engine MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 389 of 909

G–6

CHARGING SYSTEM

BATTERY INSPECTIONA6E471018520202MZR-CD (RF Turbo)

Battery

1. Inspect the battery with the following procedure.

Load test chart

Battery positive voltage with load

Back-up Current

1. Verify that the engine switch is off and that the engine key has been removed.

2. Disconnect the negative battery cable.

Caution

•Operating electrical loads while measuring the back-up current can damage the circuit tester.

3. Measure the back-up current between the negative battery terminal and the negative battery cable.

(1) If the current exceeds the maximum, remove the fuses in the main fuse block and the fuse block one by

one while measuring the back-up current.

(2) Inspect and repair harnesses and connectors on the fuse where the current has been reduced.

Back-up current

20 mA max.

End Of Sie

BATTERY RECHARGINGA6E471018520203MZR-CD (RF Turbo)

Caution

•To avoid damage to the battery, do not quick charge for over 30 min.

•When disconnecting the battery, remove the negative cable first and install it last to prevent

damage to electrical components or the battery.

•To avoid deformation or damage to the battery, remove the battery plugs while charging the

battery.

Step Inspection Result Action

1Measure open circuit

voltage of battery.Above

12.4 VGo to Step

3.

Below

12.4 VGo to next

step.

2Quick-charge for 30 min.

and recheck voltage.Above

12.4 VGo to next

step.

Below

12.4 VReplace

battery.

3Apply load test (see load

test chart) to battery using a

battery load tester and

record battery voltage after

15 s. Is voltage more than

specification?YesBattery

okay.

NoReplace

battery.

Battery Load (A)

95D31L (64) 250

115D31L (70) 320

Approximate battery temp. Minimum voltage (V)

21°C {70°F} 9.6

15°C {60°F} 9.5

10°C {50°F} 9.4

4°C {40°F} 9.3

–1°C {30°F} 9.1

–7°C {20°F} 8.9

–12°C {10°F} 8.7

–18°C {0°F} 8.5

Page 390 of 909

CHARGING SYSTEM

G–7

G

1. Remove the battery from vehicle and place it in a pan of water.

2. Connect a battery charger to the battery.

3. Adjust the charging current as follows.

4. After the battery has been recharged, measure

the battery positive voltage and verify that the

battery keeps specified voltage for more than 1 h.

•If not as specified, replace the battery.

