fuel filter MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 91 of 909

OUTLINE

F1–3

F1

CONTROL SYSTEM DIAGRAM (4WD)A6E390218881204

.

* : Equipped for L3 engine modelEnd Of Sie

9

8

7

54

3

10

19

18

17

15

16

14

13

11

12

20

29

28

27

25

26

24

23

21

22

30

3938

3735

33

36

31

32

40

6

1

2

3441

A6E39022000

1PCM

2 Ignition coil

3 Generator

4* VAD shutter valve

5 Air cleaner

6 MAF sensor

7* VAD shutter valve actuator

8* VAD control solenoid valve

9* Vacuum chamber

10* VAD check valve (one-way)

11 IAC valve

12 Purge solenoid valve

13 TP sensor

14 MAP sensor

15* VIS control solenoid valve

16 Variable tumble control solenoid valve

17* VIS shutter valve actuator

18* VIS shutter valve

19 VTCS shutter valve actuator

20 VTCS shutter valve

21 Fuel injector22* OCV

23 CMP sensor

24 EGR valve

25 Knock sensor

26 ECT sensor

27 PCV valve

28 CKP sensor

29 HO2S (front)

30 HO2S (rear)

31 Charcoal canister

32 Check valve (two-way)

33 Pressure regulator

34 Fuel filter (high-pressure)

35 Fuel pump

36 Fuel filter (low-pressure)

37 Fuel tank

38 Rollover valve

39 Pulsation damper

40 Fuel pump (transfer)

41 To PCM

Page 98 of 909

F1–10

FUEL SYSTEM

SYSTEM DIAGRAMA6E391201006203

.

End Of Sie

FUEL PUMP (TRANSFER)A6E391213350201Function

•The fuel tank for 4WD is saddle type. Fuel in the fuel gauge sender sub-unit side (right side) is pumped to the

left side of the fuel tank using the fuel pump (transfer).

Structure

•The fuel pump (transfer) is integrated into the fuel pump unit and it cannot be separately disassembled.

•The fuel pump (transfer) is composed of a relief valve and fuel jet pump.

87

5

4

3

6

1

2

:

9

10

A6E39122002

1 Filler cap

2 Pressure regulator

3 Fuel pump (transfer)

4 Fuel filter (high-pressure)

5Fuel pump6 Fuel filter (low-pressure)

