MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 621 of 909

PROPELLER SHAFT

L–5

L

End Of SiePROPELLER SHAFT REMOVAL/INSTALLATIONA6E6110250022011. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

.

7

6

4

1

1

2

4

2

6

N·m {kgf·m, ft·lbf} 37.3—52.0 {3.81—5.30, 27.6—38.3}37.3—52.0 {3.81—5.30, 27.6—38.3} 49—58

{4.2—5.9, 36—42}

49—58

{4.2—5.9, 36—42}

5

5

3

3

A6E6110W001

1Nut

(See L–6 Nut Removal Note)

2Nut

3 Bush, Spacer

4Washer5 Propeller shaft heat shield

(See L–6 Propeller Shaft Heat Shield Installation

Note)

6 Bush, Spacer

7 Propeller shaft

(See L–7 Propeller Shaft Installation Note)

Page 622 of 909

L–6

PROPELLER SHAFT

Nut Removal Note

Caution

•Do not mark with the ponch to prevent unbalance.

1. Before removing the nut, put marks on the front

companion flange, tripod joint and the rear

companion flange, rear universal joint yoke for

proper reinstallation.

Propeller Shaft Heat Shield Installation Note

Caution

•When assembling the propeller shaft heat shield to the bearing support, narrowing the bolt hole

inner diameter can lower serviceability. Align the bolt hole edge of the propeller shaft heat shield

with the bolt hole inner side of the bearing support to assemble.

1. Set the propeller shaft heat shield to the bearing

support.

Front side

Rear side

2. Bend the edges of the propeller shaft heat shield

toward the bearing support as shown.

A6J6110W006

OK NGBOLT HOLE OF

PROPELLER SHAFT HEAT SHIELD

BOLT HOLE OF

BEARING SUPPORT

A6E6110W022

PROPELLER SHAFT

HEAT SHIELDBEARING SUPPORT

EDGE

4.5—4.7

mm

A6E6110W016

4.5—4.7

mm

PROPELLER SHAFT

HEAT SHIELDBEARING SUPPORT

EDGE

A6E6110W017

Page 623 of 909

PROPELLER SHAFT

L–7

L

Propeller Shaft Installation Note

1. Align the mark made during removal, and install the propeller shaft.

Front side

2. Installing a new propeller shaft, align the

differential companion flange precast marking

with the tag on the propeller shaft.

End Of Sie

PROPELLER SHAFT DISASSEMBLY/ASSEMBLYA6E611025002202

Caution

•To prevent damage to parts when using a clamp, be sure to place an aluminum plate between

parts and the clamp.

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

A6J6110W006

MARK TA G

A6E6110W002

Page 624 of 909

L–8

PROPELLER SHAFT

.

SST

SST

SST

SST

SST

SST

R

SST

RR

R

R

R

R

R

R

SST

R

11

11

10

10

9

9

7

5

3

3

11

2

2

12

12

13

6

8

87157—177

{16.1—18.0,

116—130}

N·m {kgf·m, ft·lbf} 157—177

{16.1—18.0,

116—130}

R

R

3

1

2

4

R

A6E6110W003

1 Snap ring

(See L–9 Snap Ring Disassembly Note)

(See L–12 Bearing Cup and Snap Ring Assembly

Note)

2 Bearing cup

(See L–9 Bearing Cup Disassembly Note)

(See L–12 Bearing Cup and Snap Ring Assembly

Note)

3Spider

4 Flange yoke

5 Rear propeller shaft

6 Front propeller shaft

7 Locknut

(See L–9 Locknut Disassembly Note)

(See L–12 Locknut Assembly Note)

8 Spring washer9 Center yoke

(See L–10 Center Yoke Disassembly Note)

10 Bearing support

(See L–10 Bearing support Disassembly Note)

(See L–11 Bearing Support Assembly Note)

11 Dust cover

(See L–10 Dust Cover and Bearing Disassembly

Note)

(See L–11 Dust Cover Assembly Note)

12 Bearing

(See L–10 Dust Cover and Bearing Disassembly

Note)

(See L–11 Bearing Assembly Note)

