MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 631 of 909

M–1

M

MFRONT AND REAR AXLES

OUTLINE............................................................... M-2

OUTLINE OF CONSTRUCTION ........................ M-2

FEATURES ......................................................... M-2

SPECIFICATIONS .............................................. M-2

REAR AXLE.......................................................... M-4

REAR AXLE OUTLINE ....................................... M-4

CROSS-SECTIONAL VIEW ............................... M-4

DRIVE SHAFT....................................................... M-5

DRIVE SHAFT OUTLINE.................................... M-5

STRUCTURAL VIEW.......................................... M-5

REAR DRIVE SHAFT ......................................... M-5

REAR DIFFERENTIAL.......................................... M-6

REAR DIFFERENTIAL OUTLINE ....................... M-6

CROSS-SECTIONAL VIEW ............................... M-6

ELECTRONIC 4WD CONTROL SYSTEM............ M-7

OUTLINE ............................................................ M-7

ELECTRONIC CONTROL COUPLING .............. M-9

DIFFERENTIAL OIL TEMPERATURE

SENSOR ........................................................ M-12

4WD WARNING LIGHT .................................... M-12

4WD CONTROL MODURE .............................. M-13

4WD SYSTEM CONTROL................................ M-14

CONTROLLER AREA NETWORK (CAN) ........ M-15

ON-BOARD DIAGNOSTIC ............................... M-16

OUTLINE............................................................. M-18

SUPPLEMENTAL SERVICE

INFORMATION .............................................. M-18

LOCATION INDEX.............................................. M-19

AXLE/DRIVE SHAFT LOCATION INDEX ......... M-19

REAR DIFFERENTIAL/ELECTRONIC

4WD CONTROL SYSTEM LOCATION

INDEX ............................................................ M-20

GENERAL PROCEDURES................................. M-21

PRECAUTION (FRONT AND REAR AXLE) ..... M-21

REAR AXLE........................................................ M-22

WHEEL HUB BOLT REPL

ACEMENT ..................................................... M-22

WHEEL HUB, KNUCKLE

REMOVAL/INSTALLATION ........................... M-22

FRONT DRIVE SHAFT........................................ M-29

JOINT SHAFT (MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY ......................... M-29

JOINT SHAFT (4WD)

DISASSEMBLY/ASSEMBLY ......................... M-31

FRONT DRIVE SHAFT

(MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY ......................... M-34

FRONT DRIVE SHAFT (4WD)

DISASSEMBLY/ASSEMBLY ......................... M-39REAR DRIVE SHAFT.......................................... M-42

REAR DRIVE SHAFT PRE-INSPECTION ........ M-42

REAR DRIVE SHAFT

REMOVAL/INSTALLATION ........................... M-43

REAR DRIVE SHAFT

DISASSEMBLY/ASSEMBLY ......................... M-45

REAR DIFFERENTIAL........................................ M-48

DIFFERENTIAL OIL INSPECTION ................... M-48

DIFFERENTIAL OIL REPLACEMENT .............. M-48

OIL SEAL (SIDE GEAR) REPLACEMENT ....... M-49

OIL SEAL (COMPANION FLANGE)

