check oil MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 79 of 1865

DISASSEMBLY (CYLINDER BLOCK) 1 A

Main bearing cap

Before removing the main bearing caps, clean the

bearings, main journals, and caps, and measure the

following points.

1. Crankshaft end play. (Refer to page 1A—66.)

2. Main journal oil clearance. (Refer to page

1

A—65.)

76G01A-054

Pilot bearing (MTX)

Remove the pilot bearing from the crankshaft with the

SST.

86U01X-076

Piston and connecting rod

1. Before disassembling the piston and connecting

rod, check the oscillation torque as shown in the

figure.

If the large end does not drop by its own weight,

replace the piston or the piston pin.

79G01C-050

2. Remove the piston pin with the SST.

While removing the piston pin, check the pressure.

If it is lower than 5kN (500kg, 1,100 lb), replace

the piston pin or connecting rod.

76G01A-139

1A—47

Page 80 of 1865

INSPECTION AND REPAIR 1 A

INSPECTION AND REPAIR

1. Clean all parts, taking care to remove any gasket fragments, dirt, oil or grease, carbon, moisture

residue, or other foreign materials.

2. Inspect and repair must be performed in the order specified.

Caution

Be careful not to damage the joints or friction surfaces of aluminum alloy components (such

as the cylinder head or pistons).

