battery MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 558 of 909

ON-BOARD DIAGNOSTIC

K2–143

K2

End Of Sie

5INSPECT LINE PRESSURE

•Start engine.

•Measure line pressure.

Specification

—D range, M (2GR) range

Idle: 290—490 kPa {3.0—4.9 kgf/cm

2, 43—69

psi}

Stall: 1,550—1,750 kPa {15.8—17.8 kgf/cm

2,

225—254 psi}

—M (1GR) range, R position

Idle:550—750 kPa {5.6—7.6 kgf/cm

2, 80—

109 psi}

Stall: 1,550—1,750 kPa {15.8—17.8 kgf/cm

2,

225—254 psi}

•Is line pressure within specification?

(See K2–72 Line Pressure Test.)Yes Go to next step.

No All ranges: Replace or overhaul oil pump or control valve

body, then go to Step 10.

Any ranges: Replace or overhaul automatic transaxle, then

go to Step 10.

(See K2–99 AUTOMATIC TRANSAXLE AND TRANSFER

REMOVAL/INSTALLATION.)

6CLICK TEST OF SOLENOID VALVES

•Turn ignition key to OFF.

•Disconnect terminal component No.1(12-pin).

•Apply battery voltage to terminal component

No.1 (12-pin) terminals (transaxle case side).

—TCC solenoid vale: B

—Pressure control solenoid: D

•Verify the click sounds of TCC solenoid valve

and pressure control solenoid.

•Are there click sounds?Yes Go to next step.

No Replace TCC solenoid valve or pressure control solenoid,

then go to Step 10.

(See K2–105 CONTROL VALVE BODY REMOVAL/

INSTALLATION.)

7INSPECT DIFFERENCE BETWEEN ENGINE

SPEED AND TURBINE SPEED

•Inspect difference between engine speed and

turbine speed during TCC operation in 5GR

•Drive vehicle under following condition

—TR switch position: D range

—Gear position: 5GR

—TCC solenoid valve: ON

•Is difference between engine speed (RPM PID)

and turbine speed okay?

Difference

Below 99 rpmYes Go to Step

No Go to next step.

8INSPECT OPERATION OF EACH VALVE AND

EACH SPRING

•Remove control valve body.

•Disassemble control valve body.

•Is each valve operation okay and is return

spring okay?Yes Replace torque converter, then go to next step.

No Replace control valve body, then go to next step.

(See K2–105 CONTROL VALVE BODY REMOVAL/

INSTALLATION.)

9VERIFY TROUBLESHOOTING OF DTC P0740

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Start engine.

•Warm up ATX.

•Drive vehicle under following condition for 10

seconds or more.

—Vehicle speed (VSS PID): Within 10—87

km/h {6—54 mph}

—Gear position: 5GR

—TR switch position: D range

—TCC solenoid valve: ON

•Is there pending code present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

10VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 595 of 909

K2–180

ON-BOARD DIAGNOSTIC

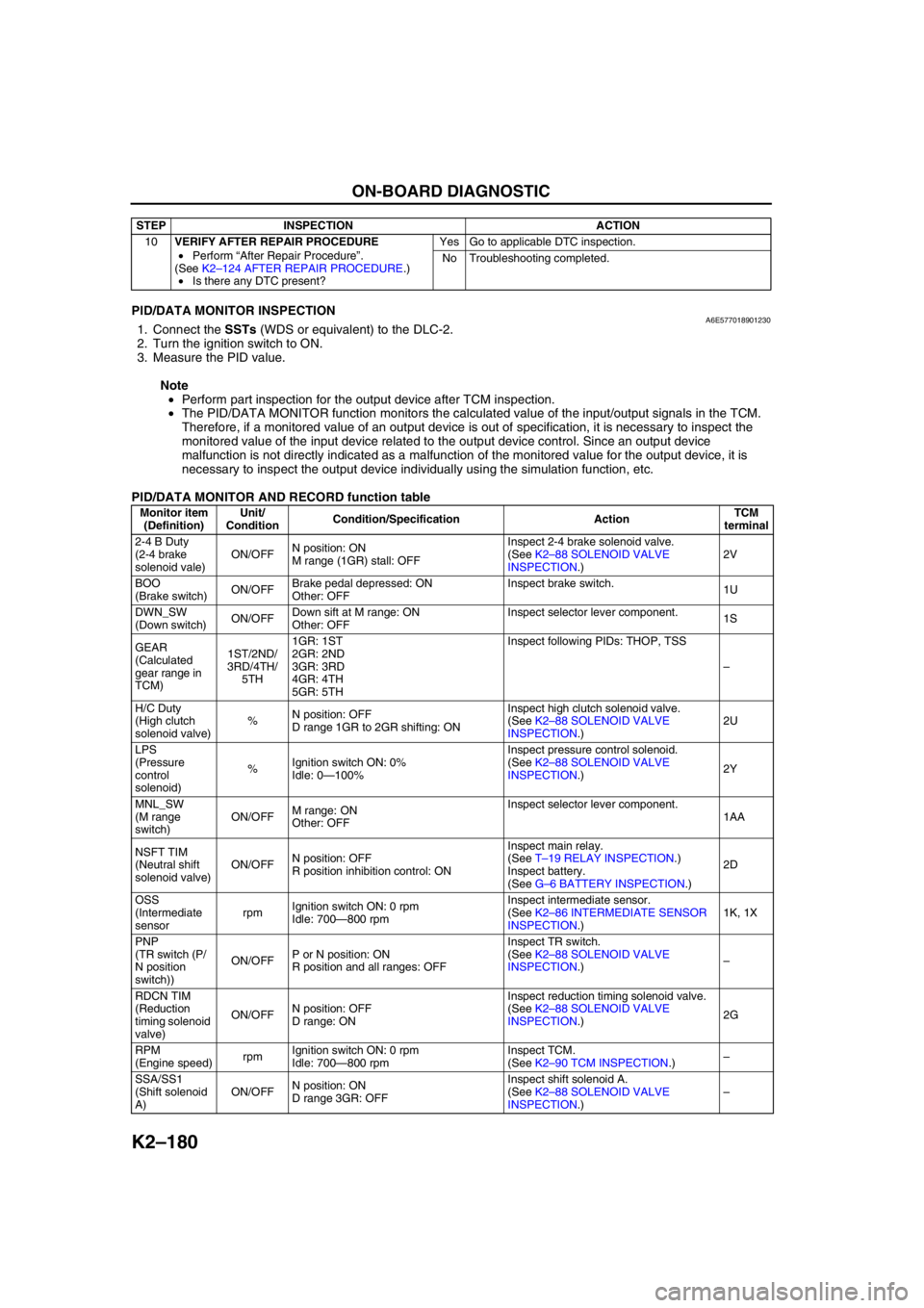

End Of SiePID/DATA MONITOR INSPECTIONA6E5770189012301. Connect the SSTs (WDS or equivalent) to the DLC-2.

2. Turn the ignition switch to ON.

3. Measure the PID value.

Note

•Perform part inspection for the output device after TCM inspection.

•The PID/DATA MONITOR function monitors the calculated value of the input/output signals in the TCM.

Therefore, if a monitored value of an output device is out of specification, it is necessary to inspect the

monitored value of the input device related to the output device control. Since an output device

malfunction is not directly indicated as a malfunction of the monitored value for the output device, it is

necessary to inspect the output device individually using the simulation function, etc.

PID/DATA MONITOR AND RECORD function table

10VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Monitor item

(Definition)Unit/

ConditionCondition/Specification ActionTCM

terminal

2-4 B Duty

(2-4 brake

solenoid vale)ON/OFFN position: ON

M range (1GR) stall: OFFInspect 2-4 brake solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2V

BOO

(Brake switch)ON/OFFBrake pedal depressed: ON

Other: OFFInspect brake switch.

1U

DWN_SW

(Down switch)ON/OFFDown sift at M range: ON

Other: OFFInspect selector lever component.

1S

GEAR

(Calculated

gear range in

TCM)1ST/2ND/

3RD/4TH/

5TH1GR: 1ST

2GR: 2ND

3GR: 3RD

4GR: 4TH

5GR: 5THInspect following PIDs: THOP, TSS

–

H/C Duty

(High clutch

solenoid valve)%N position: OFF

D range 1GR to 2GR shifting: ONInspect high clutch solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2U

LPS

(Pressure

control

solenoid)%Ignition switch ON: 0%

Idle: 0—100%Inspect pressure control solenoid.

(See K2–88 SOLENOID VALVE

INSPECTION.)2Y

MNL_SW

(M range

switch)ON/OFFM range: ON

Other: OFFInspect selector lever component.

1AA

NSFT TIM

(Neutral shift

solenoid valve)ON/OFFN position: OFF

R position inhibition control: ONInspect main relay.

(See T–19 RELAY INSPECTION.)

Inspect battery.

(See G–6 BATTERY INSPECTION.)2D

OSS

(Intermediate

sensorrpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect intermediate sensor.

(See K2–86 INTERMEDIATE SENSOR

INSPECTION.)1K, 1X

PNP

(TR switch (P/

N position

switch))ON/OFFP or N position: ON

R position and all ranges: OFFInspect TR switch.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

RDCN TIM

(Reduction

timing solenoid

valve)ON/OFFN position: OFF

D range: ONInspect reduction timing solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2G

RPM

(Engine speed)rpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect TCM.

(See K2–90 TCM INSPECTION.)–

SSA/SS1

(Shift solenoid

A)ON/OFFN position: ON

D range 3GR: OFFInspect shift solenoid A.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

