LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: start stop button, recommended oil, air suspension, differential, overheating, battery replacement, radio

Page 2461 of 4087

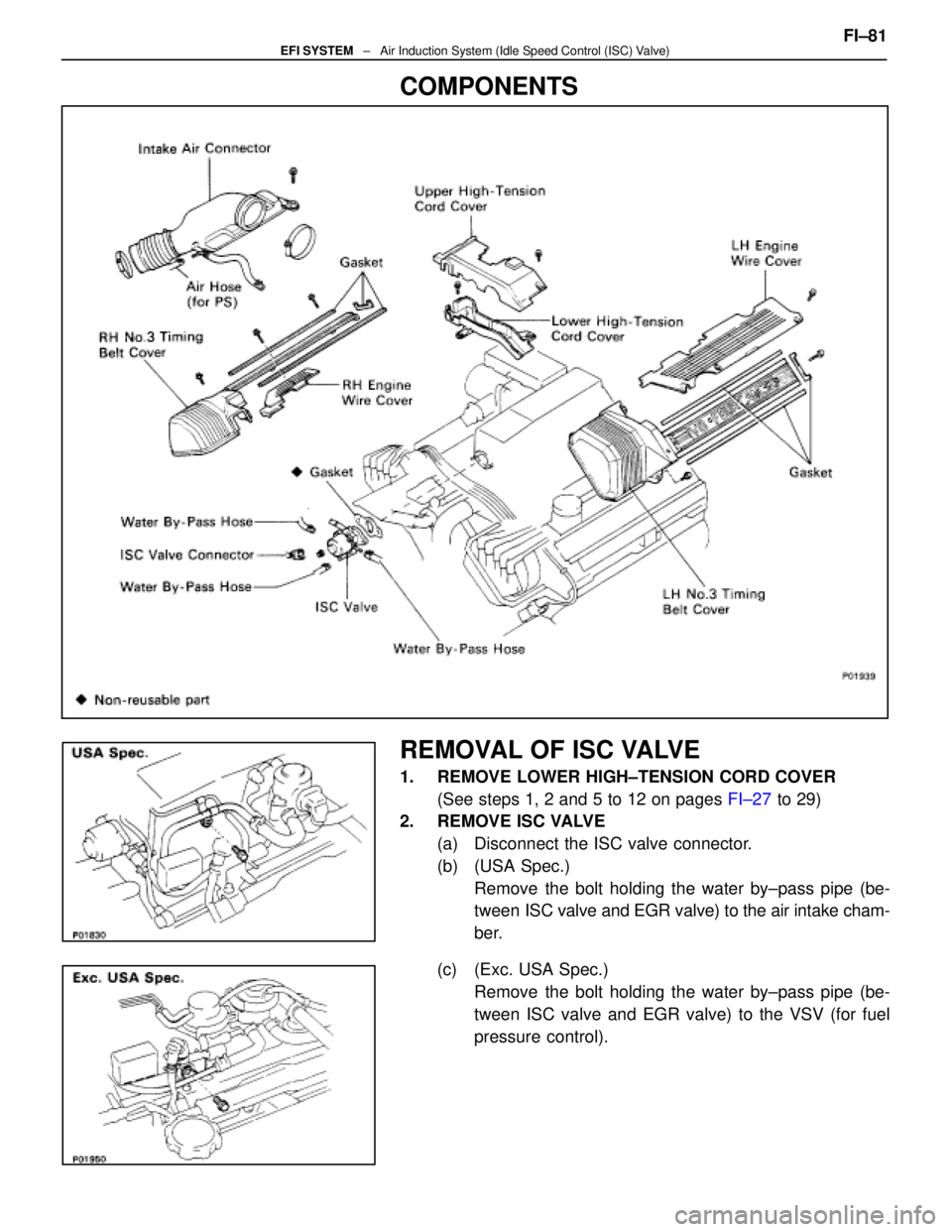

COMPONENTS

REMOVAL OF ISC VALVE

1. REMOVE LOWER HIGH±TENSION CORD COVER(See steps 1, 2 and 5 to 12 on pages FI±27 to 29)

2. REMOVE ISC VALVE

(a) Disconnect the ISC valve connector.

(b) (USA Spec.)Remove the bolt holding the water by±pass pipe (be-

tween ISC valve and EGR valve) to the air intake cham-

ber.

(c) (Exc. USA Spec.) Remove the bolt holding the water by±pass pipe (be-

tween ISC valve and EGR valve) to the VSV (for fuel

pressure control). FI±81

EFI SYSTEM

± Air Induction System (Idle Speed Control (ISC) Valve)

