MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: heater, coolant capacity, service indicator, fuel tank capacity, jump start terminals, flat tire, run flat

Page 1691 of 1865

1 5 WARNING LIGHT AND SENDER

76G15X-042

Low Fuel Level Warning Light

does not illuminate

Replace the fuel gauge unit

86U15X-060

86U15X-061

15-36

Page 1692 of 1865

WARNING LIGHT AND SENDER 1 5

76G15X-090

Seat Belt Warning Light

76G15X-043

EC-AT Mode Indicator Light

POWER and ECONO indicator lights

do

not

il-

luminate.

NG

Check the hold switch. Refer

to

page 7B—63

NG

Replace the switch.

OK

NG

Check the mode switch. Refer

to

page 7B—63

NG

Replace the switch.

fOK

Replace the bulb

or

repair the harness (Meter

to

mode switch, EC-AT switch

to

control unit).

76G15X-091

76G15X-044

15—37

Page 1693 of 1865

1 5 WARNING AND SENDER

Shift Indicator Light

All shift indicator lights do not Illuminate when ignition switch on. (other warning light are all right.)

Check the voltage

at BY

terminal

of

the inhibitor switch connector with ignition switch

on.

Terminal Voltage

BY 12V

NG

Repair the harness (Fuse box

to

inhibitor switch).

OK

Check the inhibitor switch. Refer

to

page 7B—65

NG

Replace the inhibitor switch. Check the inhibitor switch. Refer

to

page 7B—65 Replace the inhibitor switch.

OK

NG

Check the bulbs

of

the shift indicator lights.

NG

Replace the bulb.

OK

Turn the ignition switch on, and check the voltage

at

each terminal

of

the meter connector with each con-dition.

Terminal Selector lever Voltage

YL (2J) P 12V

RG (1L) R 12V

YR (2L) N 12V

Y(1V) D 12V

YB (1S) 2 12V

YW (1M) 1 12V

NG

Repair the harness (Inhibitor switch

to

meter).

76G15X-087

O/D OFF Indicator Light

OK

Repair the harness (O/D OFF switch

to

ground).

76G15X092

15-38

Page 1694 of 1865

WARNING AND SENDER 15

Coolant Level Warning Light

OK

Repair harness (Meter

to

coolant level sensor).

76G15X093

INSPECTION

Brake Fluid Level Sensor

1. Check for continuity of the sensor with an

ohmmeter.

Float level Continuity

Below

min

Yes

Above

min

No

2. If continuity is not as specified, replace the sensor.

86U15X-065

86U14X-066

Parking Brake Switch

1. Check for continuity between (R) terminal and a

body ground with an ohmmeter.

Lever Continuity

Pulled one notch Yes

Released No

2. If continuity is not as specified, adjust the switch

or replace the switch.