REPLACEMENT ............................................ M-49

REAR DIFFERENTIAL

REMOVAL/INSTALLATION ........................... M-51

REAR DIFFERENTIAL DISASSEMBLY ........... M-52

REAR DIFFERENTIAL ASSEMBLY ................. M-56

ELECTRONIC 4WD CONTROL SYSTEM.......... M-65

DIFFERENTIAL OIL TEMPERATURE

SENSOR INSPECTION ................................. M-65

DIFFERENTIAL OIL TEMPERATURE

SENSOR REMOVAL/INSTALLATION ........... M-65

4WD SOLENOID INSPECTION........................ M-66

4WD CONTROL MODURE INSPECTION ........ M-66

4WD CONTROL MODURE

REMOVAL/INSTALLATION ........................... M-67

COUPLING COMPONENT

REMOVAL/INSTALLATION ........................... M-68

COUPLING COMPONENT

DISASSEMBLY .............................................. M-69

COUPLING COMPONENT ASSEMBLY........... M-72

ON-BOARD DIAGNOSTIC.................................. M-75

WIRING DIAGRAM ........................................... M-75

ELECTRONIC 4WD CONTROL SYSTEM

ON-BOARD DIAGNOSIS ............................... M-76

DTC P1887 ....................................................... M-77

DTC P1888 ....................................................... M-79

DTC U0100 ....................................................... M-80

DTC U0101 ....................................................... M-80

DTC U0121 ....................................................... M-80

TROUBLESHOOTING......................................... M-81

SYSTEM WIRING DIAGRAM ........................... M-81

FOREWORD ..................................................... M-82

SYMPTOM TROUBLESHOOTING ................... M-82

NO.1 FREQUENT FRONT WHEEL SLIP ......... M-82

NO.2 TIGHT CORNER BRAKING .................... M-83

NO.3 ABNORMAL NOISE AND/OR

VIBRATION FROM COUPLING

COMPONENT ................................................ M-84 FEATURES

SERVICE

Page 632 of 909

M–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E630201018201•The construction and operation of the front and rear axles is the same as that of the current Mazda6 (GG)

model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E630201018202Improved rigidity, reduced noise and vibration

•Concurrent with the MZR-CD (RF Turbo) engine, the configuration of the front drive shaft and the joint shaft

has been optimized.

•Concurrent with the 4WD system, the configuration of the rear axle, the front/rear drive shafts and the joint

shaft has been optimized.

Improved handling stability and marketability

•An electronic 4WD control system has been adopted.

