (b) through (d) for cylinders

with low compression.

w If adding oil helps the compression, it is likely that the

piston rings and/or cylinder bore are worn or damage.

w If pressure stays low, a valve may be sticking or seating

is improper, or there may be leakage past the gasket.

(g) Disconnect the battery negative (±) cable.

16. REINSTALL SPARK PLUGS

Using a 16 mm plug wrench, install the 8 spark plugs.

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

17. R E C O N N E C T H I G H ± T E N S I O N C O R D S TO S PA R K

PLUGS

18. RECONNECT RH CAMSHAFT POSITION SENSOR CONNECTOR

(a) Connect the camshaft position sensor connector.

(b) Install the camshaft position sensor connector to the ignition

coil bracket.

EG±40

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1435 of 4087

(c) Measure the protrusion of the push rod from the housing end.

Protrusion:

10.5 ± 11.5 mm (0.413 ± 0.453 in.)

If the protrusion is not as specified, replace the tensioner.

EG21R±02

TIMING BELT INSTALLATION

See Components for Removal and Installation:

1. INSTALL CRANKSHAFT TIMING PULLEY

(a) Align the timing pulley set key with the key groove of thepulley.

(b) Using SST and a hammer, tap in the timing pulley, facing the flange side inward.

SST 09223±46011

2. INSTALL NO.1 IDLER PULLEY

(a) Apply adhesive 2 or 3 threads of the pivot bolt.

Adhesive: Part No. 08833±00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using a 10 mm hexagon wrench, install the plate washer and

idler pulley with the pivot bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(c) Check that the pulley bracket moves smoothly.

3. INSTALL NO.2 IDLER PULLEY

(a) Install the idler pulley with the bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(b) Check that the idler pulley moves smoothly.

4. TEMPORARILY INSTALL TIMING BELT

NOTICE: The engine should be cold.