Specification

Above 12.4 V

End Of Sie

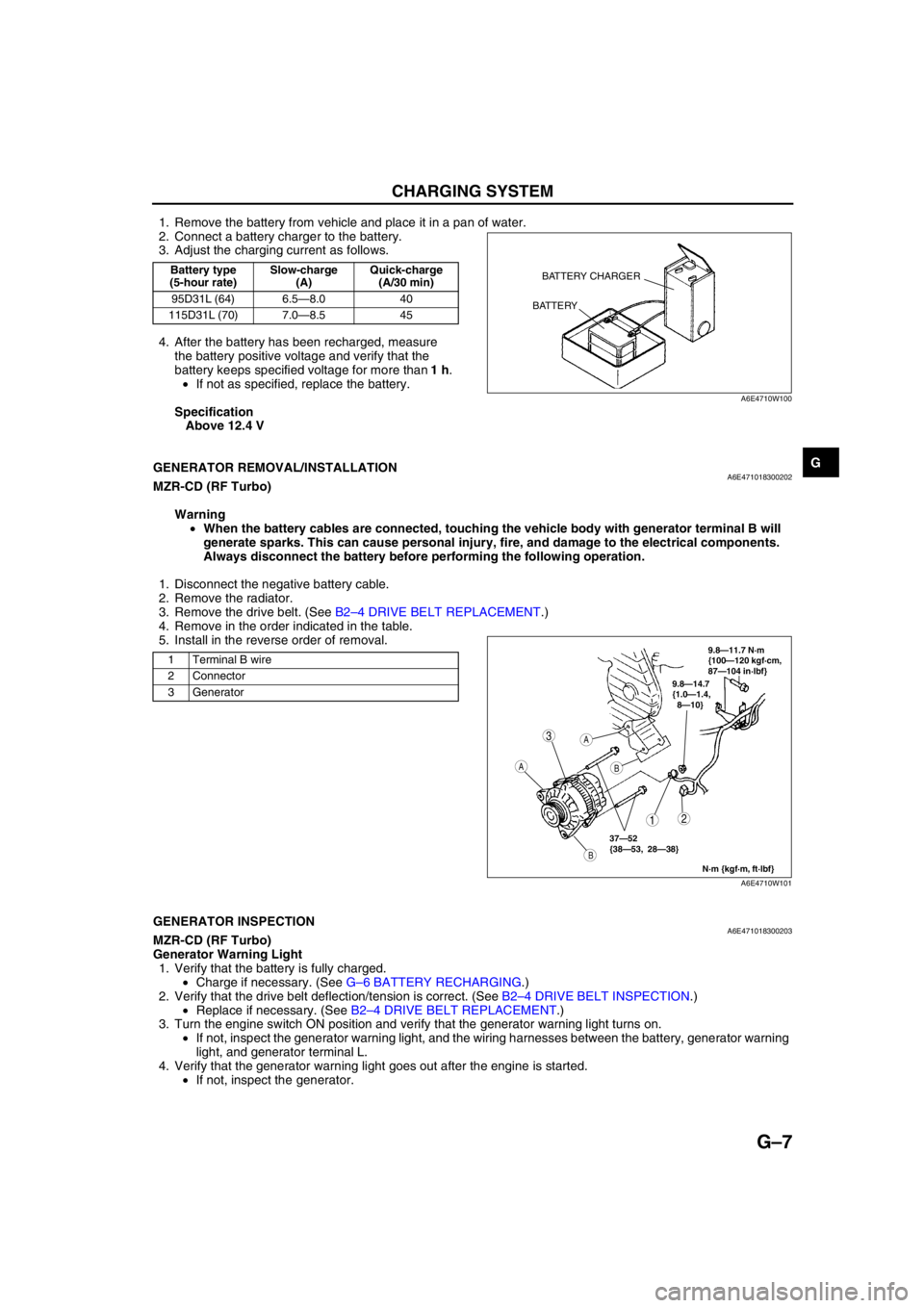

GENERATOR REMOVAL/INSTALLATIONA6E471018300202MZR-CD (RF Turbo)

Warning

•When the battery cables are connected, touching the vehicle body with generator terminal B will

generate sparks. This can cause personal injury, fire, and damage to the electrical components.

Always disconnect the battery before performing the following operation.

1. Disconnect the negative battery cable.

2. Remove the radiator.

3. Remove the drive belt. (See B2–4 DRIVE BELT REPLACEMENT.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of SieGENERATOR INSPECTIONA6E471018300203MZR-CD (RF Turbo)

Generator Warning Light

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Verify that the drive belt deflection/tension is correct. (See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Turn the engine switch ON position and verify that the generator warning light turns on.

•If not, inspect the generator warning light, and the wiring harnesses between the battery, generator warning

light, and generator terminal L.

4. Verify that the generator warning light goes out after the engine is started.

•If not, inspect the generator.

Battery type

(5-hour rate)Slow-charge

(A)Quick-charge

(A/30 min)

