battery MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1473 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

ABS-9

Possible failure

Relay box, Hydraulic unit, Harness

Disconnect Q-01 (17-pin) connector. Disconnect battery. Turn ignition switch

ON.

Check continuity

at

harness side.

Q-01 (17-pin) Continuity

RY (B) BG (G) No

NG

OK

Check that resistance between

LO

(C)

of

harness side

and

ground changes when reversing

© and

© test-leads.

NG

Check relay box. (Refer

to

page 11—87.)

OK

Repair harness.

(Control unit—Relay box-Hydraulic unit)

NG

Replace relay box.

OK

Check continuity

at

harness side.

Q-01 (17-pin) Continuity

RY (B) Ground Yes

OK

Relay control unit.

NG

Disconnect Q-09 connector. Check continuity

at

motor side.

Q-09 Continuity

RY Ground Yes

NG

Repair harness. (Motor—Ground)

OK

Check continuity

at

motor side.

Q-09 Continuity

RY B Yes

NG

Replace hydraulic unit.

OK

Repair harness. (Control unit—Relay box-Hydraulic unit)

76G11X-056

11-81

Page 1474 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

86U11X-154

ABS-11

Possible failure

Relay box, Hydraulic unit, Harness

Disconnect Q-01 (17-pin) connector. Disconnect battery. Check continuity

at

harness side.

Q-01 (17-pin) Continuity

LO(C) BG (G) No

OK

Q-01 (17-pin) Resistance

BL (E) Ground Aoorox. 7512

OK

Replace control unit.

Check resistance

at

harness side.

NG

Check relay box. (Refer

to

page 11—87.)

OK

Repair harness. (Control unit—Relay box-Hydraulic unit)

NG

Q-08 Continuitv

BL Ground No

OK

Repair harness. (Control unit—Relay box-Hydraulic unit)

NG

Replace relay box.

Disconnect Q-08 connector. Check continuity

at

relay side.

NG

76G11X-057

86U11X-156

11-82

Page 1475 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

ABS-13

Possible failure

Relay box, Hydraulic unit, Harness

Check Q-10, Q-06, and Q-08 con-

nectors

for

proper connection.

OK

Q-01 (17-pin) Resistance

BL (E) BG (G) approx. 75

Q

OK

Q-01 (17-pin) Resistance

LO (C) © probe YG(J) © probe approx.

65 Q

Q-08 (6-pin) Q-08 (2-Din) Continuity

BG LR Yes

OK

Disconnect Q-09 and Q-08 (2-pin) connectors. Check continuity

at

harness side.

Q-09 Q-08 (2-pin) Continuity

RY RY Yes

Q-09 Continuity

RY I Ground No

Q-09 Resistance

RY B approx. 0.1

Si

NG

Disconnect Q-01 (17-pin) connector. Disconnect battery. Measure resistance at harness side.

NG

Check resistance between BL (C)

and

YG

(J)

of

harness side.

OK

Check continuity

at

hydraulic unit side.

NG

OK

Turn ignition switch ON.

Check continuity

at

harness side.

Repair connector.

Check relay box. (Refer

to

page 11 —87)

NG

Replace relay box.

OK

Repair harness.

(Control unit—Relay box

or

Ignition switch—Hydraulic unit)

NG

Repair harness. (Relay box—Battery)

NG

Repair harness. (Hydraulic unit—Relay box)

NG

OK

Replace hydraulic unit

Check relay box. (Refer

to

page 11—87.)

OK

Replace control unit.