(a) Using the crankshaft pulley bolt, turn the crankshaft and align

the timing marks of the crankshaft timing pulley and oil pump

body.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±59

WhereEverybodyKnowsYourName

Page 1437 of 4087

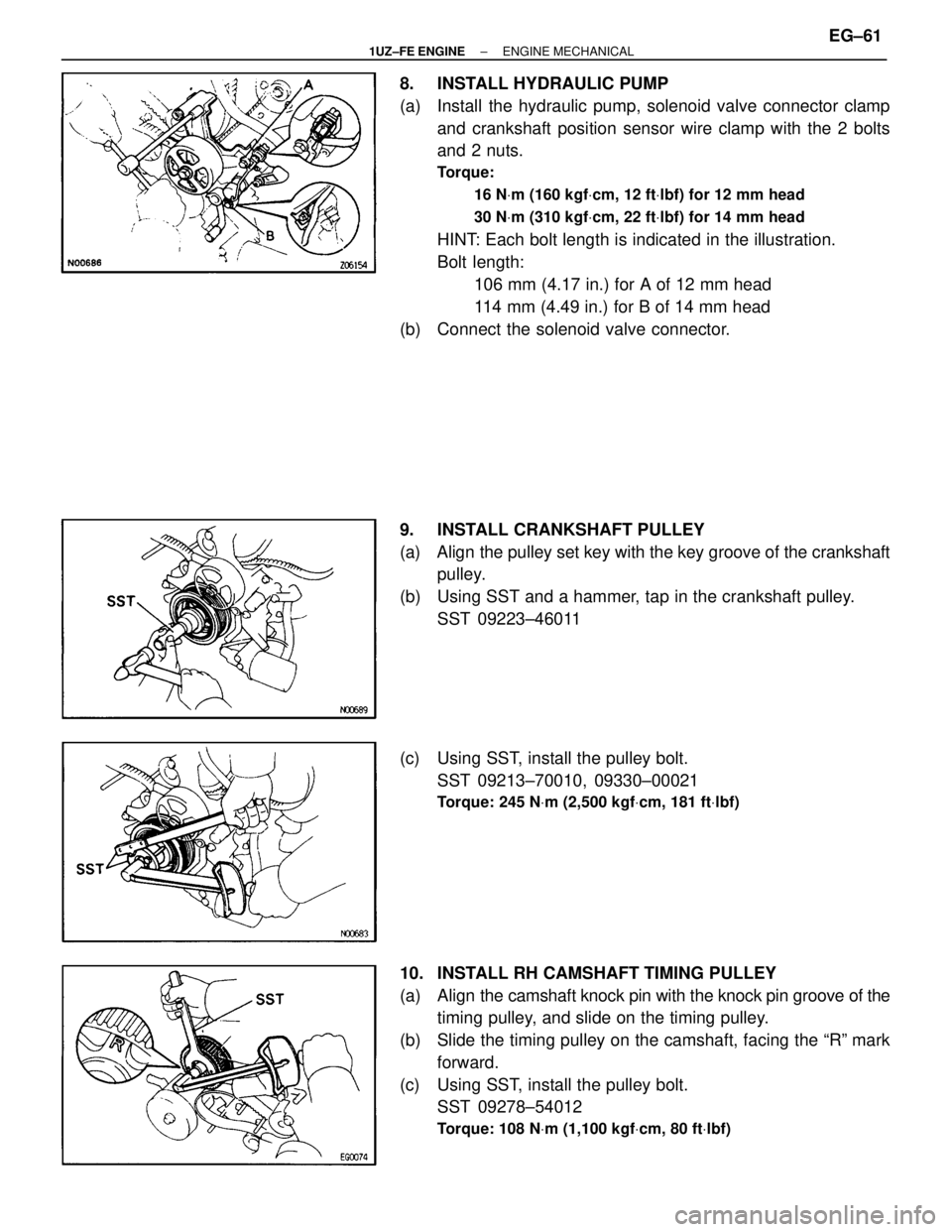

8. INSTALL HYDRAULIC PUMP

(a) Install the hydraulic pump, solenoid valve connector clampand crankshaft position sensor wire clamp with the 2 bolts

and 2 nuts.

Torque:

16 NVm (160 kgf Vcm, 12 ft Vlbf) for 12 mm head

30 N Vm (310 kgf Vcm, 22 ft Vlbf) for 14 mm head

HINT: Each bolt length is indicated in the illustration.

Bolt length:

106 mm (4.17 in.) for A of 12 mm head

114 mm (4.49 in.) for B of 14 mm head

(b) Connect the solenoid valve connector.

9. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the crankshaft pulley.

(b) Using SST and a hammer, tap in the crankshaft pulley. SST 09223±46011

(c) Using SST, install the pulley bolt. SST 09213±70010, 09330±00021

Torque: 245 N Vm (2,500 kgf Vcm, 181 ft Vlbf)

10. INSTALL RH CAMSHAFT TIMING PULLEY

(a) Align the camshaft knock pin with the knock pin groove of the

timing pulley, and slide on the timing pulley.

(b) Slide the timing pulley on the camshaft, facing the ªRº mark forward.

(c) Using SST, install the pulley bolt. SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