95D31L (64) 6.5—8.0 40

115D31L (70) 7.0—8.5 45BATTERY CHARGER

BATTERY

A6E4710W100

1 Terminal B wire

2 Connector

3 Generator

3

12

A

B

A

B

9.8—14.7

{1.0—1.4,

8—10}

N·m {kgf·m, ft·lbf}

37—52

{38—53, 28—38}

9.8—11.7 N·m

{100—120 kgf·cm,

87—104 in·lbf}

A6E4710W101

Page 391 of 909

G–8

CHARGING SYSTEM

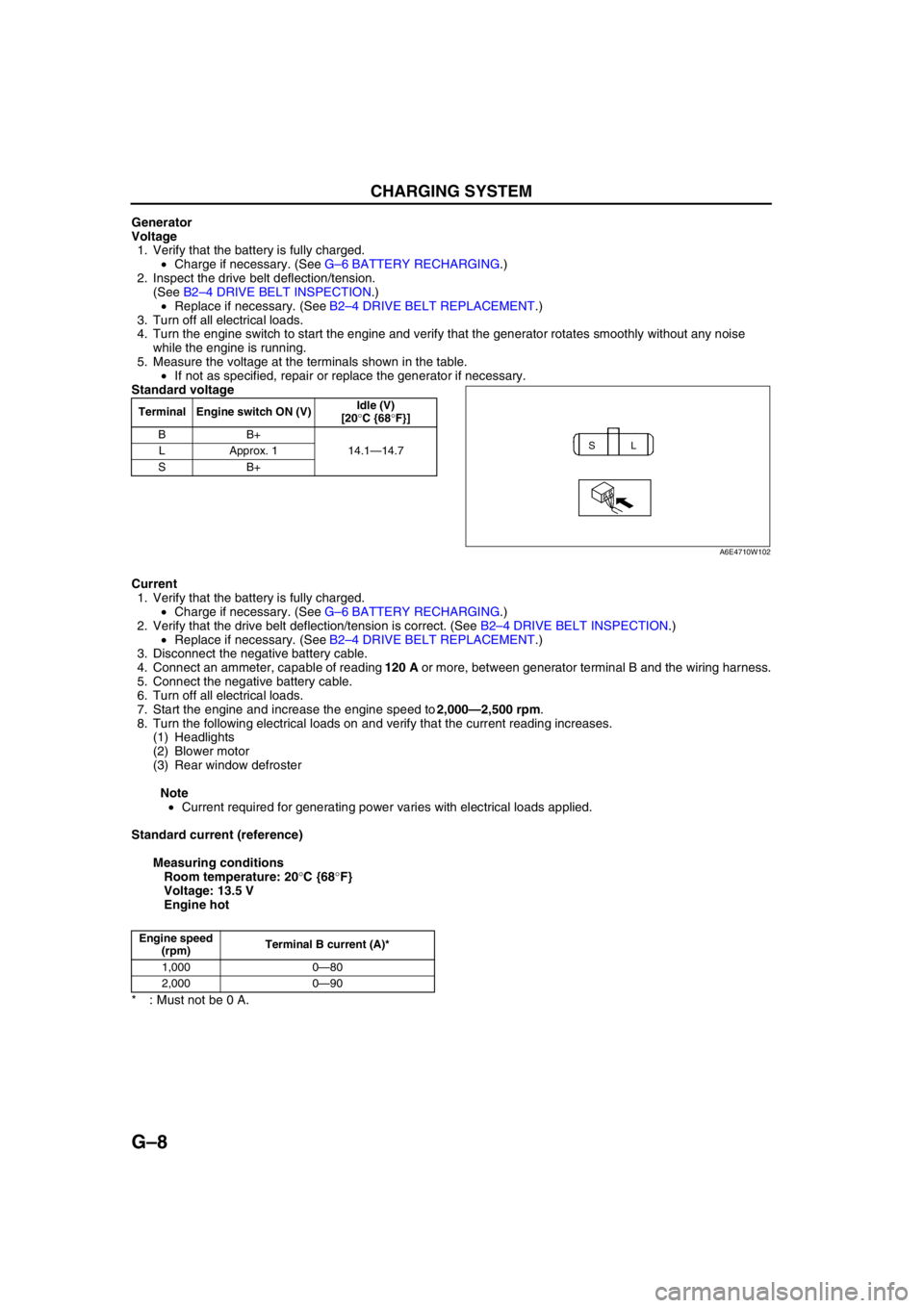

Generator

Voltage

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Inspect the drive belt deflection/tension.