86U01X-077

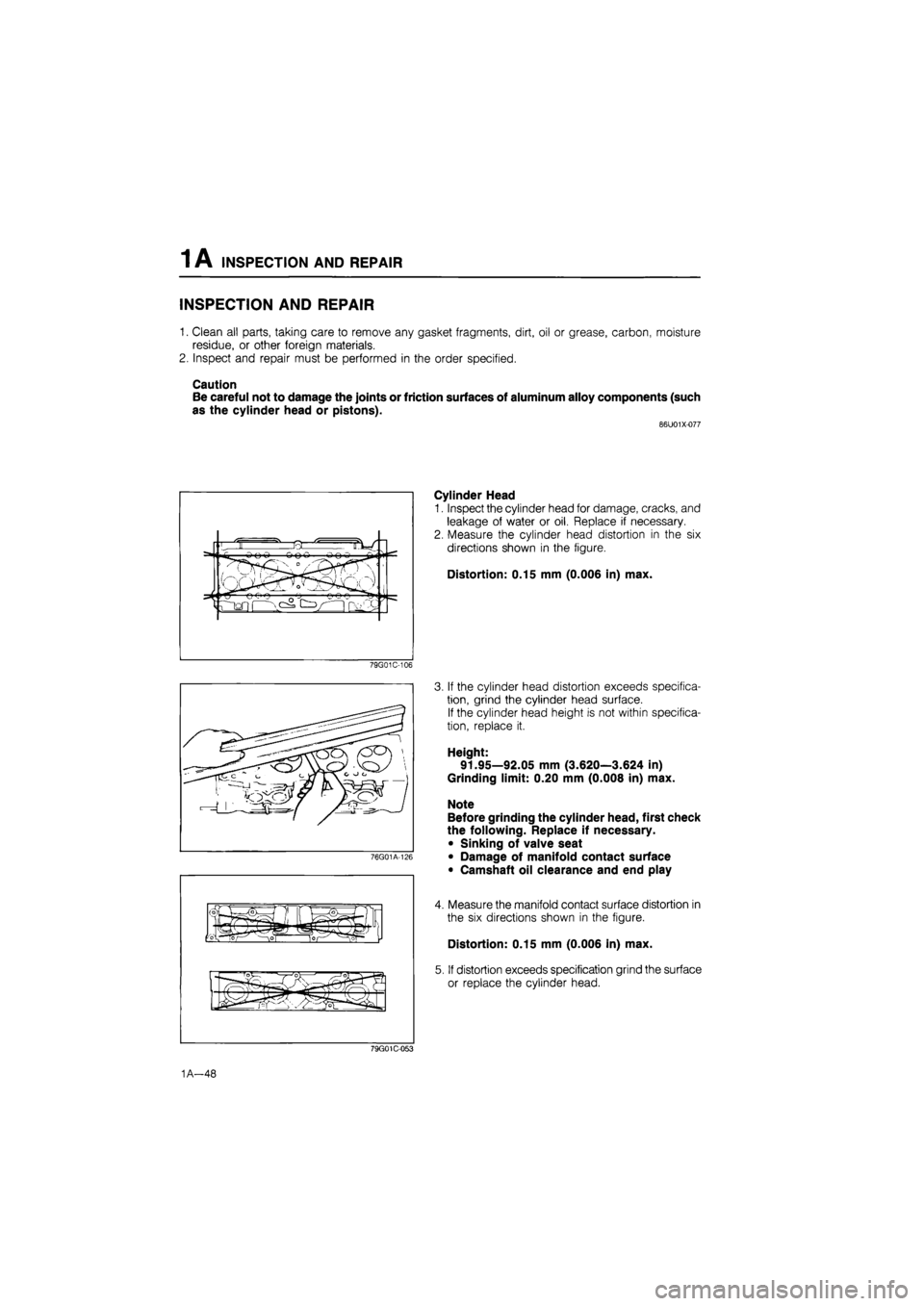

Cylinder Head

1. Inspect the cylinder head for damage, cracks, and

leakage of water or oil. Replace if necessary.

2. Measure the cylinder head distortion in the six

directions shown in the figure.

Distortion: 0.15 mm (0.006 in) max.

79G01C-106

If the cylinder head distortion exceeds specifica-

tion, grind the cylinder head surface.

If the cylinder head height is not within specifica-

tion, replace it.

Height:

91.95—92.05 mm (3.620—3.624 in)

Grinding limit: 0.20 mm (0.008 in) max.

Note

Before grinding the cylinder head, first check

the following. Replace if necessary.

• Sinking of valve seat

• Damage of manifold contact surface

• Camshaft oil clearance and end play

Measure the manifold contact surface distortion in

the six directions shown in the figure.

Distortion: 0.15 mm (0.006 in) max.

If distortion exceeds specification grind the surface

or replace the cylinder head.

79G01C-053

1A—48

Page 86 of 1865

INSPECTION AND REPAIR 1 A

mjjm

H D f IT~inr

86U01X-095

5. Measure the oil clearance of the camshaft and

camshaft caps.

(1) Remove any oil, or dirt from the journals and

bearing surface.

(2) Set the camshaft onto the cylinder head.

(3) Position plasti-gauge on top of the journals in

the axial direction.

(4) Place the camshaft caps and rocker arm shafts

in position, and tighten them to the specified

torque.

Tightening torque:

18—26

N

m (1.8—2.7 m-kg, 13—20 ft-lb)

(5) Remove the camshaft caps and measure the

oil clearance at each cap.

Oil clearance

Front and rear:

0.035—0.085 mm (0.0014—0.0033 in)

Center three journals:

0.065—0.115 mm (0.0026—0.0045 in)

Maximum: 0.15 mm (0.0059 in)

(6) If the oil clearance exceeds the maximum, re-

place the cylinder head.

86U01X-096

6. Measure the camshaft end play. If it exceeds the

maximum, replace the camshaft and/or the cylin-

der head.

End play:

0.08—0.16 mm (0.003—0.006 in)

Maximum: 0.20 mm (0.008 in)

86U01X-097

76G01A-131

1A—54

Rocker Arm and Rocker Arm Shaft

1. Check for wear or damage to the contact surface

of the rocker arm shaft and the rocker arm. Re-

place if necessary.

2. Check the oil clearance between the rocker arm

and shaft. Replace if necessary.

(1) Measure the rocker arm inner diameter.

Diameter:

19.000—19.033 mm (0.7480—0.7493 in)

...12-valve

16.000—16.027 mm (0.6299—0.6310 in)

... 8-valve

Page 87 of 1865

INSPECTION AND REPAIR 1 A

76G01A-065

76G01A-066

86U01X-100

(2) Measure the rocker arm shaft diameter.