±

1UZ±FE ENGINE ENGINE MECHANICALEG±61

WhereEverybodyKnowsYourName

Page 1438 of 4087

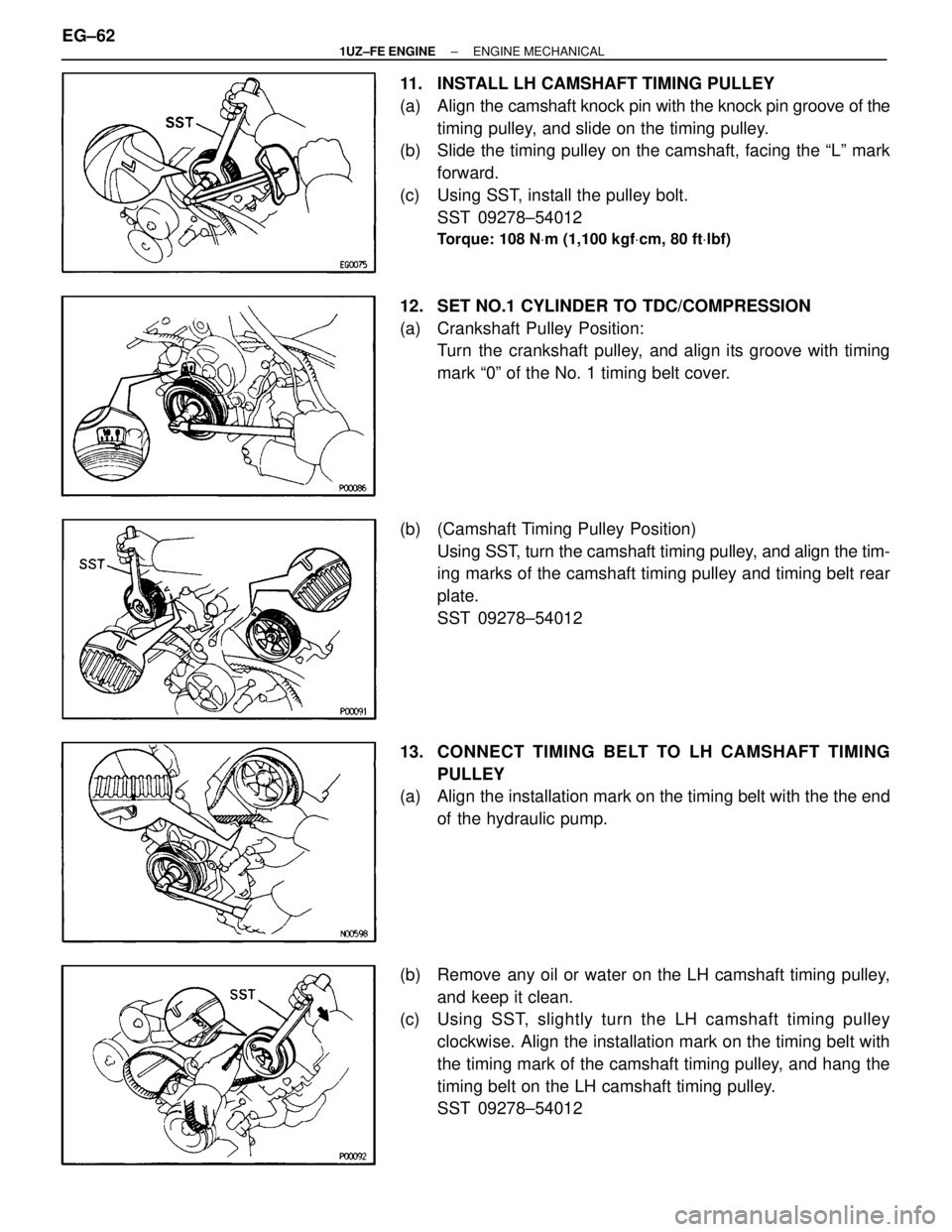

11. INSTALL LH CAMSHAFT TIMING PULLEY

(a) Align the camshaft knock pin with the knock pin groove of the

timing pulley, and slide on the timing pulley.

(b) Slide the timing pulley on the camshaft, facing the ªLº mark

forward.

(c) Using SST, install the pulley bolt. SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

12. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) Crankshaft Pulley Position:

Turn the crankshaft pulley, and align its groove with timing

mark ª0º of the No. 1 timing belt cover.

(b) (Camshaft Timing Pulley Position) Using SST, turn the camshaft timing pulley, and align the tim-

ing marks of the camshaft timing pulley and timing belt rear

plate.

SST 09278±54012

13. CONNECT TIMING BELT TO LH CAMSHAFT TIMING PULLEY

(a) Align the installation mark on the timing belt with the the end

of the hydraulic pump.

(b) Remove any oil or water on the LH camshaft timing pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing belt with

the timing mark of the camshaft timing pulley, and hang the

timing belt on the LH camshaft timing pulley.