(See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Turn off all electrical loads.

4. Turn the engine switch to start the engine and verify that the generator rotates smoothly without any noise

while the engine is running.

5. Measure the voltage at the terminals shown in the table.

•If not as specified, repair or replace the generator if necessary.

Standard voltage

Current

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Verify that the drive belt deflection/tension is correct. (See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Disconnect the negative battery cable.

4. Connect an ammeter, capable of reading 120 A or more, between generator terminal B and the wiring harness.

5. Connect the negative battery cable.

6. Turn off all electrical loads.

7. Start the engine and increase the engine speed to 2,000—2,500 rpm.

8. Turn the following electrical loads on and verify that the current reading increases.

(1) Headlights

(2) Blower motor

(3) Rear window defroster

Note

•Current required for generating power varies with electrical loads applied.

Standard current (reference)

Measuring conditions

Room temperature: 20°C {68°F}

Voltage: 13.5 V

Engine hot

* : Must not be 0 A.

End Of Sie

Terminal Engine switch ON (V)Idle (V)

[20°C {68°F}]

BB+

14.1—14.7 LApprox. 1

SB+

SL

A6E4710W102

Engine speed

(rpm)Terminal B current (A)*

1,000 0—80

2,000 0—90

Page 392 of 909

STARTING SYSTEM

G–9

G

STARTER REMOVAL/INSTALLATIONA6E471418400202

Warning

•When the battery cables are connected, touching the vehicle body with starter terminal B will

generate sparks. This can cause personal injury, fire, and damage to the electrical components.

Always disconnect the battery negative cables before performing the following operation.

1. Disconnect the negative battery cable.

2. Remove the plug hole plate. (L8, LF, and L3 engine models)

3. Remove the engine cover. (MZR-CD (RF Turbo) engine model) (See B2–9 TIMING BELT REMOVAL/

INSTALLATION.)

4. Remove the air cleaner assembly. (L8, LF, and L3 engine models).

5. Remove the under cover.

6. Remove the oil filter and oil cooler component with the cooling hose connected. Position the oil filter and oil

cooler component so that it is out of the way. (L3 engine model (4WD))

7. Remove the solenoid valve assembly with the vacuum hose and the connector connected. Position the

solenoid valve assembly so that it is out of the way. (MZR-CD (RF Turbo) engine model)

8. Remove the release cylinder with the oil pipe connected. Position the release cylinder so that it is out of the

way. (MTX)

9. Remove in the order indicated in the table.

10. Install in the reverse order of removal.

STARTING SYSTEM

Page 394 of 909

STARTING SYSTEM

G–11

G

STARTER INSPECTIONA6E471418400203MZR-CD (RF Turbo)

On-vehicle Inspection

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Crank the engine and verify that the starter rotates smoothly without any noise.

•If not as specified, inspect the following:

—Remove the starter, and inspect the magnetic switch and the starter.

—Inspect the related wiring harness and the engine switch.

No Load Test

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Connect the starter, battery, voltmeter and

ammeter as shown.

3. Operate the starter and verify that it rotates

smoothly.

4. Measure the voltage and current while the starter

is operating.

•If not as specified, replace the starter.

Specification

End Of Sie

Voltage (V)11

Current (A)Below 130

ENGINE

SWITCH

TERMINAL SB

M

STARTERVA

VOLTMETER

BATTERY

AMMETER

A6E4714W101

Page 396 of 909

H–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E490216003201•The construction and operation of the clutch is essentially carried over from that of the current MPV (LW)

models, except for the following features. (See Mazda MPV Training Manual 3340-1*-99F.)

End Of Sie

FEATURESA6E490216003202Adoption of the A65M-R manual transaxle models

•The specifications for the A65M-R manual transaxle models have been added.

Increased torque transmission capacity

•Increased clutch cover set load.

Reduced noise

•The flywheel with a damper has been adopted for the A65M-R manual transaxle model.

