fuel MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 518 of 1865

4B FUEL SYSTEM

Operating time Fuel line pressure kPa

(kg/cm2, psi)

After starting: for 120

sec.

235-275

(2.4—2.8, 34—40)

After 120 sec, 186-226 (1.9-2.3, 27-33)

6. Restart the engine.

7. Check the fuel line pressure and operating times

as shown in the chart.

76G04B-127

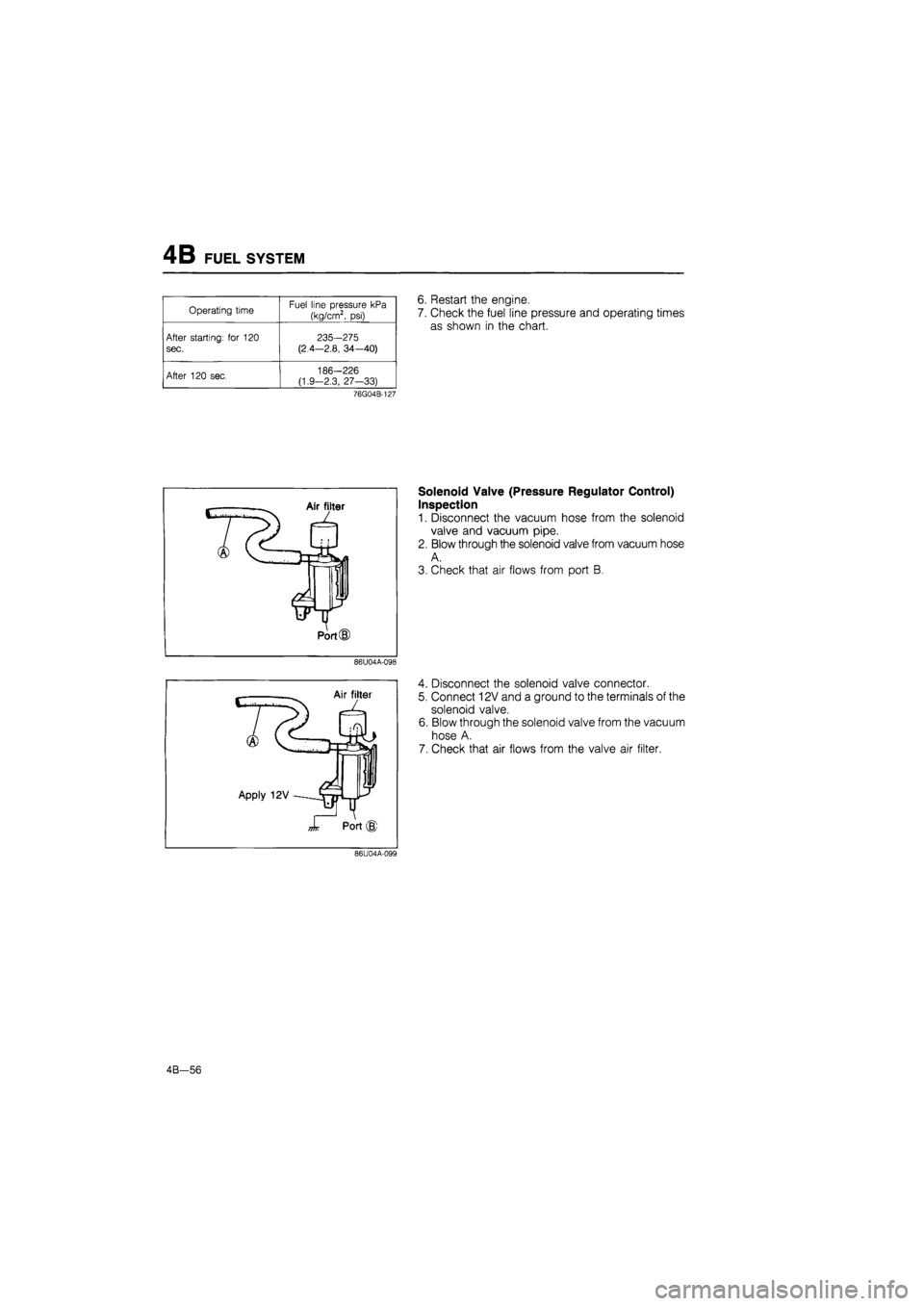

Solenoid Valve (Pressure Regulator Control)

Inspection

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-098

Air filter

Apply 12V

Port (J)

4. Disconnect the solenoid valve connector.

5. Connect 12V and a ground to the terminals of the

solenoid valve.

6. Blow through the solenoid valve from the vacuum

hose A.