SST 09278±54012

EG±62

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1440 of 4087

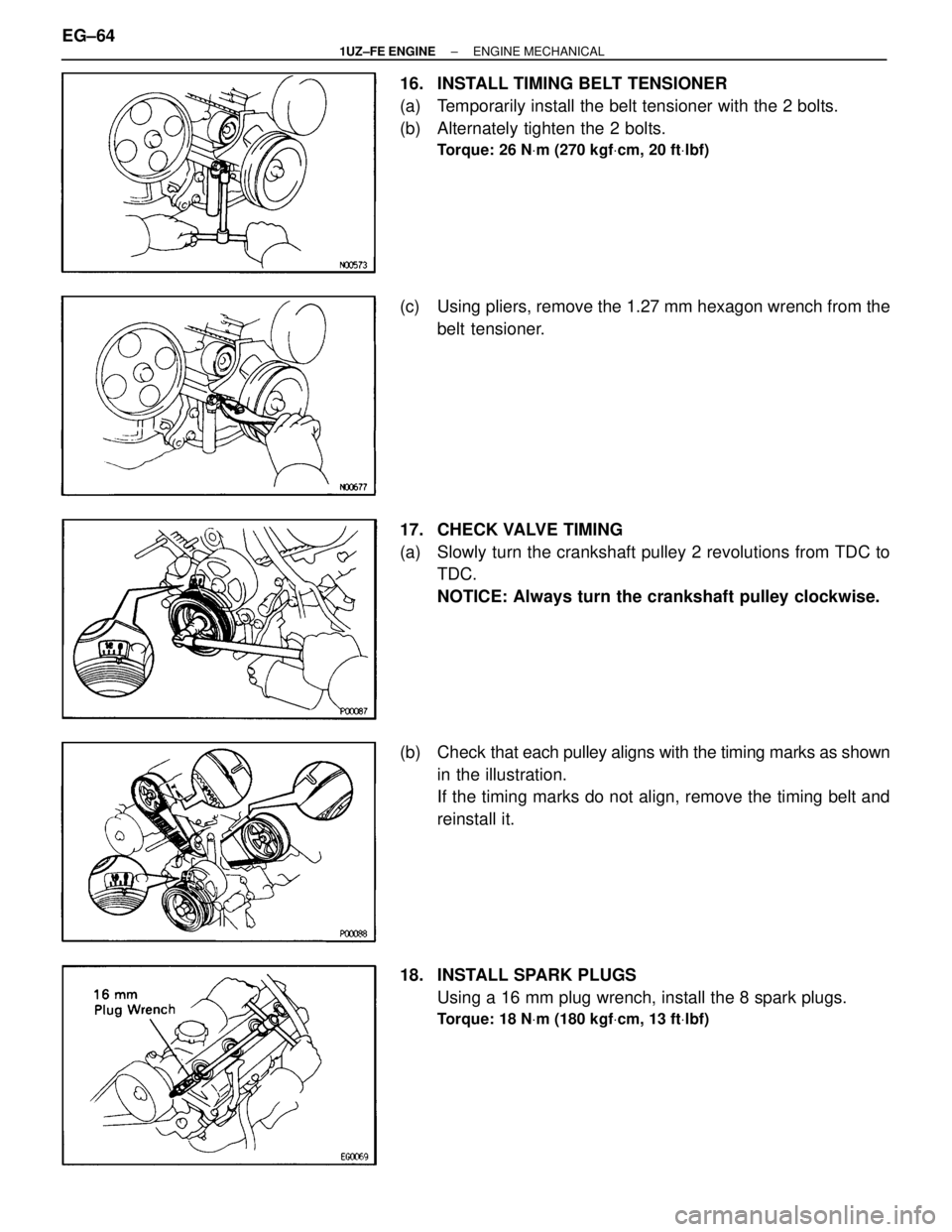

16. INSTALL TIMING BELT TENSIONER

(a) Temporarily install the belt tensioner with the 2 bolts.

(b) Alternately tighten the 2 bolts.

Torque: 26 NVm (270 kgf Vcm, 20 ft Vlbf)

(c) Using pliers, remove the 1.27 mm hexagon wrench from the

belt tensioner.

