MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1491 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

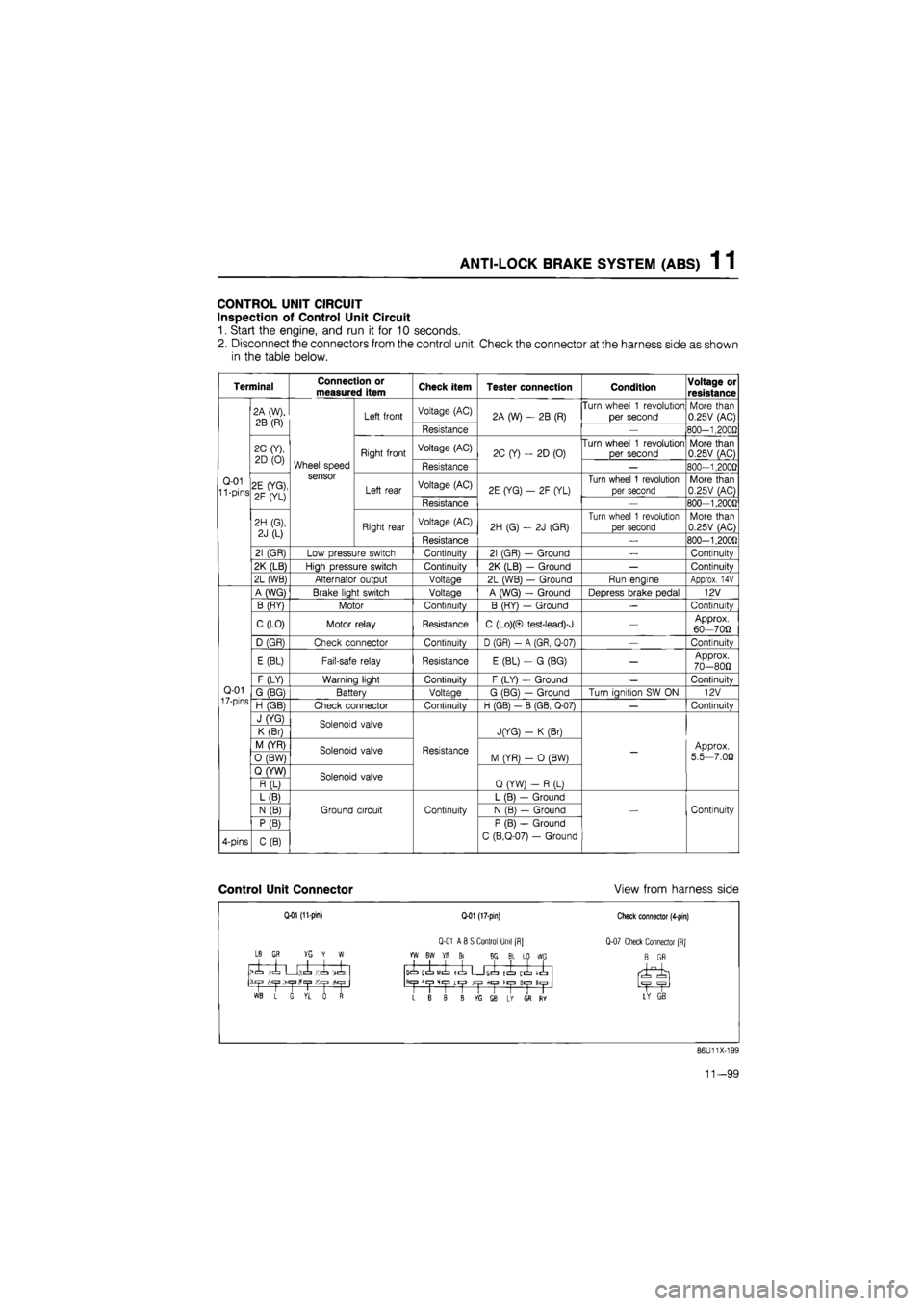

CONTROL UNIT CIRCUIT

Inspection of Control Unit Circuit

1. Start the engine, and run it for 10 seconds.

2. Disconnect the connectors from the control unit. Check the connector at the harness side as shown

in the table below.