End Of Sie

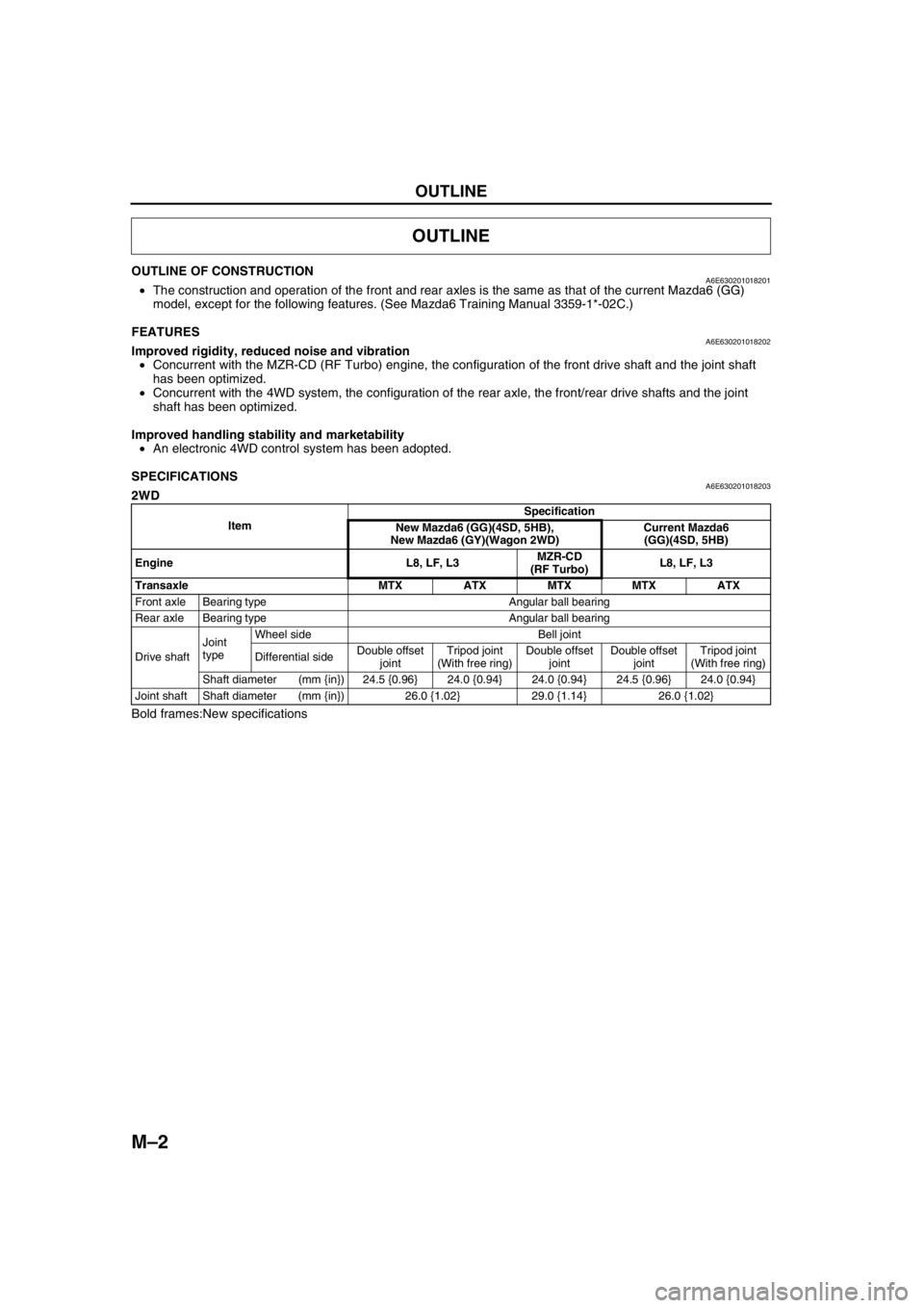

SPECIFICATIONSA6E6302010182032WD

Bold frames:New specifications

OUTLINE

ItemSpecification

New Mazda6 (GG)(4SD, 5HB),

New Mazda6 (GY)(Wagon 2WD)Current Mazda6

(GG)(4SD, 5HB)

Engine L8, LF, L3MZR-CD

(RF Turbo)L8, LF, L3

Transaxle MTX ATX MTX MTX ATX

Front axle Bearing type Angular ball bearing

Rear axle Bearing type Angular ball bearing

Drive shaftJoint

typeWheel side Bell joint

Differential sideDouble offset

jointTripod joint

(With free ring)Double offset

jointDouble offset

jointTripod joint

(With free ring)

Shaft diameter (mm {in}) 24.5 {0.96} 24.0 {0.94} 24.0 {0.94} 24.5 {0.96} 24.0 {0.94}