17. CHECK VALVE TIMING

(a) Slowly turn the crankshaft pulley 2 revolutions from TDC to TDC.

NOTICE: Always turn the crankshaft pulley clockwise.

(b) Check that each pulley aligns with the timing marks as shown

in the illustration.

If the timing marks do not align, remove the timing belt and

reinstall it.

18. INSTALL SPARK PLUGS Using a 16 mm plug wrench, install the 8 spark plugs.

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

EG±64±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1441 of 4087

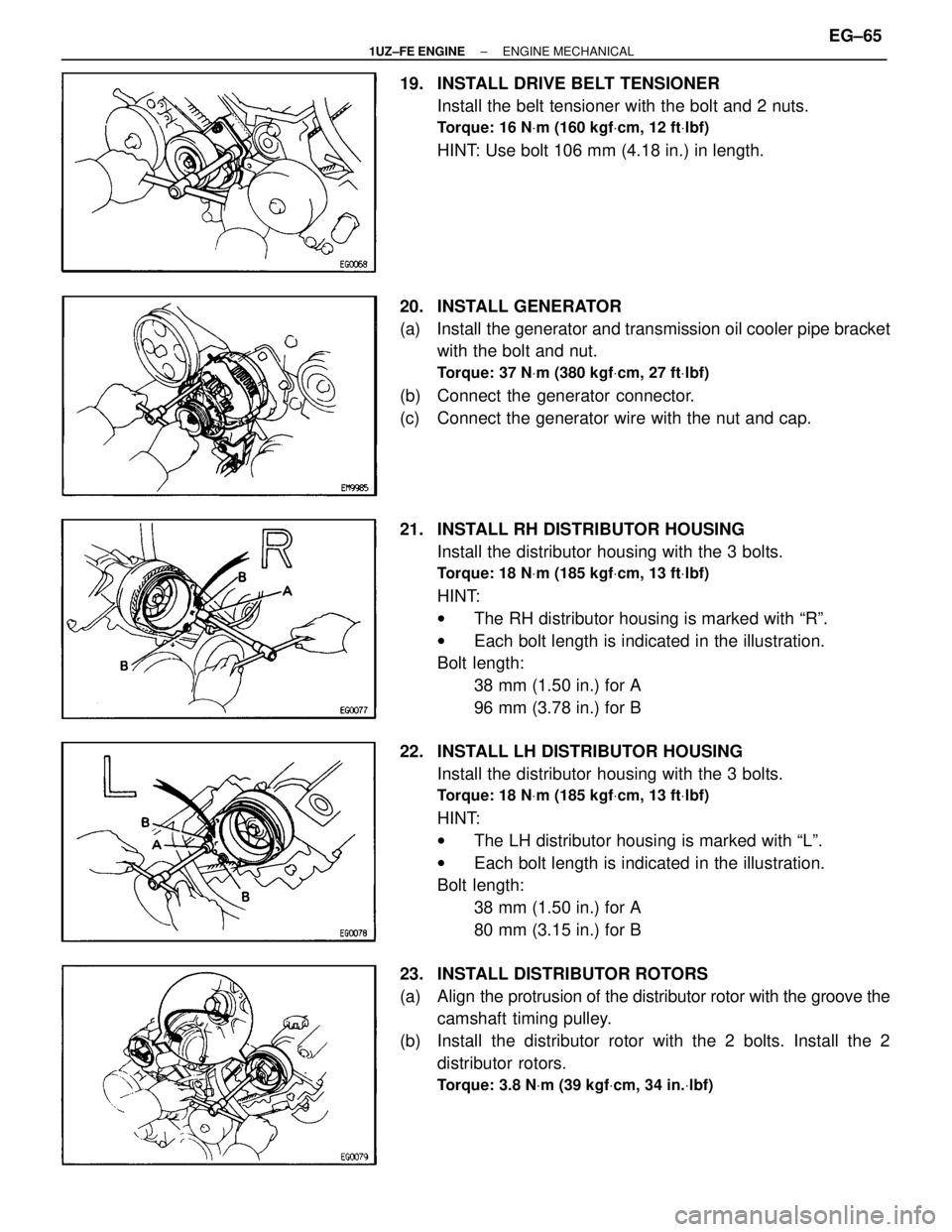

19. INSTALL DRIVE BELT TENSIONERInstall the belt tensioner with the bolt and 2 nuts.

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

HINT: Use bolt 106 mm (4.18 in.) in length.