7 Fuel pump unit

8 Pulsation damper

9 Fuel injector

10 Fuel flow

Page 114 of 909

F1–26

FUEL SYSTEM

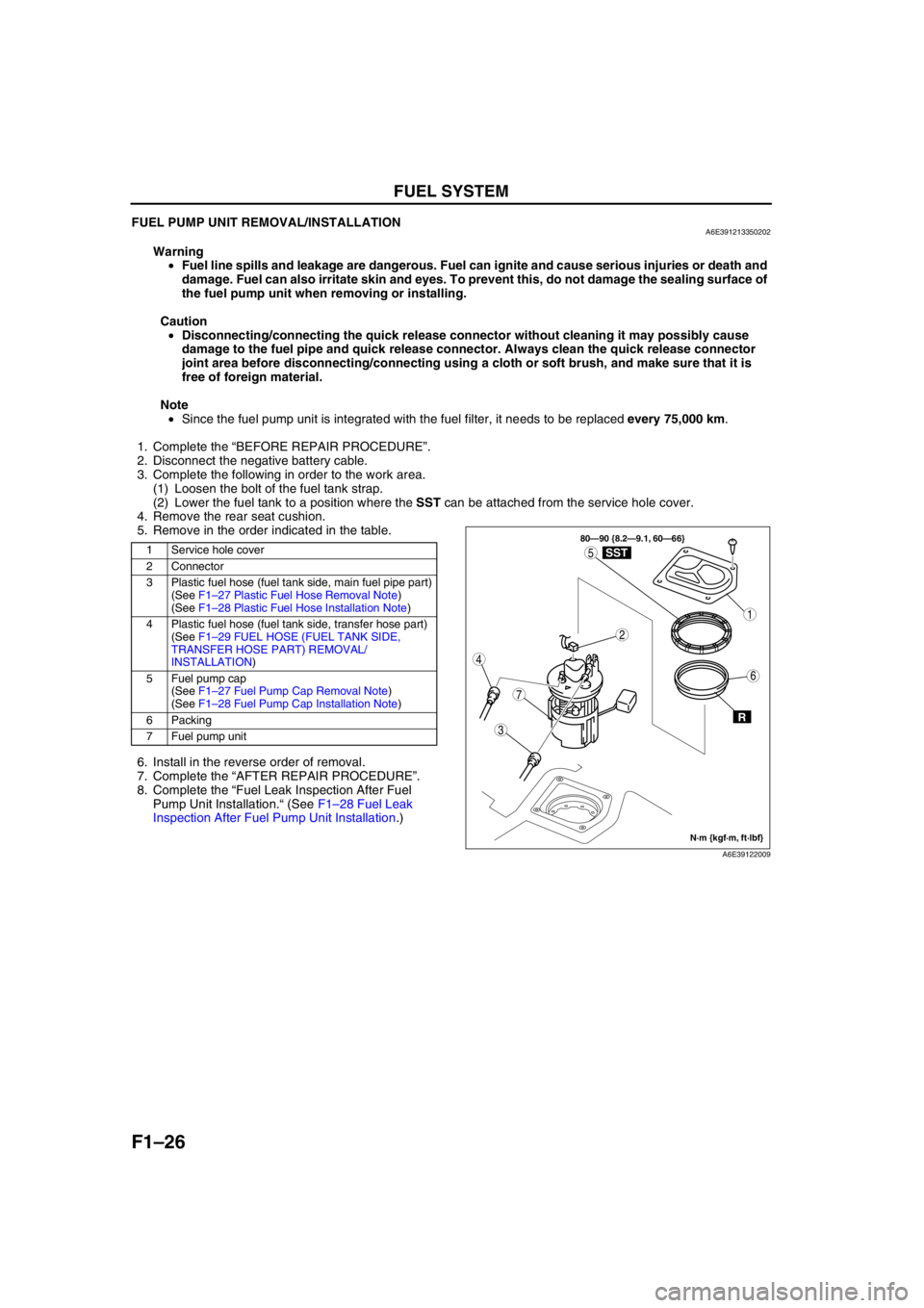

FUEL PUMP UNIT REMOVAL/INSTALLATIONA6E391213350202

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Note

•Since the fuel pump unit is integrated with the fuel filter, it needs to be replaced every 75,000 km.

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

3. Complete the following in order to the work area.

(1) Loosen the bolt of the fuel tank strap.

(2) Lower the fuel tank to a position where the SST can be attached from the service hole cover.

4. Remove the rear seat cushion.

5. Remove in the order indicated in the table.

.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”.

8. Complete the “Fuel Leak Inspection After Fuel

Pump Unit Installation.“ (See F1–28 Fuel Leak

Inspection After Fuel Pump Unit Installation.)

1 Service hole cover

2 Connector

3 Plastic fuel hose (fuel tank side, main fuel pipe part)

(See F1–27 Plastic Fuel Hose Removal Note)

(See F1–28 Plastic Fuel Hose Installation Note)

4 Plastic fuel hose (fuel tank side, transfer hose part)

(See F1–29 FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART) REMOVAL/

INSTALLATION)

5Fuel pump cap

(See F1–27 Fuel Pump Cap Removal Note)

(See F1–28 Fuel Pump Cap Installation Note)