Joint shaft Shaft diameter (mm {in}) 26.0 {1.02} 29.0 {1.14} 26.0 {1.02}

Page 633 of 909

OUTLINE

M–3

M

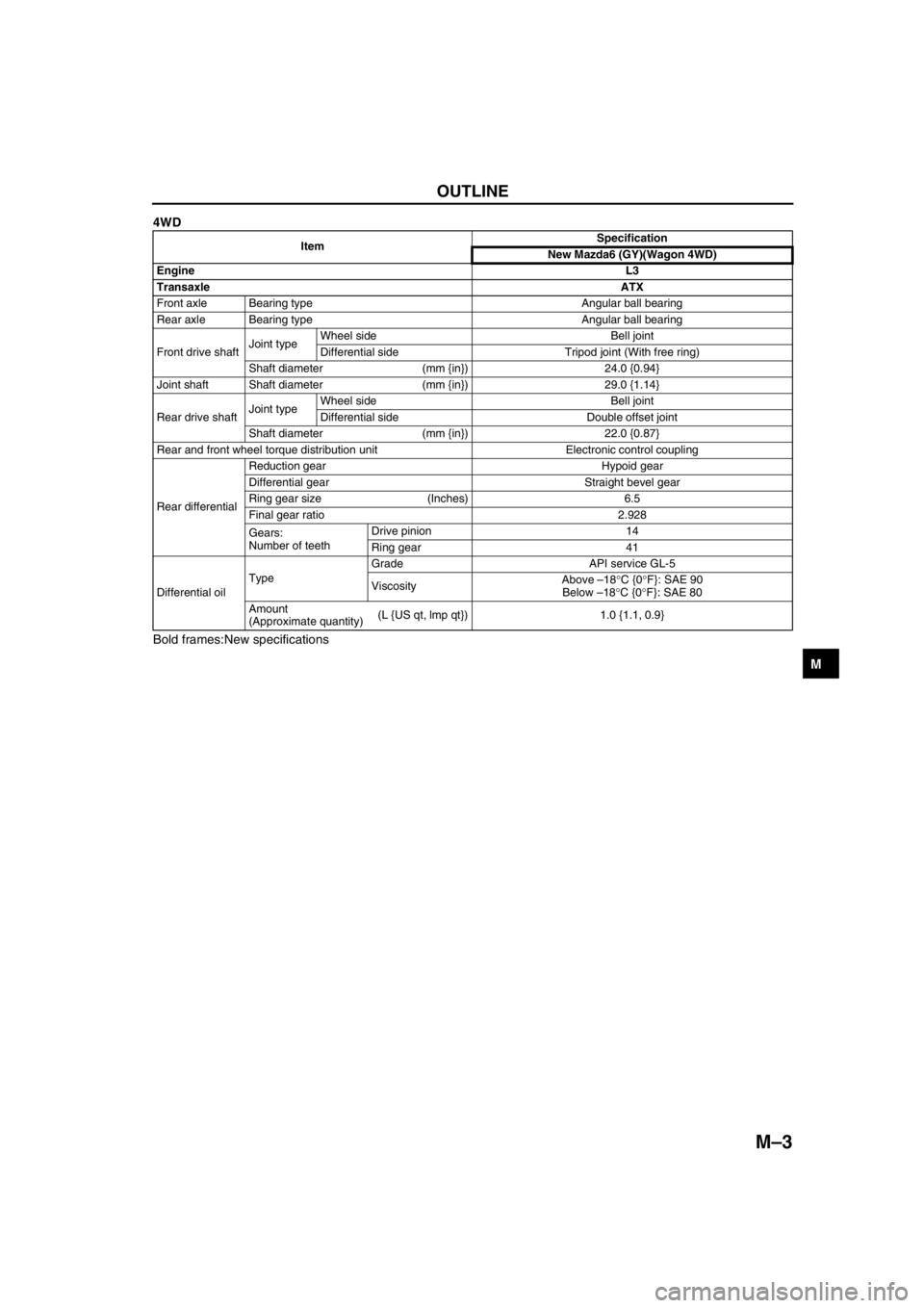

4WD

Bold frames:New specifications

End Of Sie

ItemSpecification

New Mazda6 (GY)(Wagon 4WD)

EngineL3

TransaxleATX

Front axle Bearing type Angular ball bearing

Rear axle Bearing type Angular ball bearing

Front drive shaftJoint typeWheel side Bell joint

Differential side Tripod joint (With free ring)

Shaft diameter (mm {in}) 24.0 {0.94}

Joint shaft Shaft diameter (mm {in}) 29.0 {1.14}

Rear drive shaftJoint typeWheel side Bell joint

Differential side Double offset joint

Shaft diameter (mm {in}) 22.0 {0.87}

Rear and front wheel torque distribution unit Electronic control coupling

Rear differentialReduction gear Hypoid gear

Differential gear Straight bevel gear

Ring gear size (Inches) 6.5

Final gear ratio 2.928

Gears:

Number of teethDrive pinion 14

Ring gear 41

Differential oilTypeGrade API service GL-5

ViscosityAbove –18°C {0°F}: SAE 90

Below –18°C {0°F}: SAE 80

Amount

(Approximate quantity)(L {US qt, lmp qt}) 1.0 {1.1, 0.9}

Page 634 of 909

M–4

REAR AXLE

REAR AXLE OUTLINEA6E631401018201Features

Improved drivability

•An angular ball bearing, with a low rotational resistance, has been adopted.

Improved serviceability

• A unit bearing that does not require pre-load setting has been adopted.

End Of Sie

CROSS-SECTIONAL VIEWA6E631401018202

.

End Of Sie

REAR AXLE

1

A6E63142001

1 Angular ball bearing

Page 635 of 909

DRIVE SHAFT

M–5

M

DRIVE SHAFT OUTLINEA6E631625500201Features

Improved drivability, reduced noise and vibration

•Concurrent with the MZR-CD (RF Turbo) engine and 4WD system, the configuration of the front drive shaft and

the joint shaft has been optimized.

•For 4WD models, a constant velocity joint system has been adopted for the rear drive shaft.

