lock MAZDA 6 2002 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 326 of 909

F2–174

TROUBLESHOOTING

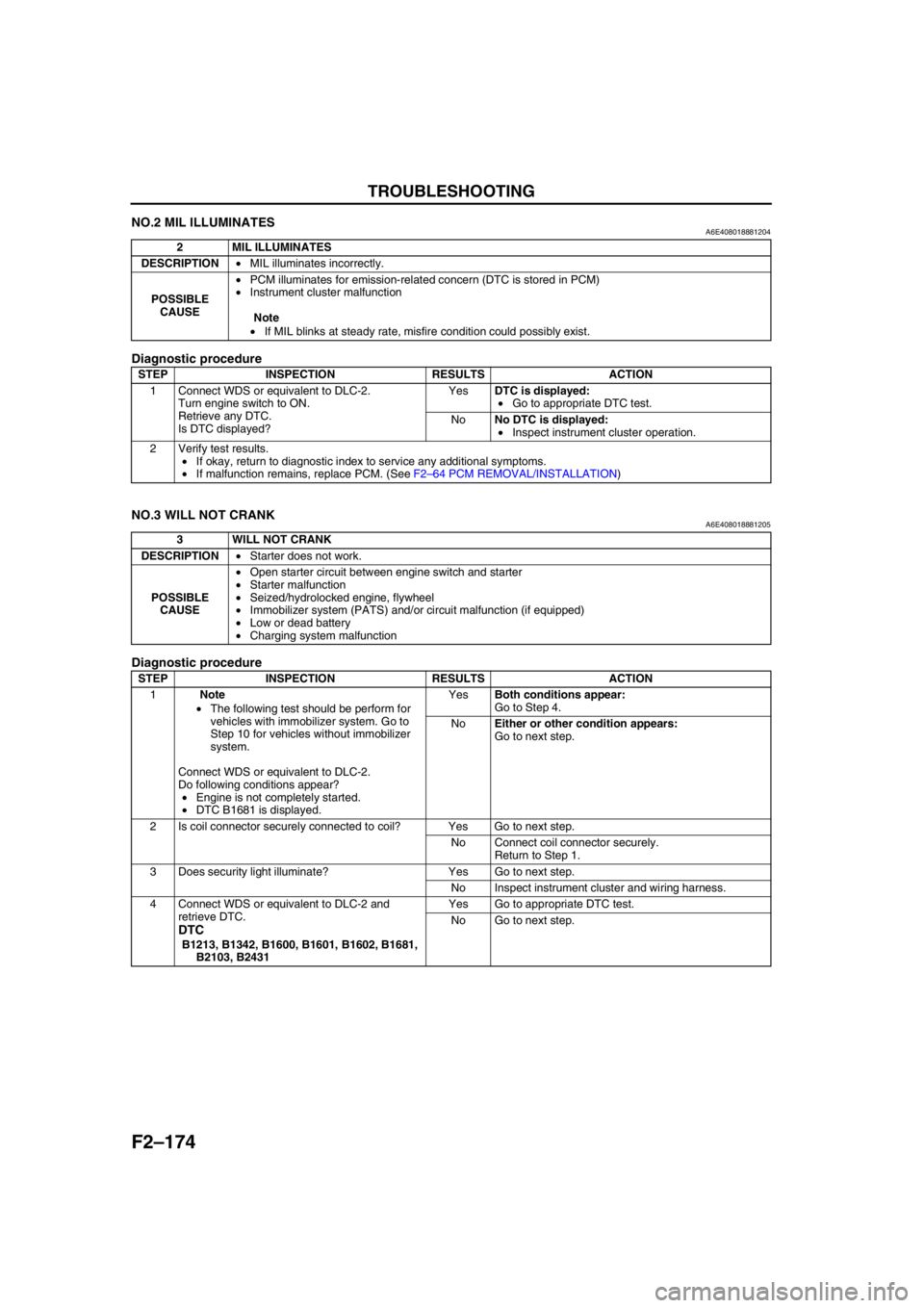

NO.2 MIL ILLUMINATESA6E408018881204

Diagnostic procedure

End Of Sie

NO.3 WILL NOT CRANKA6E408018881205

Diagnostic procedure

2 MIL ILLUMINATES

DESCRIPTION•MIL illuminates incorrectly.