End Of Sie

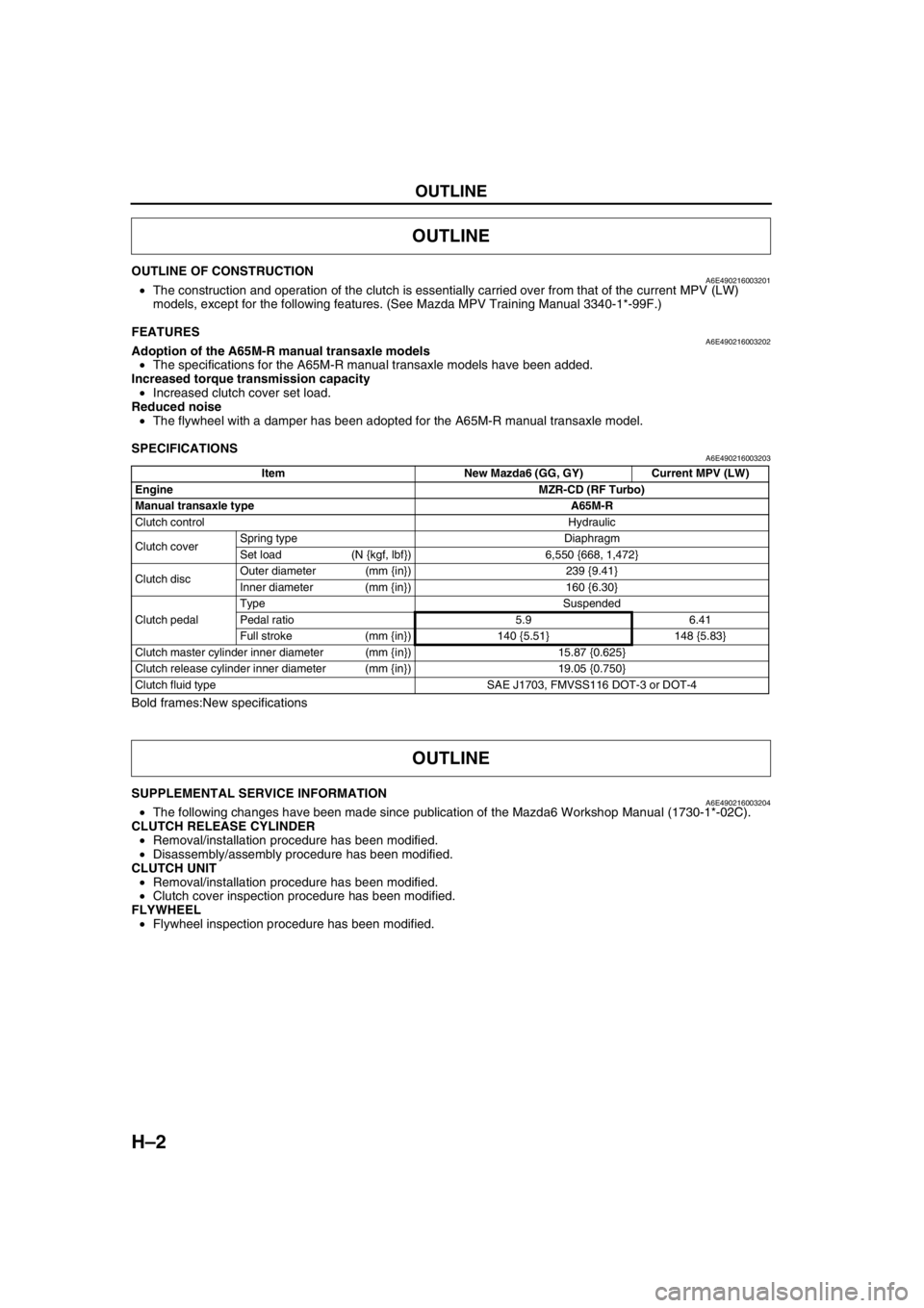

SPECIFICATIONSA6E490216003203

Bold frames:New specifications

End Of Sie

SUPPLEMENTAL SERVICE INFORMATIONA6E490216003204•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

CLUTCH RELEASE CYLINDER

•Removal/installation procedure has been modified.