6 Packing

7 Fuel pump unit

3

7

1

4

5

2

6

80—90 {8.2—9.1, 60—66}

R

SST

N·m {kgf·m, ft·lbf}

A6E39122009

Page 148 of 909

F1–60

TROUBLESHOOTING

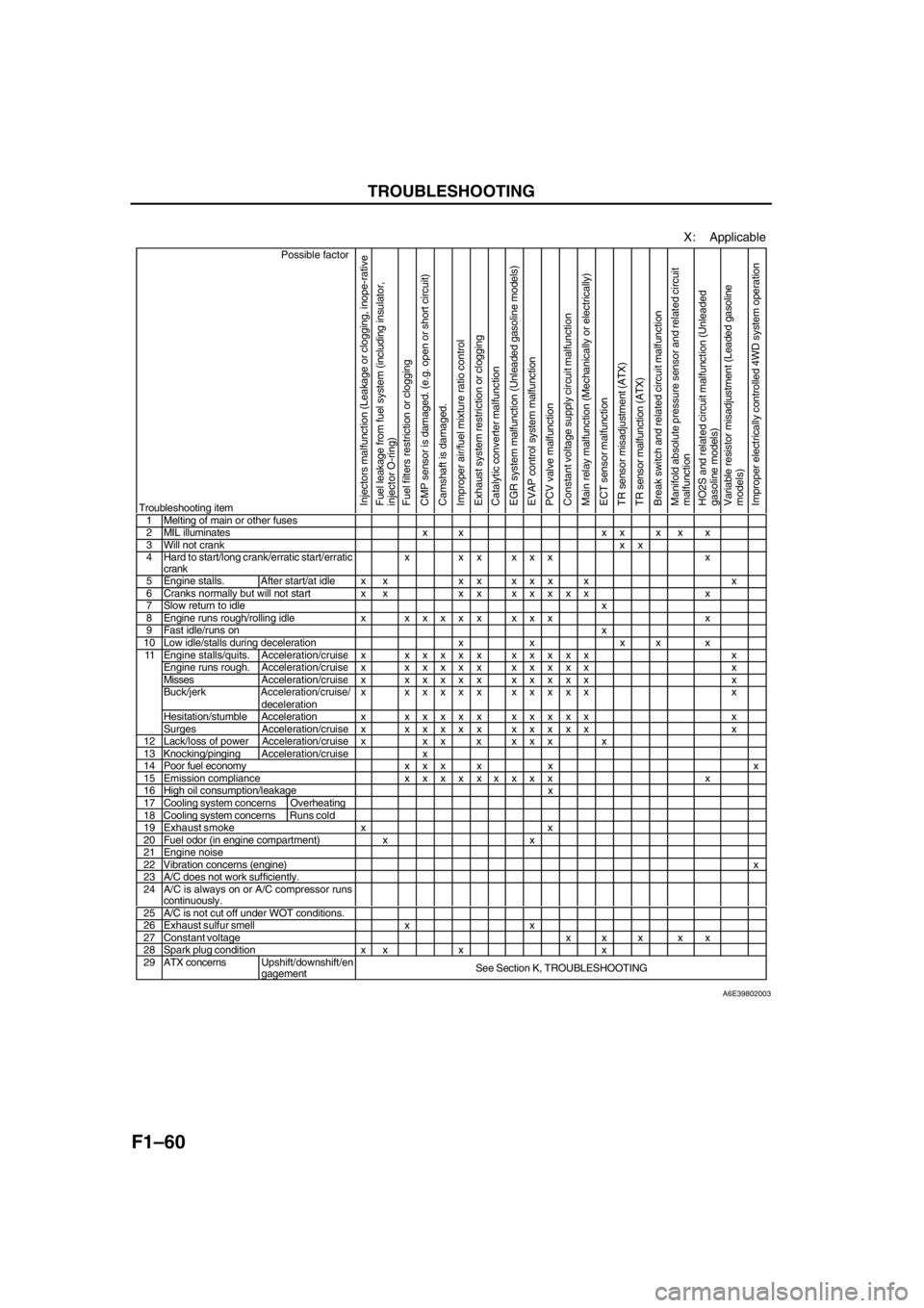

X: Applicable

Possible factor

Troubleshooting item

Injectors malfunction (Leakage or clogging, inope-rative

Fuel leakage from fuel system (including insulator,

injector O-ring)

Fuel filters restriction or clogging

CMP sensor is damaged. (e.g. open or short circuit)

Camshaft is damaged.