POSSIBLE

CAUSE•PCM illuminates for emission-related concern (DTC is stored in PCM)

•Instrument cluster malfunction

Note

•If MIL blinks at steady rate, misfire condition could possibly exist.

STEP INSPECTION RESULTS ACTION

1 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

•Go to appropriate DTC test.

NoNo DTC is displayed:

•Inspect instrument cluster operation.

2 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

3 WILL NOT CRANK

DESCRIPTION•Starter does not work.

POSSIBLE

CAUSE•Open starter circuit between engine switch and starter

•Starter malfunction

•Seized/hydrolocked engine, flywheel

•Immobilizer system (PATS) and/or circuit malfunction (if equipped)

•Low or dead battery

•Charging system malfunction

STEP INSPECTION RESULTS ACTION

1Note

•The following test should be perform for

vehicles with immobilizer system. Go to

Step 10 for vehicles without immobilizer

system.

Connect WDS or equivalent to DLC-2.

Do following conditions appear?

•Engine is not completely started.

•DTC B1681 is displayed.YesBoth conditions appear:

Go to Step 4.

NoEither or other condition appears:

Go to next step.

2 Is coil connector securely connected to coil? Yes Go to next step.

No Connect coil connector securely.

Return to Step 1.

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.

Page 327 of 909

TROUBLESHOOTING

F2–175

F2

End Of Sie

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect following:

•Battery connection

•Battery condition

•Fuses

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11 Is clicking sound heard from starter when engine

switch is turned to START?Yes Go to Step 13.

No Go to next step.

12 Inspect starting system.

Is starting system okay?Yes Inspect for seized/hydrolocked engine, flywheel.

No Repair or replace components as required.

13 Do any other electrical accessories work? Yes Go to next step.

No Inspect charging system.

14 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Inspect for following:

•START circuit in engine switch

•Open circuit between engine switch and starter

15 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 348 of 909

F2–196

TROUBLESHOOTING

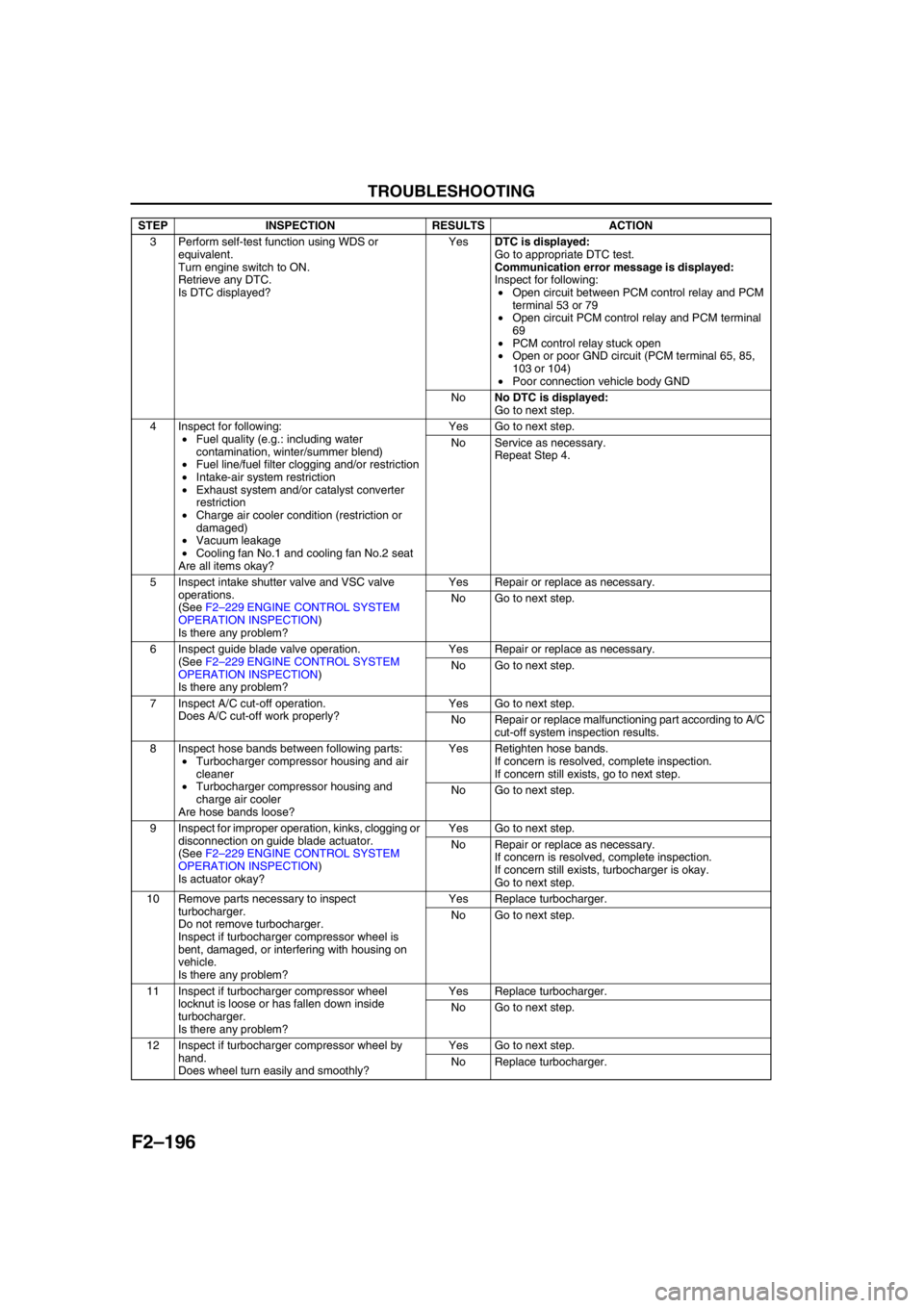

3 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

4 Inspect for following:

•Fuel quality (e.g.: including water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging and/or restriction

•Intake-air system restriction

•Exhaust system and/or catalyst converter

restriction

•Charge air cooler condition (restriction or

damaged)

•Vacuum leakage

•Cooling fan No.1 and cooling fan No.2 seat

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 4.

5 Inspect intake shutter valve and VSC valve

operations.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is there any problem?Yes Repair or replace as necessary.

No Go to next step.

6 Inspect guide blade valve operation.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is there any problem?Yes Repair or replace as necessary.

No Go to next step.

7 Inspect A/C cut-off operation.

Does A/C cut-off work properly?Yes Go to next step.

No Repair or replace malfunctioning part according to A/C

cut-off system inspection results.

8 Inspect hose bands between following parts:

•Turbocharger compressor housing and air

cleaner

•Turbocharger compressor housing and

charge air cooler

Are hose bands loose?Yes Retighten hose bands.

If concern is resolved, complete inspection.

If concern still exists, go to next step.

No Go to next step.

9 Inspect for improper operation, kinks, clogging or

disconnection on guide blade actuator.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is actuator okay?Yes Go to next step.

No Repair or replace as necessary.

If concern is resolved, complete inspection.

If concern still exists, turbocharger is okay.

Go to next step.

10 Remove parts necessary to inspect

turbocharger.

Do not remove turbocharger.

Inspect if turbocharger compressor wheel is

bent, damaged, or interfering with housing on

vehicle.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

11 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

12 Inspect if turbocharger compressor wheel by

hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger. STEP INSPECTION RESULTS ACTION

Page 352 of 909

F2–200

TROUBLESHOOTING

4 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

5 Inspect intake shutter valve and VSC valve

operations.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is there any problem?Yes Repair or replace as necessary.

No Go to next step.

6 Inspect guide blade valve operation.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is there any problem?Yes Repair or replace as necessary.

No Go to next step.