Diameter:

18.959—18.980 mm (0.7464—0.7472 in)

...12 valve

15.966—15.984 mm (0.6286—0.6293 in)

... 8 valve

(3) Subtract the shaft diameter from the rocker arm

diameter.

Oil clearance mm (in)

Standard Maximum

12-valve 0.020-0.074

(0.0008-0.0029) 0.10 (0.0039)

8-valve 0.016-0.061 (0.0006-0.0024) 0.10 (0.0039)

Hydraulic Lash Adjuster (12-valve)

Check the HLA face for wear or damage. Replace

if necessary.

Caution

Do not remove the HLA unless necessary to

prevent damaging the O-ring.

Cylinder Block

1. Check the cylinder block. Repair or replace if

necessary.

(1) Leakage damage

(2) Cracks

(3) Scoring of wall

2. Measure the distortion of the top surface of the cyl-

inder block in the six directions as shown in the

figure.

Distortion: 0.15 mm (0.006 in) max.

3. If the distortion exceeds the maximum, repair by

grinding, or replace the cylinder block.

Grinding limit: 0.20 mm (0.008 in) max.

86U01X-117

1A—55

Page 89 of 1865

INSPECTION AND REPAIR 1A

76G01A-068

Piston

1. Inspect the outer circumferences of all pistons for

seizure or scoring. Replace if necessary.

2. Measure the outer diameter of each piston at a right

angle (90°) to the piston pin, 18 mm (0.709 in)

below the oil ring land lower edge.

Piston diameter mm (in)

Size Diameter

LU

OO LL LL Standard 85.944-85.964 (3.3836-3.3844)

LU

OO LL LL 0.25 (0.010) oversize 86.194-86.214 (3.3935-3.3942)

LU

OO LL LL

0.50 (0.020) oversize 86 444-86.464 (3.4033-3.4041)

F6

Standard 80 944-80.964 (3.1868-3.1876)

F6

0.25 (0.010) oversize 81.194-81.214 (3.1966-3.1974)

F6 0.50 (0.020) oversize 81.444-81.464 (3.2065-3.2072) F6

0.75 (0.030) oversize 81.694-81.714 (3.2163-3.2171)

F6

1.00 (0.039) oversize 81.944-81.964 (3.2261-3,2269)

3. Check the piston to cylinder clearance.

ClGdrsncG1

0.036—0.075 mm (0.0014—0.0030 in)

Maximum: 0.15 mm (0.0059 in)

4. If the clearance exceeds the maximum, replace the

piston or rebore the cylinders to fit oversize pistons.

Caution

If the piston is replaced, replace the piston

rings also.

76G01A-130

Piston and Piston Ring

1. Measure the piston ring to ring land clearance

around the entire circumference using a new pis-

ton ring.

Clearance (Top and Second):

0.03—0.07 mm (0.001—0.003 in)

Maximum: 0.15 mm (0.006 in)

2. If the clearance exceeds the maximum, replace the

piston.