Improper air/fuel mixture ratio control

Exhaust system restriction or clogging

Catalytic converter malfunction

EGR system malfunction (Unleaded gasoline models)

EVAP control system malfunction

PCV valve malfunction

Constant voltage supply circuit malfunction

Main relay malfunction (Mechanically or electrically)

ECT sensor malfunction

TR sensor misadjustment (ATX)

TR sensor malfunction (ATX)

Break switch and related circuit malfunction

Manifold absolute pressure sensor and related circuit

malfunction

HO2S and related circuit malfunction (Unleaded

gasoline models)

Variable resistor misadjustment (Leaded gasoline

models)

Improper electrically controlled 4WD system operation

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crankxx4 Hard to start/long crank/erratic start/erratic

crankx xx xxx x

5 Engine stalls. After start/at idle x x x x x x x x x6 Cranks normally but will not start x x x xxxxxx x7 Slow return to idlex8 Engine runs rough/rolling idle xxxxxx xxx x9 Fast idle/runs onx10 Low idle/stalls during deceleration x x x x xEngine stalls/quits.Acceleration/cruisex xxxxx xxxxx xEngine runs rough. Acceleration/cruisex xxxxx xxxxx xMissesAcceleration/cruisex xxxxx xxxxx xBuck/jerk Acceleration/cruise/

decelerationx xxxxx xxxxx x

Hesitation/stumble Acceleration xxxxxx xxxxx x

11

Surges Acceleration/cruise xxxxxx xxxxx x

12 Lack/loss of power Acceleration/cruise x x x x x x x x13 Knocking/pingingAcceleration/cruise x14 Poor fuel economy x x x x x x15 Emission compliancexxxxxxxxx x16 High oil consumption/leakage x17 Cooling system concerns Overheating18 Cooling system concernsRuns cold19 Exhaust smoke x x20 Fuel odor (in engine compartment) x x21 Engine noise22 Vibration concerns (engine)x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smell x x27 Constant voltage x x x x x28 Spark plug condition x x x x29 ATX concernsUpshift/downshift/en

gagementSee Section K, TROUBLESHOOTING

A6E39802003

Page 153 of 909

![MAZDA 6 2002 Suplement User Guide F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR MAZDA 6 2002 Suplement User Guide F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR](/img/28/57057/w960_57057-152.png)

F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATURES ........................................................ F2-3

SPECIFICATIONS ............................................. F2-3

CONTROL SYSTEM DIAGRAM ........................ F2-4

CONTROL SYSTEM WIRING DIAGRAM.......... F2-5

INTAKE-AIR SYSTEM.......................................... F2-8

OUTLINE ........................................................... F2-8

STRUCTURAL VIEW......................................... F2-9

FUEL SYSTEM................................................... F2-10

OUTLINE ......................................................... F2-10

STRUCTURAL VIEW....................................... F2-11

EXHAUST SYSTEM........................................... F2-13

OUTLINE ......................................................... F2-13

STRUCTURAL VIEW....................................... F2-13

EMISSION SYSTEM........................................... F2-14

OUTLINE ......................................................... F2-14

STRUCTURAL VIEW....................................... F2-15

WARM UP OXIDATION CATALYTIC

CONVERTER DESCRIPTION ...................... F2-16

CONTROL SYSTEM........................................... F2-16

OUTLINE ......................................................... F2-16

STRUCTURAL VIEW....................................... F2-18

BLOCK DIAGRAM ........................................... F2-20

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F2-22

CRUISE CONTROL SYSTEM ......................... F2-23

CONTROLLER AREA NETWORK (CAN) ....... F2-24

ON-BOARD DIAGNOSTIC................................. F2-24

OUTLINE ......................................................... F2-24

DTC.................................................................. F2-24

KOEO/KOER SELF-TEST ............................... F2-26

PID/DATA MONITOR AND RECORD ............. F2-27

SIMULATION TEST ......................................... F2-27

LOCATION INDEX............................................. F2-28

INTAKE-AIR SYSTEM ..................................... F2-28

FUEL SYSTEM ................................................ F2-29

EMISSION SYSTEM........................................ F2-31

CONTROL SYSTEM........................................ F2-32

ENGINE TUNE-UP............................................. F2-34

ENGINE TUNE-UP PREPARATION ............... F2-34

IDLE SPEED INSPECTION ............................. F2-34

CORRECTION PROCEDURE ......................... F2-34

INTAKE-AIR SYSTEM........................................ F2-35

VACUUM TUBE ROUTING DIAGRAM............ F2-35

INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION .......................... F2-36

AIR CLEANER ELEMENT INSPECTION ........ F2-37

TURBOCHARGER INSPECTION ................... F2-38

GUIDE BLADE ACTUATOR INSPECTION ..... F2-39

VARIABLE BOOST CONTROL (VBC)