20. INSTALL GENERATOR

(a) Install the generator and transmission oil cooler pipe bracket with the bolt and nut.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

(b) Connect the generator connector.

(c) Connect the generator wire with the nut and cap.

21. INSTALL RH DISTRIBUTOR HOUSING

Install the distributor housing with the 3 bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT:

w The RH distributor housing is marked with ªRº.

w Each bolt length is indicated in the illustration.

Bolt length:

38 mm (1.50 in.) for A

96 mm (3.78 in.) for B

22. INSTALL LH DISTRIBUTOR HOUSING Install the distributor housing with the 3 bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT:

w The LH distributor housing is marked with ªLº.

w Each bolt length is indicated in the illustration.

Bolt length:

38 mm (1.50 in.) for A

80 mm (3.15 in.) for B

23. INSTALL DISTRIBUTOR ROTORS

(a) Align the protrusion of the distributor rotor with the groove the

camshaft timing pulley.

(b) Install the distributor rotor with the 2 bolts. Install the 2 distributor rotors.

Torque: 3.8 N Vm (39 kgf Vcm, 34 in. Vlbf)

±

1UZ±FE ENGINE ENGINE MECHANICALEG±65

WhereEverybodyKnowsYourName

Page 1442 of 4087

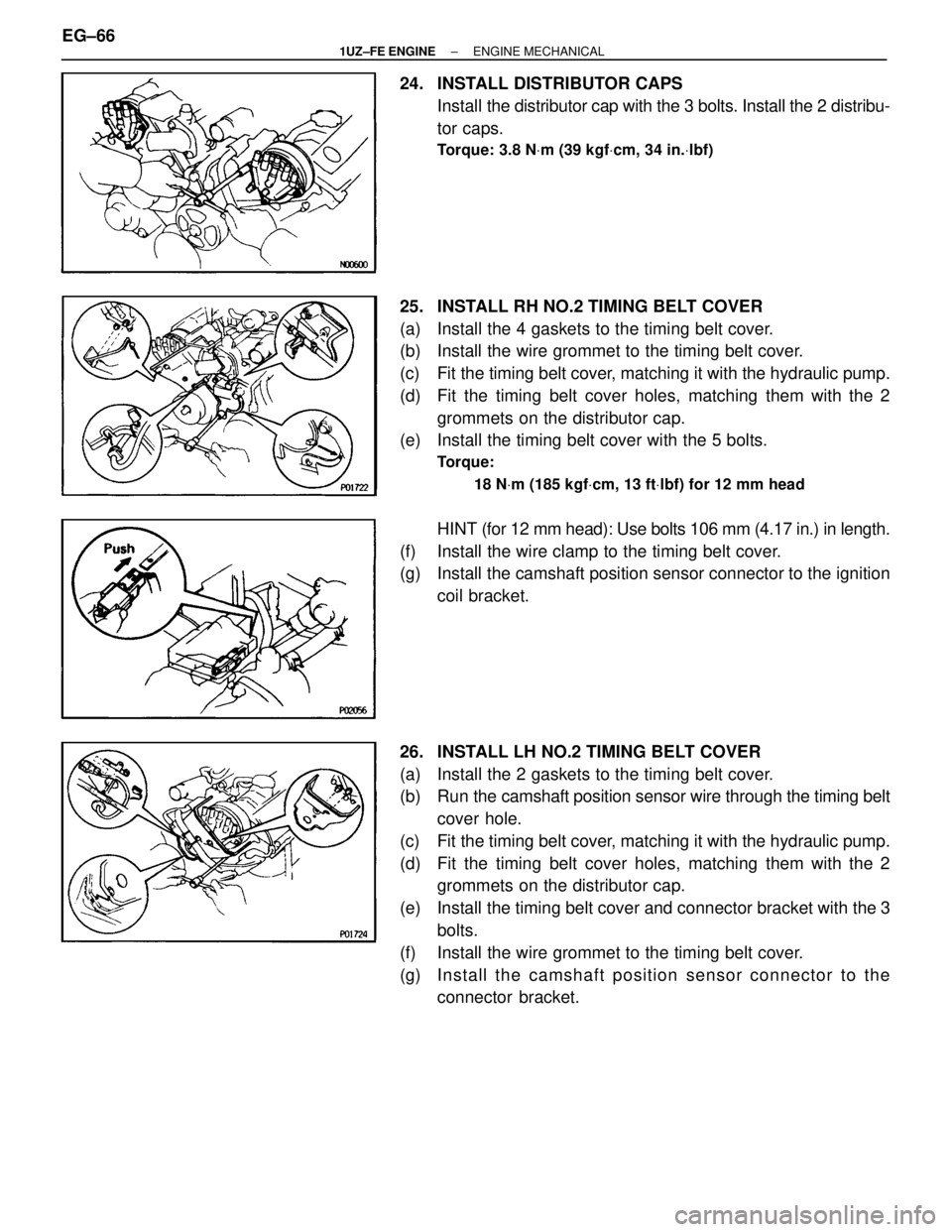