Page 596 of 909

ON-BOARD DIAGNOSTIC

K2–181

K2

End Of Sie

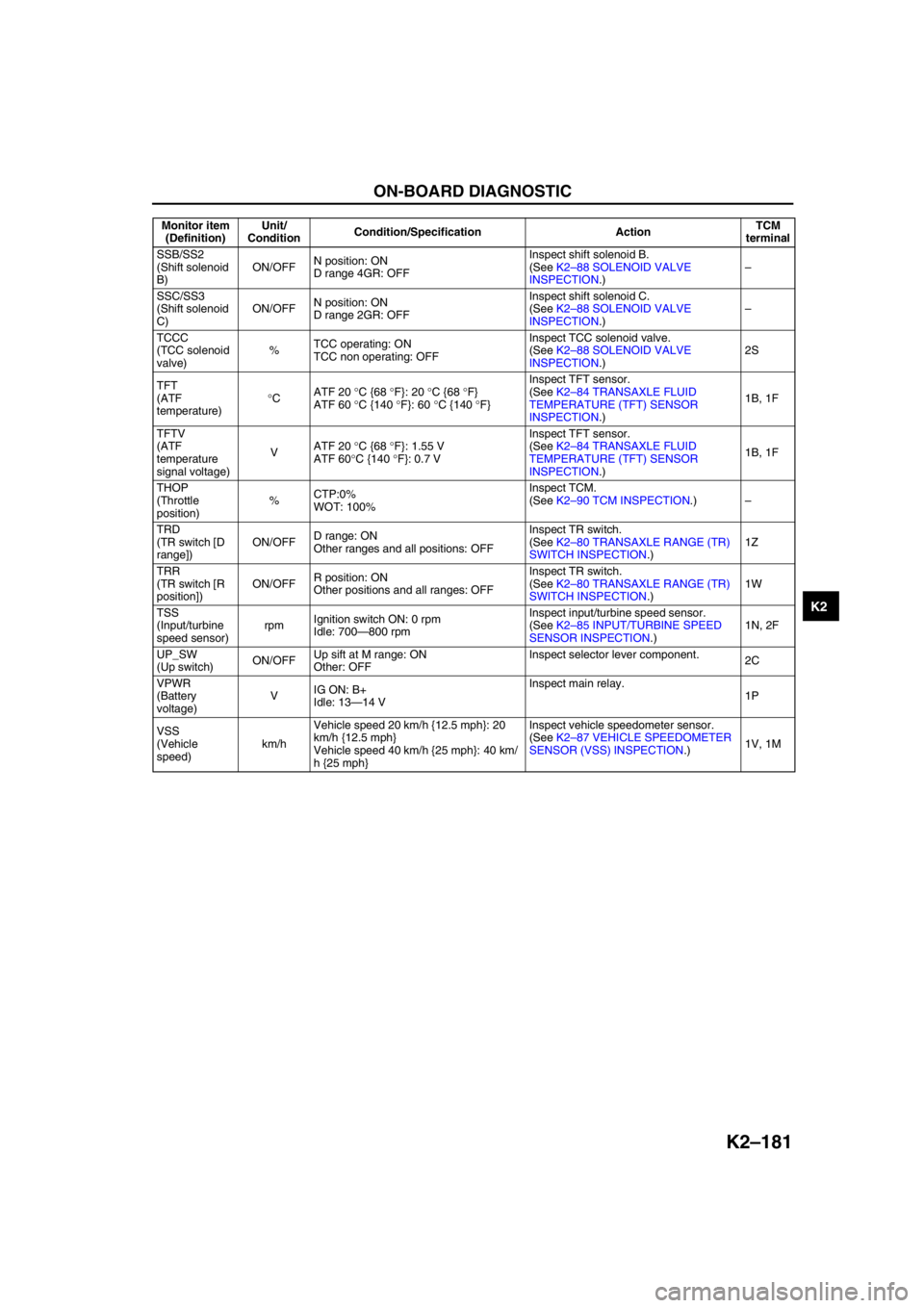

SSB/SS2

(Shift solenoid

B)ON/OFFN position: ON

D range 4GR: OFFInspect shift solenoid B.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

SSC/SS3

(Shift solenoid

C)ON/OFFN position: ON

D range 2GR: OFFInspect shift solenoid C.

(See K2–88 SOLENOID VALVE

INSPECTION.)–

TCCC

(TCC solenoid

valve)%TCC operating: ON

TCC non operating: OFFInspect TCC solenoid valve.

(See K2–88 SOLENOID VALVE

INSPECTION.)2S

TFT

(ATF

temperature)°CATF 20 °C {68 °F}: 20 °C {68 °F}

ATF 60 °C {140 °F}: 60 °C {140 °F}Inspect TFT sensor.

(See K2–84 TRANSAXLE FLUID

TEMPERATURE (TFT) SENSOR

INSPECTION.)1B, 1F

TFTV

(ATF

temperature

signal voltage)VATF 20 °C {68 °F}: 1.55 V

ATF 60°C {140 °F}: 0.7 VInspect TFT sensor.

(See K2–84 TRANSAXLE FLUID

TEMPERATURE (TFT) SENSOR

INSPECTION.)1B, 1F

THOP

(Throttle

position)%CTP:0%

WOT: 100%Inspect TCM.

(See K2–90 TCM INSPECTION.)–

TRD

(TR switch [D

range])ON/OFFD range: ON

Other ranges and all positions: OFFInspect TR switch.

(See K2–80 TRANSAXLE RANGE (TR)

SWITCH INSPECTION.)1Z

TRR

(TR switch [R

position])ON/OFFR position: ON

Other positions and all ranges: OFFInspect TR switch.

(See K2–80 TRANSAXLE RANGE (TR)

SWITCH INSPECTION.)1W

TSS

(Input/turbine

speed sensor)rpmIgnition switch ON: 0 rpm

Idle: 700—800 rpmInspect input/turbine speed sensor.

(See K2–85 INPUT/TURBINE SPEED

SENSOR INSPECTION.)1N, 2F

UP_SW

(Up switch)ON/OFFUp sift at M range: ON

Other: OFFInspect selector lever component.

2C

VPWR

(Battery

voltage)VIG ON: B+

Idle: 13—14 VInspect main relay.

1P

VSS

(Vehicle

speed)km/hVehicle speed 20 km/h {12.5 mph}: 20

km/h {12.5 mph}

Vehicle speed 40 km/h {25 mph}: 40 km/

h {25 mph}Inspect vehicle speedometer sensor.