WhereEverybodyKnowsYourName

Page 2462 of 4087

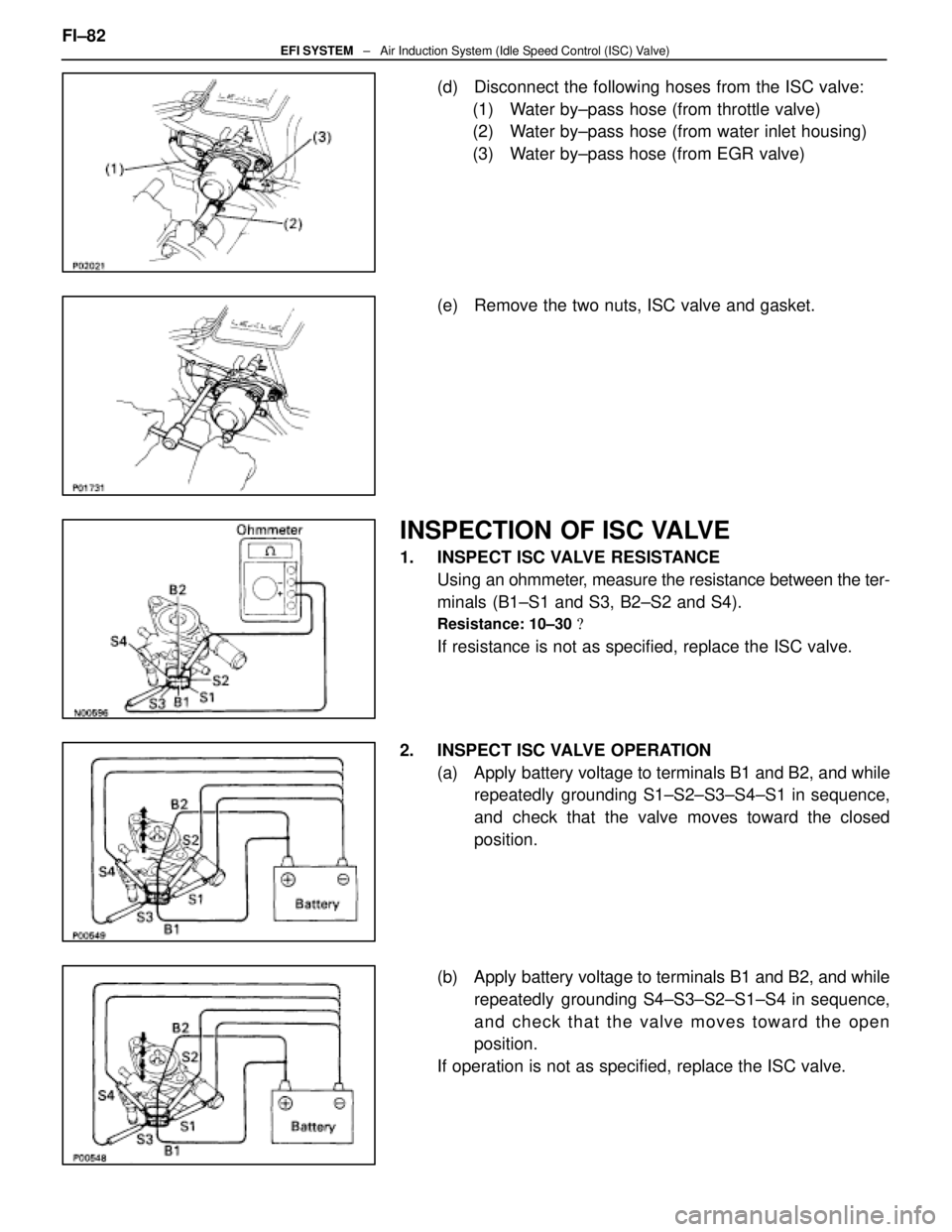

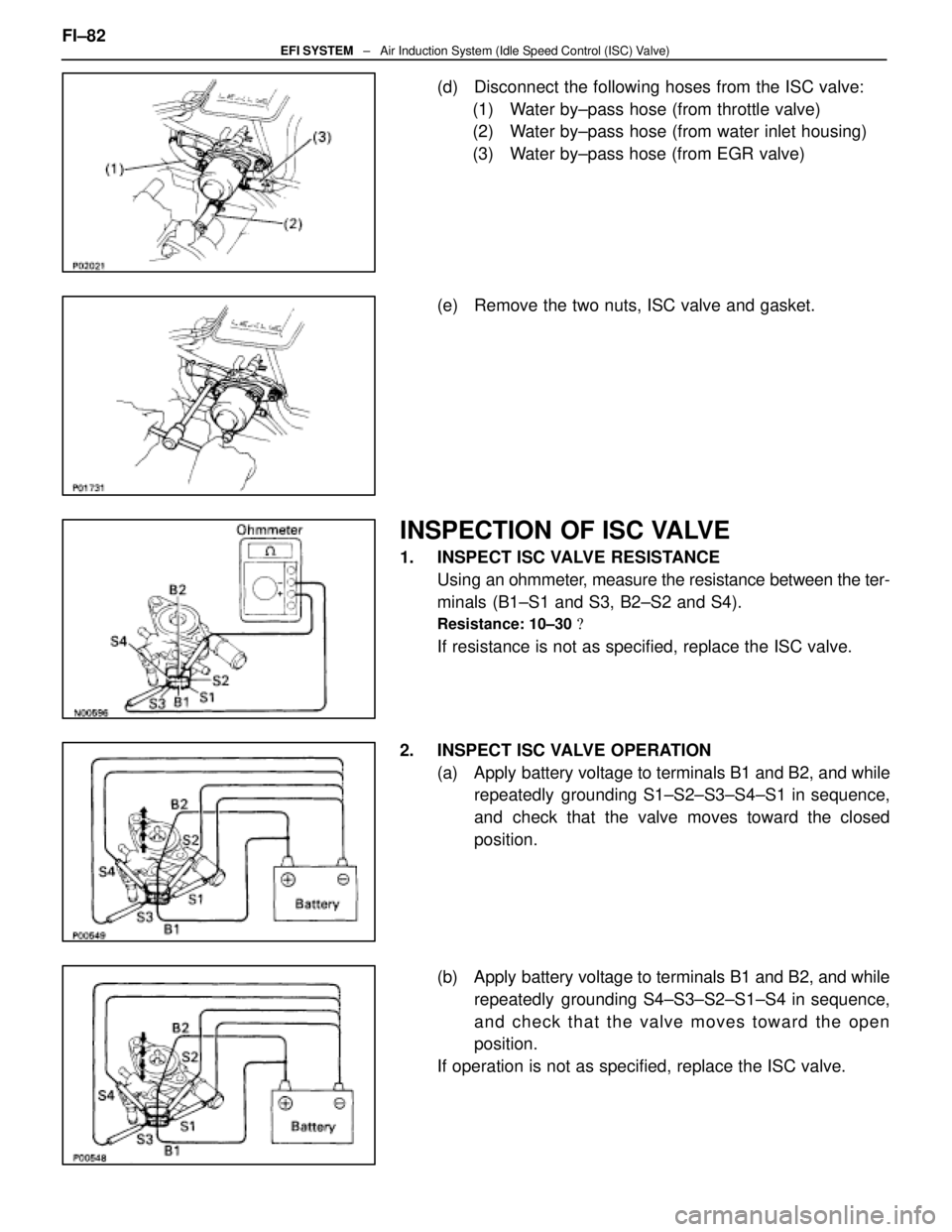

(d) Disconnect the following hoses from the ISC valve:(1) Water by±pass hose (from throttle valve)

(2) Water by±pass hose (from water inlet housing)

(3) Water by±pass hose (from EGR valve)

(e) Remove the two nuts, ISC valve and gasket.

INSPECTION OF ISC VALVE

1. INSPECT ISC VALVE RESISTANCE Using an ohmmeter, measure the resistance between the ter-

minals (B1±S1 and S3, B2±S2 and S4).

Resistance: 10±30 �

If resistance is not as specified, replace the ISC valve.

2. INSPECT ISC VALVE OPERATION (a) Apply battery voltage to terminals B1 and B2, and whilerepeatedly grounding S1±S2±S3±S4±S1 in sequence,

and check that the valve moves toward the closed

position.

(b) Apply battery voltage to terminals B1 and B2, and while repeatedly grounding S4±S3±S2±S1±S4 in sequence,

and check that the valve moves toward the open

position.