7. Check that air flows from the valve air filter.

86U04A-099

4B-56

Page 519 of 1865

FUEL SYSTEM 4B

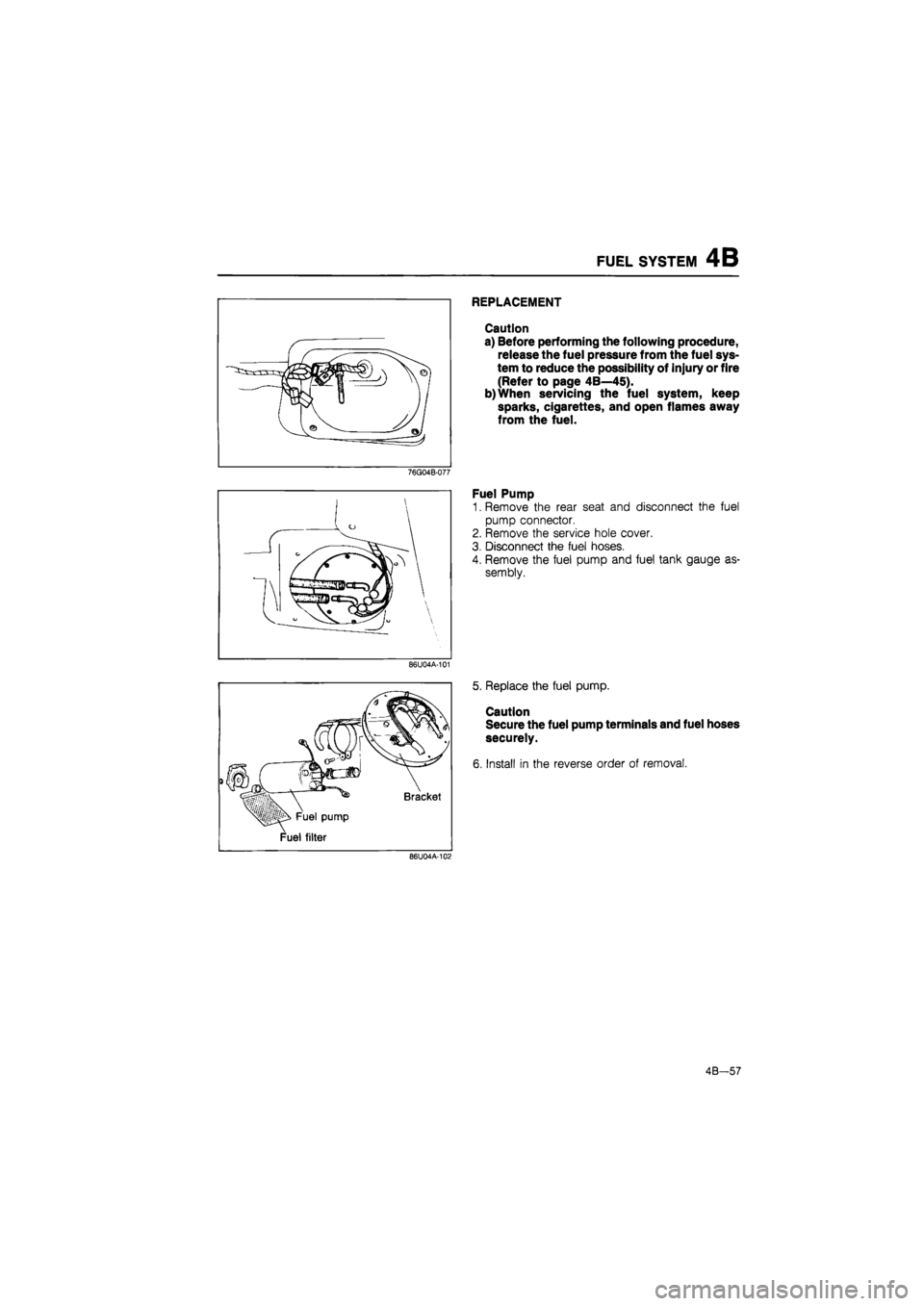

REPLACEMENT

Caution

a) Before performing the following procedure,

release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire

(Refer to page 4B—45).

b)When servicing the fuel system, keep

sparks, cigarettes, and open flames away

from the fuel.

76G04B-077

86U04A-101

M Fuel pump

Fuel filter

Bracket

86U04A-102

Fuel Pump

1. Remove the rear seat and disconnect the fuel

pump connector.

2. Remove the service hole cover.

3. Disconnect the fuel hoses.

4. Remove the fuel pump and fuel tank gauge as-

sembly.

5. Replace the fuel pump.

Caution

Secure the fuel pump terminals and fuel hoses

securely.