End Of Sie

STRUCTURAL VIEWA6E631625500202

.

End Of Sie

REAR DRIVE SHAFTA6E631625500203Structure

•Engine noise and vibration have been reduced due to adoption of a bell joint on the wheel side of the constant

velocity joint.

•A low noise and vibration double offset joint with low slide resistance has been adopted for the differential side

of the constant velocity joint. Due to this booming resonance at high speed is reduced.

•An extremely durable plastic has been adopted for the wheel side boot.

.

DRIVE SHAFT

3

1

2

A6E63162101

1 Front drive shaft

2 Joint shaft3 Rear drive shaft

5

4

31

2

A6E63162102

1 Wheel side

2 Bell joint

3 Differential side4 Double offset joint

5 Plastic boot

Page 636 of 909

M–6

REAR DIFFERENTIAL

End Of Sie

REAR DIFFERENTIAL OUTLINEA6E631927100201Features

Size and weight reduction

•A rear differential with an integrated coupling component has been adopted.

•An aluminum differential carrier has been adopted.

End Of Sie

CROSS-SECTIONAL VIEWA6E631927100202

.

End Of Sie

REAR DIFFERENTIAL

12

A6E63192001

1 Coupling component section2 Rear differential section

Page 637 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–7

M

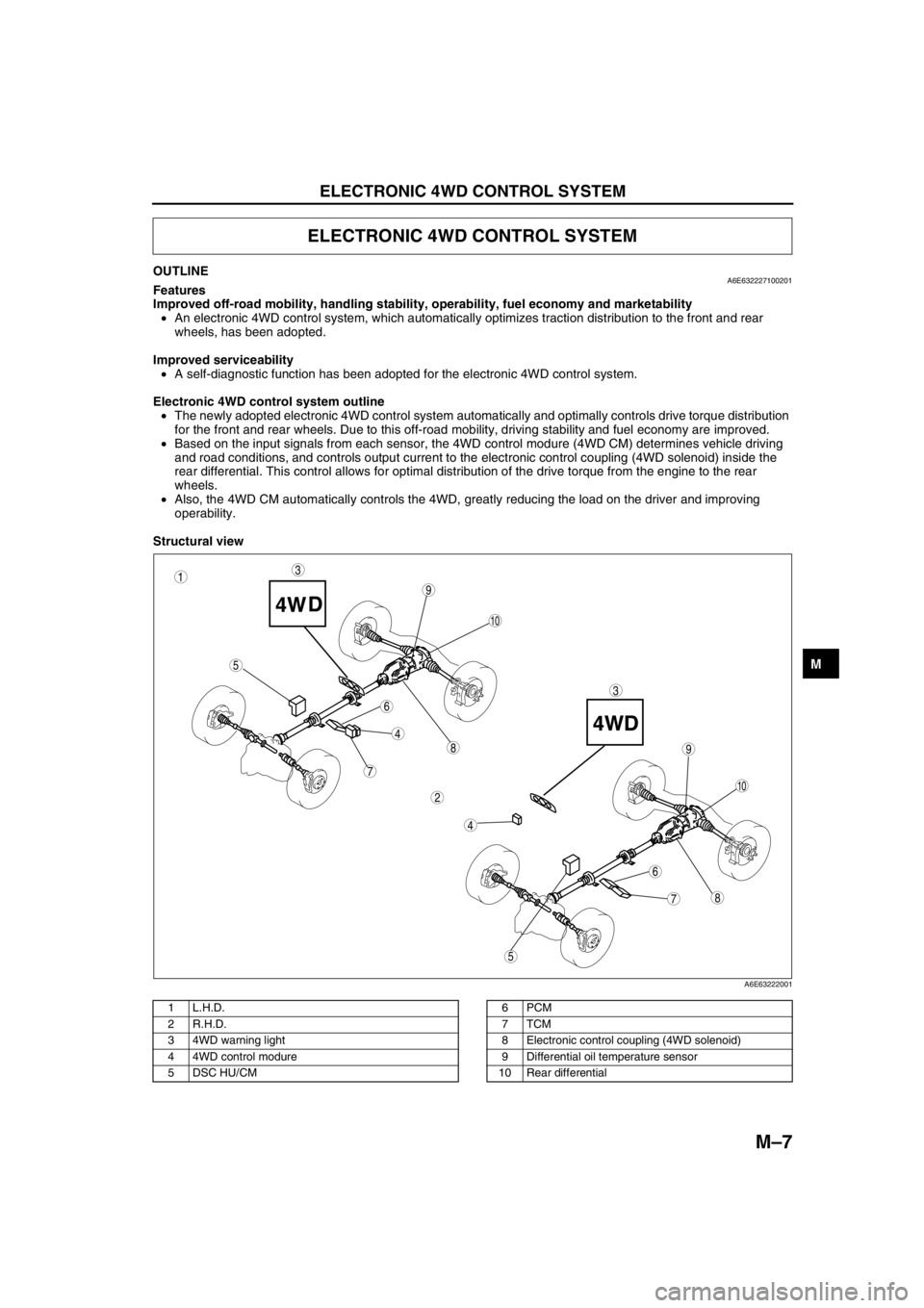

OUTLINEA6E632227100201Features

Improved off-road mobility, handling stability, operability, fuel economy and marketability

•An electronic 4WD control system, which automatically optimizes traction distribution to the front and rear

wheels, has been adopted.

Improved serviceability

•A self-diagnostic function has been adopted for the electronic 4WD control system.

Electronic 4WD control system outline

•The newly adopted electronic 4WD control system automatically and optimally controls drive torque distribution

for the front and rear wheels. Due to this off-road mobility, driving stability and fuel economy are improved.

•Based on the input signals from each sensor, the 4WD control modure (4WD CM) determines vehicle driving

and road conditions, and controls output current to the electronic control coupling (4WD solenoid) inside the

rear differential. This control allows for optimal distribution of the drive torque from the engine to the rear

wheels.

•Also, the 4WD CM automatically controls the 4WD, greatly reducing the load on the driver and improving

operability.

Structural view

.

ELECTRONIC 4WD CONTROL SYSTEM

87

5

4

3

6

9

8

7

5

4

3

10

6

1

2

9

10

A6E63222001

1L.H.D.