7 Inspect hose bands between following parts:

•Turbocharger compressor housing and air

cleaner

•Turbocharger compressor housing and

charge air cooler

Are hose bands loose?Yes Retighten hose bands.

If concern is resolved, complete inspection.

If concern still exists, go to next step.

No Go to next step.

8 Inspect for improper operation, kinks, clogging or

disconnection on guide blade actuator.

(See F2–229 ENGINE CONTROL SYSTEM

OPERATION INSPECTION)

Is actuator okay?Yes Go to next step.

No Repair or replace as necessary.

If concern is resolved, complete inspection.

If concern still exists, turbocharger is okay.

Go to next step.

9 Remove parts necessary to inspect

turbocharger.

Do not remove turbocharger.

Inspect if turbocharger compressor wheel is

bent, damaged, or interfering with housing on

vehicle.

(See F2–38 TURBOCHARGER INSPECTION)

Is there any problem?Yes Replace turbocharger.

No Go to next step.

10 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

11 Inspect turbocharger compressor wheel by

hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

12 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

13 Is any engine oil found inside turbocharger

turbine housing?YesExcessive amount of oil is found:

Replace turbocharger.

Small amount of oil is found:

Wipe oil off of vehicle, then go to next step.

No Go to next step. STEP INSPECTION RESULTS ACTION

Page 359 of 909

TROUBLESHOOTING

F2–207

F2

12 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

13 Inspect turbocharger compressor wheel by

hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

14 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

15 Is any engine oil found inside turbocharger

turbine housing?YesExcessive amount of oil is found:

Replace turbocharger.

Small amount of oil is found:

Wipe oil off of vehicle, then go to next step.

No Go to next step.

16 Is any engine oil found inside turbocharger

compressor hosing?Yes Wipe oil off of vehicle and install all removed parts in

Step 10. Then, go to next step.

No Turbocharger is okay.

Install all parts removed in Step10.

Then, go to next step.

17 Perform EGR system inspection.

Is EGR system okay?Yes Go to next step.

No Repair or replace malfunctioning part according to

EGR system operation results.

18 Inspect EGR water cooler for following:

•Coolant passage clogging/restriction

•Exhaust gas clogging/restriction

Is EGR water cooler okay?Yes Go to next step.

No Service as necessary.

19 Inspect glow system operation.

(See T–19 RELAY INSPECTION)

Is glow system operation normal?Yes Go to next step.

No Repair or replace malfunctioning part according to

glow system operation results.

20 Visually inspect CKP sensor and teeth of pulse

wheel.

Are CKP sensor and teeth of pulse wheel okay?Yes Go to next step.

No Replace malfunctioning parts.

21 Measure gap between CKP sensor and teeth of

pulse wheel.

Specification

1.5—2.5 mm {0.059—0.098 in}

Is gap within specification?Yes Go to next step.

No Adjust CKP sensor position.

22 Visually inspect CMP sensor and teeth of pulse

wheel.

Are CMP sensor and teeth of pulse wheel okay?Yes Inspect following PIDs:

(See F2–65 PCM INSPECTION)

•ECT

•IAT

•MAF

•MAP

•RPM

•VSS

If PID value is not as specified, repair or replace

malfunctioning parts.

If PID value is okay, go to next step.

No Replace malfunctioning parts.

23 Inspect fuel pressure sensor.

(See F2–79 FUEL PRESSURE SENSOR

INSPECTION)

Is fuel pressure okay?Yes Go to next step.

No Replace common rail.

24 Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

Is suction control valve okay?Yes Go to next step.

No Repair supply pump.

(See F2–54 SUPPLY PUMP INSPECTION) STEP INSPECTION RESULTS ACTION

Page 361 of 909

TROUBLESHOOTING

F2–209

F2

NO.16 HIGH OIL CONSUMPTION/LEAKAGEA6E408018881218

Diagnostic Procedure

16 HIGH OIL CONSUMPTION/LEAKAGE

DESCRIPTION•Oil consumption is excessive.