(See K2–87 VEHICLE SPEEDOMETER

SENSOR (VSS) INSPECTION.)1V, 1M Monitor item

(Definition)Unit/

ConditionCondition/Specification ActionTCM

terminal

Page 638 of 909

M–8

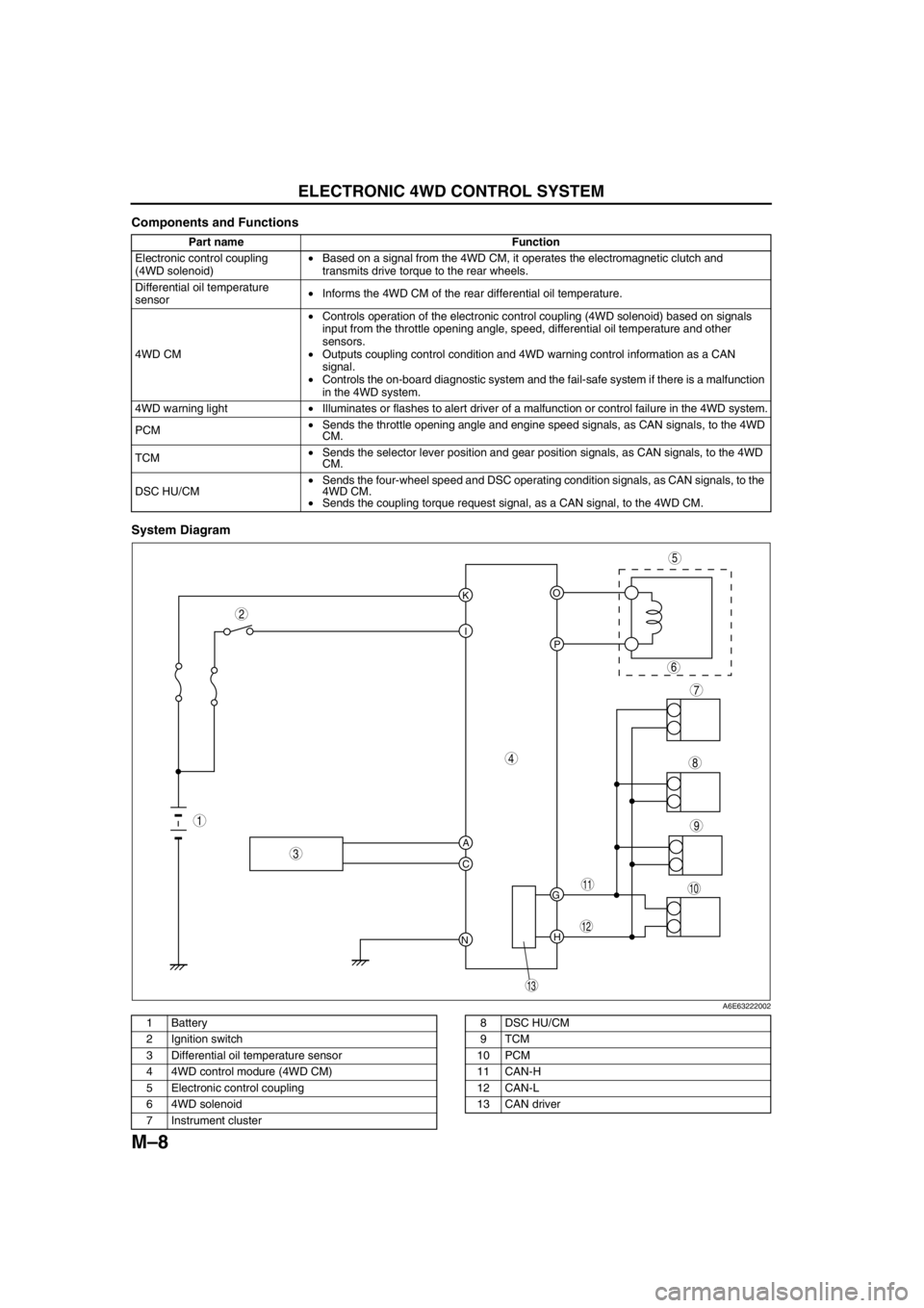

ELECTRONIC 4WD CONTROL SYSTEM

Components and Functions

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver

Page 647 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–17

M

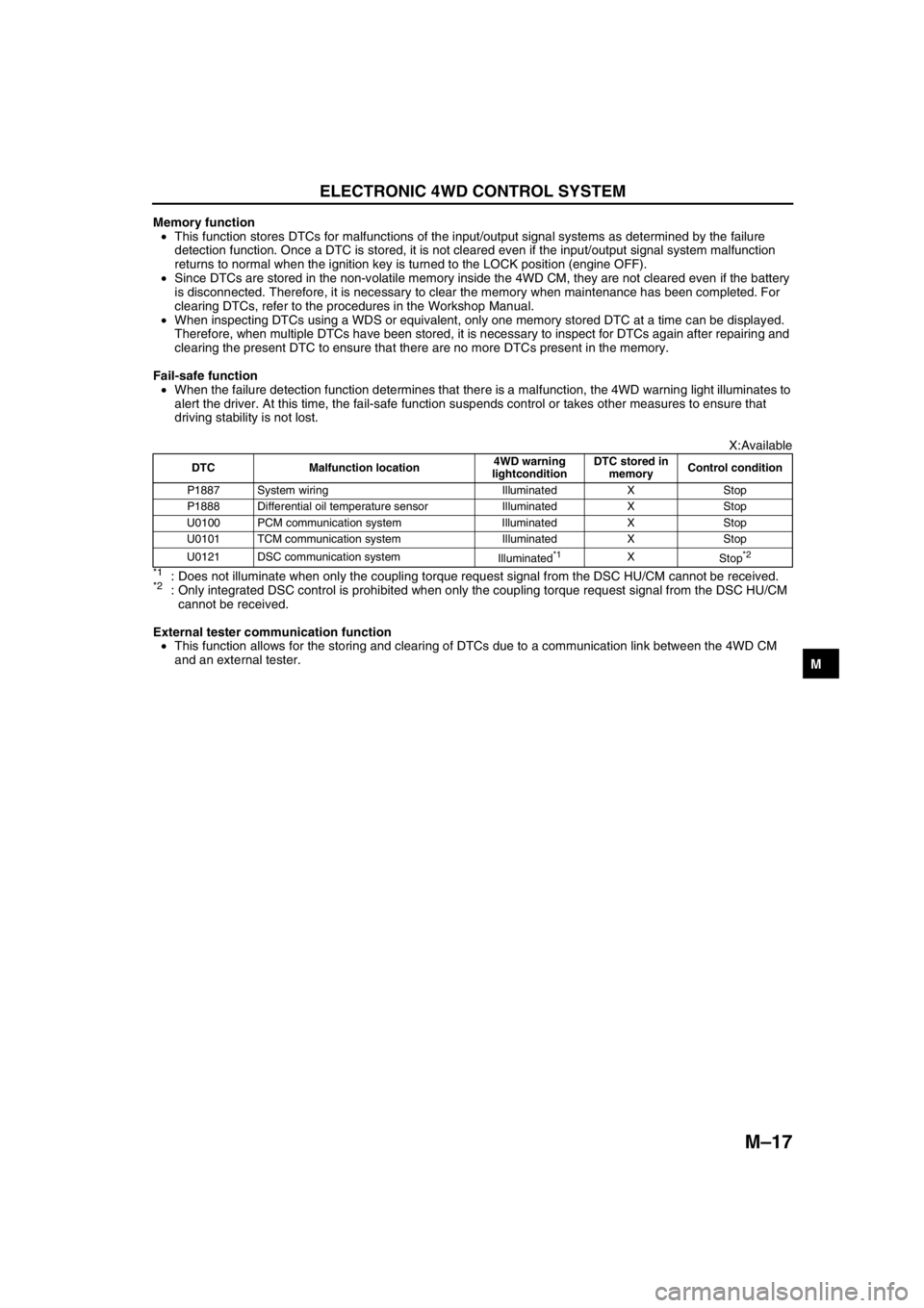

Memory function

•This function stores DTCs for malfunctions of the input/output signal systems as determined by the failure

detection function. Once a DTC is stored, it is not cleared even if the input/output signal system malfunction

returns to normal when the ignition key is turned to the LOCK position (engine OFF).

•Since DTCs are stored in the non-volatile memory inside the 4WD CM, they are not cleared even if the battery

is disconnected. Therefore, it is necessary to clear the memory when maintenance has been completed. For

clearing DTCs, refer to the procedures in the Workshop Manual.

•When inspecting DTCs using a WDS or equivalent, only one memory stored DTC at a time can be displayed.

Therefore, when multiple DTCs have been stored, it is necessary to inspect for DTCs again after repairing and

clearing the present DTC to ensure that there are no more DTCs present in the memory.

Fail-safe function

•When the failure detection function determines that there is a malfunction, the 4WD warning light illuminates to

alert the driver. At this time, the fail-safe function suspends control or takes other measures to ensure that

driving stability is not lost.

X:Available