NG

Replace relay box

76G11X-058

11-83

Page 1478 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

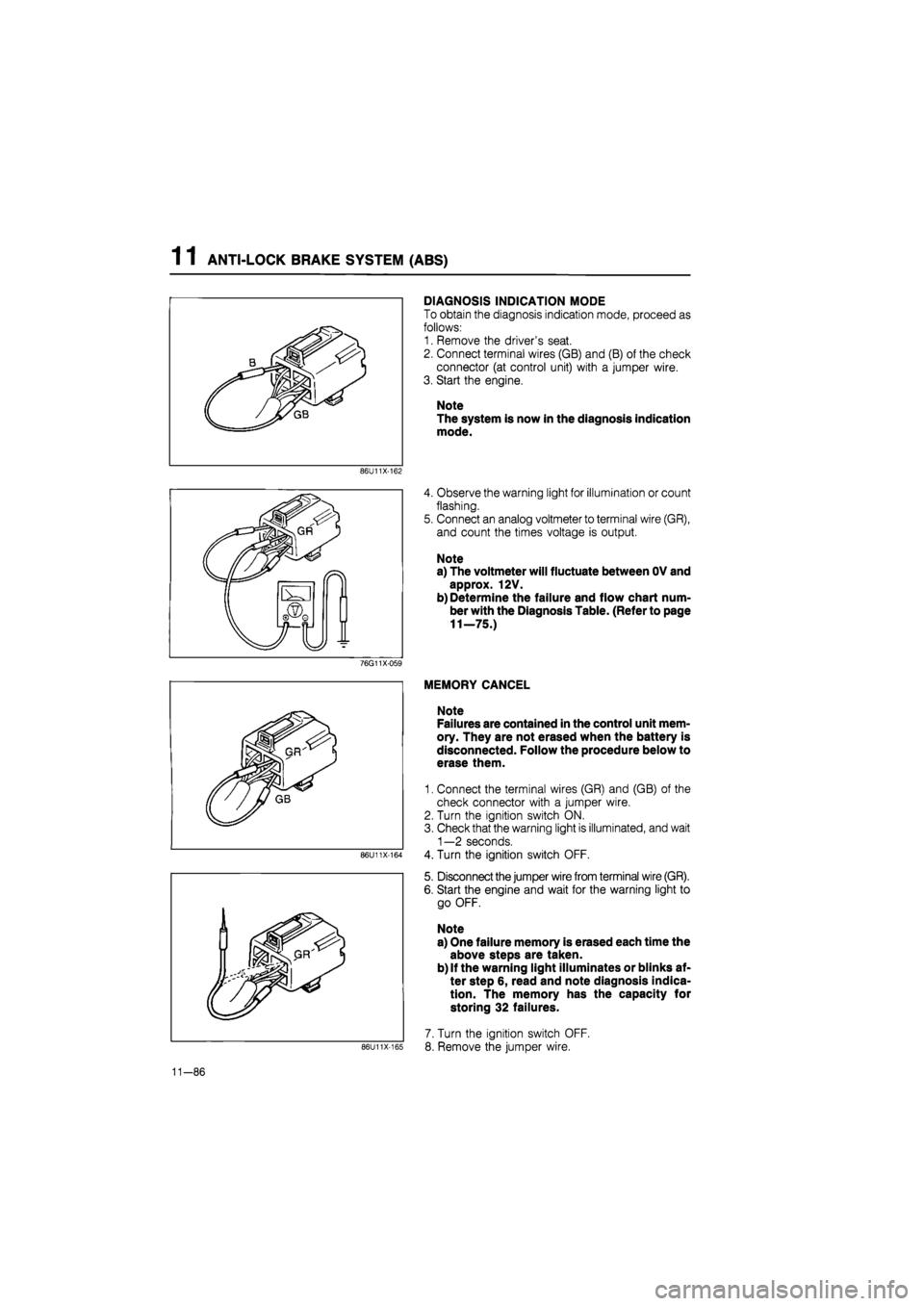

DIAGNOSIS INDICATION MODE

To obtain the diagnosis indication mode, proceed as

follows:

1. Remove the driver's seat.

2. Connect terminal wires (GB) and (B) of the check

connector (at control unit) with a jumper wire.

3. Start the engine.

Note

The system is now in the diagnosis indication

mode.

86U11X-162

4. Observe the warning light for illumination or count

flashing.

5. Connect an analog voltmeter to terminal wire (GR),

and count the times voltage is output.

Note

a) The voltmeter will fluctuate between OV and

approx. 12V.

b) Determine the failure and flow chart num-

ber with the Diagnosis Table. (Refer to page

11—75.)

76G11X-059

86U11X-164

86U11X-165

MEMORY CANCEL

Note

Failures are contained in the control unit mem-

ory. They are not erased when the battery is

disconnected. Follow the procedure below to

erase them.

1. Connect the terminal wires (GR) and (GB) of the

check connector with a jumper wire.

2. Turn the ignition switch ON.

3. Check that the warning light is illuminated, and wait

1—2 seconds.