69G01A-125

1A—57

Page 91 of 1865

INSPECTION AND REPAIR 1 A

76G01A-070

76G01A-071

86U01X-109

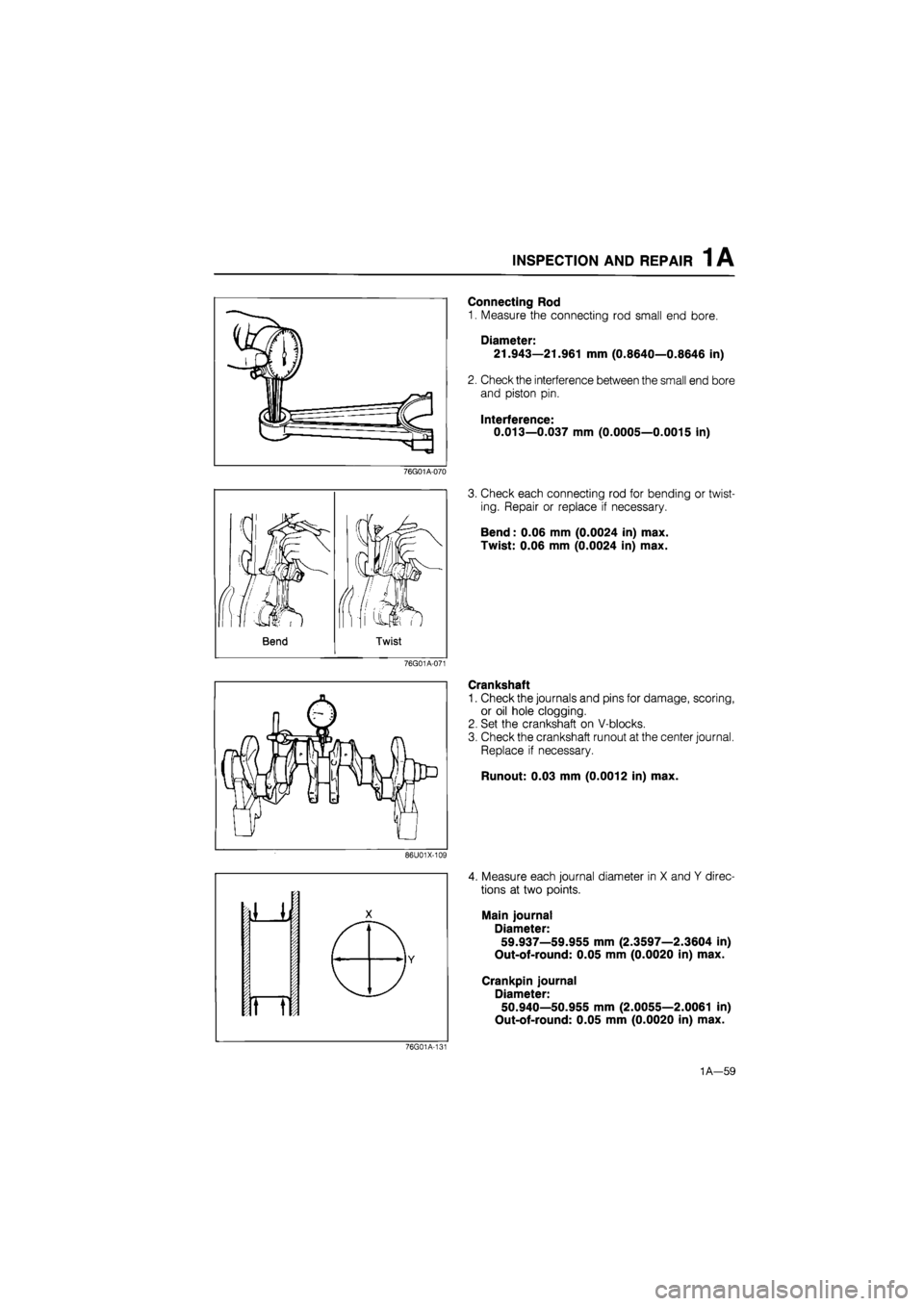

Connecting Rod

1. Measure the connecting rod small end bore.

Diameter: 21.943—21.961 mm (0.8640—0.8646 in)

2. Check the interference between the small end bore

and piston pin.

Interference:

0.013—0.037 mm (0.0005—0.0015 in)

3. Check each connecting rod for bending or twist-

ing. Repair or replace if necessary.

Bend: 0.06 mm (0.0024 in) max.

Twist: 0.06 mm (0.0024 in) max.

Crankshaft

1. Check the journals and pins for damage, scoring,

or oil hole clogging.

2. Set the crankshaft on V-blocks.

3. Check the crankshaft runout at the center journal.

Replace if necessary.

Runout: 0.03 mm (0.0012 in) max.

4. Measure each journal diameter in X and Y direc-

tions at two points.

Main journal

Diameter:

59.937—59.955 mm (2.3597—2.3604 in)

Out-of-round: 0.05 mm (0.0020 in) max.

