battery MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 849 of 909

T–38

AIR BAG SYSTEM

6. Tie all tires together with wire.

7. Connect the SST (Deployment tool) to the SST

(Adapter harness).

8. Connect the red clip of the SST (Deployment tool)

to the positive battery terminal and the black clip

to the negative battery terminal.

9. Verify that the red light on the SST (Deployment

tool) is illuminated.

10. Make sure all persons are standing at least 6 m

{20 ft} from the vehicle.

11. Press the activation switch on the SST

(Deployment tool) to deploy the curtain air bag

module.

End Of Sie

A6E8130W034

49 H066 002

49 L066 002

A6E8130W155

49 H066 002

ACTIVATION

SWITCH

A6E8130W028

Page 859 of 909

![MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–47

T

5INSPECT INSTRUMENT CLUSTER

CONNECTOR

•Disconnect negative battery cable.

•Disconnect instrument cluster connector.

•Are poor conn MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–47

T

5INSPECT INSTRUMENT CLUSTER

CONNECTOR

•Disconnect negative battery cable.

•Disconnect instrument cluster connector.

•Are poor conn](/img/28/57057/w960_57057-858.png)

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–47

T

5INSPECT INSTRUMENT CLUSTER

CONNECTOR

•Disconnect negative battery cable.

•Disconnect instrument cluster connector.

•Are poor connection detection bars of

instrument cluster connector okay?Yes Go to next step.

No Replace wiring harness.

6•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 8.

7INSPECT WIRING HARNESS BETWEEN DSC

HU/CM AND INSTRUMENT CLUSTER

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

DSC HU/CM and instrument cluster

terminals for short to ground, short power

supply, and open circuit:

—AF—2W (CAN_L)

—AG—2X (CAN_H)

•Is wiring harness okay?Yes Replace instrument cluster, then go to Step 17.

No Replace wiring harness.

8INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND INSTRUMENT

CLUSTER

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

ABS (ABS/TCS) HU/CM and instrument

cluster terminals for short to ground, short

power supply, and open circuit:

—R—2W (CAN_L)

—O—2X (CAN_H)

•Is wiring harness okay?Yes Replace instrument cluster, then go to Step 17.

No Replace wiring harness.

9INSPECT ABS (ABS/TCS) HU/CM OR DSC

HU/CM CONNECTOR

•Disconnect negative battery cable.

•Disconnect ABS (ABS/TCS) HU/CM or DSC

HU/CM connector.

•Is the connector for the ABS (ABS/TCS) HU/

CM or DSC HU/CM connected correctly?Yes Go to next step.

No Replace wiring harness.

10•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 12.

11INSPECT WIRING HARNESS BETWEEN DSC

HU/CM AND INSTRUMENT CLUSTER

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

DSC HU/CM and instrument cluster

terminals for short to ground, short power

supply, and open circuit:

—AF—2W (CAN_L)

—AG—2X (CAN_H)

•Is wiring harness okay?Yes Replace DSC HU/CM, then go to Step 17.

No Replace wiring harness.

12INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND INSTRUMENT

CLUSTER

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

ABS (ABS/TCS) HU/CM and instrument

cluster terminals for short to ground, short

power supply, and open circuit:

—R—2W (CAN_L)

—O—2X (CAN_H)

•Is wiring harness okay?Yes Replace ABS (ABS/TCS) HU/CM, then go to Step 17.

No Replace wiring harness.

13INSPECT PCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM connected

correctly?Yes Go to next step.

No Replace wiring harness. STEP INSPECTION ACTION

Page 861 of 909

![MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–49

T

22DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

C?Yes Go to Step 36.

No Go to next step.

2 MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–49

T

22DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

C?Yes Go to Step 36.

No Go to next step.

2](/img/28/57057/w960_57057-860.png)

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–49

T

22DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

C?Yes Go to Step 36.

No Go to next step.

23DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

B or the TCM?Yes Go to Step 39.

No Go to next step.

24DETERMINING THE LOCATION OF A

MALFUNCTION

•Is the malfunctioning part the wiring harness

A or the PCM?Yes Go to Step 43.

No Go to next step.

25INSPECT INSTRUMENT CLUSTER

CONNECTOR

•Disconnect negative battery cable.