SOLENOID VALVE INSPECTION ................ F2-40VARIABLE BOOST CONTROL (VBC)

CHECK VALVE INSPECTION ...................... F2-41

VARIABLE SWIRL CONTROL (VSC)

VALVE ACTUATOR INSPECTION ............... F2-41

VARIABLE SWIRL CONTROL (VSC)

SOLENOID VALVE INSPECTION ................ F2-42

GLOW PLUG REMOVAL/INSTALLATION ...... F2-42

GLOW PLUG INSPECTION ............................ F2-43

GLOW PLUG LEAD INSPECTION .................. F2-43

ACCELERATOR PEDAL COMPONENT

REMOVAL/INSTALLATION .......................... F2-44

ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-44

FUEL SYSTEM................................................... F2-45

BEFORE REPAIR PROCEDURE .................... F2-45

AFTER REPAIR PROCEDURE ....................... F2-45

FUEL TANK REMOVAL/INSTALLATION ........ F2-45

FUEL TANK INSPECTION .............................. F2-49

NONRETURN VALVE INSPECTION............... F2-50

FUEL FILTER COMPONENT

REMOVAL/INSTALLATION .......................... F2-50

FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-51

FUEL WARMER INSPECTION........................ F2-51

SEDIMENTOR WATER DRAINING................. F2-52

SEDIMENTOR SWITCH INSPECTION ........... F2-52

SUPPLY PUMP REMOVAL/INSTALLATION .. F2-53

SUPPLY PUMP INSPECTION......................... F2-54

SUCTION CONTROL VALVE INSPECTION ... F2-54

COMMON RAIL INSPECTION ........................ F2-54

FUEL INJECTOR REMOVAL/INSTALLATION F2-55

FUEL INJECTOR INSPECTION ...................... F2-56

EXHAUST SYSTEM........................................... F2-57

EXHAUST SYSTEM INSPECTION ................. F2-57

EXHAUST SYSTEM

REMOVAL/INSTALLATION .......................... F2-57

EMISSION SYSTEM........................................... F2-59

EGR VALVE REMOVAL/INSTALLATION........ F2-59

EGR VALVE INSPECTION .............................. F2-59

EGR SOLENOID VALVE (VACUUM)

INSPECTION ................................................ F2-60

EGR SOLENOID VALVE (VENT)

