Exhaust MAZDA 626 1987 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 680 of 1865

INTAKE AIR SYSTEM 4D

INTAKE MANIFOLD

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

3. Check for air/exhaust leakage.

76G04D-020

3. Vacuum hose (RF-CX)

4. Water thermo switch connector

5. Intake manifold

Inspection

1. Check the intake manifold for cracks and damage.

2. Inspect the flatness of the mounting surface using

a straight edge and a feeler gauge. Replace if

necessary.

Distortion: 0.05 mm (0.002 in) max.

19—26 N m (1.9—2.6 m-kg, 14—21 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

8—11 N-m (B0—110 cm-kg, 69—95 In-lb)

8—11 Nm (80—110 cm-kg, 69—95 In-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

34—49 N-m (3.5—5.0 m-kg, 25—36 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb) 22—26 N-m (2.2—2.7 m-kg, 16—20 ft-lb)

22—26 N m (2.2—2.7 m-kg, 16—20 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

1. Comprex supercharger

(Refer to page 4D—13.: RF-CX)

2. Exhaust manifold

(Refer to page 4D—19.: RF-CX)

76G04D-021

4D-9

Page 681 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

SUPERCHARGING SYSTEM (RF-CX)

TROUBLESHOOTING GUIDE

Engine

hard

starting

Poor

acceleration

Excessive

blue

smoke

Excessive

black

smoke

Excessive

compressed

air

temperature

(Buzzser

sounds)

Excessive

noise

Possible Cause Remedy (reference page)

*

*

Comprex supercharger Rotor stuck Casing damaged Rotor bearing damaged

Replace (4D—14)

* * * Drive system

of

Comprex supercharger Drive belt loose

or

worn Repair

or

replace

(4D-12) * Idler pulley damaged

Repair

or

replace

(4D-12) * Pulley bolt loose

or

worn

Repair

or

replace

(4D-12)

* Wastegate

Valve

not

open Clean

or

repace (4D-12) ik * Valve

not

closed

Clean

or

repace (4D-12)

* * Starting valve

Valve

not

open Repair

or

replace (4D-15)

* * Valve

not

closed

Repair

or

replace (4D-15) * Bypass valve

not

open

Repair

or

replace (4D-15)

* * Bypass valve

not

closed

Repair

or

replace (4D-15)

* Intercooler dirty Clean

or

replace (4D-16)

* * * * Intake

air

system Fresh

air

side clogged (Air cleaner

ele-

ment,

etc.)

Repair

or

replace * Compressed

air

side clogged (Intercool-

er,

etc.)

Repair

or

replace

* Fresh

air

side leaks

Repair

or

replace

* * * Compressed

air

side leaks

Repair

or

replace

* Exhaust system

Exhaust

gas

breaked Repair

* * * * * Exhaust pipe clogged

Repair

* Silencer damaged

(in

fender,

in air

clean-er,

in air

funnel, Comprex insulator) Repair

or

replace

* Bolt

and nut

loosend Repair

76G04D-022

4D—10

Page 682 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

ON-VEHICLE INSPECTION

Boost Pressure

1. Connect a pressure gauge to the hose from the

intake manifold.

2. (On chassis dynomometer, full load)

(1) Set the vehicle on a chassis dynomometer.

(2) Run the vehicle in gear at 3,000 rpm with the

acceleration pedal fully depressed.

(3) Measure the boost pressure.

Boost pressure:

82 kPa (0.87 kg/cm2, 8.1 psi)

Note

The above inspection should be done on a

chassis dynomometer. If a dynomometer is

not available follow the below procedure.

3. (Off chassis dynomometer, no load)

(1) Shift the transaxle out off gear.

(2) Run the engine in neutral at 3,000 rpm of the

engine no load.

Measure the boost pressure.

Boost pressure:

5 kPa (0.05 kg/cm2, 0.7 psi)

Note

The boost pressure is varied by engine speed

and engine load.

(3) Remove the starting valve bypass hose.

(4) Check that the bypass valve is closed at 3,000

rpm.

4.

If

the pressure is below specification, check the fol-

lowing. Replace the Comprex supercharger if

necessary.

(1) Intake air and exhaust passages leakage

(2) Intake air and exhaust passages clogged

(3) Wastegate (Refer to 4D—12.)

(4) Starting valve (Refer to 4D—15.)