13 Center propeller shaft

Page 625 of 909

PROPELLER SHAFT

L–9

L

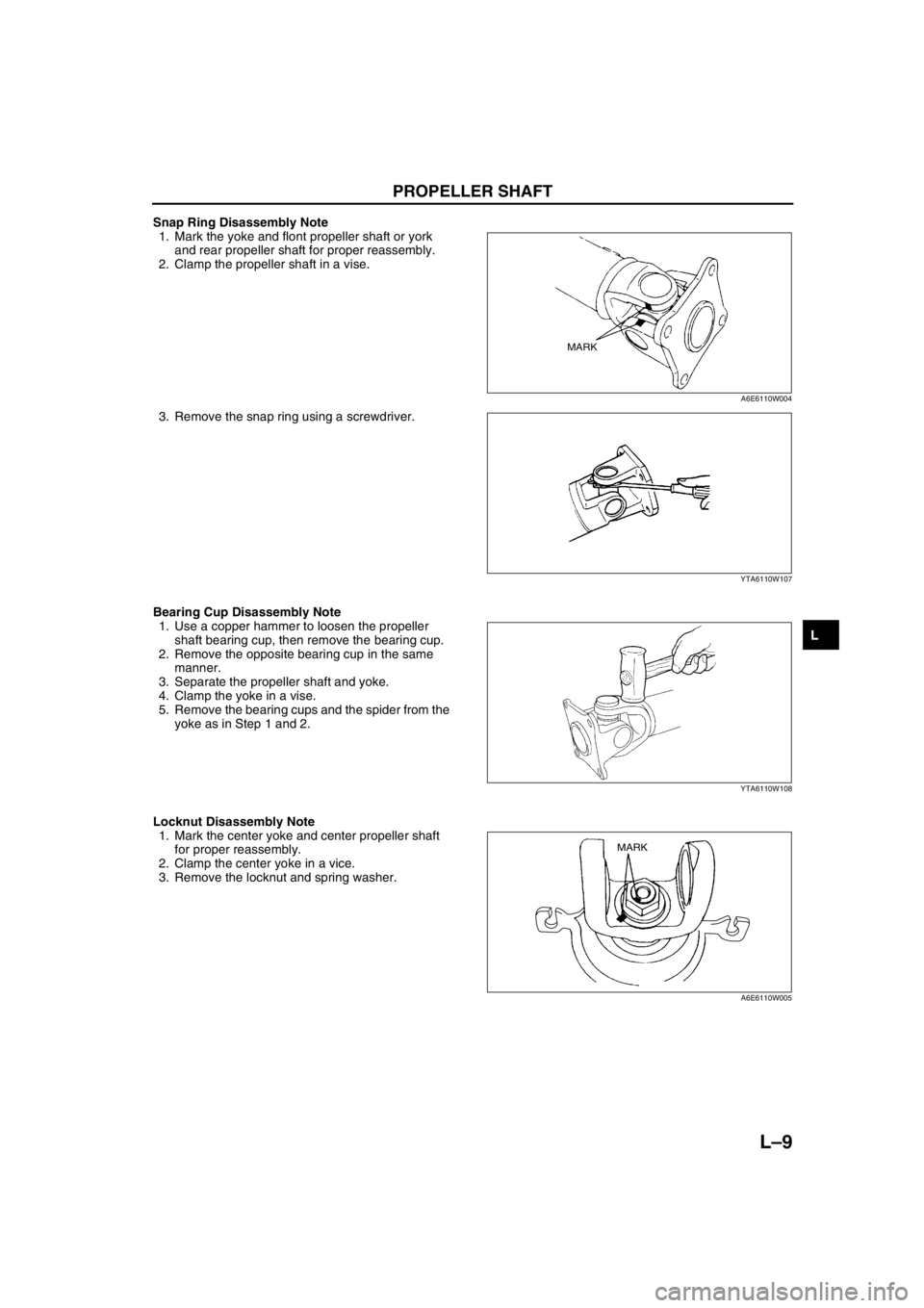

Snap Ring Disassembly Note

1. Mark the yoke and flont propeller shaft or york

and rear propeller shaft for proper reassembly.

2. Clamp the propeller shaft in a vise.

3. Remove the snap ring using a screwdriver.

Bearing Cup Disassembly Note

1. Use a copper hammer to loosen the propeller

shaft bearing cup, then remove the bearing cup.

2. Remove the opposite bearing cup in the same

manner.