INSPECTION ................................................ F2-60

EGR CONTROL SOLENOID VALVE

INSPECTION ................................................ F2-61

INTAKE SHUTTER VALVE ACTUATOR

INSPECTION ................................................ F2-62

INTAKE SHUTTER SOLENOID VALVE

INSPECTION ................................................ F2-63

CONTROL SYSTEM........................................... F2-64

PCM REMOVAL/INSTALLATION .................... F2-64

PCM INSPECTION .......................................... F2-65

PCM CONFIGURATION .................................. F2-68

CLUTCH SWITCH INSPECTION .................... F2-68

NEUTRAL SWITCH INSPECTION .................. F2-69

IDLE SWITCH INSPECTION ........................... F2-70

IDLE SWITCH ADJUSTMENT ......................... F2-71

ACCELERATOR POSITION SENSOR

INSPECTION ................................................ F2-72

ACCELERATOR POSITION SENSOR

ADJUSTMENT .............................................. F2-73 FEATURES

SERVICE

Page 156 of 909

F2–4

OUTLINE

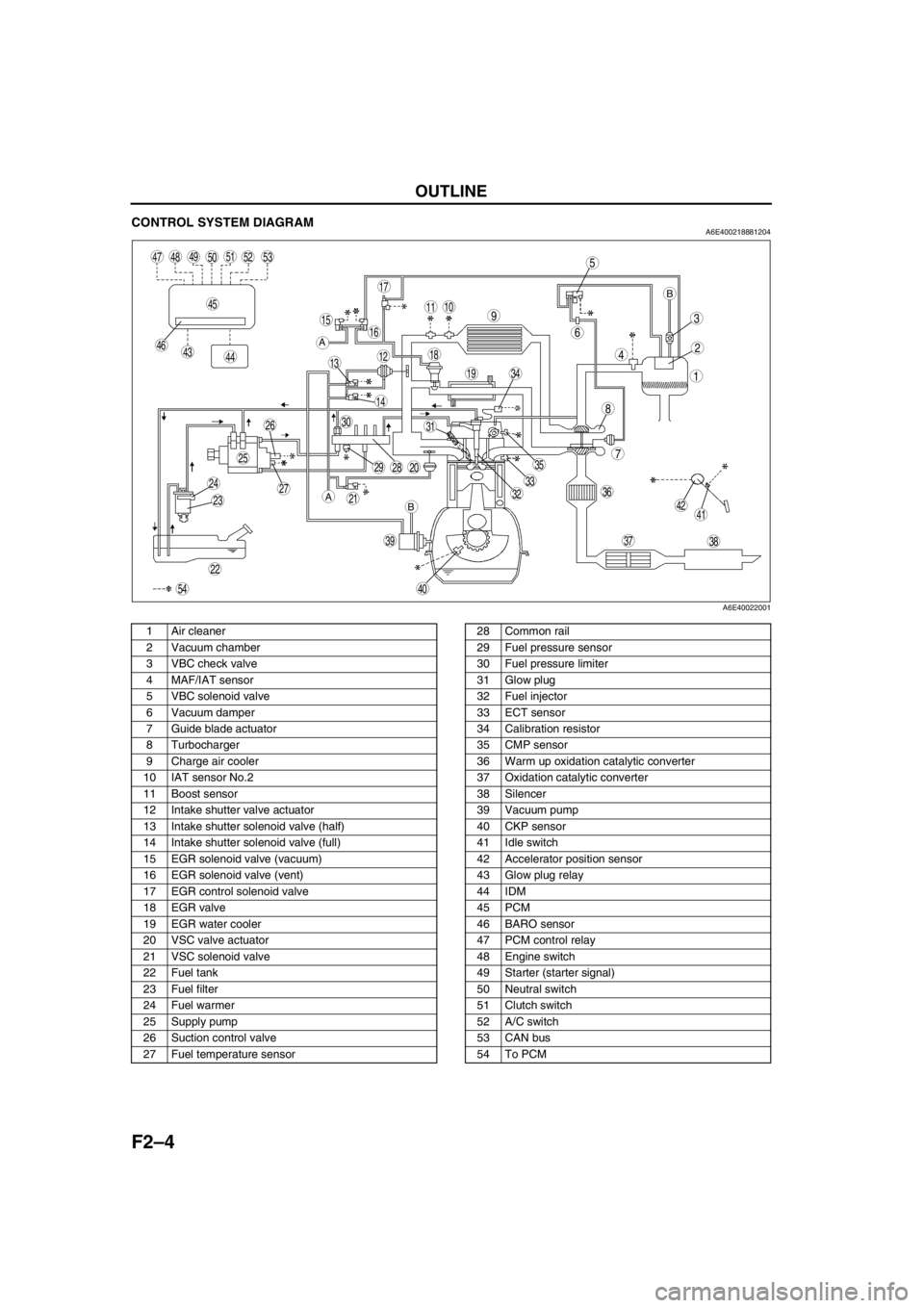

CONTROL SYSTEM DIAGRAMA6E400218881204

.

