engine oil MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 57 of 909

B2–26

REAR OIL SEAL

REAR OIL SEAL REPLACEMENTA6E2322113992011. Remove the flywheel. (See H–5 CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R manual transaxle

models).)

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

.

Rear Oil Seal Removal Note

1. Cut the oil seal lip using a razor knife.

2. Remove the oil seal using a screwdriver protected

with a rag.

Rear Oil Seal Installation Note

1. Apply clean engine oil to the oil seal lip.

2. Push the oil seal slightly in by hand.

3. Tap the oil seal in evenly using the SST and a

hammer.

End Of Sie

REAR OIL SEAL

1 Rear oil seal

(See B2–26 Rear Oil Seal Removal Note)

(See B2–26 Rear Oil Seal Installation Note)

SST

R

OILOIL1

A6E2322W100

OIL SEAL LIP

A6E2322W101

RAG

A6E2322W102

0—0.5 mm

{0—0.019 in}

HAMMERREAR COVER

REAR OIL SEAL

49 G033 107A

A6E2322W103

Page 58 of 909

ENGINE

B2–27

B2

ENGINE REMOVAL/INSTALLATIONA6E232401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant, engine oil, and transaxle oil.

3. Remove the radiator.

4. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the air cleaner and air hose. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

6. Disconnect the fuel hose. (See F2–45 BEFORE REPAIR PROCEDURE.)

7. Remove the front pipe. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the battery and tray. (See G–5 BATTERY REMOVAL/INSTALLATION.)

9. Remove the shift cable, select cable and clutch release cylinder related to the transaxle. (See J2–7 MANUAL

TRANSAXLE REMOVAL/INSTALLATION.)

10. Remove the clutch release cylinder.

11. Remove the vacuum hose and the heater hose.

12. Disconnect the P/S oil pump pressure pipe and P/S oil pump relief hose from the P/S oil pump side. (See N–16

POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/INSTALLATION.)

Note

•The P/S oil pump will not be removed from the engine.

13. Remove the A/C compressor with the pipe still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure it. (See U–11 A/C COMPRESSOR REMOVAL/INSTALLATION.)

14. Remove the joint shaft.

15. Remove the front drive shaft (LH) from the transaxle.

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Fill the engine coolant, engine oil, and transaxle oil.

19. Bleed the air from the fuel line. (See F2–45 AFTER REPAIR PROCEDURE.)

20. Start the engine and:

•Inspect the pulleys and the drive belt for runout and contact.

•Inspect the engine oil, engine coolant transaxle oil, P/S fluid, and fuel for leakage.

•Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

21. Perform a road test.

22. Reinspect the engine oil, engine coolant, transaxle oil, and P/S fluid levels.

ENGINE

Page 63 of 909

B2–32

ENGINE

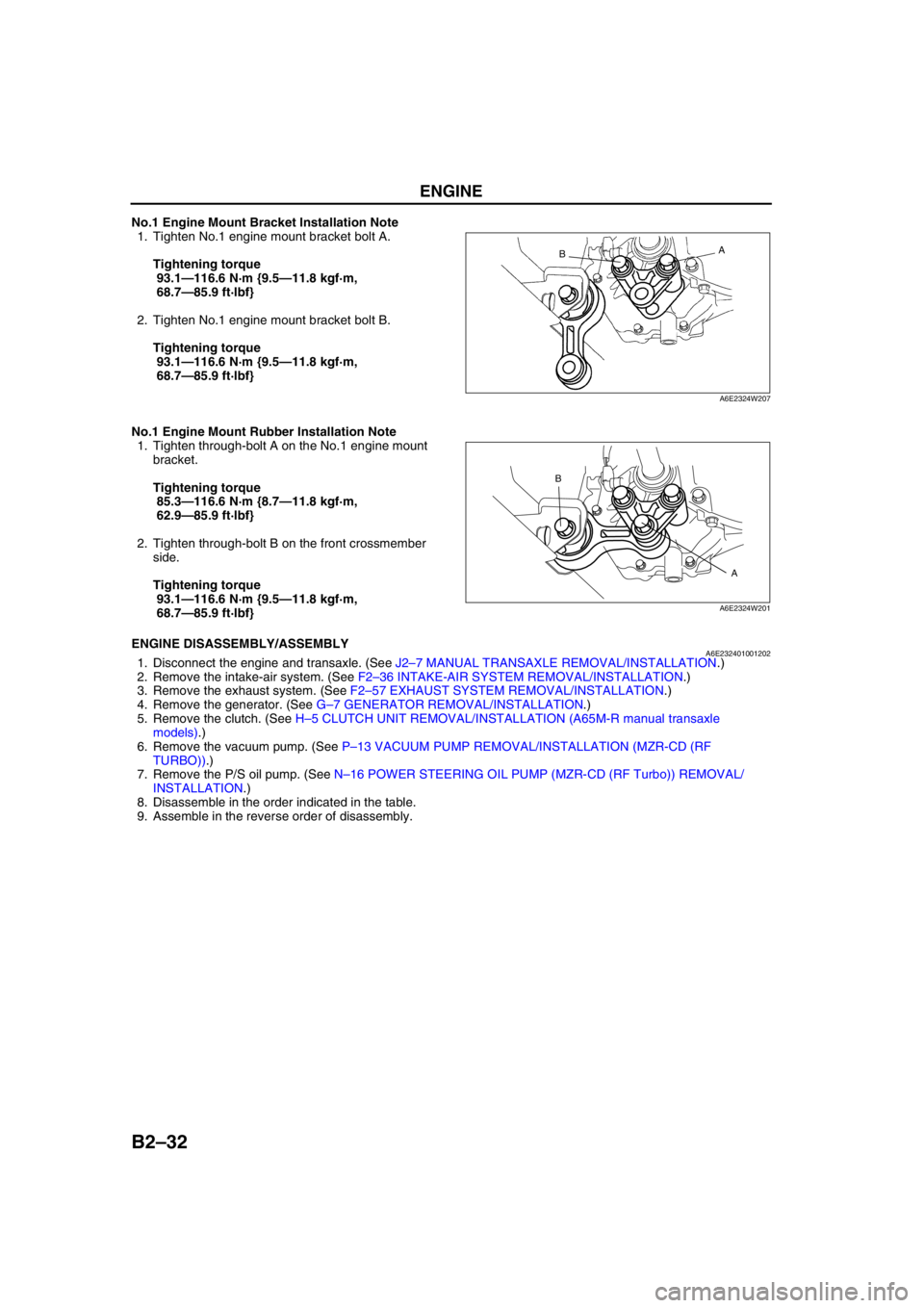

No.1 Engine Mount Bracket Installation Note

1. Tighten No.1 engine mount bracket bolt A.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m,

68.7—85.9 ft·lbf}

2. Tighten No.1 engine mount bracket bolt B.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m,

68.7—85.9 ft·lbf}

No.1 Engine Mount Rubber Installation Note

1. Tighten through-bolt A on the No.1 engine mount

bracket.

Tightening torque

85.3—116.6 N·m {8.7—11.8 kgf·m,

62.9—85.9 ft·lbf}

2. Tighten through-bolt B on the front crossmember

side.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m,

68.7—85.9 ft·lbf}

End Of SieENGINE DISASSEMBLY/ASSEMBLYA6E2324010012021. Disconnect the engine and transaxle. (See J2–7 MANUAL TRANSAXLE REMOVAL/INSTALLATION.)

2. Remove the intake-air system. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

3. Remove the exhaust system. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

4. Remove the generator. (See G–7 GENERATOR REMOVAL/INSTALLATION.)

5. Remove the clutch. (See H–5 CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R manual transaxle

models).)

6. Remove the vacuum pump. (See P–13 VACUUM PUMP REMOVAL/INSTALLATION (MZR-CD (RF

TURBO)).)

7. Remove the P/S oil pump. (See N–16 POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/

INSTALLATION.)