(5) Fuel system (Injection nozzle... refer to page

4D—31, injection pump...refer to page 4D—24,

etc.)

5. If the pressure exceeds specification, check the

wastegate operation. (Refer to page 4D—12.)

4D—11

Page 684 of 1865

SUPERCHARGING SYSTEM (RF-CX) 4D

COMPREX SUPERCHARGER

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

3. Check for air/exhaust leakage.

8—11 N m ''"'^'gs , (80—110 cm-kg, 69—95 In-lb)

8—11 N-m (80—110 cm-kg, 69—95 In-lb)

IsSJ 19-26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

34—49 N m (3.5—5.0 m-kg, 25—36 ft-lb)

22—26 N-m (2.2—2.7 m-kg, 16—20 ft-lb)

76G04D-029

1. Air hose

2. Air funnel assembly

3. Exhaust pipe

4. Supercharger insulator

5. Exhaust manihold stay

6. Drive belt

7. Exhaust joint pipe

8. Idle pulley

9. Comprex supercharger

Caution

a) Be careful not to bend the rod or bracket

of the wastegate.

b) Cover the intake and exhaust ports to pre-

vent dirt or other material from entering.

76G04D-030

4D—13

Page 685 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

Inspection

Air casing, exhaust casing, rotor housing

Check the air casing, exhaust casing, and rotor hous-

ing for cracks or damage. Replace the Comprex su-

percharger if necessary.

76G04D-031

Rotor and rotor bearing

Check that the rotor turns smoothly. Replace the Com-

prex supercharger if necessary.

76G04D-032

L sSRs^w^

j^r^SllfeJN

I^glji

H/yxA

Air funnel

Check the air funnel and insulator for cracks or

damaged. Replace if necessary.

76G04D-033

4D—14

Page 689 of 1865

4D EXHAUST SYSTEM

EXHAUST SYSTEM

STRUCTURAL VIEW

1. Exhaust manifold 4. Pre-silencer

2. Comprex supercharger (RF-CX) 5. Main silencer

3. Air funnel assembly

4D-18

Page 690 of 1865

EXHAUST SYSTEM 4D

EXHAUST MANIFOLD

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

3. Check for exhaust leakage.

Inspection

1. Check the exhaust manifold for cracks and

damage.

2. Inspect the flatness of the mounting surface using

the straight edge and a feeler gauge. Replace if

necessary.

Distortion: 0.05 mm (0.002 in) max.

1. Comprex supercharger (Refer to page 4D—13.: only RF-CX)

2. Exhaust manifold

4D—19

Page 691 of 1865

EXHAUST SYSTEM 4D

EXHAUST PIPE AND MAIN SILENCER

Removal and Installation

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

3. Check for exhaust leakage.

64—89 N-m

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

76G04D-045

1. Front exhaust pipe bracket 4. Silencer hanger

2. Front exhaust pipe 5. Middle pipe

3. Pre-silencer 6. Main silencer

4D—20

Page 819 of 1865

REMOVAL 7A

RF-N and RF-CX

1. Battery

2. Air cleaner assembly

3. Vacuum hose

4. Intercooler pipe and hose

(RF-CX)

5. Electric fan

6. Speedometer cable

7. Ground(s)

8. Clutch release cylinder

9. Pressure and return hoses

(power steering)