End Of Sie

5

4

3

6

1

2

8

7

910

13

11

12

19

18

17

1516

14

202928

27

25

26

24

2321

22

30

393837

35

3633

31

32

40

34

494847

45

464443

4142

50

54

515253

A

A

BB

A6E40022001

1 Air cleaner

2 Vacuum chamber

3 VBC check valve

4 MAF/IAT sensor

5 VBC solenoid valve

6 Vacuum damper

7 Guide blade actuator

8 Turbocharger

9 Charge air cooler

10 IAT sensor No.2

11 Boost sensor

12 Intake shutter valve actuator

13 Intake shutter solenoid valve (half)

14 Intake shutter solenoid valve (full)

15 EGR solenoid valve (vacuum)

16 EGR solenoid valve (vent)

17 EGR control solenoid valve

18 EGR valve

19 EGR water cooler

20 VSC valve actuator

21 VSC solenoid valve

22 Fuel tank

23 Fuel filter

24 Fuel warmer

25 Supply pump

26 Suction control valve

27 Fuel temperature sensor28 Common rail

29 Fuel pressure sensor

30 Fuel pressure limiter

31 Glow plug

32 Fuel injector

33 ECT sensor

34 Calibration resistor

35 CMP sensor

36 Warm up oxidation catalytic converter

37 Oxidation catalytic converter

38 Silencer

39 Vacuum pump

40 CKP sensor

41 Idle switch

42 Accelerator position sensor

43 Glow plug relay

44 IDM

45 PCM

46 BARO sensor

47 PCM control relay

48 Engine switch

49 Starter (starter signal)

50 Neutral switch

51 Clutch switch

52 A/C switch

53 CAN bus

54 To PCM

Page 162 of 909

F2–10

FUEL SYSTEM

End Of Sie

OUTLINEA6E401201006201•The fuel system is essentially carried over from that of the current MPV (LW) MZR-CD (RF Turbo) engine

model. (See MPV Wordshop Manual Supplement 1737-1*-02D.)

×:Applicable

*1: With fuel warmer

End Of Sie

FUEL SYSTEM

ItemMazda6

(GG, GY)Current

MPV (LW)

Remark for new model

MZR-CD (RF Turbo)

Fuel tank×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Shape has been changed

Fuel gauge sender unit×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Shape has been changed

Fuel filter bodyFuel filter×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Priming pump×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Fuel warmer

*1×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Common rail injection system×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Page 163 of 909

FUEL SYSTEM

F2–11

F2

STRUCTURAL VIEWA6E401201006202Engine room side

.

1

2

3

4

5

6

7

9

8

10

11

12

10

A6E40122031

1 Fuel warmer

2 Sedimentor switch

3 Supply pump

4 Suction control valve

5 Common rail

6 Priming pump7 L.H.D.

8 Fuel injector

9 Priming pump

10 Fuel filter

11 R.H.D.

12 Sedimentor switch

Page 182 of 909

F2–30

LOCATION INDEX

Fuel tank side

.

End Of Sie

21

A6E40002004

1 Fuel tank

(See F2–45 FUEL TANK REMOVAL/

INSTALLATION)

(See F2–49 FUEL TANK INSPECTION)

2 Nonreturn valve

(See F2–50 NONRETURN VALVE INSPECTION)

3 Sedimentor switch

(See F2–52 SEDIMENTOR SWITCH INSPECTION)

4 Fuel filter

(See F2–50 FUEL FILTER COMPONENT

REMOVAL/INSTALLATION)

(See F2–51 FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY)

5 Fuel warmer

(See F2–51 FUEL WARMER INSPECTION)6 Priming pump

(See F2–52 SEDIMENTOR WATER DRAINING)

7 Supply pump

(See F2–53 SUPPLY PUMP REMOVAL/

INSTALLATION)

(See F2–54 SUPPLY PUMP INSPECTION)

8 Suction control valve

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

9 Common rail

(See F2–54 COMMON RAIL INSPECTION)

10 Fuel injector

(See F2–55 FUEL INJECTOR REMOVAL/

INSTALLATION)

(See F2–56 FUEL INJECTOR INSPECTION)