•Disconnect instrument cluster connector.

•Are poor connection detection bars of

instrument cluster connector okay?Yes Go to next step.

No Replace wiring harness.

26INSPECT WIRING HARNESS BETWEEN

INSTRUMENT CLUSTER AND 4WD

CONTROL MODULE

•Disconnect 4WD control module connector.

•Inspect the following wiring harness between

4WD control module and instrument cluster

terminals for short to ground, short power

supply, and open circuit:

—H—2W (CAN_L)

—G—2X (CAN_H)

•Is wiring harness okay?Yes Replace instrument cluster, then go to Step 45.

No Replace wiring harness.

27INSPECT 4WD CONTROL MODULE

CONNECTOR

•Disconnect negative battery cable.

•Disconnect 4WD control module connector.

•Is the connector for the 4WD control module

connected correctly?Yes Go to next step.

No Replace wiring harness.

28INSPECT WIRING HARNESS BETWEEN 4WD

CONTROL MODULE AND INSTRUMENT

CLUSTER

•Disconnect instrument cluster connector.

•Inspect the following wiring harness between

4WD control module and instrument cluster

terminals for short to ground, short power

supply, and open circuit:

—H—2W (CAN_L)

—G—2X (CAN_H)

•Is wiring harness okay?Yes Replace 4WD control module, then go to Step 45.

No Replace wiring harness.

29•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 31.

30INSPECT WIRING HARNESS BETWEEN DSC

HU/CM AND 4WD CONTROL MODULE

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

DSC HU/CM and 4WD control module

terminals for short to ground, short power

supply, and open circuit:

—AF—H (CAN_L)

—AG—G (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness. STEP INSPECTION ACTION

Page 862 of 909

![MAZDA 6 2002 Workshop Manual Suplement T–50

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

31INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the MAZDA 6 2002 Workshop Manual Suplement T–50

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

31INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the](/img/28/57057/w960_57057-861.png)

T–50

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

31INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

ABS (ABS/TCS) HU/CM and 4WD control

module terminals for short to ground, short

power supply, and open circuit:

—R—H (CAN_L)

—O—G (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness.

32INSPECT ABS (ABS/TCS) HU/CM OR DSC

HU/CM CONNECTOR

•Disconnect negative battery cable.

•Disconnect ABS (ABS/TCS) HU/CM or DSC

HU/CM connector.

•Is the connector for the ABS (ABS/TCS) HU/

CM or DSC HU/CM connected correctly?Yes Go to next step.

No Replace wiring harness.

33•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 35.

34INSPECT WIRING HARNESS BETWEEN DSC

HU/CM AND 4WD CONTROL MODULE

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

DSC HU/CM and 4WD control module

terminals for short to ground, short power

supply, and open circuit:

—AF—H (CAN_L)

—AG—G (CAN_H)

•Is wiring harness okay?Yes Replace DSC HU/CM, then go to Step 45.

No Replace wiring harness.

35INSPECT WIRING HARNESS BETWEEN ABS

(ABS/TCS) HU/CM AND 4WD CONTROL

MODULE

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

ABS (ABS/TCS) HU/CM and 4WD control

module terminals for short to ground, short

power supply, and open circuit:

—R—H (CAN_L)

—O—G (CAN_H)

•Is wiring harness okay?Yes Replace ABS (ABS/TCS) HU/CM, then go to Step 45.

No Replace wiring harness.

36•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 38.

37INSPECT WIRING HARNESS BETWEEN TCM

AND DSC HU/CM

•Disconnect TCM connector.

•Inspect the following wiring harness between

TCM and DSC HU/CM terminals for short to

ground, short power supply, and open circuit:

—2J—AF (CAN_L)

—2M—AG (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness.

38INSPECT WIRING HARNESS BETWEEN TCM

AND ABS (ABS/TCS) HU/CM

•Disconnect TCM connector.

•Inspect the following wiring harness between

TCM and ABS (ABS/TCS) HU/CM terminals

for short to ground, short power supply, and

open circuit:

—2J—R (CAN_L)

—2M—O (CAN_H)

•Is wiring harness okay?Yes Go to Step 45.