4. Turn the ignition switch OFF.

5. Disconnect the jumper wire from terminal wire (GR).

6. Start the engine and wait for the warning light to

go OFF.

Note

a) One failure memory is erased each time the

above steps are taken.

b) If the warning light illuminates or blinks af-

ter step 6, read and note diagnosis indica-

tion. The memory has the capacity for

storing 32 failures.

7. Turn the ignition switch OFF.

8. Remove the jumper wire.

11-86

Page 1487 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

86U11X-190

86U11X-191

76G11X098

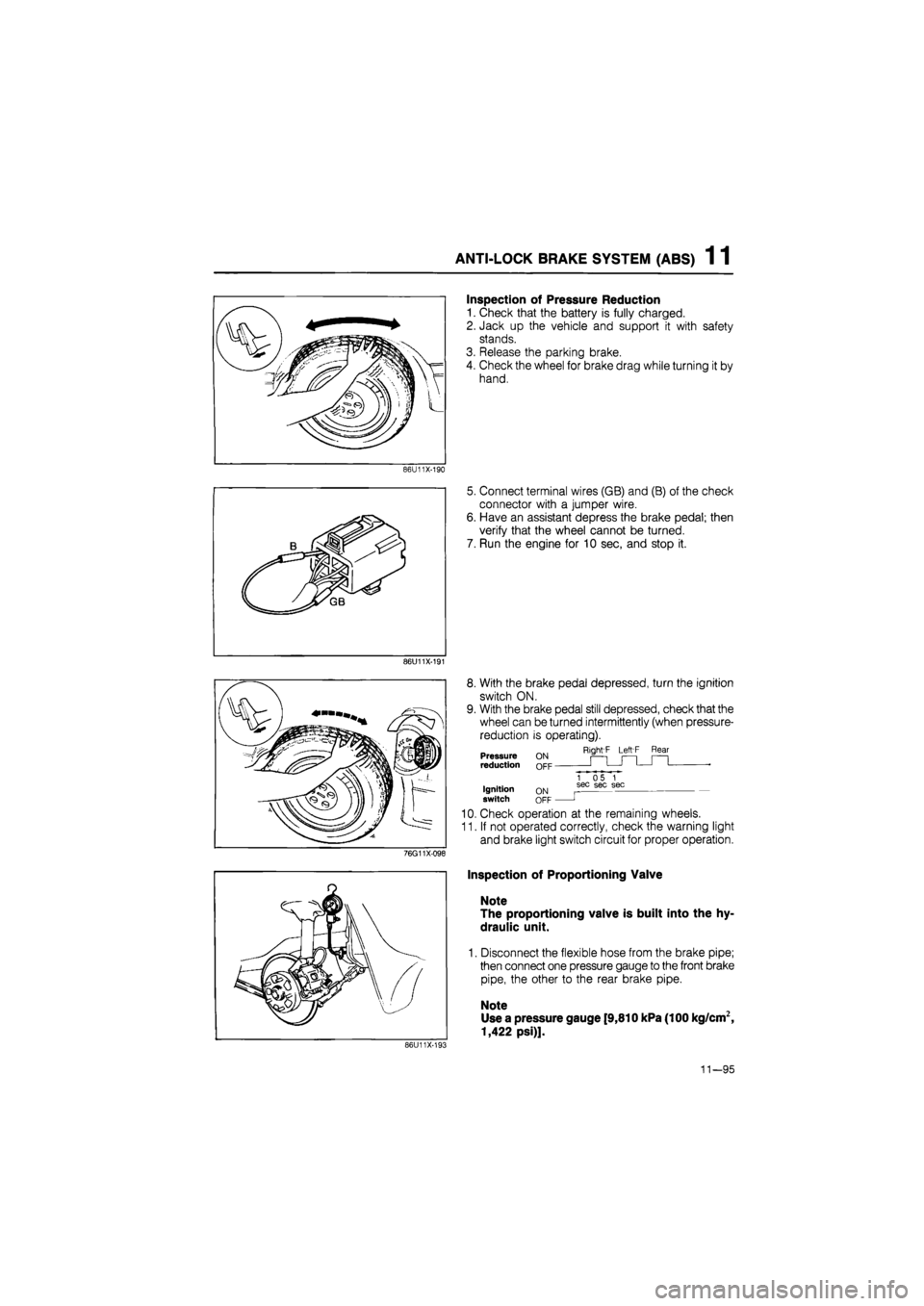

Inspection of Pressure Reduction

1. Check that the battery is fully charged.

2. Jack up the vehicle and support it with safety

stands.