Terminal Connection or measured item Check item Tester connection Condition Voltage or

resistance

Q-01 11 -pins

2A (W),

2B (R)

Wheel speed sensor

Left front Voltage (AC) 2A (W)

- 2B

(R) Turn wheel

1

revolution

per second More than 0.25V (AC)

Q-01 11 -pins

2A (W),

2B (R)

Wheel speed sensor

Left front

Resistance

2A (W)

- 2B

(R)

—

800-1.2000

Q-01 11 -pins

2C (Y),

2D

(0)

Wheel speed sensor

Right front Voltage (AC) 2C (Y)

-

2D (0) Turn wheel

1

revolution

per second More than 0.25V (AC)

Q-01 11 -pins

2C (Y),

2D

(0)

Wheel speed sensor

Right front

Resistance

2C (Y)

-

2D (0)

—

800-1,2000

Q-01 11 -pins 2E (YG),

2F (YL)

Wheel speed sensor

Left rear Voltage (AC) 2E (YG)

- 2F

(YL) Turn wheel

1

revolution

per second More than 0.25V (AC) Q-01 11 -pins 2E (YG),

2F (YL)

Wheel speed sensor

Left rear

Resistance

2E (YG)

- 2F

(YL)

—

800-1,200G

Q-01 11 -pins

2H (G).

2J

(L)

Wheel speed sensor

Right rear Voltage (AC) 2H (G)

- 2J

(GR)

Turn wheel

1

revolution

per second More than 0.25V (AC)

Q-01 11 -pins

2H (G).

2J

(L)

Wheel speed sensor

Right rear

Resistance

2H (G)

- 2J

(GR)

_

800-1,200fl

Q-01 11 -pins

21 (GR) Low pressure switch Continuity 21 (GR)

-

Ground

—

Continuity

Q-01 11 -pins

2K (LB) High pressure switch Continuity 2K (LB)

-

Ground

—

Continuity

Q-01 11 -pins

2L (WB) Alternator output Voltage 2L (WB)

-

Ground Run engine Approx.

14V

Q-01

17-pins

A (WG) Brake light switch Voltage A (WG)

-

Ground Depress brake pedal 12V

Q-01

17-pins

B (RY) Motor Continuity B (RY)

—

Ground

—

Continuity

Q-01

17-pins

C (LO) Motor relay Resistance C (Lo)(© test-lead)-J

—

Approx. 60—700

Q-01

17-pins

D (GR) Check connector Continuity D (GR)

- A

(GR, Q-07)

—

Continuity

Q-01

17-pins

E (BL) Fail-safe relay Resistance E (BL)

- G

(BG)

—

Approx. 70-800

Q-01

17-pins

F (LY) Warning light Continuity F (LY)

-

Ground

—

Continuitv Q-01

17-pins G (BG) Battery Voltage G (BG)

—

Ground Turn ianition

SW ON

12V Q-01

17-pins H (GB) Check connector Continuitv H (GB)

- B

(GB. Q-07)

—

Continuitv

Q-01

17-pins

J (YG) Solenoid valve

Resistance

JfYG)

- K

(Br)

-

Approx.

5.5—7.00

Q-01

17-pins

K (Br) Solenoid valve

Resistance

JfYG)

- K

(Br)

-

Approx.

5.5—7.00

Q-01

17-pins

M (YR) Solenoid valve Resistance M (YR)

- 0

(BW)

-

Approx.

5.5—7.00

Q-01

17-pins

0 (BW) Solenoid valve Resistance M (YR)

- 0

(BW)

-

Approx.

5.5—7.00

Q-01

17-pins

Q (YW) Solenoid valve

Resistance

Q (YW)

- R

(L)

-

Approx.

5.5—7.00

Q-01

17-pins

R (L) Solenoid valve

Resistance

Q (YW)

- R

(L)

-

Approx.