No Replace wiring harness. STEP INSPECTION ACTION

Page 863 of 909

![MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–51

T

End Of Sie

39INSPECT TCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM con MAZDA 6 2002 Workshop Manual Suplement ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–51

T

End Of Sie

39INSPECT TCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM con](/img/28/57057/w960_57057-862.png)

ON-BOARD DIAGNOSTIC [MULTIPLEX COMMUNICATION SYSTEM]

T–51

T

End Of Sie

39INSPECT TCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect TCM connector.

•Is the connector for the TCM connected

correctly?Yes Go to next step.

No Replace wiring harness.

40•Is vehicle equipped with DSC? Yes Go to next step.

No Go to step 42.

41INSPECT WIRING HARNESS BETWEEN TCM

AND DSC HU/CM

•Disconnect DSC HU/CM connector.

•Inspect the following wiring harness between

TCM and DSC HU/CM terminals for short to

ground, short power supply, and open circuit:

—2J—AF (CAN_L)

—2M—AG (CAN_H)

•Is wiring harness okay?Yes Replace TCM, then go to Step 45.

No Replace wiring harness.

42INSPECT WIRING HARNESS BETWEEN TCM

AND ABS (ABS/TCS) HU/CM

•Disconnect ABS (ABS/TCS) HU/CM

connector.

•Inspect the following wiring harness between

TCM and ABS (ABS/TCS) HU/CM terminals

for short to ground, short power supply, and

open circuit:

—2J—R (CAN_L)

—2M—O (CAN_H)

•Is wiring harness okay?Yes Replace TCM, then go to Step 45.

No Replace wiring harness.

43INSPECT PCM CONNECTOR

•Disconnect negative battery cable.

•Disconnect PCM connector.

•Is the connector for the PCM connected

correctly?Yes Go to next step.

No Replace wiring harness.

44INSPECT WIRING HARNESS BETWEEN TCM

AND PCM

•Disconnect TCM connector.

•Inspect the following wiring harness between

TCM and PCM terminals for short to ground,

short power supply, and open circuit:

—2J—2R (CAN_L)

—2M—2U (CAN_H)

•Is wiring harness okay?Yes Replace PCM, then go to next step.

No Replace wiring harness.

45CHECK DTC INDICATE

•Connect PCM connector.

•Connect TCM connector.

•Connect ABS (ABS/TCS) HU/CM or DSC

HU/CM connector.

•Connect 4WD control module connector.

•Connect instrument cluster connector.

•Clear DTC from module memory using SST

(WDS or equivalent).

•Perform KOEO/KOER self-test.

•Are DTC’s U0073, U1900 and/or U2516

indicated?Yes Repeat from Step 18.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 873 of 909

U–10

BASIC SYSTEM

A/C UNIT REMOVAL/INSTALLATIONA6E8516611302011. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system.

3. Drain the engine coolant.

4. Remove the dashboard.

5. Remove the theft-deterrent control module.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug open fittings after removing any refrigeration

cycle parts to keep moisture or foreign material out of the cycle.

6. Remove in the order indicated in the table. Do not allow compressor oil to spill.

.

BASIC SYSTEM

1

L.H.D.R.H.D.

3

2

R

R

N·m {kgf·cm, in·lbf} 6.86—9.80

{70.0—99.9,

60.8—86.7}

R

R

3

2

1

4

A6E85162001

1 Heater hose

2 Cooler pipe No.4 (L.H.D.) or cooler pipe No.5

(R.H.D.)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION) (R.H.D.)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)3 Cooler pipe No.3

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION) (R.H.D.)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

4A/C unit

(See U–11 A/C Unit Installation Note)

Page 874 of 909

BASIC SYSTEM

U–11

U

7. Install in the reverse order of removal.

8. Perform the refrigerant system performance test.

A/C Unit Installation Note

1. When installing a new A/C unit or evaporator, add a supplemental amount of ATMOS GU10 compressor oil into

the refrigerant cycle.

Supplemental amount (approximate quantity)

40 ml {40 cc, 1.4 fl oz}

End Of Sie

A/C COMPRESSOR REMOVAL/INSTALLATIONA6E8516614502011. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system.