POSSIBLE

CAUSE•Improper engine oil level

•Improper dipstick

•Improper engine oil viscosity

•Engine internal parts malfunction

•Oil leakage

•Turbocharger malfunction

STEP INSPECTION RESULTS ACTION

1 Verify following:

•Proper dipstick

•Proper engine viscosity

•Engine oil level

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Remove to necessary to inspect turbocharger.

Note

•Do not remove turbocharger.

Inspect if turbocharger compressor wheel is

bent, damaged, or interfering with housing on

vehicle.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

3 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

4 Turn turbocharger compressor wheel by hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

5 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

6 Is any engine oil found inside turbocharger

turbine housing?YesExcessive amount of oil is found:

Replace turbocharger.

Small amount of oil is found:

Wipe oil off of vehicle, then go to next step.

No Go to next step.

7 Is any engine oil found inside turbocharger

compressor housing?Yes Wipe oil off of vehicle, then go to next step.

No Go to next step.

8 Is any engine oil found around oil pipes attached

on turbocharger center housing?Yes If oil leaks from damaged pipe, replace oil pipe.

Then, go to next step.

No Go to next step.

9 Is any engine oil found inside air intake pipes or

hoses?Yes Wipe engine oil off.

No Turbocharger is okay.

Install all parts removed in Step 2.

Then go to next step.

10 Is engine compression correct?

(See B2–8 COMPRESSION INSPECTION)Yes Inspect oil leakage from outside of engine.

No Inspect for following:

•Damaged valve seat

•Worn valve stem and valve guide

•Worn or stuck piston ring

•Worn piston, piston ring or cylinder

Service as necessary.

11 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 363 of 909

TROUBLESHOOTING

F2–211

F2

End Of Sie

3Note

•The following test should be performed on

the vehicles with A/C system. Go to next

step for vehicles without A/C system

Start engine and run it at idle speed.

Turn A/C switch off.

Does A/C compressor disengaged?Yes Go to next step.

No Go to symptom troubleshooting “NO.24 A/C ALWAYS

ON OR A/C COMPRESSOR RUNS

CONTINUOUSLY”.

4 Start engine and run it at idle speed.

Turn A/C switch on if equipped.

Do cooling fan No.1 and/or cooling fan No.2

operate?Yes Go to next step.

NoCooling fan No.1 does not operate:

Inspect for following:

•Cooling fan relay No.1 is stuck open

•Cooling fan motor No.1 malfunction

•Cooling fan motor No.1 GND open

•Open circuit between cooling fan motor No.1 and

relay

•Open circuit between cooling fan relay No.1 and

PCM terminal 102

•Open battery power circuit of cooling fan relay

No.1

Cooling fan No.2 does not operate:

Inspect for following:

•Cooling fan relay No.2 is stuck open

•Cooling fan motor No.2 malfunction

•Cooling fan motor No.2 GND open

•Open circuit between Cooling fan motor No.2 and

relay

•Open circuit between Cooling fan relay No.2 and

PCM terminal 76

•Open battery power circuit of Cooling fan relay

No.2

5 Is drive belt okay? Yes Go to next step.

No Replace drive belt.

6 Perform EGR system inspection.

Is EGR system okay?Yes Go to next step.

No Repair or replace malfunctioning part according to

EGR system operation results.

7 Perform coolant heater system inspection.

(See E–10 THERMOSTAT INSPECTION)

Is coolant heater system okay?Yes Go to next step.

No Repair or replace malfunctioning part according to

coolant heater system operation results.

8 Cool down engine.

Remove thermostat and inspect operation.

Is thermostat okay?Yes Thermostat is okay.

Inspect cylinder block for leakage or blockage.

No Replace thermostat.

9 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 367 of 909

TROUBLESHOOTING

F2–215

F2

End Of Sie

15 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

16 Inspect if turbocharger compressor wheel by

hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

17 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

18 Is any engine oil found inside turbocharger

compressor housing?Yes Wipe oil off of vehicle and install all removed parts in

Step 15. Then, go to next step.

No Turbocharger is okay.

Install all parts removed is Step 15. Then, go to next

step.

19 Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

Is suction control valve okay?Yes Go to next step.