*1: Does not illuminate when only the coupling torque request signal from the DSC HU/CM cannot be received.*2: Only integrated DSC control is prohibited when only the coupling torque request signal from the DSC HU/CM

cannot be received.

External tester communication function

•This function allows for the storing and clearing of DTCs due to a communication link between the 4WD CM

and an external tester.

End Of Sie

DTC Malfunction location4WD warning

lightconditionDTC stored in

memoryControl condition

P1887 System wiring Illuminated X Stop

P1888 Differential oil temperature sensor Illuminated X Stop

U0100 PCM communication system Illuminated X Stop

U0101 TCM communication system Illuminated X Stop

U0121 DSC communication system

Illuminated

*1X

Stop*2

Page 651 of 909

GENERAL PROCEDURES

M–21

M

PRECAUTION (FRONT AND REAR AXLE)A6E631001018201Wheel and Tire Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}

Brake Line Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid gets on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

2. If any brake line has been disconnected any time during the procedure, add brake fluid, bleed the brakes, and

inspect for leakage after the procedure has been completed.

Suspension Arm Removal/Installation

1. Tighten any part of the suspension that uses rubber bushings only after vehicle has been lowered and

unloaded.

Note

•Unloaded: Fuel tank is full. Engine coolant and engine oil are at specified level. Spare tire, jack, and tools

are in designated position.

Connector Disconnection

1. Disconnect the negative (-) battery cable before disconnecting connectors.

Electronic Control 4WD System Parts

1. After servicing the electronic control 4WD system parts, verify that no DTC has been stored. Clear any DTCs

remaining in the memory.