If operation is not as specified, replace the ISC valve.

FI±82

EFI SYSTEM

± Air Induction System (Idle Speed Control (ISC) Valve)

WhereEverybodyKnowsYourName

Page 2463 of 4087

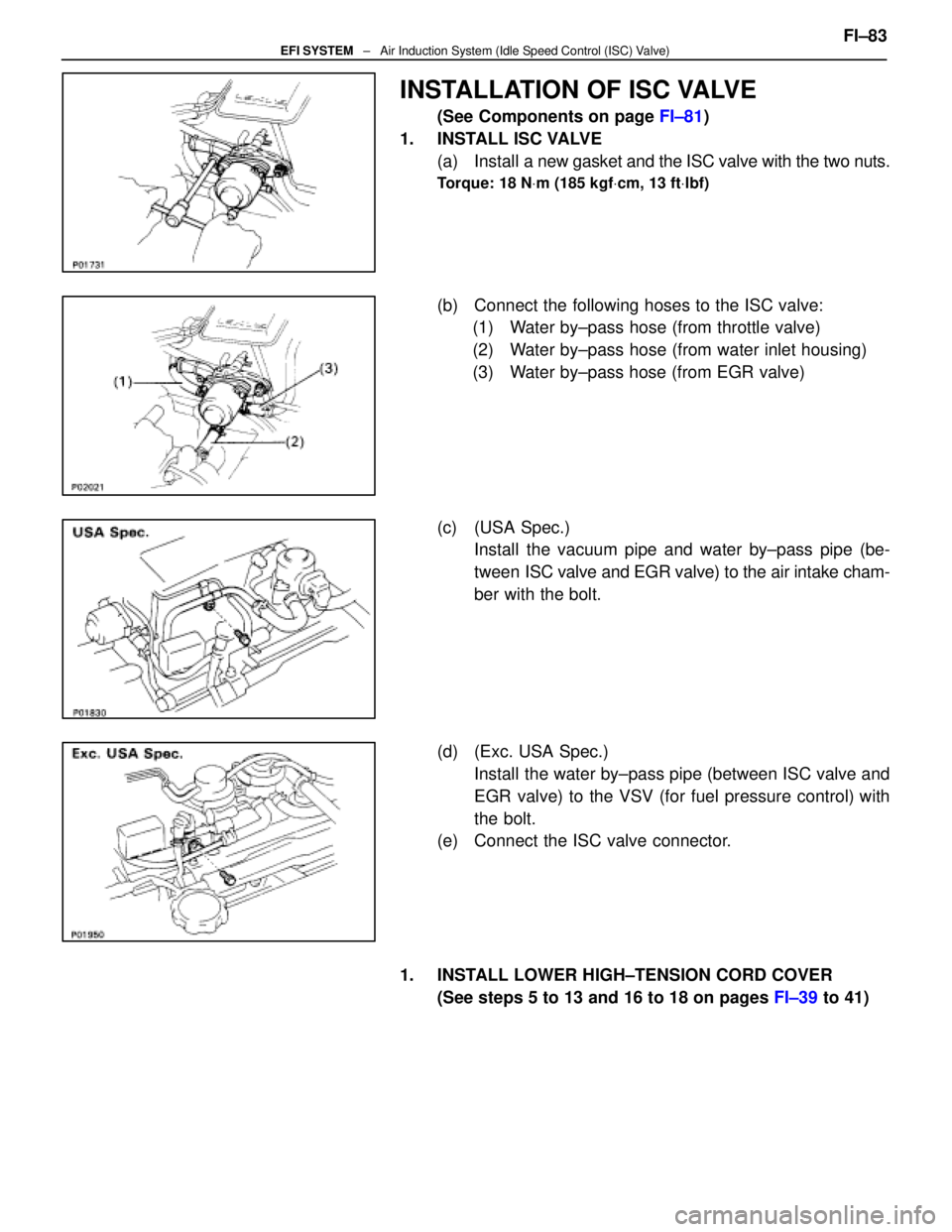

INSTALLATION OF ISC VALVE

(See Components on page FI±81)

1. INSTALL ISC VALVE (a) Install a new gasket and the ISC valve with the two nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(b) Connect the following hoses to the ISC valve:

(1) Water by±pass hose (from throttle valve)

(2) Water by±pass hose (from water inlet housing)

(3) Water by±pass hose (from EGR valve)

(c) (USA Spec.) Install the vacuum pipe and water by±pass pipe (be-

tween ISC valve and EGR valve) to the air intake cham-

ber with the bolt.

(d) (Exc. USA Spec.) Install the water by±pass pipe (between ISC valve and

EGR valve) to the VSV (for fuel pressure control) with

the bolt.

(e) Connect the ISC valve connector.

1. INSTALL LOWER HIGH±TENSION CORD COVER (See steps 5 to 13 and 16 to 18 on pages FI±39 to 41)FI±83

EFI SYSTEM

± Air Induction System (Idle Speed Control (ISC) Valve)