No Repair supply pump.

(See F2–54 SUPPLY PUMP INSPECTION)

20 Is engine compression correct?

(See B2–8 COMPRESSION INSPECTION)Yes Go to next step.

No Inspect for following:

•Damaged valve seat

•Worn valve stem and valve guide

•Worn or stuck piston ring

•Worn piston, piston ring or cylinder

•Improper valve timing

Service as necessary.

21 Inspect IDM.

(See F2–84 INJECTOR DRIVER MODULE

(IDM) INSPECTION)

Is IDM okay?Yes Go to next step.

No Repair or replace as necessary.

22 Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Inspect following:

•Boost sensor

•Fuel pressure limiter (built-in common rail)

•Fuel pressure sensor

•Fuel return line restriction or clogging

Service as necessary.

No Repair or replace as necessary.

23 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 371 of 909

TROUBLESHOOTING

F2–219

F2

End Of Sie

14 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

15 Turn turbocharger compressor wheel by hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

16 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

17 Is any engine oil found inside turbocharger

turbine housing?YesExcessive amount of oil is found:

Replace turbocharger.

Small amount of oil is found:

Wipe oil off of vehicle, then go to next step.

No Go to next step.

18 Is any engine oil found inside turbocharger

compressor housing?Yes Wipe oil off of vehicle, then go to next step.

No Go to next step.

19 Is any exhaust gas leakage found around

location where turbocharger is attached to

exhaust manifold?Yes Remove turbocharger.

Inspect for cracks on center housing inlet surface.

If cracks are found, replace turbocharger.

No Go to next step.

20 Are any center housing and turbine housing

attaching bolts loose?Yes Retighten loose bolts.

If a bolt is found to be missing, attach appropriate new

bolts.

No Turbocharger is okay.

Install all parts removed in Step 13.

Go to next step.

21 Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

Is suction control valve okay?Yes Go to next step.

No Repair supply pump.

(See F2–54 SUPPLY PUMP INSPECTION)

22 Inspect fuel injector and fuel injector gasket.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Inspect for following:

•Metal flow

•Bent connecting rod

•Damaged valve seat

•Incorrect valve clearance

No Repair or replace as necessary.