•Disassembly/assembly procedure has been modified.

CLUTCH UNIT

•Removal/installation procedure has been modified.

•Clutch cover inspection procedure has been modified.

FLYWHEEL

•Flywheel inspection procedure has been modified.

End Of Sie

OUTLINE

Item New Mazda6 (GG, GY) Current MPV (LW)

EngineMZR-CD (RF Turbo)

Manual transaxle type A65M-R

Clutch control Hydraulic

Clutch coverSpring type Diaphragm

Set load (N {kgf, lbf}) 6,550 {668, 1,472}

Clutch discOuter diameter (mm {in}) 239 {9.41}

Inner diameter (mm {in}) 160 {6.30}

Clutch pedalType Suspended

Pedal ratio 5.9 6.41

Full stroke (mm {in}) 140 {5.51} 148 {5.83}

Clutch master cylinder inner diameter (mm {in}) 15.87 {0.625}

Clutch release cylinder inner diameter (mm {in}) 19.05 {0.750}

Clutch fluid type SAE J1703, FMVSS116 DOT-3 or DOT-4

OUTLINE

Page 399 of 909

CLUTCH UNIT

H–5

H

CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R MANUAL TRANSAXLE MODELS)A6E4920160002011. Remove in the order indicated in the table.

2. Install in the reverse order oremoval.

.

CLUTCH UNIT

SST

SST

SSTSEALANT

25—33

{2.6—3.3, 19—24}

151.3—161.1

{15.43—16.42, 111.6—118.8} 18.6—25.5

{1.90—2.60, 13.8—18.8}

1

GREASE

GREASE

GREASE

GREASE

GREASE

5

6

7

8

4

3

2

(MOLYBDENUM SULFIDE) TRANSAXLE SIDE ENGINE SIDE

N·m {kgf·m, ft·lbf}

A6E4920W010

1 Clutch release cylinder

2 Manual transaxle

(See J2–7 MANUAL TRANSAXLE REMOVAL/

INSTALLATION)

3Boot

4 Clutch release collar

5 Clutch release fork6 Clutch cover

(See H–6 Clutch Cover and Disc Removal Note)

(See H–7 Clutch Cover Installation Note)

7Clutch disc

(See H–6 Clutch Cover and Disc Removal Note)

(See H–7 Clutch Disc Installation Note)

8 Flywheel

(See H–6 Flywheel Removal Note)

(See H–6 Flywheel Installation Note)