WhereEverybodyKnowsYourName

Page 2464 of 4087

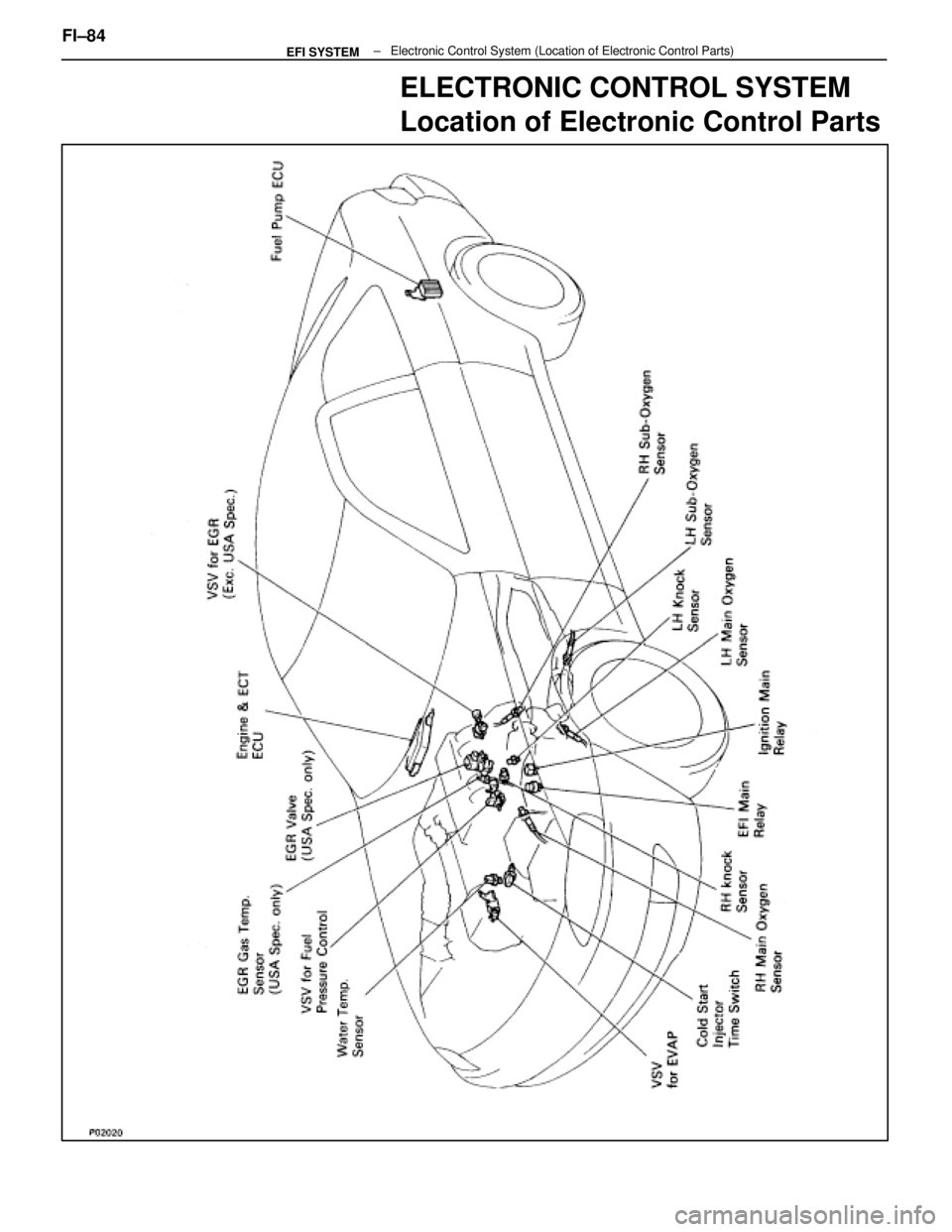

ELECTRONIC CONTROL SYSTEM

Location of Electronic Control Parts

FI±84 ± Electronic Control\

System (Location of Electronic Control Parts)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2465 of 4087

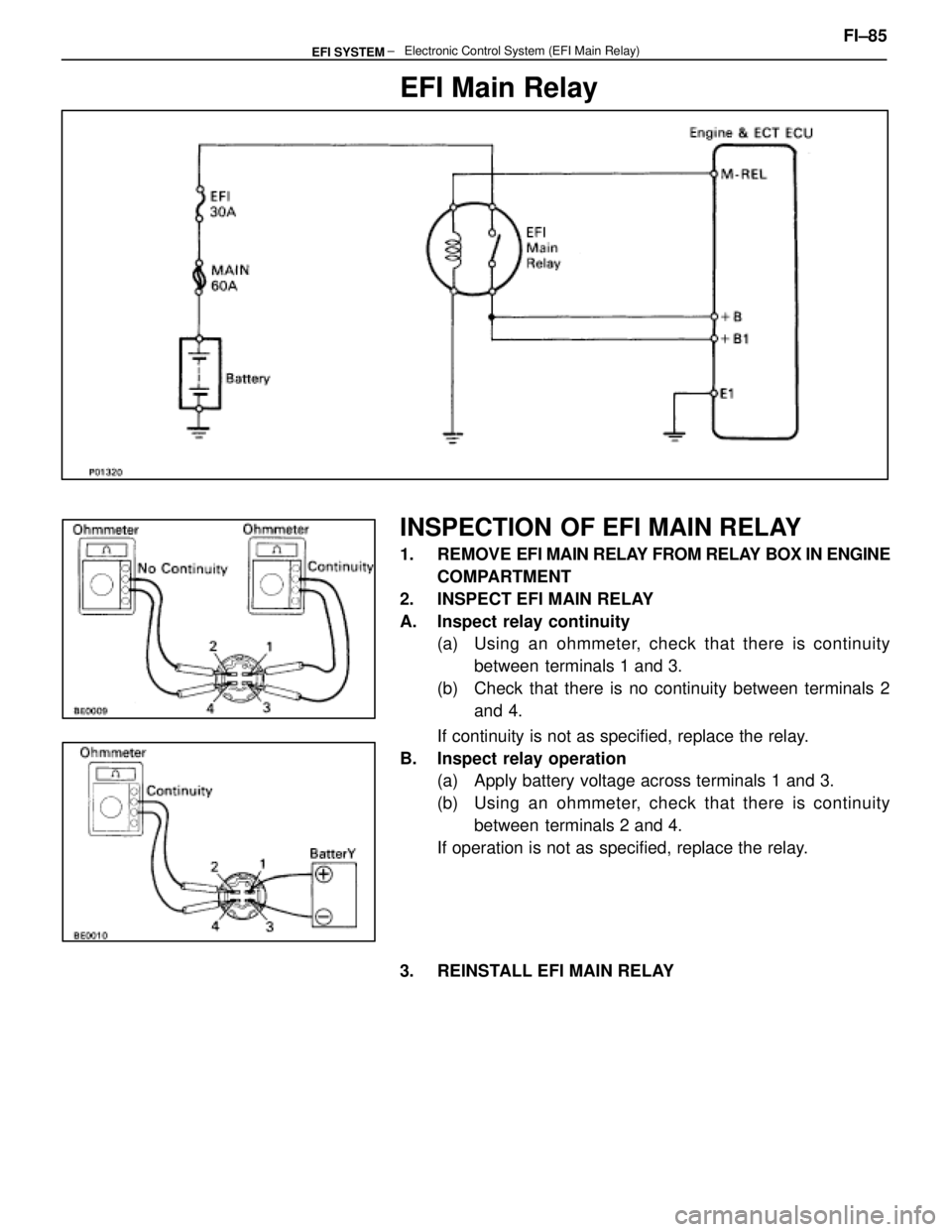

EFI Main Relay

INSPECTION OF EFI MAIN RELAY

1. REMOVE EFI MAIN RELAY FROM RELAY BOX IN ENGINE

COMPARTMENT

2. INSPECT EFI MAIN RELAY

A. Inspect relay continuity (a) Using an ohmmeter, check that there is continuity

between terminals 1 and 3.

(b) Check that there is no continuity between terminals 2 and 4.