2 R.H.D.

3 4WD warning light

4 4WD control modure

5 DSC HU/CM6PCM

7TCM

8 Electronic control coupling (4WD solenoid)

9 Differential oil temperature sensor

10 Rear differential

Page 638 of 909

M–8

ELECTRONIC 4WD CONTROL SYSTEM

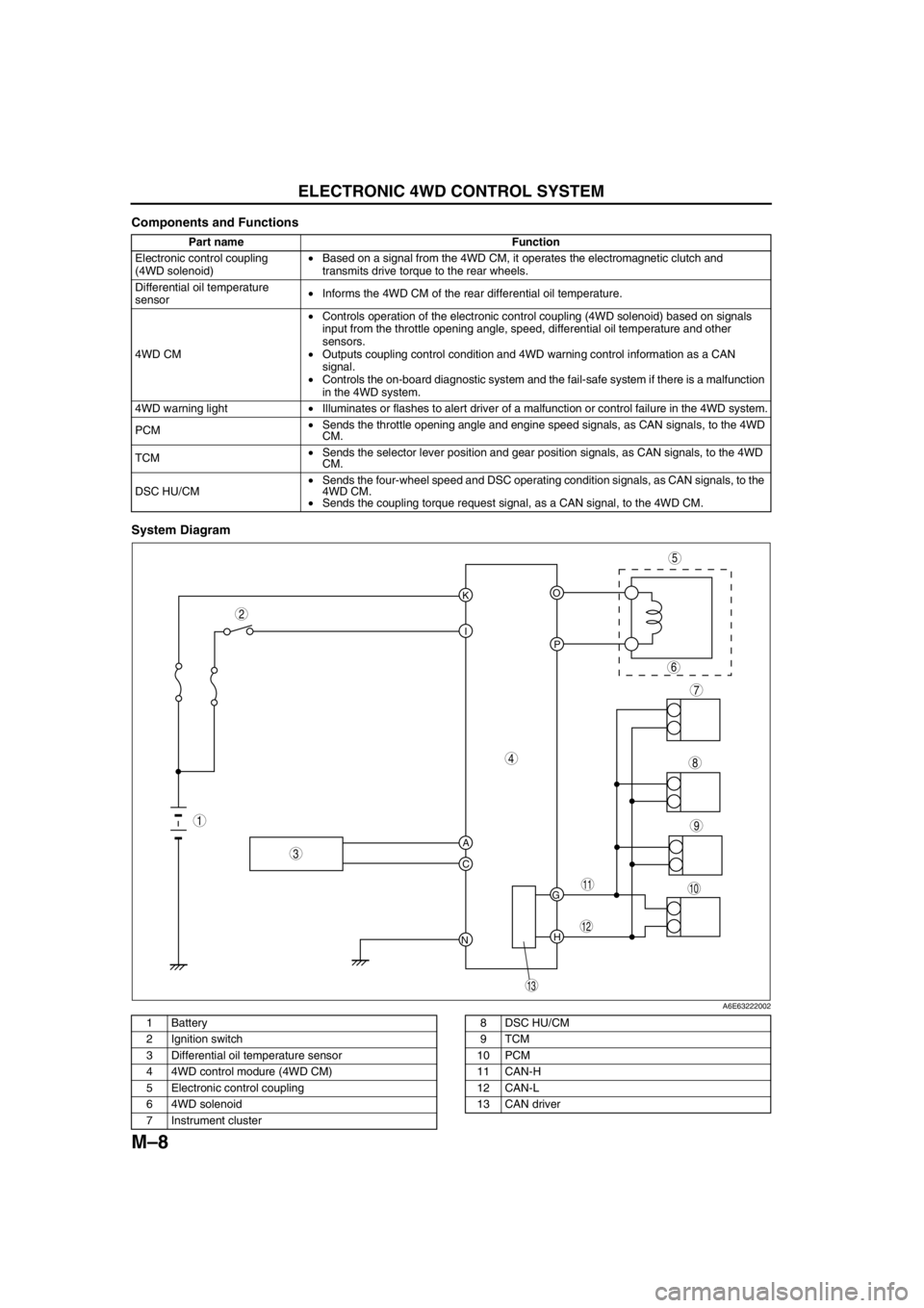

Components and Functions

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver

Page 639 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–9

M

End Of SieELECTRONIC CONTROL COUPLINGA6E632227100202Outline

Features

•An electromagnetic clutch, which operates smoothly due to the lack influence from the front and rear wheel

traction force, has been adopted for the electronic control coupling system.

•The construction of the coupling enables the torque formed by the pilot clutch to be amplified by the cam

mechanism, thus allowing the main clutch to obtain a high degree of torque. Due to this, size and weight

reduction of the component parts has been achieved.

Construction

•The electronic control coupling basically consists of an electromagnetic clutch, a cam mechanism and a torque

transmission system.

•The electromagnetic clutch consists of a 4WD solenoid (electromagnetic coil), rear-housing that forms a

magnetic path, pilot clutch, and armature. The cam mechanism consists of a pilot cam, balls, and main cam.

The torque transmission system consists of a main clutch and hydraulic oil (ATF).

.

9

8

7

5

43

10

13

1112

6

12

A6E63222003

1 Front wheel side

2 Rear wheel side

3 Torque transmission system

4 Electromagnetic clutch

5 Rear housing

6 4WD solenoid (Electromagnetic coil)

7 Cam mechanism8Ball

9 Main clutch

10 Main cam

11 Armature

12 Pilot clutch

13 Pilot cam

Page 640 of 909

M–10

ELECTRONIC 4WD CONTROL SYSTEM

Operation

4WD solenoid control current is OFF

•When the 4WD solenoid control current is OFF, no torque is generated in the pilot clutch because there is no

current flowing to the 4WD solenoid. At the same time, the pilot cam and the main cam rotate in the same

direction via the balls, and the main cam does not exert any push force on the main clutch side. Therefore, the

traction from the front wheels is not transmitted to the rear wheels.

.

8

7

5

4

3

6

12

56

7

A6E63222004

1 Main clutch

2 Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)5Main cam

6Pilot cam

7Ball

8 Armature