8. Disassemble in the order indicated in the table.

9. Assemble in the reverse order of disassembly.

A

B

A6E2324W207

A B

A6E2324W201

Page 65 of 909

D–1

D

DLUBRICATION SYSTEM

OUTLINE................................................................ D-2

OUTLINE OF CONSTRUCTION.......................... D-2

SPECIFICATIONS ............................................... D-2

STRUCTURAL VIEW ...........................................D-4

LUBRICATION SYSTEM........................................ D-5

LUBRICATION FLOW CHART ............................ D-5

OUTLINE................................................................ D-6

SUPPLEMENTAL SERVICE INFORMATION .....D-6

LUBRICATION SYSTEM........................................ D-6

LOCATION INDEX ............................................... D-6

OIL PRESSURE INSPECTION..............................D-7

OIL PRESSURE INSPECTION............................ D-7

ENGINE OIL........................................................... D-8

ENGINE OIL INSPECTION.................................. D-8

ENGINE OIL REPLACEMENT.............................D-8

OIL FILTER............................................................. D-9

OIL FILTER REPLACEMENT ..............................D-9

OIL COOLER.......................................................... D-9

OIL COOLER REMOVAL/INSTALLATION ..........D-9

OIL PAN................................................................ D-10

OIL PAN REMOVAL/INSTALLATION................ D-10 FEATURES

SERVICE

Page 66 of 909

D–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E330202000201•The construction and the operation of the oil cooler and the oil filter for the new Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model is the same as the current Mazda MPV (LW) MZR-CD (RF Turbo) engine model. (See

Mazda MPV Workshop Manual Supplement 1737-1*-02D.)

•The construction and the operation of the lubrication system except for the oil cooler and oil filter for the new

Mazda6 (GG, GY) MZR-CD (RF Turbo) engine model is the same as the current Mazda 626, 626 Station

Wagon (GF, GW) RF Turbo engine model. (European specs.) (See Mazda 626, 626 Station Wagon RF Turbo

Workshop Manual Supplement 1614-10-98D.)

•The construction and the operation of the lubrication system for the new Mazda6 (GG, GY) L8, LF, and L3

engine models is the same as the current Mazda6 (GG) engine model L8, LF, and L3 engine models. (See

Mazda6 Training Manual 3359-1*-02C, Mazda6 Workshop Manual 1730-1*-02C.)

End Of Sie

SPECIFICATIONSA6E330202000202Gasoline engine

* : Always verify the oil level with the dipsticks since the engine oil capacity differs according to dipstick

specifications. (See Mazda6 Workshop Manual 1730-1*-02C Section D.)

Recommended Engine Oil (Gasoline Engine)

•The maintenance intervals on the scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

OUTLINE

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3*

Lubrication system Force-fed type

Oil coolerWater-cooled

Oil pressure

(approximate quantity)

[oil temperature: 100°C

{212°F}](kPa {kgf/cm

2, psi})

min [rpm]234—521

{2.39—5.31, 33.9—75.5}

[3,000]395—649

{4.03—6.61,

57.3—94.1}

[3,000]

Oil pumpType Trochoid gear type

Relief pressure

(approximate

quantity) (kPa {kgf/cm

2,

psi})500—600

{5.09—6.11, 72.6—87.0}

Oil filterType Full-flow, Paper element

Bypass pressure

(approximate

quantity)(kPa kgf/cm

2, psi})80—120

{0.9—1.2, 12.8—17.0}

Oil capacity

(approximate

quantity)Total

(dry engine)(L {US qt, lmp qt}) 4.6 {4.8, 4.0} Dipstick A: 4.2 {4.4, 3.7}

Dipstick B: 5.1 {5.4, 4.5}

Oil replacement (L {US qt, lmp qt}) 3.9 {4.0, 3.4} Dipstick A: 3.1 {3.3, 2.7}

Dipstick B: 4.0 {4.2, 3.5}

Oil and oil filter

replacement(L {US qt, lmp qt}) 4.3 {4.5, 3.8} Dipstick A: 3.5 {3.7, 3.1}

Dipstick B: 4.4 {4.6, 3.9}

ItemSpecification

New Mazda6

(GG, GY), Current Mazda6

(GG)New Mazda6

(GG, GY), Current Mazda6

(GG)