5.5—7.00

Q-01

17-pins

L (B)

Ground circuit Continuity

L (B)

—

Ground

Continuity

Q-01

17-pins

N

(B)

Ground circuit Continuity N (B)

—

Ground Continuity

Q-01

17-pins

P (B)

Ground circuit Continuity

P (B)

—

Ground

C (B.Q-07)

-

Ground

Continuity

4-pins C(B)

Ground circuit Continuity

P (B)

—

Ground

C (B.Q-07)

-

Ground

Continuity

Control Unit Connector View from harness side

Q-01 (11-pin)

LB

GR YG Y W

>1 ,1 U;.l Ki -X

1 L G VL rf

Q-01 (17-pin)

Q-01 ABS Control Unit [R]

YW BW YR Br 8G BL LO WG

icL olL

MIL

ICL G(=L tl ij^" llyl

>1

CjJ

Lt|J JCjJ fiC|3 H«|3

L B B B ffi SB L* GS RY

Check connector (4-pin)

Q-07 Check Connector [RJ

B GR

LY GB

86U11X-199

11—99

Page 1492 of 1865

12

WHEELS AND TIRES

OUTLINE 12— 2

SPECIFICATIONS 12— 2

TROUBLESHOOTING GUIDE 12— 2

WHEELS AND TIRES 12—3

INSPECTION AND ADJUSTMENT 12— 3

TIRE ROTATION 12—4

WHEEL BALANCE 12— 5

WHEEL MOUNTING 12— 5

SPECIAL NOTE 12—5

86U12X-001

Page 1493 of 1865

1 2 OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

Type

Item Standard Temporary spare (if equipped)

Wheel

Size

5-J

x 13

4-T

x 15

Wheel

Size 5 1/2-JJ

x 14

4-T

x 15

Wheel

Size

6-JJ

x 15

4-T

x 15

Wheel

Off set mm (in) 42 (1.65) 53 (2.09)

Wheel Diameter

of

pitch circle

mm

(in) 114.3 (4.5) Wheel

Material Steel

or

aluminum alloy Steel

Wheel

Number

of

fixing nuts

13 inch-wheel 4

4

or 5

Wheel

Number

of

fixing nuts 14 inch-wheel 5 4

or 5

Wheel

Number

of

fixing nuts 15 inch-wheel 5 4

or 5

Tire

Size

13 inch-wheel

6.45—13—6PR

165 SR13 165/80R13 82S 185/70HR13 185/70R13 85H

T125/70D15

Tire

Size 14 inch-wheel

185/70HR14 185/70R14 87H 185/70R14 88H 185/70VR14

T125/70D15

Tire

Size

15 inch-wheel 195/60R15 86H

195/60VR15

T125/70D15

Tire

Air pressure

kPa (kg/cm2,

psi)

Front 216 (2.2, 31) or 196 (2.0, 28) "See tire labels for application 412(4.2, 60)

Tire

Air pressure

kPa (kg/cm2,

psi) Rear 177 (1.8, 26)

412(4.2, 60)

TROUBLESHOOTING GUIDE 76G12X-001

Problem Possible Cause Remedy Page

Premature tire wear

Incorrect tire pressure Adjust 12-

2

Tire squeal

Incorrect tire pressure Tire deterioration

Adjust ReDlace

12-

2

Road noise or body vibration

Insufficient tire pressure Unbalanced wheel(s) Deformed wheel(s)

or

tire(s) Irregular tire wear

Adjust Adjust Repair

or

replace Reolace

-1

12-

2

12-

5

Steering wheel vibration

Irregular tire wear Right and left tread depths different Deformed

or

unbalanced wheel(s) Deformed tire(s) Unequal tire pressures Loose lug nuts

Replace Replace

Replace

or

adjust Replace Adjust Tiahten

12-

5

12—

2

12-

5

Uneven (one-sided) braking

Unequal tire pressures Adjust 12-

2

Steering wheel doesn't return properly, or pulls to either left or right while vehicle moving on level road surface