3. Remove the right side splash shield.

4. Loosen the drive belt and remove it.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug open fittings after removing any refrigeration

cycle parts to keep moisture or foreign material out of the cycle.

5. Remove in the order indicated in the table. Do not

allow compressor oil to spill.

.

6. Install in the reverse order of removal.

7. Adjust the drive belt.

8. Perform the refrigerant system performance test.

A/C Compressor Installation Note

1. Remove the following amount of compressor oil from the new A/C compressor when replacing the A/C

compressor.

Compressor oil to be removed (approximate quantity)

150 ml {150 cc, 5.07 fl oz} – [compressor oil from old A/C compressor + 15 ml {15 cc, 0.5 fl oz}]

End Of Sie

1 Cooler hose (HI)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

2 Cooler hose (LO)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

3 Magnetic clutch connector

4A/C compressor

(See U–11 A/C Compressor Installation Note)

4

3

1

2

N·m {kgf·cm, in·lbf} 6.86—9.80

{70.0—99.9,

60.8—86.7}

R

R

6.86—9.80

{70.0—99.9,

60.8—86.7}

17.6—26.5 N·m

{1.80—2.70 kgf·m,

13.0—19.5 ft·lbf}

A6E85162005

Page 875 of 909

U–12

BASIC SYSTEM

CONDENSER REMOVAL/INSTALLATIONA6E8516614802011. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system.

3. Remove the shroud panel.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug all open fittings after removing any

refrigeration cycle parts to keep moisture or foreign material out of the cycle.

4. Remove in the order indicated in the table. Do not

allow compressor oil to spill.

.

5. Install in the reverse order of removal.

6. Perform the refrigerant system performance test.

Condenser Installation Note

1. When installing a new condenser, add a supplemental amount of ATMOS GU10 compressor oil inlet the

refrigerant cycle.

Supplemental amount (approximate quantity)

35 ml {35 cc, 1.2 fl oz}

End Of Sie

1 Cooler pipe No.1

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

2 Cooler pipe No.2

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

3 Condenser

(See U–12 Condenser Installation Note)

N·m {kgf·cm, in·lbf}

R

3

1

2

6.86—9.80

{70.0—99.9, 60.8—86.7}

R

A6E8516W013

Page 876 of 909

BASIC SYSTEM

U–13

U

REFRIGERANT LINES REMOVAL/INSTALLATIONA6E8516614602011. Remove the battery.

2. Discharge the refrigerant from the system.

3. Remove the washer tank.

4. Remove the air cleaner cover, air cleaner element and air cleaner case. (See F2–36 INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION.)

5. Remove the sedimentor.

6. Remove the No.3 engine mount.

7. Remove the water heater unit.

8. Remove the shroud panel.

9. Remove the right splash shield.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug all open fittings after removing any

refrigeration cycle parts to keep moisture or foreign material out of the cycle.