Crankpin journal

Diameter:

50.940—50.955 mm (2.0055—2.0061 in)

Out-of-round: 0.05 mm (0.0020 in) max.

76G01A-131

1A—59

Page 92 of 1865

INSPECTION AND REPAIR 1 A

Crankpin

,/f

Main journal

76G01A-132

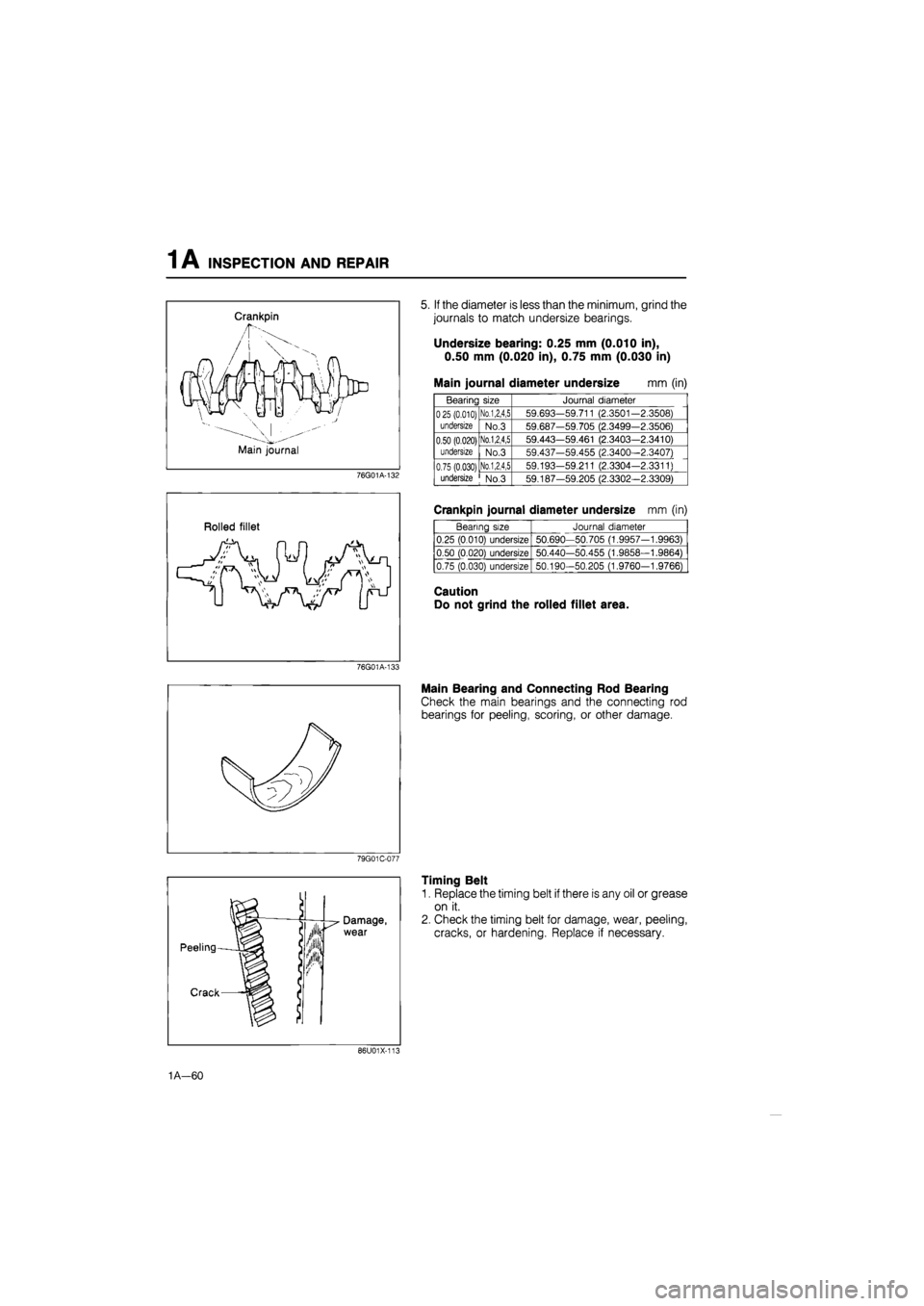

5. If the diameter is less than the minimum, grind the

journals to match undersize bearings.