End Of Sie

GENERAL PROCEDURES

Page 695 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–65

M

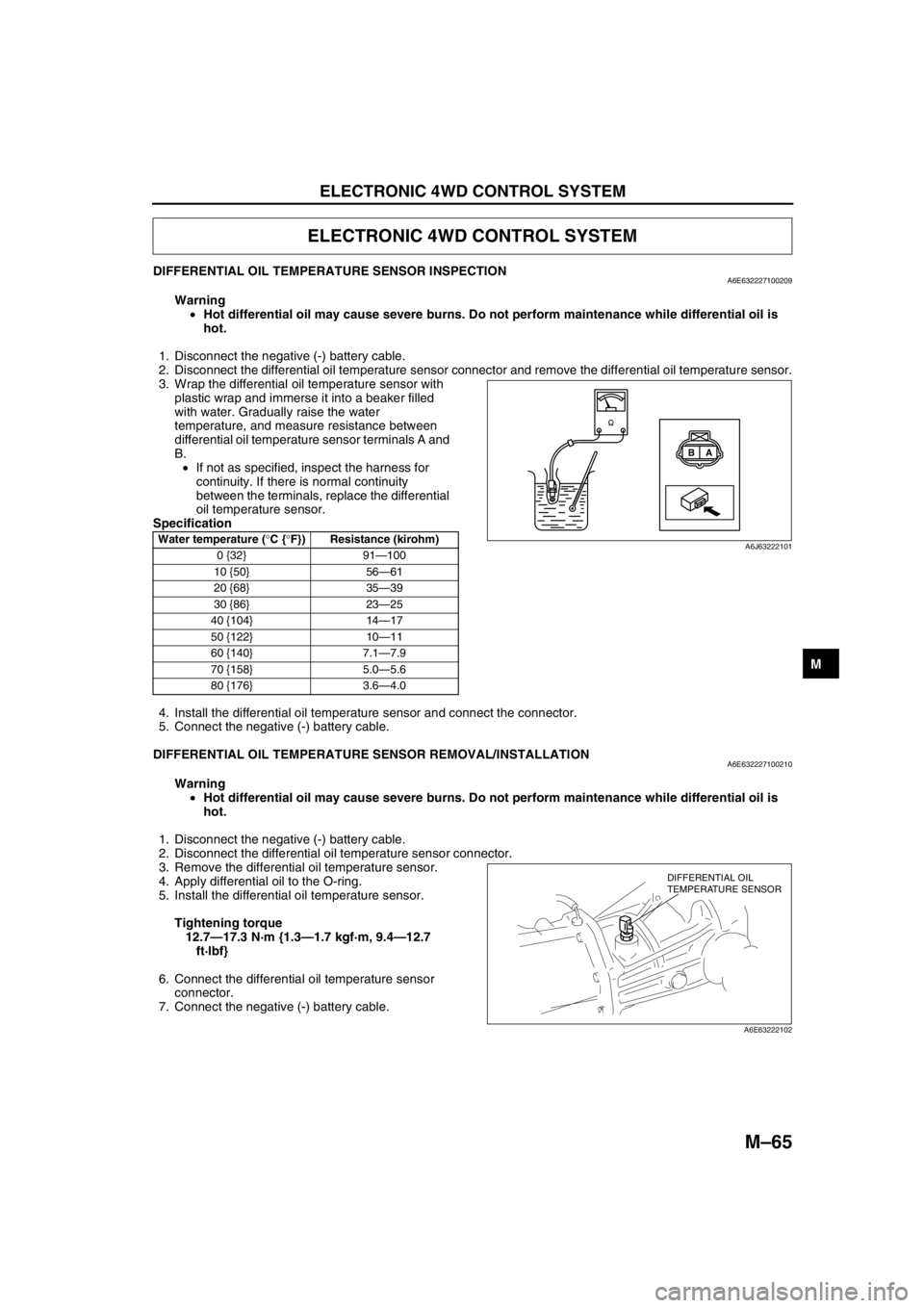

DIFFERENTIAL OIL TEMPERATURE SENSOR INSPECTIONA6E632227100209

Warning

•Hot differential oil may cause severe burns. Do not perform maintenance while differential oil is

hot.

1. Disconnect the negative (-) battery cable.

2. Disconnect the differential oil temperature sensor connector and remove the differential oil temperature sensor.

3. Wrap the differential oil temperature sensor with

plastic wrap and immerse it into a beaker filled

with water. Gradually raise the water

temperature, and measure resistance between

differential oil temperature sensor terminals A and

B.

•If not as specified, inspect the harness for

continuity. If there is normal continuity

between the terminals, replace the differential

oil temperature sensor.

Specification

4. Install the differential oil temperature sensor and connect the connector.

5. Connect the negative (-) battery cable.

End Of Sie

DIFFERENTIAL OIL TEMPERATURE SENSOR REMOVAL/INSTALLATIONA6E632227100210

Warning

•Hot differential oil may cause severe burns. Do not perform maintenance while differential oil is

hot.

1. Disconnect the negative (-) battery cable.

2. Disconnect the differential oil temperature sensor connector.

3. Remove the differential oil temperature sensor.

4. Apply differential oil to the O-ring.

5. Install the differential oil temperature sensor.

Tightening torque

12.7—17.3 N·m {1.3—1.7 kgf·m, 9.4—12.7

ft·lbf}

6. Connect the differential oil temperature sensor

connector.

7. Connect the negative (-) battery cable.

End Of Sie

ELECTRONIC 4WD CONTROL SYSTEM

Water temperature (°C {°F}) Resistance (kirohm)