Incorrect tire pressure Irregular tire wear (left and right are different) Unequal tire pressures Different types

or

brands

of

tires mixed (right/left) Improperly tightened lug nuts

Adjust Replace Adjust Replace Tighten

12-

2

12—

2

12-

5

General driving in-stability

Unequal tire pressures Deformed

or

unbalanced wheel(s) Loose lug nuts

Adjust Replace

or

adjust Tiahten

12-

2

12-

5

12-

5

Excessive steering wheel play

Loose lug nuts Tighten 12-

5

76G12X-002

12-2

Page 1494 of 1865

WHEELS AND TIRES 1 2

86U12X-004

\k

y

i jYj

/ <4/

/ v Wear platform

Wear indicators

86U12X-005

(a) (b)

Shoulder wear Center wear

(c)

Feathered edge

(d)

*f tftiit t

Toe-in or toe-out wear Uneven wear

WHEELS AND TIRES

INSPECTION AND ADJUSTMENTS

Check the following, and adjust or replace as

necessary.

1. Air pressure

Check the air pressure of all tires, including the

spare tire, with an air pressure gauge.

(Refer to page 12—2.)

Caution

The air pressure must be measured when the

tire is cold.

2. Tire wear

Specifications

Remaining tread

Ordinary tires: 1.6 mm (0.063 in) min.

(Tire should be replaced if wear indicators are

exposed.)

Snow tires: 50% of tread

(Tire should be replaced if wear indicators are

exposed.)

Troubleshooting guide

Abnormal tire wear patterns shown in the illustra-

tion can occur. Refer to the chart for the probable

causes and remedies.

Probable cause Remedy

(a) • Underinflation (both sides worn) • Incorrect camber (one side worn) • Hard cornering • Lack of rotation

• Measure and adjust pressure • Repair or replace axle and suspension parts • Reduce speed • Rotate tires

(b) • Overinflation

• Lack of rotation

• Measure and adjust pressure • Rotate tires

(c) • Incorrect toe-in • Adjust toe-in

(d) • Incorrect camber or caster • Malfunctioning suspension • Unbalanced wheel • Out-of-round brake drum or disc • Other mechanical con-ditions • Lack of rotation

• Repair or replace axle and suspension parts • Repair or replace • Balance or replace • Correct or replace

• Correct or replace

• Rotate tires

76G12X-003

12-3

Page 1495 of 1865

12 WHEELS AND TIRES

86U12X-007

86U12X-008

3. Wheel deflection

Set the probe of a dial indicator against the wheel,

and turn the wheel one full revolution.

Wheel deflection limit mm (in)

Horizontal Vertical

Steel wheel 2.5 (0.098) 2.0 (0.079) Aluminum wheel 2.0 (0.079) 2.0 (0.079)

4. Cracks, damage, or foreign matter (such as metal

pieces, nails, and stones) in the tire and cracks,

deformation, and damage to the wheel

5. Loose wheel lug nut(s)

6. Air leaking from the valve stem

TIRE ROTATION

To prolong tire life and assure uniform wear, rotate

the tires every 6,000 km (3,750 miles) or sooner if ir-

regular wear develops.

Caution

a) Do not include "TEMPORARY USE ONLY"

spare tire in rotation.

b) After rotating the tires, adjust each tire to

the specified air pressure. (Refer to page

12—2.)

Note

The optional unidirectional wheels are marked

to indicate direction of travel.

Unidirectional wheel

Left side Right side

Front Front

76G12X-004

12—4

Page 1496 of 1865

WHEELS AND TIRES 1 2

WHEEL BALANCE

If a wheel becomes unbalanced or if a tire is replaced

or repaired, the wheel must once again be balanced

to within specification.

Maximum unbalance (at rim edge): g (oz)

13 inch-wheel 11 (0.39)

14 inch-wheel 10 (0.35)

15 inch-wheel 9 (0.32)

76G12X-005

Balance

weight

Outside

Balance

weight

86U12X-011

Caution

a) Do not use more than two balance weights

on the inner or outer side of the wheel, if

the total weight exceeds 100 g (3.5 oz), re-

balance after moving the tire around on the

rim.

b) Attach the balance weights tightly so that

they do not protrude more than 3 mm (0.12

in) beyond the wheel edge.

c) Select suitable balance weights for steel or

aluminum alloy wheels.

d)Do not use an on-car balancer on ATX

models. Use of this type of balancer may

cause clutch damage.