15—39

Page 1695 of 1865

15 WARNING AND SENDER

86U15X-068

86U15X069

86U15X-070

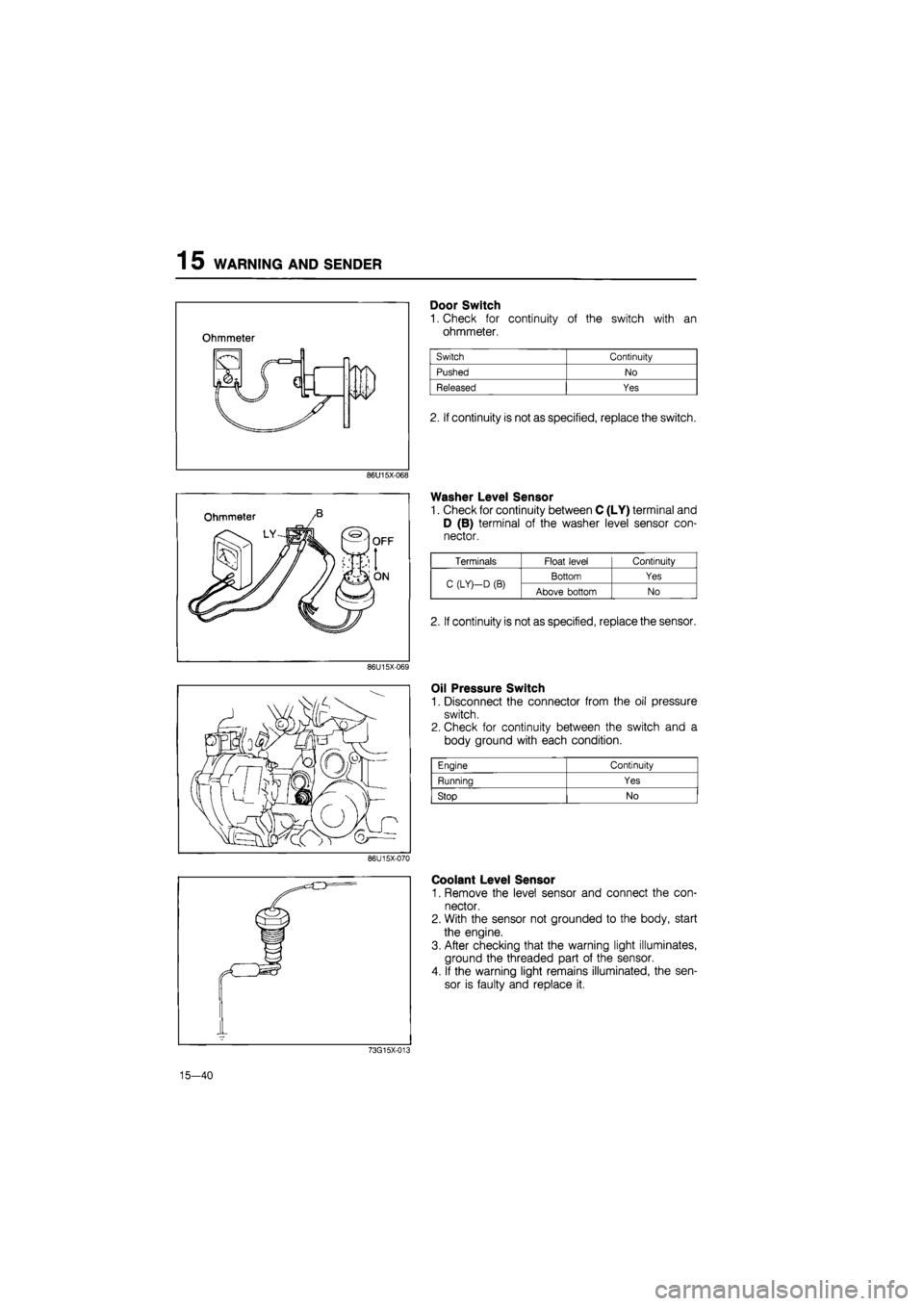

Door Switch

1. Check for continuity of the switch with an

ohmmeter.

2. If continuity is not as specified, replace the switch.

Washer Level Sensor

1. Check for continuity between C (LY) terminal and

D (B) terminal of the washer level sensor con-

nector.

Oil Pressure Switch

1. Disconnect the connector from the oil pressure

switch.

2. Check for continuity between the switch and a

body ground with each condition.

Coolant Level Sensor

1. Remove the level sensor and connect the con-

nector.

2. With the sensor not grounded to the body, start

the engine.

3. After checking that the warning light illuminates,

ground the threaded part of the sensor.

4. If the warning light remains illuminated, the sen-

sor is faulty and replace it.

73G15X-013

15—40

Engine Continuity

Running Yes

Stop No

Terminals Float level Continuity

C (LY)—D

(B)

Bottom Yes C (LY)—D

(B)

Above bottom No

2. If continuity is not as specified, replace the sensor.

Page 1696 of 1865

CENTRAL PROCESSING UNIT (CPU) 1 5

CENTRAL PROCESSING UNIT (CPU)