L8, LF, L3

Engine oil GradeAPI SL

ACEA A3

Viscosity (SAE) 5W-30, 10W-40 5W-20

RemarksMazda genuine Dexelia oil e.g. —

Page 67 of 909

OUTLINE

D–3

D

Diesel engine

Bold frames: New specifications

Recommended Engine Oil (Diesel Engine)

•The maintenance intervals on the scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Bold frames: New specifications

End Of Sie

ItemSpecification

New Mazda6

(GG, GY)Current

Mazda 626, 626

Station Wagon

(GF, GW)Current

Mazda MPV

(LW)

MZR-CD (RF Turbo) RF TurboMZR-CD (RF

Turbo)

Lubrication system Force-fed type—

Oil cooler Water-cooled—

Oil pressure

(approximate quantity)

[oil temperature: 100°C {212°F}](kPa {kgf/cm

2, psi})

min [rpm]147 {1.5, 21} [1,000],

343 {3.5, 50} [3,000]—

Oil pumpType Trochoid gear type—Trochoid gear type

Relief pressure

(approximate

quantity)(kPa {kgf/cm

2, psi})

[rpm]580—700

{5.9—7.1,

84.1—101.5}

[3,000]—580—700

{5.9—7.1,

84.1—101.5}

[3,000]

Oil filterTypeFull-flow,

Paper element—Full-flow,

Paper element

Bypass pressure

(approximate

quantity)(kPa kgf/cm

2, psi})78—118

{0.8—1.2,

11.3—17.1} —78—118

{0.8—1.2,

11.3—17.1}

Oil capacity

(approximate

quantity)Total

(dry engine)(L {US qt, lmp qt}) 5.5 {5.8, 4.8} 5.4 {5.7, 4.8} —

Oil replacement (L {US qt, lmp qt}) 4.8 {5.1, 4.2} 4.5 {4.8, 4.0}—

Oil and oil filter

replacement(L {US qt, lmp qt}) 5.0 {5.3 ,4.4} 4.7 {5.0, 4.1} —

ItemSpecification

New Mazda6

(GG, GY)Current

Mazda 626, 626

Station Wagon

(GF, GW)

MZR-CD (RF Turbo) RF Turbo

Engine oil GradeAPI CF CD, CE, CF-4 CD

ACEA B1 or B3 B3 B3 or B4—

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30 5W-30, 10W-30

RemarksMazda genuine

Dexelia oil e.g.——

Page 70 of 909

D–6

OUTLINE, LUBRICATION SYSTEM

SUPPLEMENTAL SERVICE INFORMATIONA6E330202000204•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Oil pressure

•Inspection procedure has been adopted. (MZR-CD (RF Turbo) engine model)

Engine oil

•Inspection procedure has been adopted. (MZR-CD (RF Turbo) engine model)

•Replacement procedure has been adopted. (MZR-CD (RF Turbo) engine model)

Oil filter

•Replacement procedure has been adopted. (MZR-CD (RF Turbo) engine model)

Oil cooler

•Removal/Installation procedure has been adopted. (MZR-CD (RF Turbo) engine model)

Oil pan

•Removal/Installation procedure has been adopted. (MZR-CD (RF Turbo) engine model)

End Of Sie

LOCATION INDEXA6E333014100201MZR-CD (RF Turbo)

.

End Of Sie

OUTLINE

LUBRICATION SYSTEM

4

3

1

2

A6E3300W003

1 Oil pressure switch

(See D–7 OIL PRESSURE INSPECTION)

2 Oil filter

(See D–9 OIL FILTER REPLACEMENT)3 Oil cooler

(See D–9 OIL COOLER REMOVAL/

INSTALLATION)

4 Oil pan

(See D–10 OIL PAN REMOVAL/INSTALLATION)

Page 71 of 909

OIL PRESSURE INSPECTION

D–7

D

OIL PRESSURE INSPECTIONA6E331001003201MZR-CD (RF Turbo)

Warning

•Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after working with engine oil.

•Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

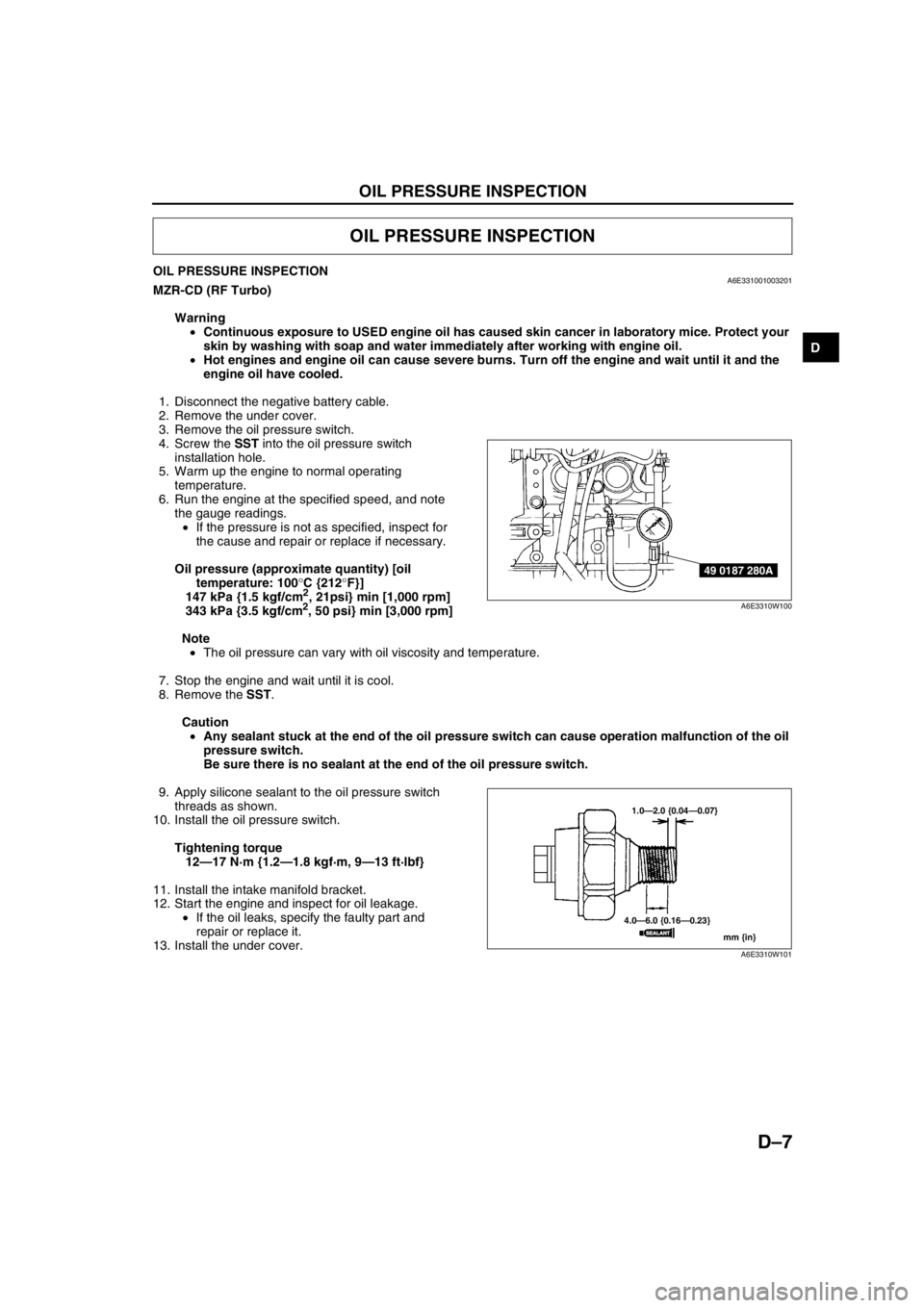

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the oil pressure switch.

4. Screw the SST into the oil pressure switch

installation hole.

5. Warm up the engine to normal operating

temperature.

6. Run the engine at the specified speed, and note

the gauge readings.