Undersize bearing: 0.25 mm (0.010 in),

0.50 mm (0.020 in), 0.75 mm (0.030 in)

Main journal diameter undersize mm (in)

Bearing size Journal diameter

025 (0.010)

undersize

No.1,2,4,5 59.693-59.711 (2.3501-2.3508) 025 (0.010)

undersize No.3 59.687-59.705 (2.3499-2.3506)

0.50 (0.020)

undersize

No.1,2,4,5 59.443-59.461 (2.3403—2.3410) 0.50 (0.020)

undersize No.3 59.437-59.455 (2.3400—2.3407)

0.75 (0.030) undersize

No.1,2,4,5 59.193-59.211 (2.3304-2.3311) 0.75 (0.030) undersize No.3 59.187-59.205 (2.3302-2.3309)

Rolled fillet

Crankpin journal diameter undersize mm (in)

Bearing size Journal diameter

0.25 (0.010) undersize 50.690—50.705 (1.9957-1.9963)

0.50 (0.020) undersize 50.440-50.455 (1.9858—1.9864)

0.75 (0.030) undersize 50.190-50.205 (1.9760-1.9766)

Caution

Do not grind the rolled fillet area.

76G01A-133

Main Bearing and Connecting Rod Bearing

Check the main bearings and the connecting rod

bearings for peeling, scoring, or other damage.

79G01C-077

Timing Belt

1. Replace the timing belt if there is any oil or grease

on it.

2. Check the timing belt for damage, wear, peeling,

cracks, or hardening. Replace if necessary.