STRUCTURAL VIEW

86U15X-071

FUNCTIONS

System Function

Sound Alarm System

Key reminder alarm

Sound Alarm System

Liaht-off reminder alarm

Sound Alarm System

Seat belt alarm

Timer System

Seat belt timer

Timer System

Kev illumination liaht timer

Timer System

Interior light timer

76G15X-008

15—41

Page 1697 of 1865

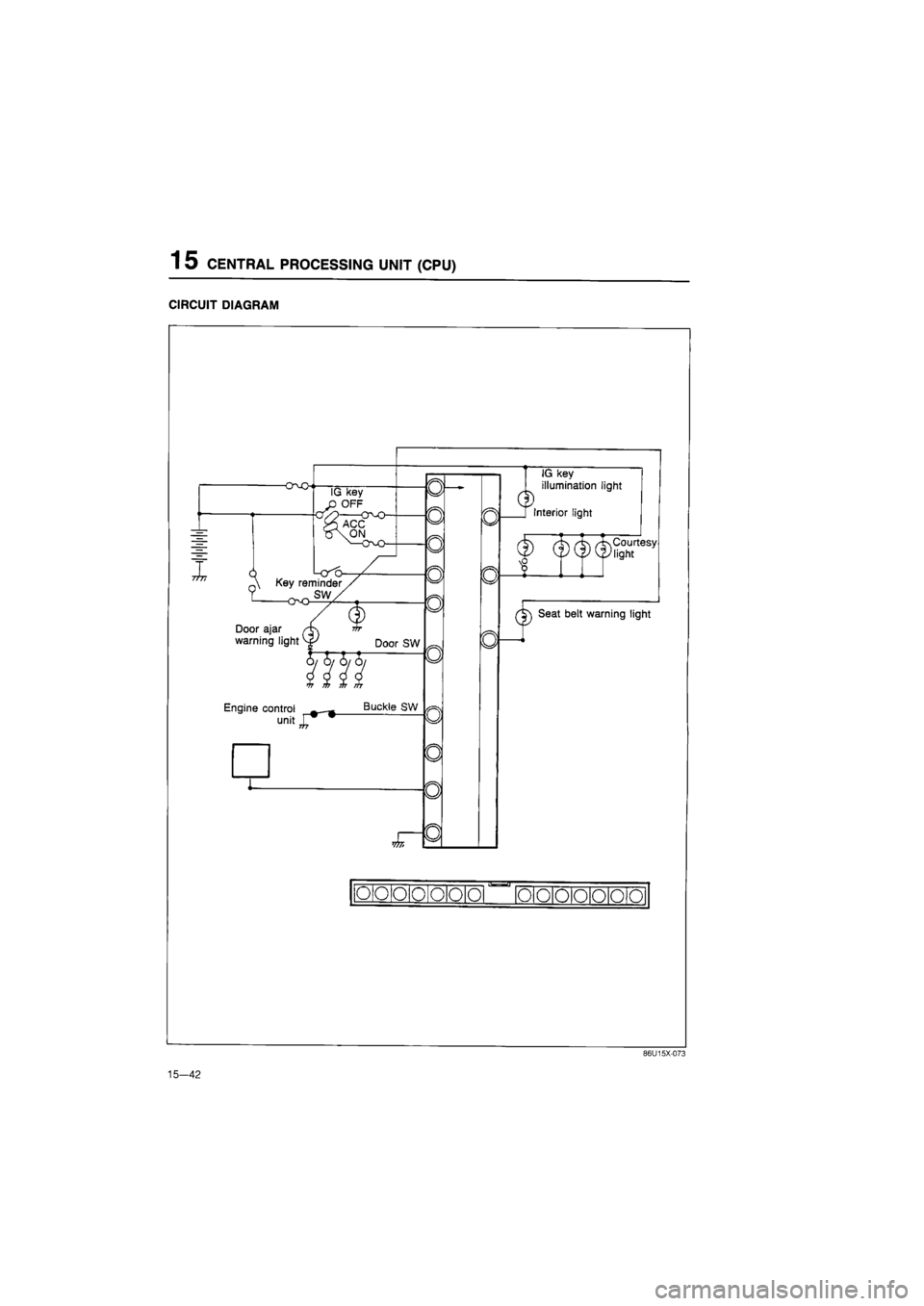

1 5 CENTRAL PROCESSING UNIT (CPU)

CIRCUIT DIAGRAM

-O-vO

I &

IG key

OFF

n\ Key reminder

Door ajar

warning light vf Door SW

llfl Engine control —_

unitj^"

Buckle SW

W7i

0

o

o

0

o

0

o

o

o

a

Q

u

n

dD

IG key

illumination light

[ Interior light

(f)

(f) (|)

teesy

J

cF Seat belt warning light

o o o 0 o o o

•a-

o o o o o o o

15-42

86U15X-073

Page 1698 of 1865

CENTRAL PROCESSING UNIT (CPU) 1 5

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Disconnect the CPU connectors.

3. Release the lock and remove the CPU from the

joint box.

4. Install in the reverse order of removal.

ON-VEHICLE INSPECTION

Note: Check the voltage between "a through

I" terminal and ground.

Check the continuity between "m,

n" terminal and ground.

86U15X-075

Terminal Connecting

to

Measurement condition Measurement value

a Interior light and courtesy lights Any time Approx.

12V

b Batterv Anv time Approx.

12V

c No used

— —

d Ground Anv time OV

e Seat belt warning light Ignition switch

ON

Approx.

12V

f Enaine control unit Enaine runnina Approx.

12V

g Key cylinder illumination light Any time Approx.

12V

i Key reminder switch Insert the key into the cylinder

Pull out the key from the cylinder

Approx.

12V

OV

j Ignition switch (ON) Ignition switch

ON

Ignition switch OFF

or

ACC

Approx.

12V

OV

k Ignition switch (ACC) Ignition switch

ON or

ACC

Ignition switch OFF

Approx.

12V

OV

I Light switch (In the combination switch) Turn the light switch ACC and

ON

Light switch OFF

Approx.

12V

OV

m Seat belt switch Seat belt fastened

Seat belt unfastered

OQ

OO

n Door switch Door closed

Door open

OO

on

76G15X-009

15—43

Page 1699 of 1865

1 5 TURN AND HAZARD LIGHT

TURN AND HAZARD LIGHT

STRUCTURAL VIEW

86U15X-077

15—44

Page 1700 of 1865

TURN AND HAZARD LIGHT 1 5

CIRCUIT DIAGRAM

86U15X-078

15—45

Trending: manual transmission, compression ratio, alarm, open gas tank, fog light, steering, Catalytic