6. Install in the reverse order of removal.

4B—57

Page 520 of 1865

4B FUEL SYSTEM

76G04B-078

76G04B-079

Insulator

Injector

Grommet

Delivery

pipe

Pressure regulator

76G04B-080

Injector O-ring Correct

1 #J

Grommet Delivery pipe

Wrong

£a

/

^ Wrong IF

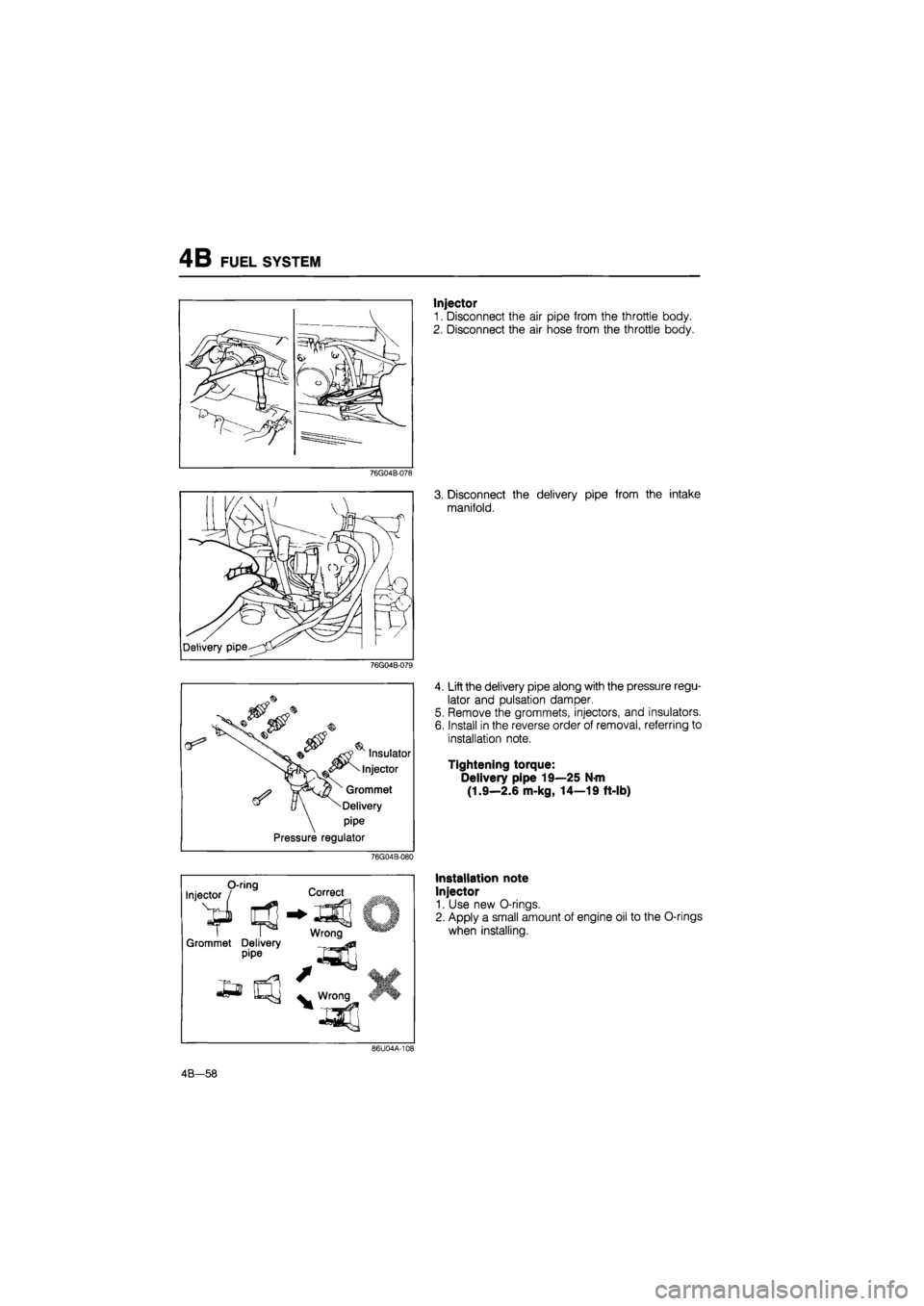

Injector

1. Disconnect the air pipe from the throttle body.

2. Disconnect the air hose from the throttle body.

3. Disconnect the delivery pipe from the intake

manifold.

4. Lift the delivery pipe along with the pressure regu-

lator and pulsation damper.

5. Remove the grommets, injectors, and insulators.

6. Install in the reverse order of removal, referring to

installation note.