Page 409 of 909

MANUAL TRANSAXLE

J2–7

J2

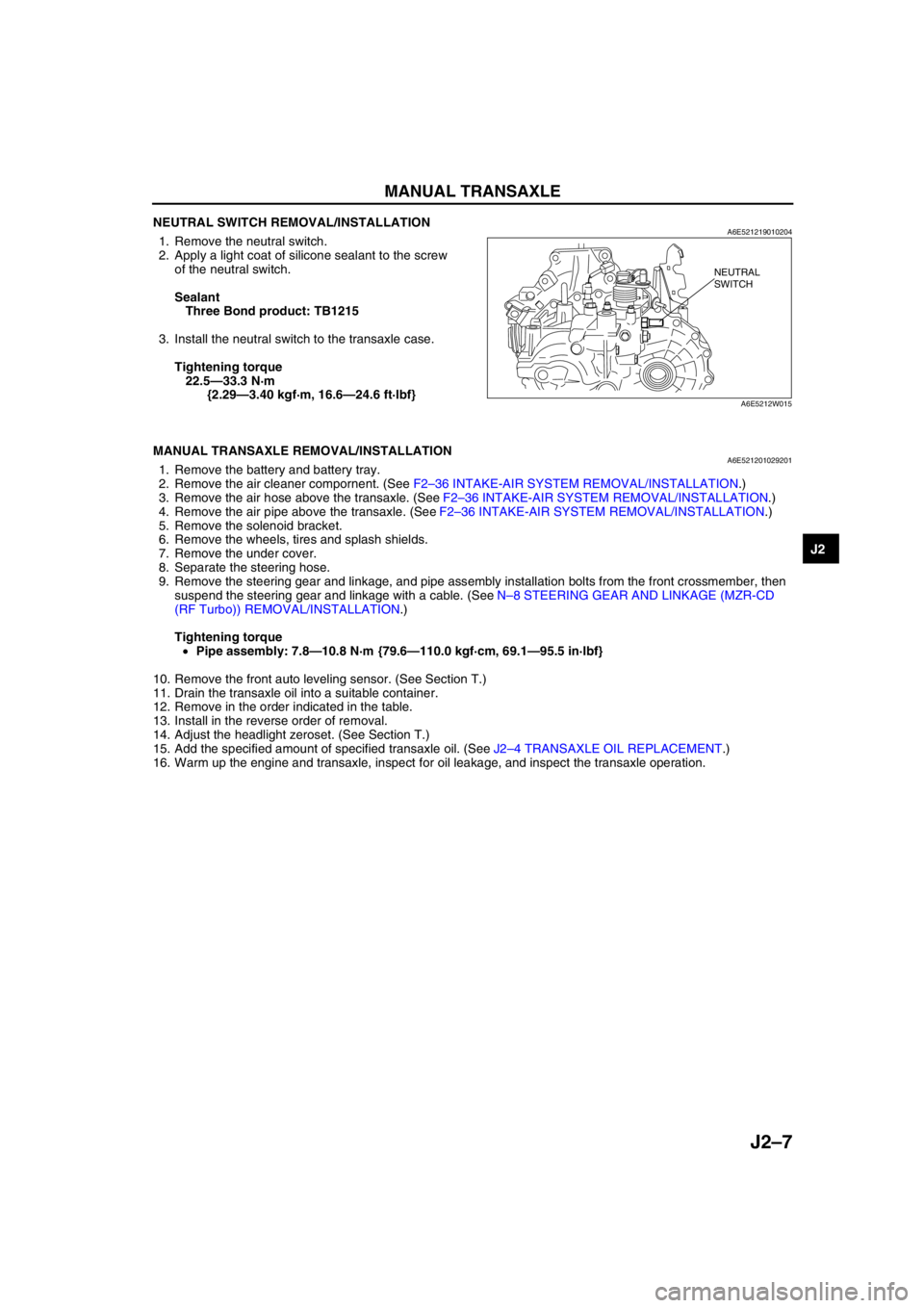

NEUTRAL SWITCH REMOVAL/INSTALLATIONA6E5212190102041. Remove the neutral switch.

2. Apply a light coat of silicone sealant to the screw

of the neutral switch.

Sealant

Three Bond product: TB1215

3. Install the neutral switch to the transaxle case.

Tightening torque

22.5—33.3 N·m

{2.29—3.40 kgf·m, 16.6—24.6 ft·lbf}

End Of Sie

MANUAL TRANSAXLE REMOVAL/INSTALLATIONA6E5212010292011. Remove the battery and battery tray.

2. Remove the air cleaner compornent. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

3. Remove the air hose above the transaxle. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

4. Remove the air pipe above the transaxle. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

5. Remove the solenoid bracket.

6. Remove the wheels, tires and splash shields.

7. Remove the under cover.

8. Separate the steering hose.

9. Remove the steering gear and linkage, and pipe assembly installation bolts from the front crossmember, then

suspend the steering gear and linkage with a cable. (See N–8 STEERING GEAR AND LINKAGE (MZR-CD

(RF Turbo)) REMOVAL/INSTALLATION.)