WHEEL MOUNTING

Tighten the lug nuts to the specified torque in a criss-

cross fashion.

Tightening torque:

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

Caution

a) The wheel-to-hub contact surfaces must be

clean.

b) Never apply oil to the nuts, bolts, or wheels;

doing so might cause looseness or seizure

of the lug nuts.

86U12X-012

SPECIAL NOTE

Regarding wheels and tires:

1. Do not use wheels or tires other than the specified types.

2. Aluminum wheels are easily scratched. When washing them, use a soft cloth, never a wire brush.

If the vehicle is steam cleaned, do not allow boiling water to contact the wheels.

3. If alkaline compounds (such as salt water or road salts), get on aluminum wheels, wash them as

soon as possible to prevent damage. Use only a neutral detergent.

86U12X-013

12-5

Page 1497 of 1865

1 2 WHEELS AND TIRES

Regarding tire replacement:

Note the following points when tires are to be removed from or mounted onto the wheels.

1. Be careful not to scratch the tire bead, the rim bead, or the edge of the rim.

2. Apply a soapy solution to the tire bead and the edge of the rim.

3. Use a wire brush, sandpaper, or cloth to clean and remove all rust, dirt, etc., from the rim edge

and the rim bead. For aluminum wheels, use only a cloth for this purpose; never use a wire brush

or sandpaper.

4. Remove any pebbles, glass, nails, etc., embedded in the tire tread.

5. Be sure the air valve is installed correctly.

6. After mounting a tire onto a wheel, inflate the tire to 250—300 kPa (2.55—3.06 kg/cm2,35.55—42.66

psi). Check to be sure that the bead is seated correctly onto the rim and that there are no air leaks.

Then reduce the pressure to the specified level.

7. If a tire iron is used to change a tire on an aluminum wheei, be sure to use a piece of rubber be-

tween the iron lever and the wheel in order to avoid damage to the wheel. Work should be done

on a rubber mat, not on a hard or rough surface. 76G12X-006

12—6

Page 1498 of 1865

13

SUSPENSION

OUTLINE 13— 2

STRUCTURAL VIEW 13— 2

SPECIFICATIONS 13— 4

TROUBLESHOOTING GUIDE 13—11

FRONT SHOCK ABSORBER AND

SPRING 13—13

REMOVAL AND INSTALLATION 13—13

DISASSEMBLY AND ASSEMBLY 13—15

FRONT LOWER ARM 13—18

REMOVAL AND INSTALLATION 13—18

FRONT STABILIZER (4WS) 13—23

REMOVAL AND INSTALLATION 13—23

FRONT STABILIZER 13—27

REMOVAL AND INSTALLATION 13—27

REAR SHOCK ABSORBER AND SPRING .. 13—29

REMOVAL AND INSTALLATION 13—29

DISASSEMBLY AND ASSEMBLY 13—32

LATERAL LINK AND TRAILING LINK 13—34

REMOVAL AND INSTALLATION 13—34

REAR LOWER ARM AND TRAILING

LINK (4WS) 13—36

REMOVAL AND INSTALLATION 13—36

REAR STABILIZER 13—39

REMOVAL AND INSTALLATION 13—39

REAR STABILIZER AND CONTROL

LINK (4WS) 13—41

REMOVAL AND INSTALLATION 13—41

REAR CROSSMEMBER (4WS) 13—44

REMOVAL AND INSTALLATION 13—44

FRONT WHEEL ALIGNMENT 13—50

REAR WHEEL ALIGNMENT 13—52

76G13X-001

Page 1499 of 1865

13 OUTLINE

OUTLINE

STRUCTURAL VIEW

Front Suspension

86U13X-002

13—2

Page 1500 of 1865

OUTLINE 13

Rear Suspension

4-wheel steering (4WS)

86U13X-003

13—3