10. Remove in the order indicated in the table. Do not allow compressor oil to spill.

11. Install in the reverse order of removal.

Page 878 of 909

BASIC SYSTEM, CONTROL SYSTEM

U–15

U

End Of Sie

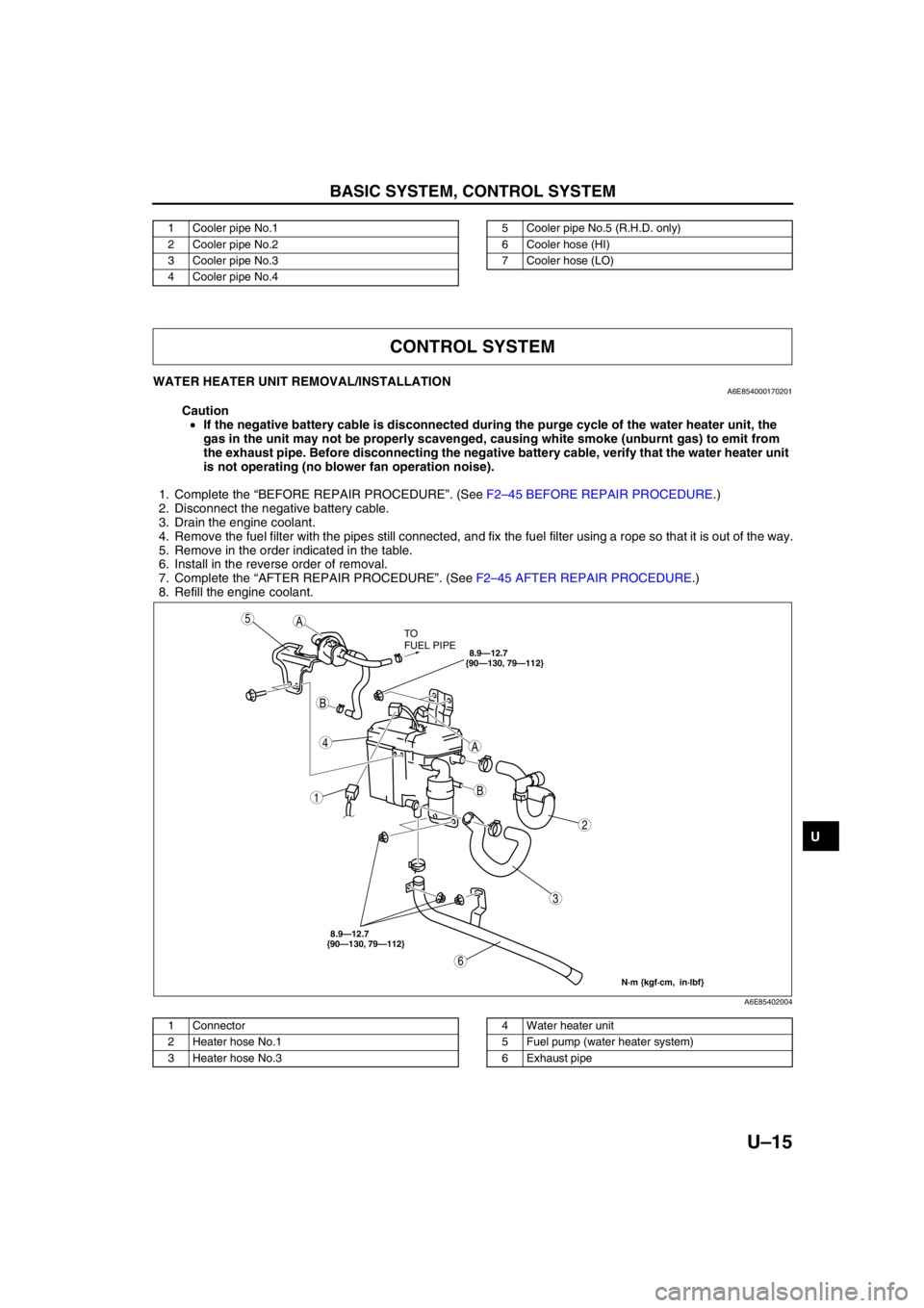

WATER HEATER UNIT REMOVAL/INSTALLATIONA6E854000170201

Caution

•If the negative battery cable is disconnected during the purge cycle of the water heater unit, the

gas in the unit may not be properly scavenged, causing white smoke (unburnt gas) to emit from

the exhaust pipe. Before disconnecting the negative battery cable, verify that the water heater unit

is not operating (no blower fan operation noise).

1. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

2. Disconnect the negative battery cable.

3. Drain the engine coolant.

4. Remove the fuel filter with the pipes still connected, and fix the fuel filter using a rope so that it is out of the way.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”. (See F2–45 AFTER REPAIR PROCEDURE.)

8. Refill the engine coolant.

.

End Of Sie

1 Cooler pipe No.1

2 Cooler pipe No.2

3 Cooler pipe No.3

4 Cooler pipe No.45 Cooler pipe No.5 (R.H.D. only)

6 Cooler hose (HI)

7 Cooler hose (LO)

CONTROL SYSTEM

A

A

B

B

5

4

3

1

2

6

TO

FUEL PIPE

8.9—12.7

{90—130, 79—112}

N·m {kgf·cm, in·lbf}

8.9—12.7

{90—130, 79—112}

A6E85402004

1 Connector

2 Heater hose No.1

3 Heater hose No.34 Water heater unit

5 Fuel pump (water heater system)

6 Exhaust pipe