•If the pressure is not as specified, inspect for

the cause and repair or replace if necessary.

Oil pressure (approximate quantity) [oil

temperature: 100°C {212°F}]

147 kPa {1.5 kgf/cm

2, 21psi} min [1,000 rpm]

343 kPa {3.5 kgf/cm2, 50 psi} min [3,000 rpm]

Note

•The oil pressure can vary with oil viscosity and temperature.

7. Stop the engine and wait until it is cool.

8. Remove the SST.

Caution

•Any sealant stuck at the end of the oil pressure switch can cause operation malfunction of the oil

pressure switch.

Be sure there is no sealant at the end of the oil pressure switch.

9. Apply silicone sealant to the oil pressure switch

threads as shown.

10. Install the oil pressure switch.

Tightening torque

12—17 N·m {1.2—1.8 kgf·m, 9—13 ft·lbf}

11. Install the intake manifold bracket.

12. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and

repair or replace it.

13. Install the under cover.

End Of Sie

OIL PRESSURE INSPECTION

49 0187 280A

A6E3310W100

1.0—2.0 {0.04—0.07}

4.0—6.0 {0.16—0.23}

mm {in}

SEALANTSEALANT

A6E3310W101

Page 72 of 909

D–8

ENGINE OIL

ENGINE OIL INSPECTIONA6E331214001201MZR-CD (RF Turbo)

1. Position the vehicle on level ground.

2. Warm up the engine to normal operating temperature.

3. Stop the engine and wait for 5 min.

4. Verify that the oil level is between the L and F marks on the dipstick and check the engine oil condition.

•If the oil level is below the L mark, add engine oil. (See D–8 ENGINE OIL REPLACEMENT.)