24. INSTALL DISTRIBUTOR CAPSInstall the distributor cap with the 3 bolts. Install the 2 distribu-

tor caps.

Torque: 3.8 N Vm (39 kgf Vcm, 34 in. Vlbf)

25. INSTALL RH NO.2 TIMING BELT COVER

(a) Install the 4 gaskets to the timing belt cover.

(b) Install the wire grommet to the timing belt cover.

(c) Fit the timing belt cover, matching it with the hydraulic pump.

(d) Fit the timing belt cover holes, matching them with the 2

grommets on the distributor cap.

(e) Install the timing belt cover with the 5 bolts.

Torque:

18 NVm (185 kgf Vcm, 13 ft Vlbf) for 12 mm head

HINT (for 12 mm head): Use bolts 106 mm (4.17 in.) in length.

(f) Install the wire clamp to the timing belt cover.

(g) Install the camshaft position sensor connector to the ignition coil bracket.

26. INSTALL LH NO.2 TIMING BELT COVER

(a) Install the 2 gaskets to the timing belt cover.

(b) Run the camshaft position sensor wire through the timing belt

cover hole.

(c) Fit the timing belt cover, matching it with the hydraulic pump.

(d) Fit the timing belt cover holes, matching them with the 2 grommets on the distributor cap.

(e) Install the timing belt cover and connector bracket with the 3 bolts.

(f) Install the wire grommet to the timing belt cover.

(g) In sta ll th e ca msh a ft po sitio n se n so r c onnector to the

connector bracket.