If continuity is not as specified, replace the relay.

B. Inspect relay operation (a) Apply battery voltage across terminals 1 and 3.

(b) Using an ohmmeter, check that there is continuity

between terminals 2 and 4.

If operation is not as specified, replace the relay.

3. REINSTALL EFI MAIN RELAY FI±85

± Electronic Control System (EFI Main Relay\

)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2466 of 4087

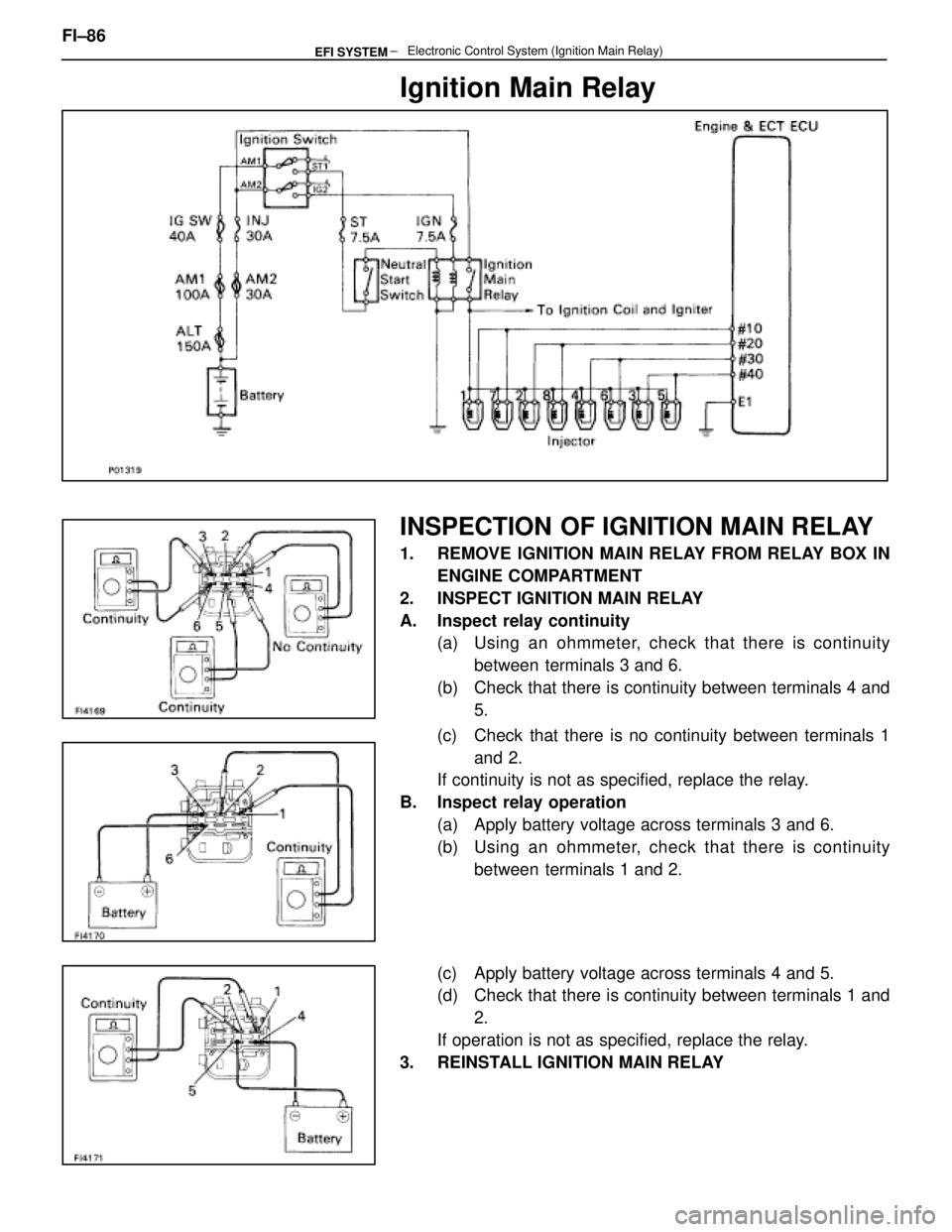

Ignition Main Relay

INSPECTION OF IGNITION MAIN RELAY

1. REMOVE IGNITION MAIN RELAY FROM RELAY BOX INENGINE COMPARTMENT

2. INSPECT IGNITION MAIN RELAY

A. Inspect relay continuity (a) Using an ohmmeter, check that there is continuity

between terminals 3 and 6.

(b) Check that there is continuity between terminals 4 and 5.

(c) Check that there is no continuity between terminals 1 and 2.

If continuity is not as specified, replace the relay.

B. Inspect relay operation (a) Apply battery voltage across terminals 3 and 6.

(b) Using an ohmmeter, check that there is continuitybetween terminals 1 and 2.

(c) Apply battery voltage across terminals 4 and 5.

(d) Check that there is continuity between terminals 1 and 2.

If operation is not as specified, replace the relay.