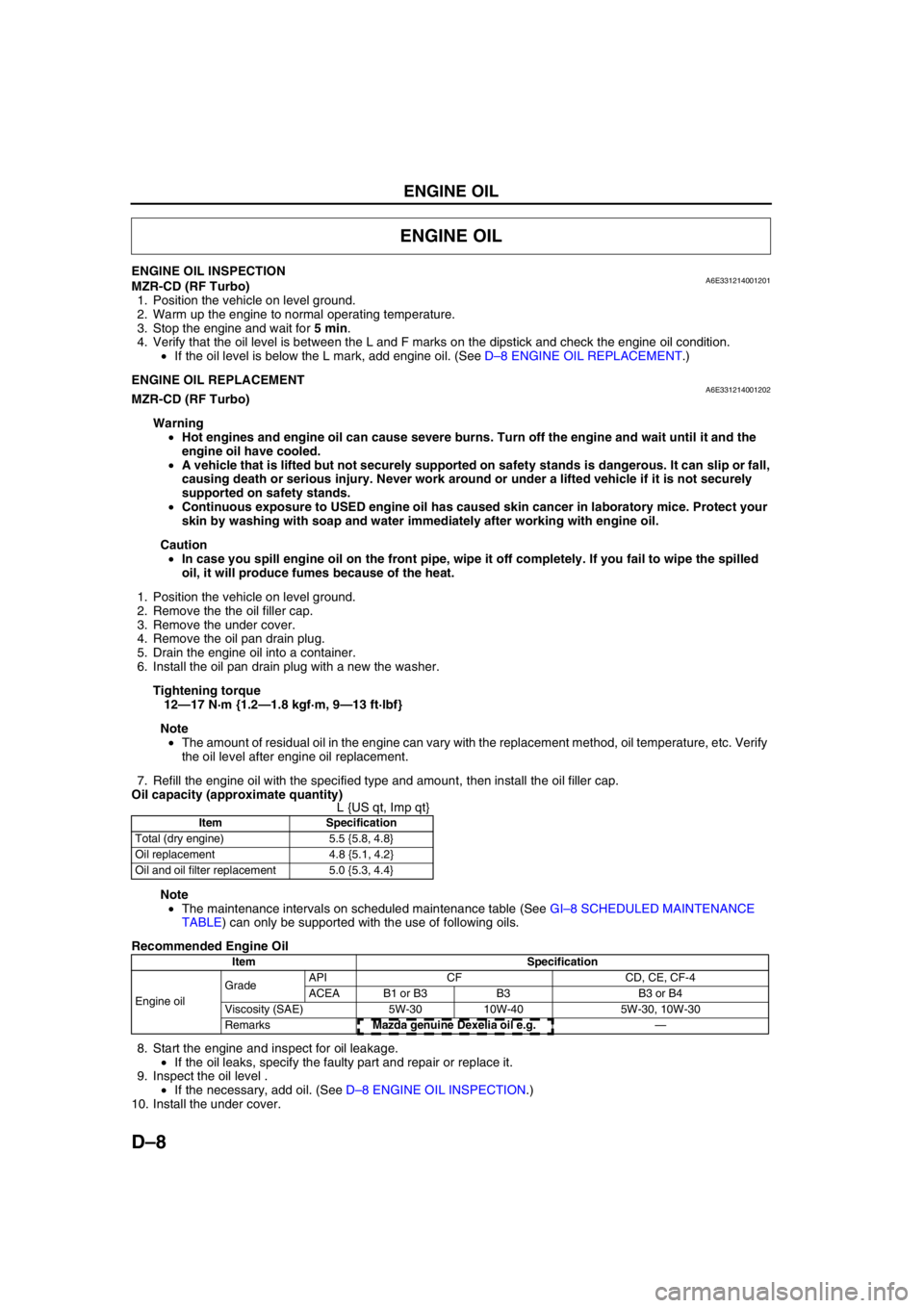

End Of SieENGINE OIL REPLACEMENTA6E331214001202MZR-CD (RF Turbo)

Warning

•Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

•A vehicle that is lifted but not securely supported on safety stands is dangerous. It can slip or fall,

causing death or serious injury. Never work around or under a lifted vehicle if it is not securely

supported on safety stands.

•Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after working with engine oil.

Caution

•In case you spill engine oil on the front pipe, wipe it off completely. If you fail to wipe the spilled

oil, it will produce fumes because of the heat.

1. Position the vehicle on level ground.

2. Remove the the oil filler cap.

3. Remove the under cover.

4. Remove the oil pan drain plug.

5. Drain the engine oil into a container.

6. Install the oil pan drain plug with a new the washer.

Tightening torque

12—17 N·m {1.2—1.8 kgf·m, 9—13 ft·lbf}

Note

•The amount of residual oil in the engine can vary with the replacement method, oil temperature, etc. Verify

the oil level after engine oil replacement.

7. Refill the engine oil with the specified type and amount, then install the oil filler cap.

Oil capacity (approximate quantity)

L {US qt, Imp qt}

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Recommended Engine Oil

8. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

9. Inspect the oil level .

•If the necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Install the under cover.

End Of Sie

ENGINE OIL

Item Specification

Total (dry engine) 5.5 {5.8, 4.8}

Oil replacement 4.8 {5.1, 4.2}

Oil and oil filter replacement 5.0 {5.3, 4.4}

Item Specification

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3 B3 B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