3. Separate the propeller shaft and yoke.

4. Clamp the yoke in a vise.

5. Remove the bearing cups and the spider from the

yoke as in Step 1 and 2.

Locknut Disassembly Note

1. Mark the center yoke and center propeller shaft

for proper reassembly.

2. Clamp the center yoke in a vice.

3. Remove the locknut and spring washer.

MARK

A6E6110W004

YTA6110W107

YTA6110W108

MARK

A6E6110W005

Page 626 of 909

L–10

PROPELLER SHAFT

Center Yoke Disassembly Note

1. Remove the center yoke using the SST.

Center yoke (front side)

Center yoke (rear side)

Bearing support Disassembly Note

1. Remove the bearing support using the SST.

Dust Cover and Bearing Disassembly Note

1. Remove the dust cover and bearing from bearing

support using the SST and a press.

49 0839 425C

A6J6110W017

49 0839 425C

49 H027 002

A6J6110W011

49 0839 425C

49 G030 370

A6J6110W012

BEARING BEARING SUPPORT

DUSR COVER

49 F015 002

49 0636 145

A6E6110W007

Page 627 of 909

PROPELLER SHAFT

L–11

L

Bearing Assembly Note

1. Install the bearing onto the bearing support using

the SST and a press.

Dust Cover Assembly Note

1. Install the dust cover onto the bearing support

using the SST and a press.

Bearing Support Assembly Note

1. Install the bearing support using the SST.

Bearing side (front side)

Bearing support (rear side)