0 {32} 91—100

10 {50} 56—61

20 {68} 35—39

30 {86} 23—25

40 {104} 14—17

50 {122} 10—11

60 {140} 7.1—7.9

70 {158} 5.0—5.6

80 {176} 3.6—4.0

A B

A6J63222101

DIFFERENTIAL OIL

TEMPERATURE SENSOR

A6E63222102

Page 696 of 909

M–66

ELECTRONIC 4WD CONTROL SYSTEM

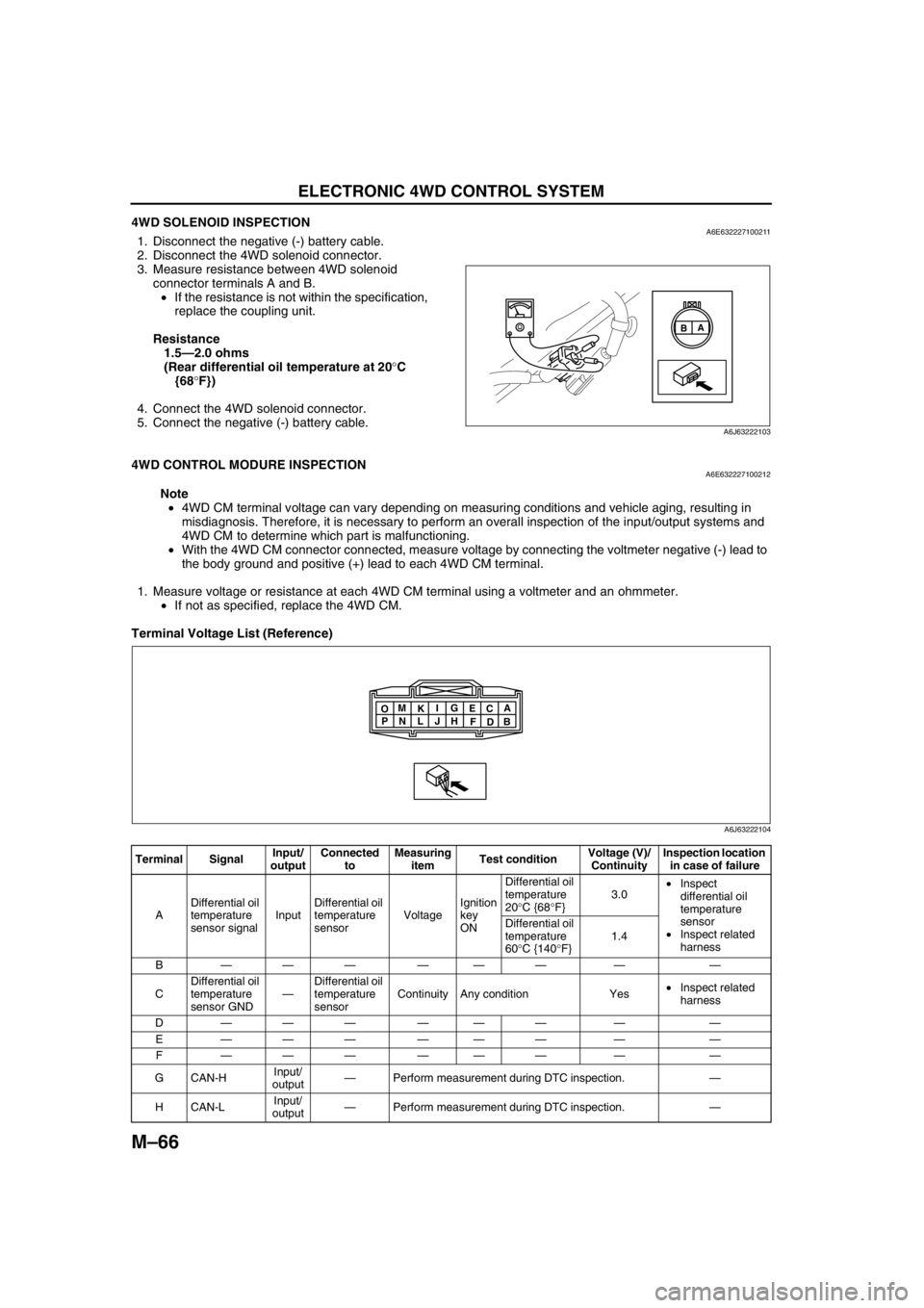

4WD SOLENOID INSPECTIONA6E6322271002111. Disconnect the negative (-) battery cable.

2. Disconnect the 4WD solenoid connector.

3. Measure resistance between 4WD solenoid

connector terminals A and B.

•If the resistance is not within the specification,

replace the coupling unit.

Resistance

1.5—2.0 ohms

(Rear differential oil temperature at 20°C

{68°F})

4. Connect the 4WD solenoid connector.

5. Connect the negative (-) battery cable.

End Of Sie

4WD CONTROL MODURE INSPECTIONA6E632227100212

Note

•4WD CM terminal voltage can vary depending on measuring conditions and vehicle aging, resulting in

misdiagnosis. Therefore, it is necessary to perform an overall inspection of the input/output systems and

4WD CM to determine which part is malfunctioning.

•With the 4WD CM connector connected, measure voltage by connecting the voltmeter negative (-) lead to

the body ground and positive (+) lead to each 4WD CM terminal.

1. Measure voltage or resistance at each 4WD CM terminal using a voltmeter and an ohmmeter.

•If not as specified, replace the 4WD CM.