3. Release the parking brake.

4. Check the wheel for brake drag while turning it by

hand.

5. Connect terminal wires (GB) and (B) of the check

connector with a jumper wire.

6. Have an assistant depress the brake pedal; then

verify that the wheel cannot be turned.

7. Run the engine for 10 sec, and stop it.

8. With the brake pedal depressed, turn the ignition

switch ON.

9. With the brake pedal still depressed, check that the

wheel can be turned intermittently (when pressure-

reduction is operating).

Right'F Left F Rear Pressure reduction

Ignition switch ON OFF

1 05 1 sec sec sec

J

10. Check operation at the remaining wheels.

11. If not operated correctly, check the warning light

and brake light switch circuit for proper operation.

Inspection of Proportioning Valve

Note

The proportioning valve is built into the hy-

draulic unit.

1. Disconnect the flexible hose from the brake pipe;

then connect one pressure gauge to the front brake

pipe, the other to the rear brake pipe.

Note

Use a pressure gauge [9,810 kPa (100 kg/cm2,

1,422 psi)].

86U11X-193

11—95

Page 1491 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

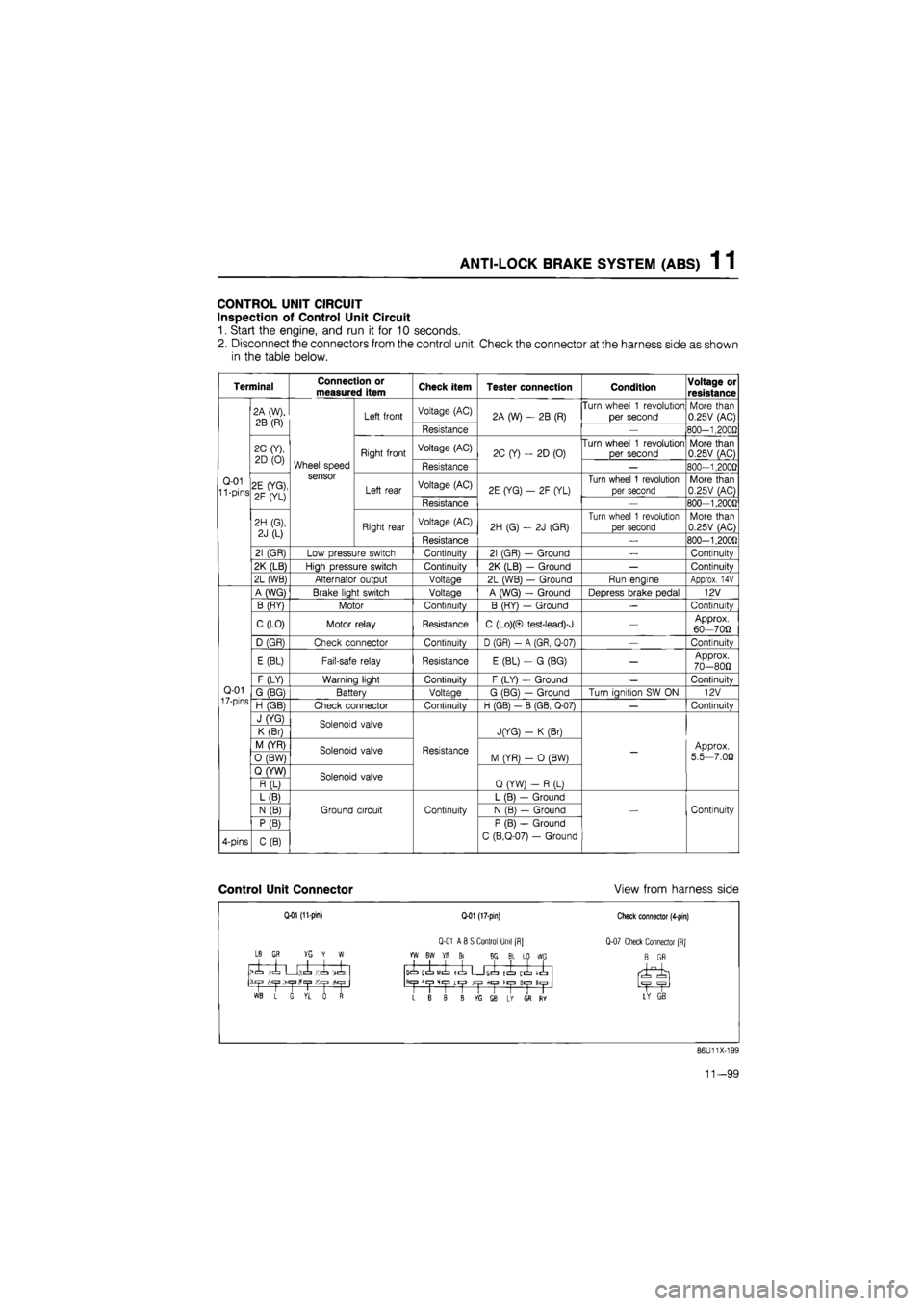

CONTROL UNIT CIRCUIT

Inspection of Control Unit Circuit

1. Start the engine, and run it for 10 seconds.

2. Disconnect the connectors from the control unit. Check the connector at the harness side as shown

in the table below.

Terminal Connection or measured item Check item Tester connection Condition Voltage or

resistance

Q-01 11 -pins

2A (W),

2B (R)

Wheel speed sensor

Left front Voltage (AC) 2A (W)

- 2B

(R) Turn wheel

1

revolution

per second More than 0.25V (AC)

Q-01 11 -pins

2A (W),

2B (R)

Wheel speed sensor

Left front

Resistance

2A (W)

- 2B

(R)

—

800-1.2000

Q-01 11 -pins

2C (Y),