49 G030 797

49 H033 101

49 U027 005

A6J6110W014

49 F401 331

49 B034 201

49 U027 005

A6J6110W015

49 F401 335A

49 F401 331

A6J6110W018

49 F401 331

49 B034 201

A6J6110W019

Page 628 of 909

L–12

PROPELLER SHAFT

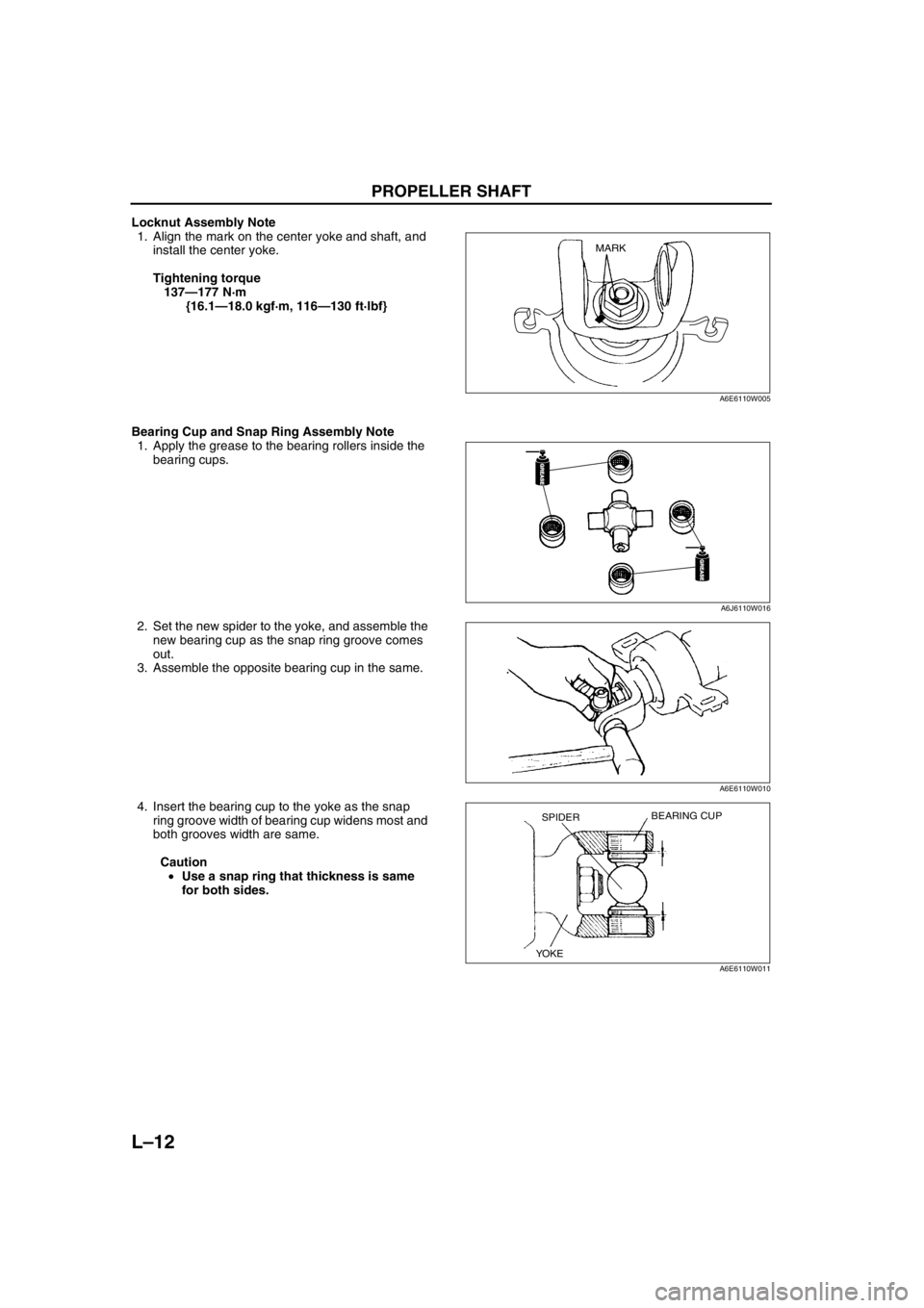

Locknut Assembly Note

1. Align the mark on the center yoke and shaft, and

install the center yoke.

Tightening torque

137—177 N·m

{16.1—18.0 kgf·m, 116—130 ft·lbf}

Bearing Cup and Snap Ring Assembly Note

1. Apply the grease to the bearing rollers inside the

bearing cups.

2. Set the new spider to the yoke, and assemble the

new bearing cup as the snap ring groove comes

out.

3. Assemble the opposite bearing cup in the same.

4. Insert the bearing cup to the yoke as the snap

ring groove width of bearing cup widens most and

both grooves width are same.

Caution

•Use a snap ring that thickness is same

for both sides.