3. REINSTALL IGNITION MAIN RELAY

FI±86

± Electronic Control System (Igniti\

on Main Relay)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2467 of 4087

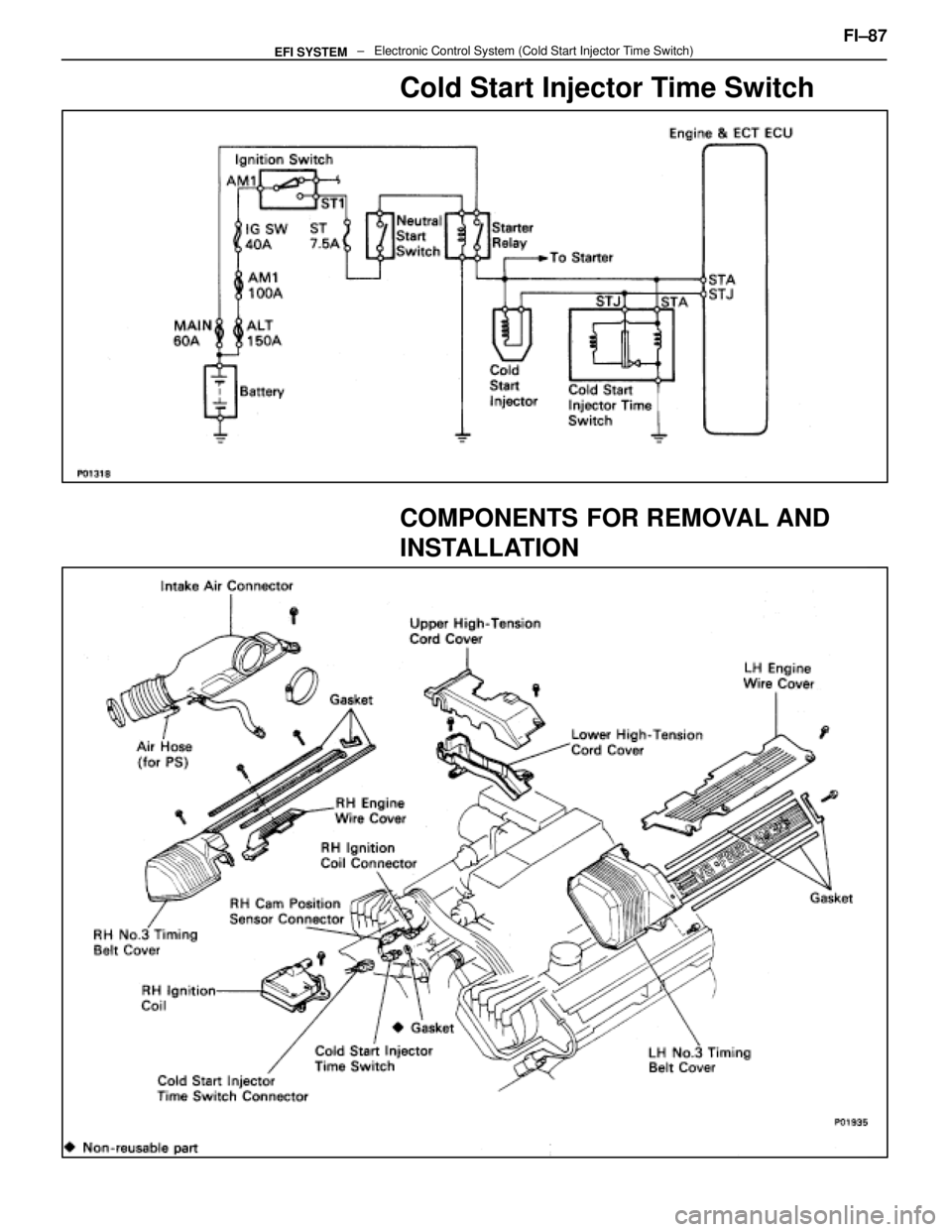

Cold Start Injector Time Switch

COMPONENTS FOR REMOVAL AND

INSTALLATION

FI±87 ± Electronic Control System (Cold St\

art Injector Time Switch)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2468 of 4087