Page 202 of 909

F2–50

FUEL SYSTEM

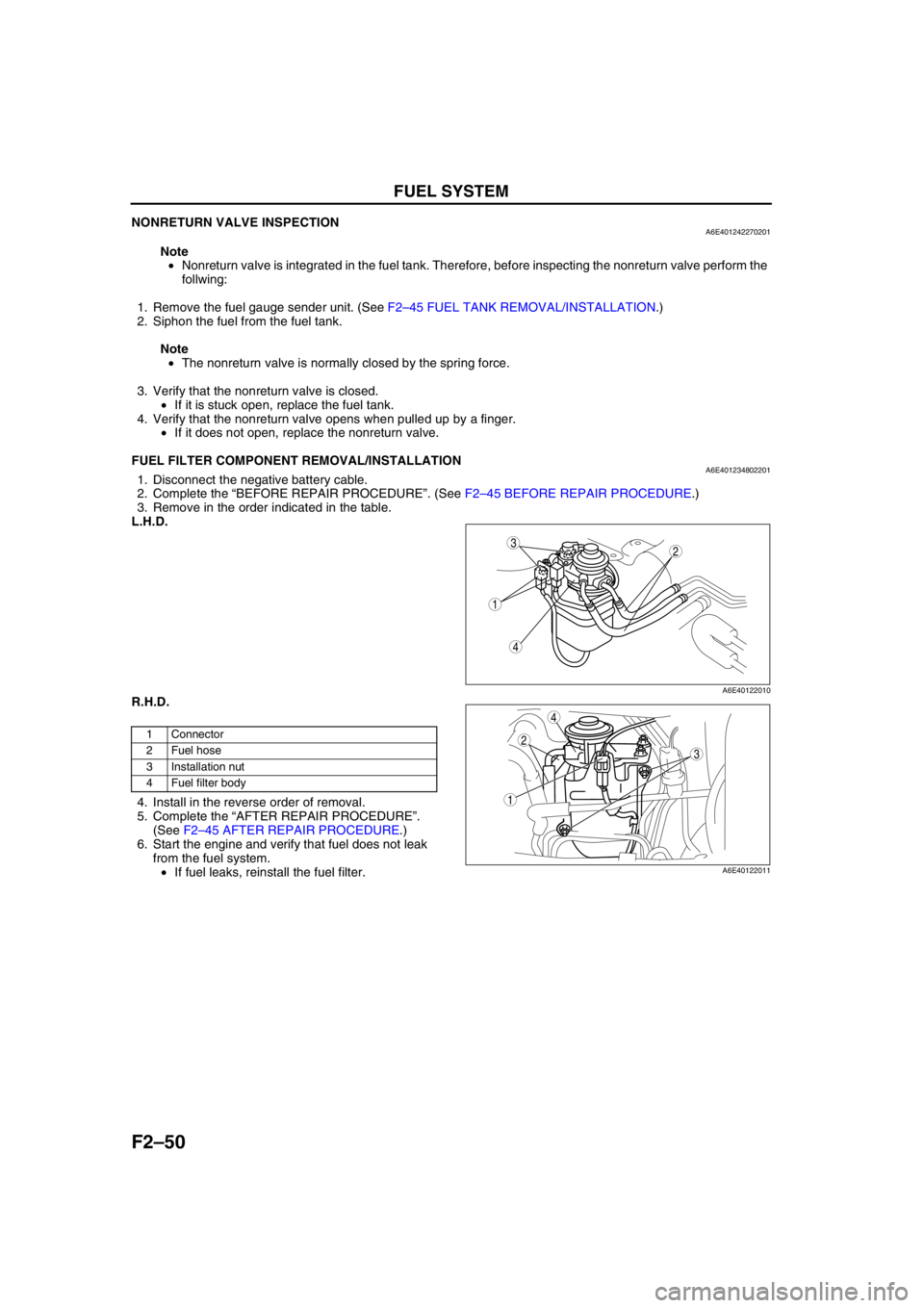

NONRETURN VALVE INSPECTIONA6E401242270201

Note

•Nonreturn valve is integrated in the fuel tank. Therefore, before inspecting the nonreturn valve perform the

follwing:

1. Remove the fuel gauge sender unit. (See F2–45 FUEL TANK REMOVAL/INSTALLATION.)

2. Siphon the fuel from the fuel tank.

Note

•The nonreturn valve is normally closed by the spring force.

3. Verify that the nonreturn valve is closed.

•If it is stuck open, replace the fuel tank.

4. Verify that the nonreturn valve opens when pulled up by a finger.

•If it does not open, replace the nonreturn valve.

End Of Sie

FUEL FILTER COMPONENT REMOVAL/INSTALLATIONA6E4012348022011. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Remove in the order indicated in the table.

L.H.D.

R.H.D.

.

4. Install in the reverse order of removal.

5. Complete the “AFTER REPAIR PROCEDURE”.

(See F2–45 AFTER REPAIR PROCEDURE.)

6. Start the engine and verify that fuel does not leak

from the fuel system.

•If fuel leaks, reinstall the fuel filter.

End Of Sie

1

4

23

A6E40122010

1 Connector

2Fuel hose

3 Installation nut

4 Fuel filter body

4

1

2

3

A6E40122011