MARK

A6E6110W005

GREASEGREASE

GREASEGREASE

A6J6110W016

A6E6110W010

BEARING CUPSPIDER

YOKE

A6E6110W011

Page 629 of 909

PROPELLER SHAFT

L–13

L

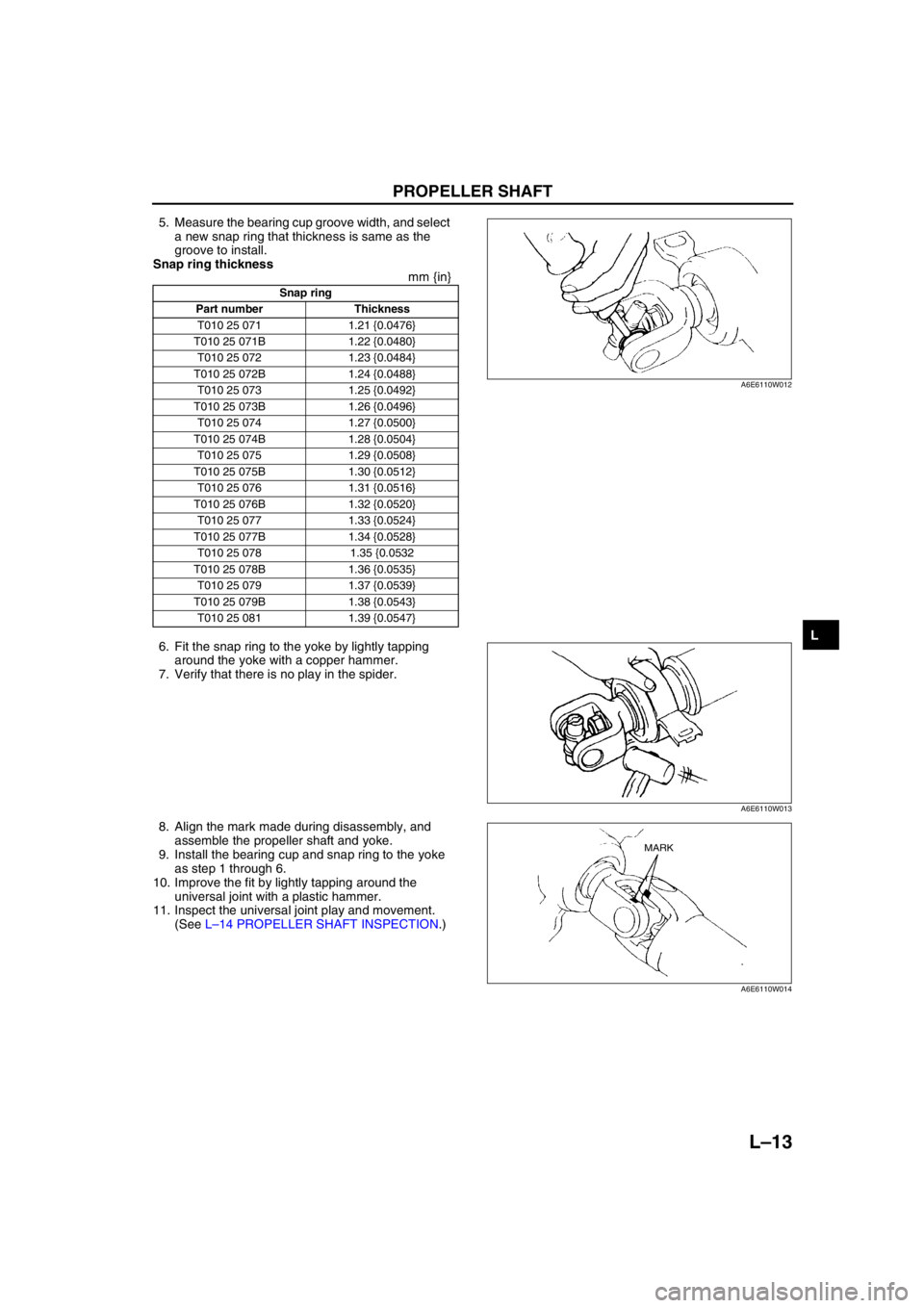

5. Measure the bearing cup groove width, and select

a new snap ring that thickness is same as the

groove to install.

Snap ring thickness

mm {in}

6. Fit the snap ring to the yoke by lightly tapping

around the yoke with a copper hammer.

7. Verify that there is no play in the spider.

8. Align the mark made during disassembly, and

assemble the propeller shaft and yoke.

9. Install the bearing cup and snap ring to the yoke

as step 1 through 6.

10. Improve the fit by lightly tapping around the

universal joint with a plastic hammer.

11. Inspect the universal joint play and movement.

(See L–14 PROPELLER SHAFT INSPECTION.)

End Of Sie

Snap ring

Part number Thickness

T010 25 071 1.21 {0.0476}

T010 25 071B 1.22 {0.0480}

T010 25 072 1.23 {0.0484}

T010 25 072B 1.24 {0.0488}

T010 25 073 1.25 {0.0492}

T010 25 073B 1.26 {0.0496}

T010 25 074 1.27 {0.0500}

T010 25 074B 1.28 {0.0504}

T010 25 075 1.29 {0.0508}

T010 25 075B 1.30 {0.0512}

T010 25 076 1.31 {0.0516}

T010 25 076B 1.32 {0.0520}

T010 25 077 1.33 {0.0524}

T010 25 077B 1.34 {0.0528}

T010 25 078 1.35 {0.0532

T010 25 078B 1.36 {0.0535}

T010 25 079 1.37 {0.0539}

T010 25 079B 1.38 {0.0543}

T010 25 081 1.39 {0.0547}

A6E6110W012

A6E6110W013

MARK

A6E6110W014

Page 630 of 909

L–14

PROPELLER SHAFT

PROPELLER SHAFT INSPECTIONA6E6110250022031. Disassemble the propeller shaft.

2. Measure the propeller shaft runout with a dial

indicator.

•If the runout is excessive, replace the

propeller shaft.

Runout limit

0.3 mm {0.01 in}

3. Move the universal joint in the direction shown,

and inspect joint play.

•If the joint play is not within the specification,

adjust the universal joint using snap rings.

Starting torque

0.29—0.78 N·m {3.0—7.9 kgf·cm}

End Of Sie

A6E6110W015

YTA6110W120