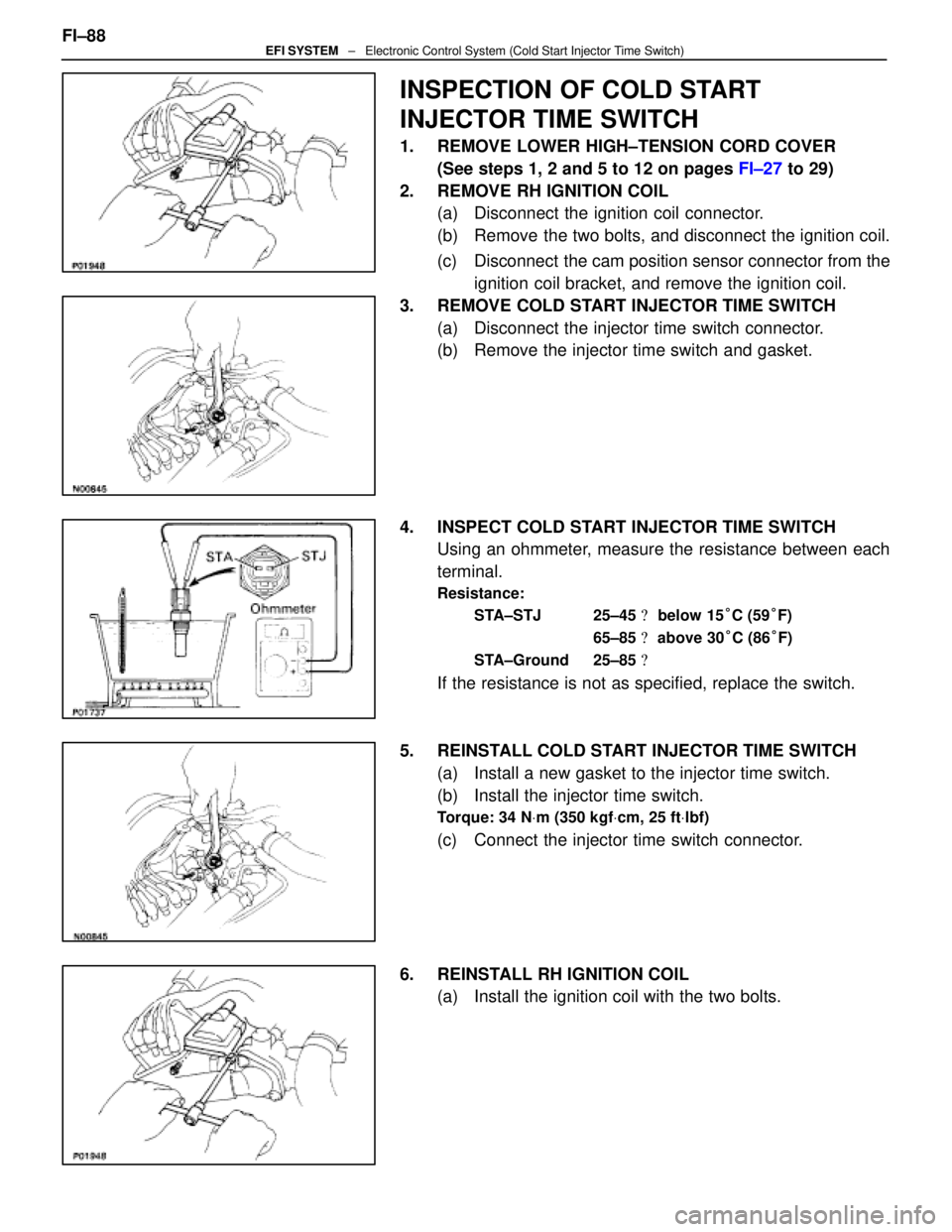

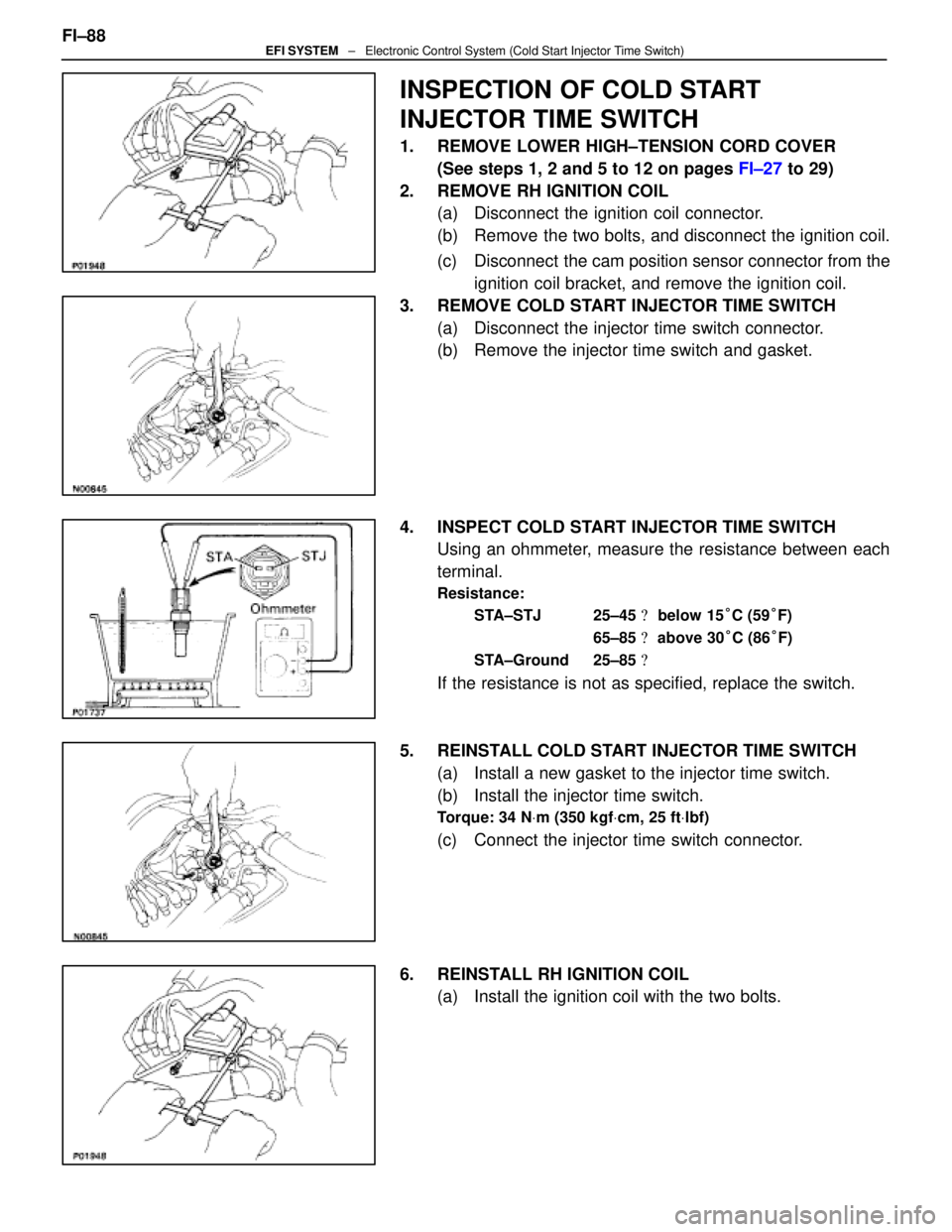

INSPECTION OF COLD START

INJECTOR TIME SWITCH

1. REMOVE LOWER HIGH±TENSION CORD COVER(See steps 1, 2 and 5 to 12 on pages FI±27 to 29)

2. REMOVE RH IGNITION COIL (a) Disconnect the ignition coil connector.

(b) Remove the two bolts, and disconnect the ignition coil.

(c) Disconnect the cam position sensor connector from the

ignition coil bracket, and remove the ignition coil.

3. REMOVE COLD START INJECTOR TIME SWITCH (a) Disconnect the injector time switch connector.

(b) Remove the injector time switch and gasket.

4. INSPECT COLD START INJECTOR TIME SWITCH Using an ohmmeter, measure the resistance between each

terminal.

Resistance:

STA±STJ 25±45 � below 15 °C (59 °F)

65±85 � above 30 °C (86 °F)

STA±Ground 25±85 �

If the resistance is not as specified, replace the switch.

5. REINSTALL COLD START INJECTOR TIME SWITCH (a) Install a new gasket to the injector time switch.

(b) Install the injector time switch.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(c) Connect the injector time switch connector.

6. REINSTALL RH IGNITION COIL (a) Install the ignition coil with the two bolts.

FI±88

EFI SYSTEM

± Electronic Control System (Cold Start Injector Time Switch)