EG±66

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1443 of 4087

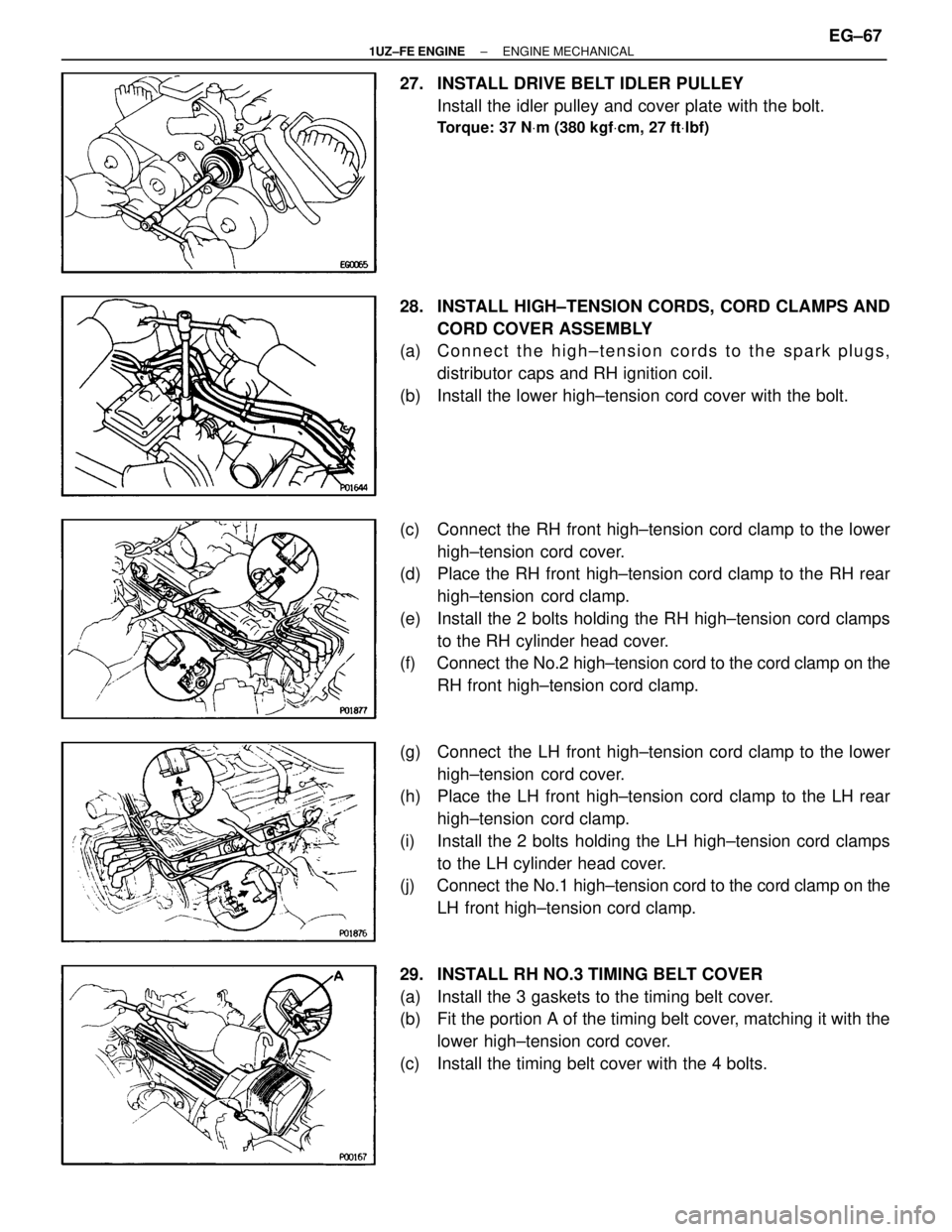

27. INSTALL DRIVE BELT IDLER PULLEYInstall the idler pulley and cover plate with the bolt.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

28. INSTALL HIGH±TENSION CORDS, CORD CLAMPS AND

CORD COVER ASSEMBLY

(a) C onnect the high±tension cords to the spark plugs,

distributor caps and RH ignition coil.

(b) Install the lower high±tension cord cover with the bolt.

(c) Connect the RH front high±tension cord clamp to the lower high±tension cord cover.

(d) Place the RH front high±tension cord clamp to the RH rear

high±tension cord clamp.

(e) Install the 2 bolts holding the RH high±tension cord clamps to the RH cylinder head cover.

(f) Connect the No.2 high±tension cord to the cord clamp on the

RH front high±tension cord clamp.

(g) Connect the LH front high±tension cord clamp to the lower high±tension cord cover.

(h) Place the LH front high±tension cord clamp to the LH rear

high±tension cord clamp.

(i) Install the 2 bolts holding the LH high±tension cord clamps to the LH cylinder head cover.

(j) Connect the No.1 high±tension cord to the cord clamp on the

LH front high±tension cord clamp.

29. INSTALL RH NO.3 TIMING BELT COVER

(a) Install the 3 gaskets to the timing belt cover.

(b) Fit the portion A of the timing belt cover, matching it with the lower high±tension cord cover.

(c) Install the timing belt cover with the 4 bolts.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±67

WhereEverybodyKnowsYourName