Tightening torque

•Pipe assembly: 7.8—10.8 N·m {79.6—110.0 kgf·cm, 69.1—95.5 in·lbf}

10. Remove the front auto leveling sensor. (See Section T.)

11. Drain the transaxle oil into a suitable container.

12. Remove in the order indicated in the table.

13. Install in the reverse order of removal.

14. Adjust the headlight zeroset. (See Section T.)

15. Add the specified amount of specified transaxle oil. (See J2–4 TRANSAXLE OIL REPLACEMENT.)

16. Warm up the engine and transaxle, inspect for oil leakage, and inspect the transaxle operation.

NEUTRAL

SWITCH

A6E5212W015

Page 411 of 909

MANUAL TRANSAXLE

J2–9

J2

No.1 Engine Mount Bracket Removal Note

1. Separate the fuel pipe nearby engine hanger.

2. Support the engine using the SST before

removing the No.1 engine mount.

3. Remove the No.1 engine mount.

Manual Transaxle Removal Note

1. Remove the stud of the No.4 engine mount.

2. Loosen the SST (49 E017 5A0)and lean the

engine toward the transaxle.

3. Support the transaxle on a jack.

4. Remove the transaxle mounting bolts.

5. Remove the transaxle.

9 Lower arm (front, rear) ball joint

(See Section R)

10 Damper fork

11 Tie-rod end ball joint

(See N–8 STEERING GEAR AND LINKAGE

(MZR-CD (RF Turbo)) REMOVAL/INSTALLATION)

12 Stabilizer control link

13 Drive shaft (left side)

(SeeSection M)

14 Drive shaft (right side)

(SeeSection M)

15 Joint shaft

(SeeSection M)

16 Flexible pipe

(See F2–57 EXHAUST SYSTEM REMOVAL/

INSTALLATION)17 No.1 engine mount

(See J2–9 No.1 Engine Mount Bracket Removal

Note)

(See J2–11 No.1 Engine Mount Installation Note)

18 Crossmember bracket

19 Crossmember, steering pipe

(See Section R)

20 No.4 engine mount bracket

(See J2–10 No.4 Engine Mount Installation Note)

21 No.4 engine mount rubber

(See J2–10 No.4 Engine Mount Installation Note)

22 Transaxle mounting bolt (lower side)

23 Manual transaxle

(See J2–9 Manual Transaxle Removal Note)

(See J2–10 Manual Transaxle Installation Note)

49 E017 5A0

A6E5212W019

STUD

A6E5212W020

A6E5212W021

Page 412 of 909

J2–10

MANUAL TRANSAXLE

Manual Transaxle Installation Note

1. Set the transaxle on a jack and lift into place.

2. Install the transaxle mounting bolts.

3. Install the stud of the No.4 engine mount.

Tightening torque

27.4—40.2 N·m

{2.80—4.09 kgf·m, 20.2—29.6 ft·lbf}

4. Tighten the SST (49 E017 5A0)so that the engine

is located at the specified position.

No.4 Engine Mount Installation Note

1. Verify that the No.4 engine mount rubber is installed as shown.

2. Lightly tighten the bolt A and B.

3. Align the contacted area to front frame of the bolt C to the front frame.

4. Tighten the bolt A, then bolt B.

5. Tighten the bolt C, then bolt D.

Tightening torque

A,B,C,D: 58.8—80.4 N·m

{6.00—8.19 kgf·m, 43.4—59.2 ft·lbf}

6. Verify that the No.4 engine mount bracket is

installed as shown.

7. Lightly tighten the bolt E.

8. Set the transaxle on a garage jack and lift it.

9. Align the hole of the No.4 engine mount bracket

with the stud bolts of transaxle.

10. Lightly tighten the nut F, G and bolt H.

11. Tighten the nut F, G in order of F→G, then bolt H.

A6E5212W022

STUD

A6E5212W020

D

H

C

FB

A

GE

A6E5212W024

TRANSAXLE

GARAGE JACK

A6E5212W023