WhereEverybodyKnowsYourName

Page 2469 of 4087

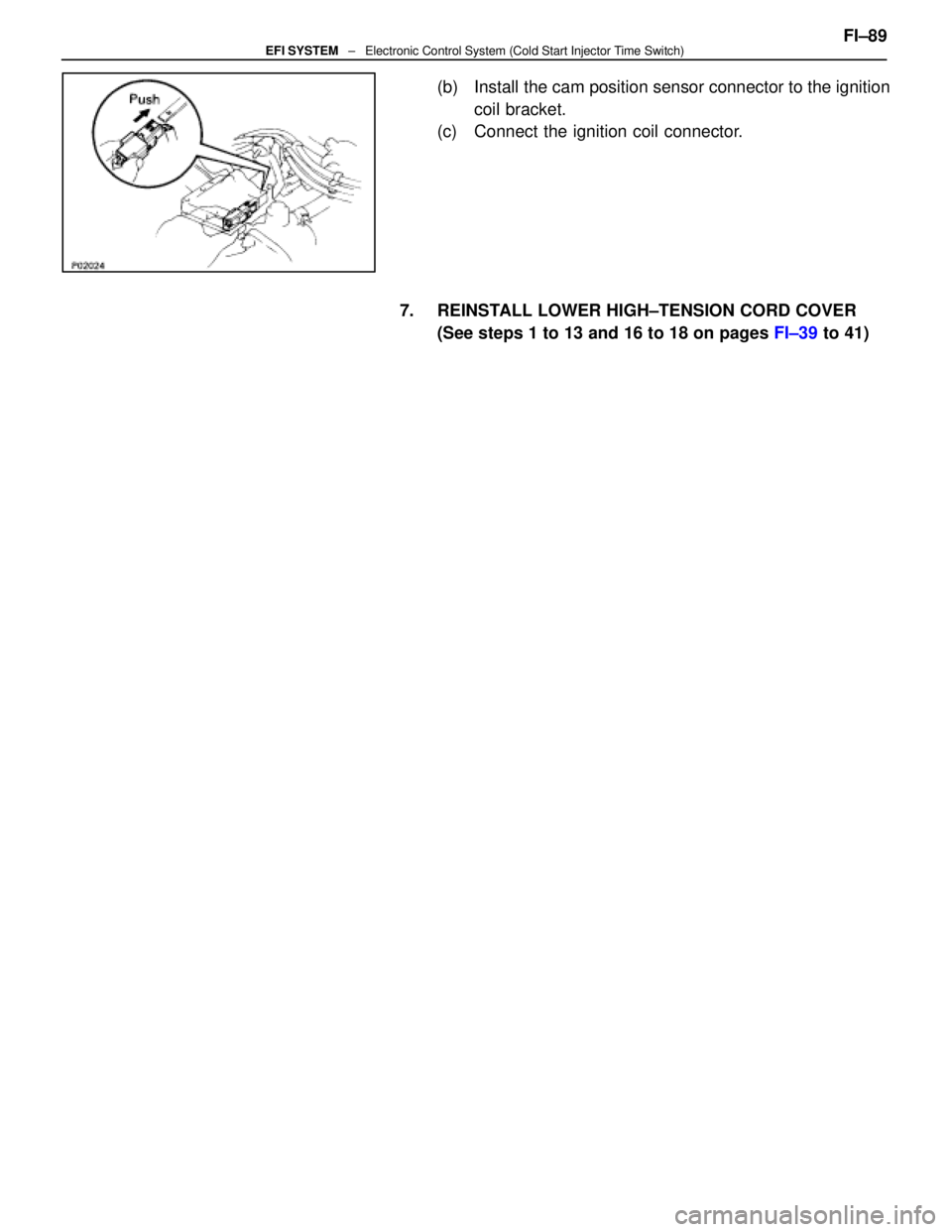

(b) Install the cam position sensor connector to the ignitioncoil bracket.

(c) Connect the ignition coil connector.

7. REINSTALL LOWER HIGH±TENSION CORD COVER (See steps 1 to 13 and 16 to 18 on pages FI±39 to 41)FI±89

EFI SYSTEM

± Electronic Control System (Cold Start Injector Time Switch)

WhereEverybodyKnowsYourName

Page 2470 of 4087

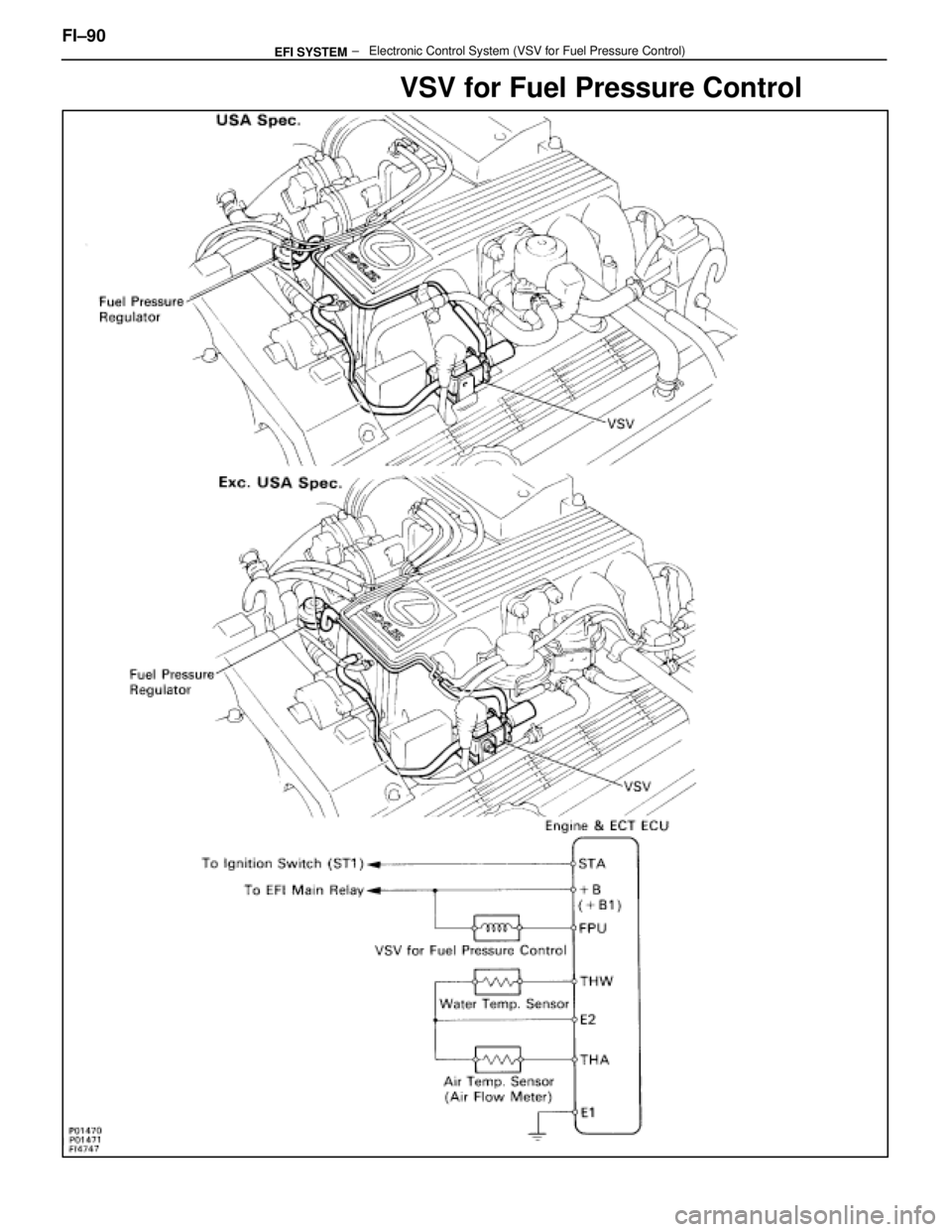

VSV for Fuel Pressure Control

FI±90 ± Electronic Control System (VSV for Fue\

l Pressure Control)EFI SYSTEM

WhereEverybodyKnowsYourName

Trending: hood open, wheel bolt torque, ABS, wheel alignment, dimensions, run flat, brake rotor