Page 73 of 909

OIL FILTER, OIL COOLER

D–9

D

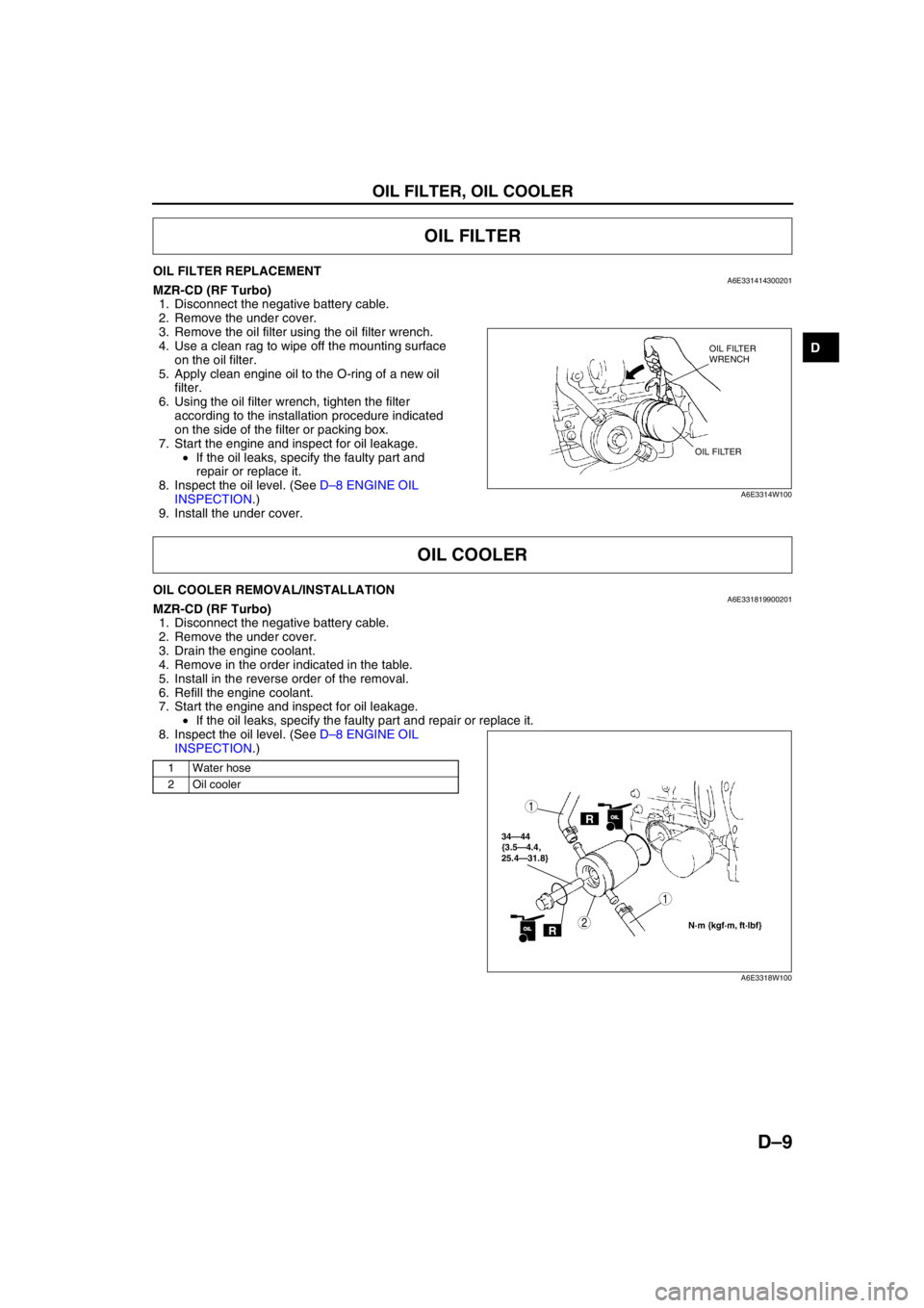

OIL FILTER REPLACEMENTA6E331414300201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the oil filter using the oil filter wrench.

4. Use a clean rag to wipe off the mounting surface

on the oil filter.

5. Apply clean engine oil to the O-ring of a new oil

filter.

6. Using the oil filter wrench, tighten the filter

according to the installation procedure indicated

on the side of the filter or packing box.

7. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and

repair or replace it.

8. Inspect the oil level. (See D–8 ENGINE OIL

INSPECTION.)

9. Install the under cover.

End Of Sie

OIL COOLER REMOVAL/INSTALLATIONA6E331819900201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine coolant.

4. Remove in the order indicated in the table.

5. Install in the reverse order of the removal.

6. Refill the engine coolant.

7. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

8. Inspect the oil level. (See D–8 ENGINE OIL

INSPECTION.)

.

End Of Sie

OIL FILTER

OIL FILTER

WRENCH

OIL FILTER

A6E3314W100

OIL COOLER

1 Water hose

2 Oil cooler

ROILOIL

34—44

{3.5—4.4,

25.4—31.8}

1

2N·m {kgf·m, ft·lbf}ROILOIL

1

A6E3318W100