Terminal Voltage List (Reference)

A

B

A6J63222103

Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

ADifferential oil

temperature

sensor signalInputDifferential oil

temperature

sensorVoltageIgnition

key

ONDifferential oil

temperature

20°C {68°F}3.0•Inspect

differential oil

temperature

sensor

•Inspect related

harness Differential oil

temperature

60°C {140°F}1.4

B——— ——— — —

CDifferential oil

temperature

sensor GND—Differential oil

temperature

sensorContinuity Any condition Yes•Inspect related

harness

D——— ——— — —

E——— ——— — —

F——— ——— — —

GCAN-HInput/

output—Perform measurement during DTC inspection.—

HCAN-LInput/

output—Perform measurement during DTC inspection.—

A

B C

D E

F G

H I

J K

L M

N O

P

A6J63222104

Page 697 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–67

M

End Of Sie

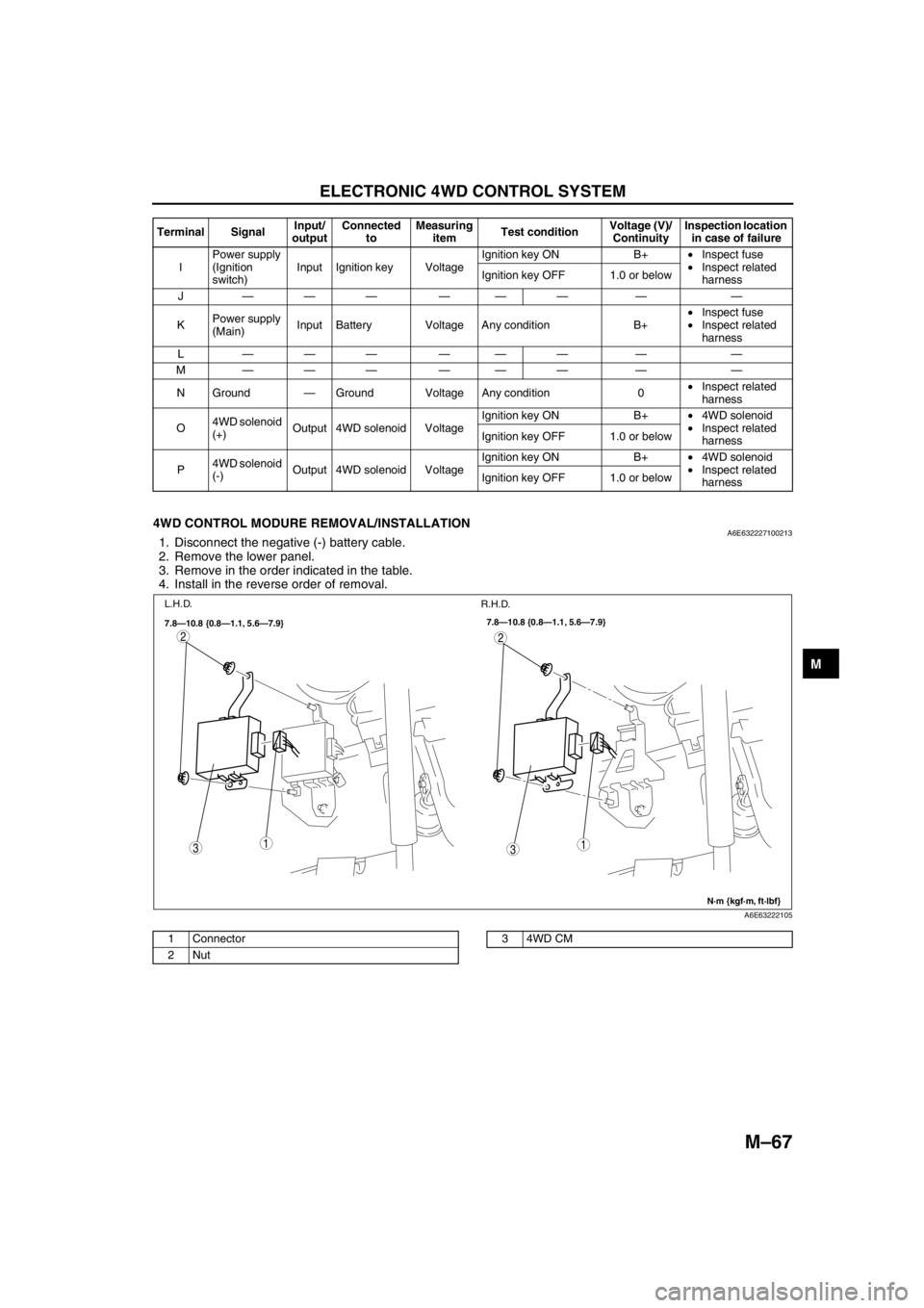

4WD CONTROL MODURE REMOVAL/INSTALLATIONA6E6322271002131. Disconnect the negative (-) battery cable.

2. Remove the lower panel.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

End Of Sie

IPower supply

(Ignition

switch)Input Ignition key VoltageIgnition key ON B+•Inspect fuse

•Inspect related

harness Ignition key OFF 1.0 or below

J——— ——— — —

KPower supply

(Main)Input Battery Voltage Any condition B+•Inspect fuse

•Inspect related

harness

L——— ——— — —

M——— ——— — —

N Ground—Ground Voltage Any condition 0•Inspect related

harness

O4WD solenoid

(+)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below

P4WD solenoid

(-)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

31

2

31

2

7.8—10.8 {0.8—1.1, 5.6—7.9}

N·m {kgf·m, ft·lbf} 7.8—10.8 {0.8—1.1, 5.6—7.9}

L.H.D.

R.H.D.

A6E63222105

1 Connector

2Nut34WD CM

Page 705 of 909

ON-BOARD DIAGNOSTIC

M–75

M

WIRING DIAGRAMA6E637027100201

End Of Sie

ON-BOARD DIAGNOSTIC

IGNITION SWITCH

BATTERY

DIFFERENTIAL OIL

TEMPERATURE

SENSOR4WD CM4WD SOLENOID ELECTRONIC CONTROL

COUPLING

CAN DRIVERINSTRUMENT CLUSTER

CAN-H

CAN-LPCM DSC HU/CM KO

P I

A

C

NH G

TCM

A6E63702002