Tightening torque:

Delivery pipe 19—25 N-m

(1.9—2.6 m-kg, 14—19 ft-lb)

Installation note

Injector

1. Use new O-rings.

2. Apply a small amount of engine oil to the O-rings

when installing.

86U04A-108

4B-58

Page 521 of 1865

FUEL SYSTEM 4B

3. Install the injectors and the injector insulators.

86U04A-109

Delivery Pipe

1. Remove the pulsation damper and pressure regu-

lator from the delivery pipe.

2. Remove the injectors (Refer to page 4B—58).

76G04B-081

Replace the delivery pipe.

Install in the reverse order of removal, referring to

installation note.

Tightening torque:

Pressure regulator

8—11 Nm (0.8—1.1 m-kg, 69—95 in-lb)

Delivery pipe

19—25

N

m (1.9—2.6 m-kg, 14—19 ft-lb)

76G04B-082

Installation note

Injector

Refer to page 4B—58.

4B—59

Page 522 of 1865

4B FUEL SYSTEM

Pressure Regulator

1. Disconnect the vacuum hose and fuel return hose.

2. Remove the pressure regulator.

3. Install in the reverse order of removal.

Tightening torque:

8—11 N-m (0.8—1.1 m-kg, 69—95 in-lb)

76G04B-084

Pulsation Damper

1. Loosen the pulsation damper and remove it.

2. Install in the reverse order of removal.

76G04B-085

^-Fuel hose

ML*? ^-Fuel pump

^silntank filter

ti* e

76G04B-086

h

tS

Is o

Sjfbj

Fuel Filter

Low pressure side

Refer to page 4B—57.

86U04A-116

High pressure side

The fuel filter must be replaced at the intervals out-

lined in the maintenance schedule.

Warning

Always work away from sparks or open

flames.

1. Disconnect the fuel hoses from the fuel filter.

2. Remove the fuel filter and the bracket.

3. Install a new filter and the bracket.

4. Connect the fuel hoses.

Note

When installing the filter, push the fuel hoses

fully onto the fuel filter and secure the hoses

with spring clamps.

4B-60

Page 523 of 1865

FUEL SYSTEM 4B

FUEL TANK

Removal

Caution

a) Before performing the following procedure, release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire. (Refer to page 4B—45)

b) When removing the fuel tank, keep sparks, cigarettes, and open flames away from the

fuel tank.

Remove in the sequence shown in the figure.

76G04B-087

Note

Drain the fuel from the fuel tank before removing the tank.

1. Fuel pump connectors 5. Breather hose

2. Fuel hoses 6. Fuel tank strap

3. Evaporative hoses 7. Fuel tank

4. Fuel filler hose

4B—61

Page 524 of 1865

4B FUEL SYSTEM

Inspection

1. Check the fuel tank for cracks and corrosion.

2. If any defect is found, repair or replace the tank.

Warning

Before repairing, clean the fuel tank thorough-

ly with steam to sufficiently remove all explo-

sive gas.

86U04A-118

Installation

Install in the reverse order of removal, referring to the installation note.

Torque Specifications

22—30 N-m (2.2—3.1 m-kg, 16—22 ft-lb)

4B—62

86U04A-119

Page 525 of 1865

FUEL SYSTEM 4B

Fuel filler hose: Push in at least 35 mm (1.4 in)

Others: At least 25 mm (1.0 in)

Installation note

1. Push the hose ends of the main fuel hose, fuel re-

turn hose and evaporation hoses onto the fuel tank

fittings at least 25 mm (1.0 in).

2. Push the fuel filler hose ends onto the fuel tank pipe

and filler pipe at least 35 mm (1.4 in).

86u04a-120

4B-63

Page 526 of 1865

4B DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

This system consists of the dashpot and fuel cut system. The dashpot is to prevent after-burn so that

the throttle valve gradually closes during deceleration.

The control unit detects engine deceleration judging from the engine speed and the idle switch, and

signals a fuel cut operation to match the engines need, based on the coolant temperature and the

driving condition.

4B—64

Page 527 of 1865

DECELERATION CONTROL SYSTEM 4B

COMPONENT DESCRIPTIONS

Component Function Remarks

Brake light switch Detects braking operation (deceleration);

sends signal to engine control unit

Clutch switch Detects in-gear condition;

sends signal to engine control unit Switch ON when clutch pedal released

Dashpot (MTX) Prevents sudden closing of throttle valve during deceleration or shifting Adjustment speed: 1,900—2,100 rpm

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed in throttle sensor

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Neutral switch Detects in-gear condition; sends signal to engine control unit Switch ON when in-gear

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04B-089

4B—65