2D

(0)

Wheel speed sensor

Right front Voltage (AC) 2C (Y)

-

2D (0) Turn wheel

1

revolution

per second More than 0.25V (AC)

Q-01 11 -pins

2C (Y),

2D

(0)

Wheel speed sensor

Right front

Resistance

2C (Y)

-

2D (0)

—

800-1,2000

Q-01 11 -pins 2E (YG),

2F (YL)

Wheel speed sensor

Left rear Voltage (AC) 2E (YG)

- 2F

(YL) Turn wheel

1

revolution

per second More than 0.25V (AC) Q-01 11 -pins 2E (YG),

2F (YL)

Wheel speed sensor

Left rear

Resistance

2E (YG)

- 2F

(YL)

—

800-1,200G

Q-01 11 -pins

2H (G).

2J

(L)

Wheel speed sensor

Right rear Voltage (AC) 2H (G)

- 2J

(GR)

Turn wheel

1

revolution

per second More than 0.25V (AC)

Q-01 11 -pins

2H (G).

2J

(L)

Wheel speed sensor

Right rear

Resistance

2H (G)

- 2J

(GR)

_

800-1,200fl

Q-01 11 -pins

21 (GR) Low pressure switch Continuity 21 (GR)

-

Ground

—

Continuity

Q-01 11 -pins

2K (LB) High pressure switch Continuity 2K (LB)

-

Ground

—

Continuity

Q-01 11 -pins

2L (WB) Alternator output Voltage 2L (WB)

-

Ground Run engine Approx.

14V

Q-01

17-pins

A (WG) Brake light switch Voltage A (WG)

-

Ground Depress brake pedal 12V

Q-01

17-pins

B (RY) Motor Continuity B (RY)

—

Ground

—

Continuity

Q-01

17-pins

C (LO) Motor relay Resistance C (Lo)(© test-lead)-J

—

Approx. 60—700

Q-01

17-pins

D (GR) Check connector Continuity D (GR)

- A

(GR, Q-07)

—

Continuity

Q-01

17-pins

E (BL) Fail-safe relay Resistance E (BL)

- G

(BG)

—

Approx. 70-800

Q-01

17-pins

F (LY) Warning light Continuity F (LY)

-

Ground

—

Continuitv Q-01

17-pins G (BG) Battery Voltage G (BG)

—

Ground Turn ianition

SW ON

12V Q-01

17-pins H (GB) Check connector Continuitv H (GB)

- B

(GB. Q-07)

—

Continuitv

Q-01

17-pins

J (YG) Solenoid valve

Resistance

JfYG)

- K

(Br)

-

Approx.