23 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 389 of 909

G–6

CHARGING SYSTEM

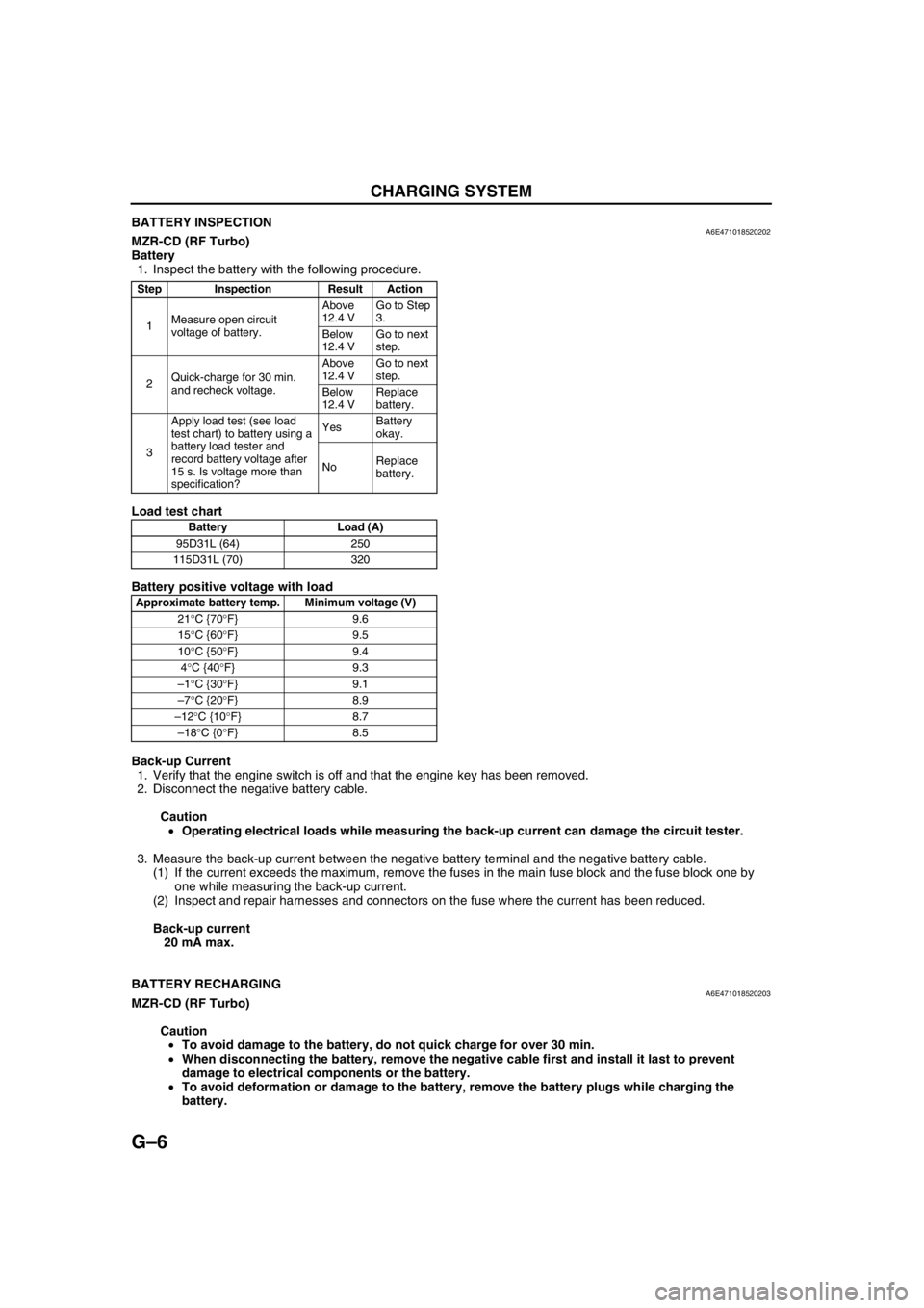

BATTERY INSPECTIONA6E471018520202MZR-CD (RF Turbo)

Battery

1. Inspect the battery with the following procedure.

Load test chart

Battery positive voltage with load

Back-up Current

1. Verify that the engine switch is off and that the engine key has been removed.

2. Disconnect the negative battery cable.

Caution

•Operating electrical loads while measuring the back-up current can damage the circuit tester.

3. Measure the back-up current between the negative battery terminal and the negative battery cable.

(1) If the current exceeds the maximum, remove the fuses in the main fuse block and the fuse block one by

one while measuring the back-up current.

(2) Inspect and repair harnesses and connectors on the fuse where the current has been reduced.

Back-up current

20 mA max.

End Of Sie

BATTERY RECHARGINGA6E471018520203MZR-CD (RF Turbo)

Caution

•To avoid damage to the battery, do not quick charge for over 30 min.

•When disconnecting the battery, remove the negative cable first and install it last to prevent

damage to electrical components or the battery.

•To avoid deformation or damage to the battery, remove the battery plugs while charging the

battery.

Step Inspection Result Action

1Measure open circuit

voltage of battery.Above

12.4 VGo to Step

3.

Below

12.4 VGo to next

step.

2Quick-charge for 30 min.

and recheck voltage.Above

12.4 VGo to next

step.

Below

12.4 VReplace

battery.

3Apply load test (see load

test chart) to battery using a

battery load tester and

record battery voltage after

15 s. Is voltage more than

specification?YesBattery

okay.

NoReplace

battery.

Battery Load (A)

95D31L (64) 250

115D31L (70) 320

Approximate battery temp. Minimum voltage (V)

21°C {70°F} 9.6

15°C {60°F} 9.5

10°C {50°F} 9.4

4°C {40°F} 9.3

–1°C {30°F} 9.1

–7°C {20°F} 8.9

–12°C {10°F} 8.7

–18°C {0°F} 8.5