86U01X-117

1A—60

Page 93 of 1865

INSPECTION AND REPAIR 1 A

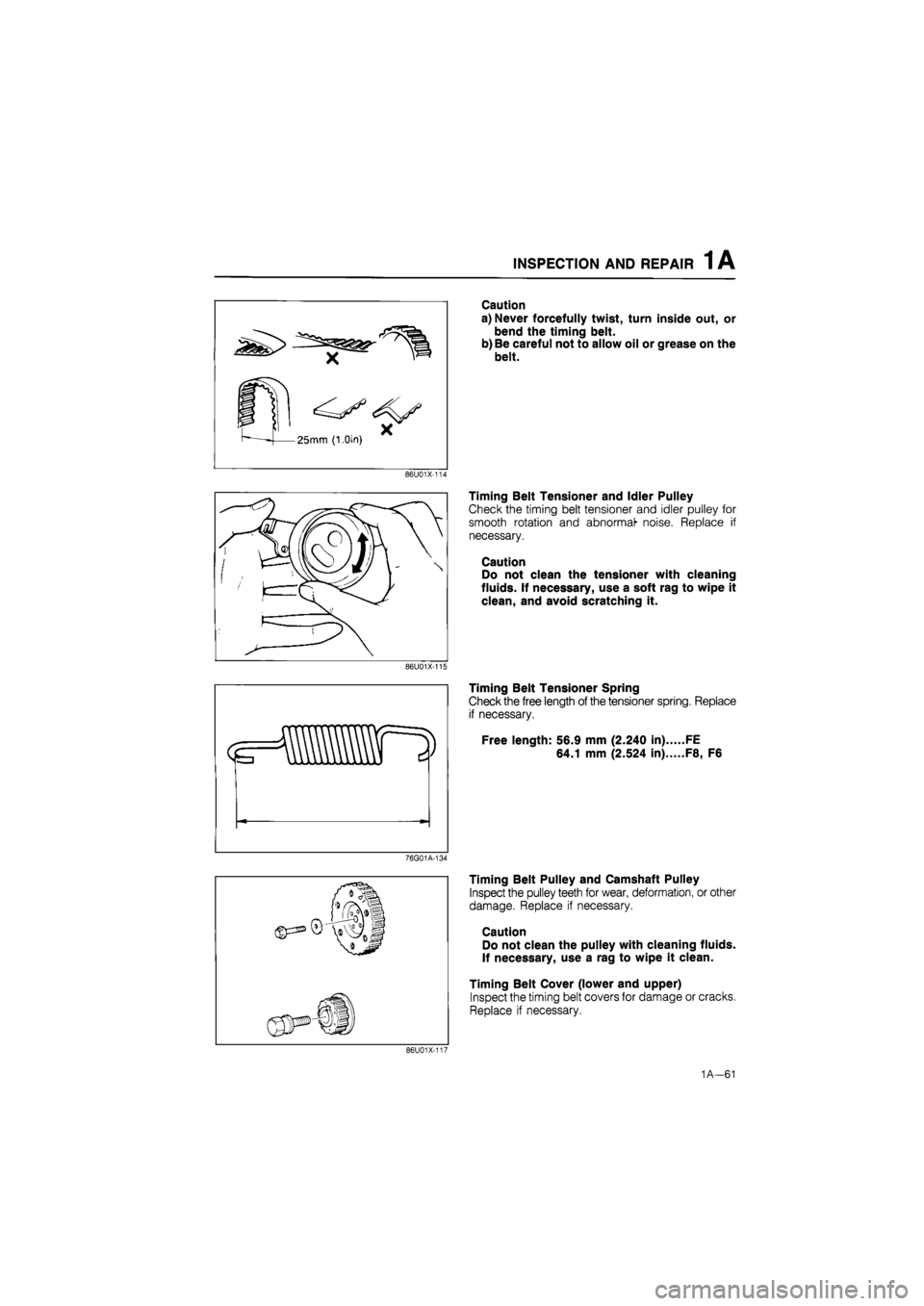

Caution

a) Never forcefully twist, turn inside out, or

bend the timing belt.

b) Be careful not to allow oil or grease on the

belt.

86U01X-114

Timing Belt Tensioner and Idler Pulley

Check the timing belt tensioner and idler pulley for

smooth rotation and abnormal- noise. Replace if

necessary.

Caution

Do not clean the tensioner with cleaning

fluids. If necessary, use a soft rag to wipe it

clean, and avoid scratching it.

86U01X-115

Timing Belt Tensioner Spring

Check the free length of the tensioner spring. Replace

if necessary.

Free length: 56.9 mm (2.240 in) FE

64.1 mm (2.524 in) F8, F6

76G01A-134

Timing Belt Pulley and Camshaft Pulley

Inspect the pulley teeth for wear, deformation, or other

damage. Replace if necessary.

Caution

Do not clean the pulley with cleaning fluids.

If necessary, use a rag to wipe it clean.

Timing Belt Cover (lower and upper)

Inspect the timing belt covers for damage or cracks.

Replace if necessary.