5.5—7.00

Q-01

17-pins

K (Br) Solenoid valve

Resistance

JfYG)

- K

(Br)

-

Approx.

5.5—7.00

Q-01

17-pins

M (YR) Solenoid valve Resistance M (YR)

- 0

(BW)

-

Approx.

5.5—7.00

Q-01

17-pins

0 (BW) Solenoid valve Resistance M (YR)

- 0

(BW)

-

Approx.

5.5—7.00

Q-01

17-pins

Q (YW) Solenoid valve

Resistance

Q (YW)

- R

(L)

-

Approx.

5.5—7.00

Q-01

17-pins

R (L) Solenoid valve

Resistance

Q (YW)

- R

(L)

-

Approx.

5.5—7.00

Q-01

17-pins

L (B)

Ground circuit Continuity

L (B)

—

Ground

Continuity

Q-01

17-pins

N

(B)

Ground circuit Continuity N (B)

—

Ground Continuity

Q-01

17-pins

P (B)

Ground circuit Continuity

P (B)

—

Ground

C (B.Q-07)

-

Ground

Continuity

4-pins C(B)

Ground circuit Continuity

P (B)

—

Ground

C (B.Q-07)

-

Ground

Continuity

Control Unit Connector View from harness side

Q-01 (11-pin)

LB

GR YG Y W

>1 ,1 U;.l Ki -X

1 L G VL rf

Q-01 (17-pin)

Q-01 ABS Control Unit [R]

YW BW YR Br 8G BL LO WG

icL olL

MIL

ICL G(=L tl ij^" llyl

>1

CjJ

Lt|J JCjJ fiC|3 H«|3

L B B B ffi SB L* GS RY

Check connector (4-pin)

Q-07 Check Connector [RJ

B GR

LY GB

86U11X-199

11—99

Page 1561 of 1865

1 4 REAR HATCH

/ { / t

K'

86U14X-023

86U14X-024

86U14X-025

REMOVAL

1. Disconnect the negative battery cable.

2. Remove the rear hatch trim.

3. Disconnect the connector, then remove the car-

go room light.

4. Remove the rear hatch screen.

Caution

Remove the screen carefully so that it may be

reused.

5. Disconnect the rear defogger and wiper motor con-

nectors, then remove the wire harness through the

rear hatch.

6. Remove the wiper arm.

7. Remove the wiper motor.

86U14X-026

14—10

Page 1579 of 1865

1 4 HEADLIGHT AND COMBINATION LIGHT

HEADLIGHT AND COMBINATION LIGHT

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure, referring to removal note for the specially marked parts.

3. Install in the reverse order of removal.

76G14X-005

1. Screw

2. Turn signal light assembly

3. Screw

4. Radiator grille

5. Bolts

6. Bolts

7. Headlight assembly

8. Screws

9. Light garnish

10. Headlight bulb

60 + 55W/55W

11. Parking light bulb 5W

12. Turn signal light bulb

21W

14—28

Page 1583 of 1865

1 4 REAR COMBINATION LIGHTS

REAR COMBINATION LIGHTS

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure.

3. Install in the reverse order of removal.

76G14X-010

Hatchback

1. End trim

2. Nuts

3. Lens and body

4. Cover

5. Bulb: Turn signal light 21W

Brake and tail light 21W

Side marker light 5W

Sedan and Coupe/MX-6

1. End trim

2. Nuts

3. Lens and body

4. Cover

5. Bulb: Turn signal light 21W

Brake and tail light 21W

Side marker light 5W

14—32

Page 1586 of 1865

LICENSE PLATE

LIGHT

AND CORGO ROOM LIGHT

1

4

LICENSE PLATE LIGHT AND CORGO ROOM LIGHT

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure.

3. Install in the reverse order of removal.

76G14X-011

Sedan and Coupe/MX-6

License plate light

1. Screws

2. Lens

3. Bulb 5W x 2

Back up light

4. End trim

5. Bulb 21W

6. Nuts

7. Rear finisher

Hatchback

Corgo room light

1. Lens

2. Switch and bulb assembly 5W

License plate light

3. Side trim

4. Lower trim

5. End trim

6. Screws

7. Lens

8. Bulb 5W x 2

9. Rear finisher

14-35