10. Starter

11. Wheel

12. Splash shield

13. Stabilizer

14. Joint shaft

15. Extension bar

16. Control rod

76G07A-011

17. Exhaust pipe bracket

18. Water pipe

19. Gusset plate (rear)

20. Gusset plate (front)

21. Under cover

22. Engine mount No.4

23. Engine mount No.2

24. Crossmember

7 A—13

Page 949 of 1865

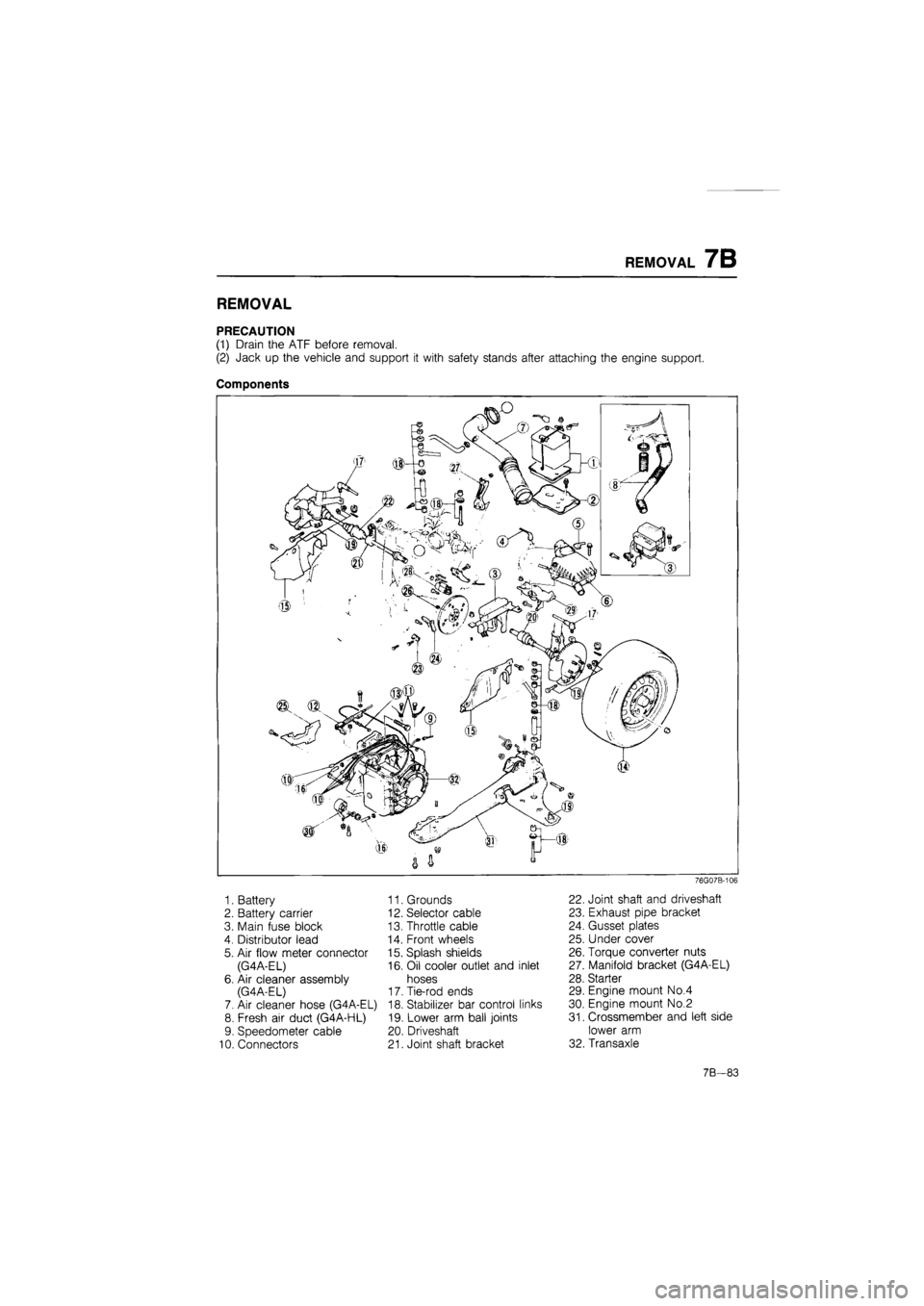

REMOVAL 7B

REMOVAL

PRECAUTION

(1) Drain the ATF before removal.

(2) Jack up the vehicle and support it with safety stands after attaching the engine support.

Components

1. Battery

2. Battery carrier

3. Main fuse block

4. Distributor lead

5. Air flow meter connector

(G4A-EL)

6. Air cleaner assembly

(G4A-EL)

7. Air cleaner hose (G4A-EL)

8. Fresh air duct (G4A-HL)

9. Speedometer cable

10. Connectors

11. Grounds

12. Selector cable

13. Throttle cable

14. Front wheels

15. Splash shields

16. Oil cooler outlet and inlet

hoses

17. Tie-rod ends

18. Stabilizer bar control links

19. Lower arm ball joints

20. Driveshaft

21. Joint shaft bracket

76G07B-106

22. Joint shaft and driveshaft

23. Exhaust pipe bracket

24. Gusset plates

25. Under cover

26. Torque converter nuts

27. Manifold bracket (G4A-EL)

28. Starter

29. Engine mount No.4

30. Engine mount No.2

31. Crossmember and left side

lower arm

32. Transaxle

7B—83