86U01X-117

1A—61

Page 95 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 A

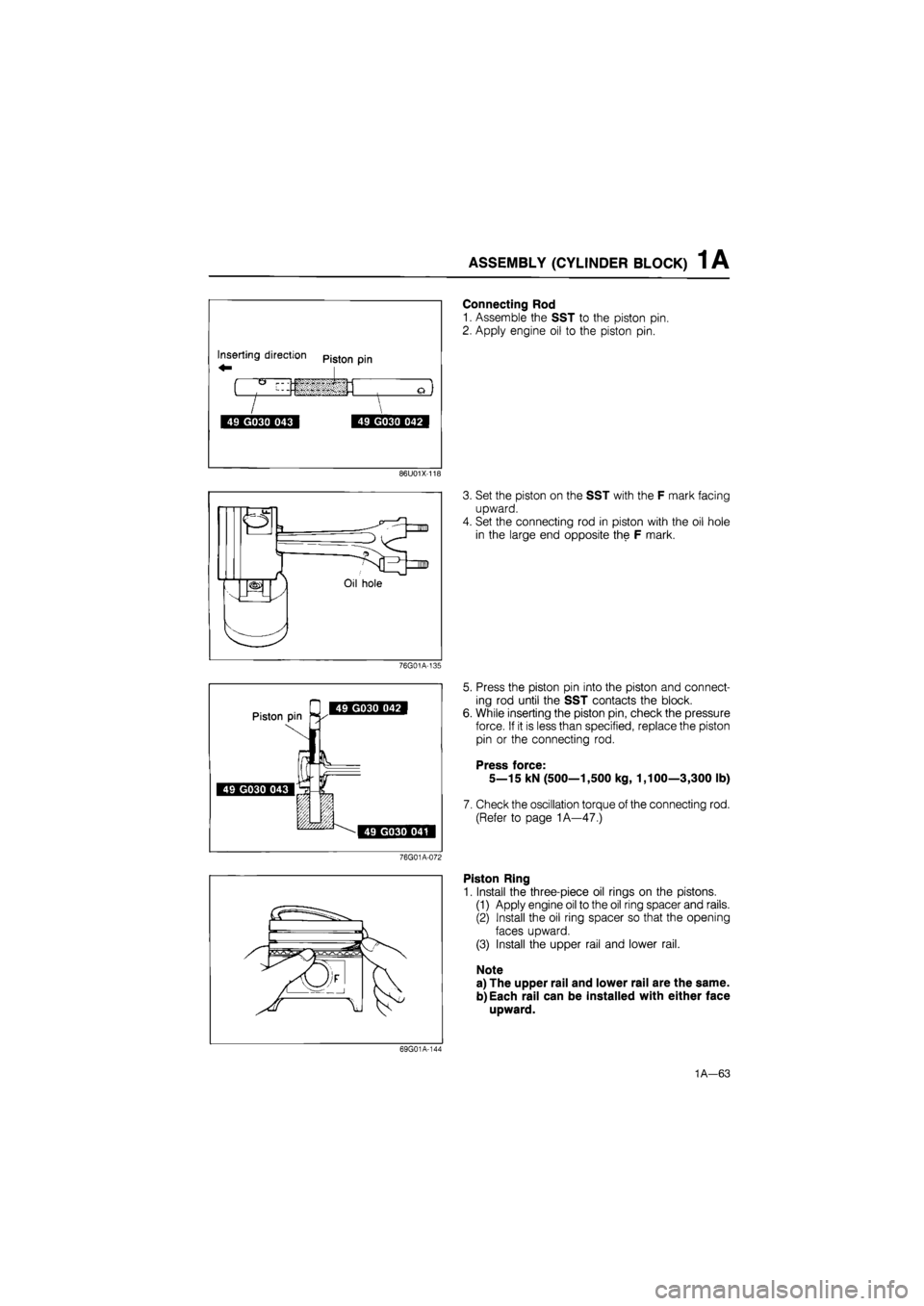

Connecting Rod

1. Assemble the SST to the piston pin.

2. Apply engine oil to the piston pin.

86U01X-118

3. Set the piston on the SST with the F mark facing

upward.

4. Set the connecting rod in piston with the oil hole

in the large end opposite the F mark.

76G01A-135

5. Press the piston pin into the piston and connect-

ing rod until the SST contacts the block.

While inserting the piston pin, check the pressure

force. If it is less than specified, replace the piston

pin or the connecting rod.

Press force:

5—15 kN (500—1,500 kg, 1,100—3,300 lb)

Check the oscillation torque of the connecting rod.

(Refer to page 1A—47.)

76G01A-072

Piston Ring

1. Install the three-piece oil rings on the pistons.

(1) Apply engine oil to the oil ring spacer and rails.

(2) Install the oil ring spacer so that the opening

faces upward.

(3) Install the upper rail and lower rail.

Note

a) The upper rail and lower rail are the same.

b) Each rail can be installed with either face

upward.

69G01A-144

1A—63

Page 96 of 1865

1 A ASSEMBLY (CYLINDER BLOCK)

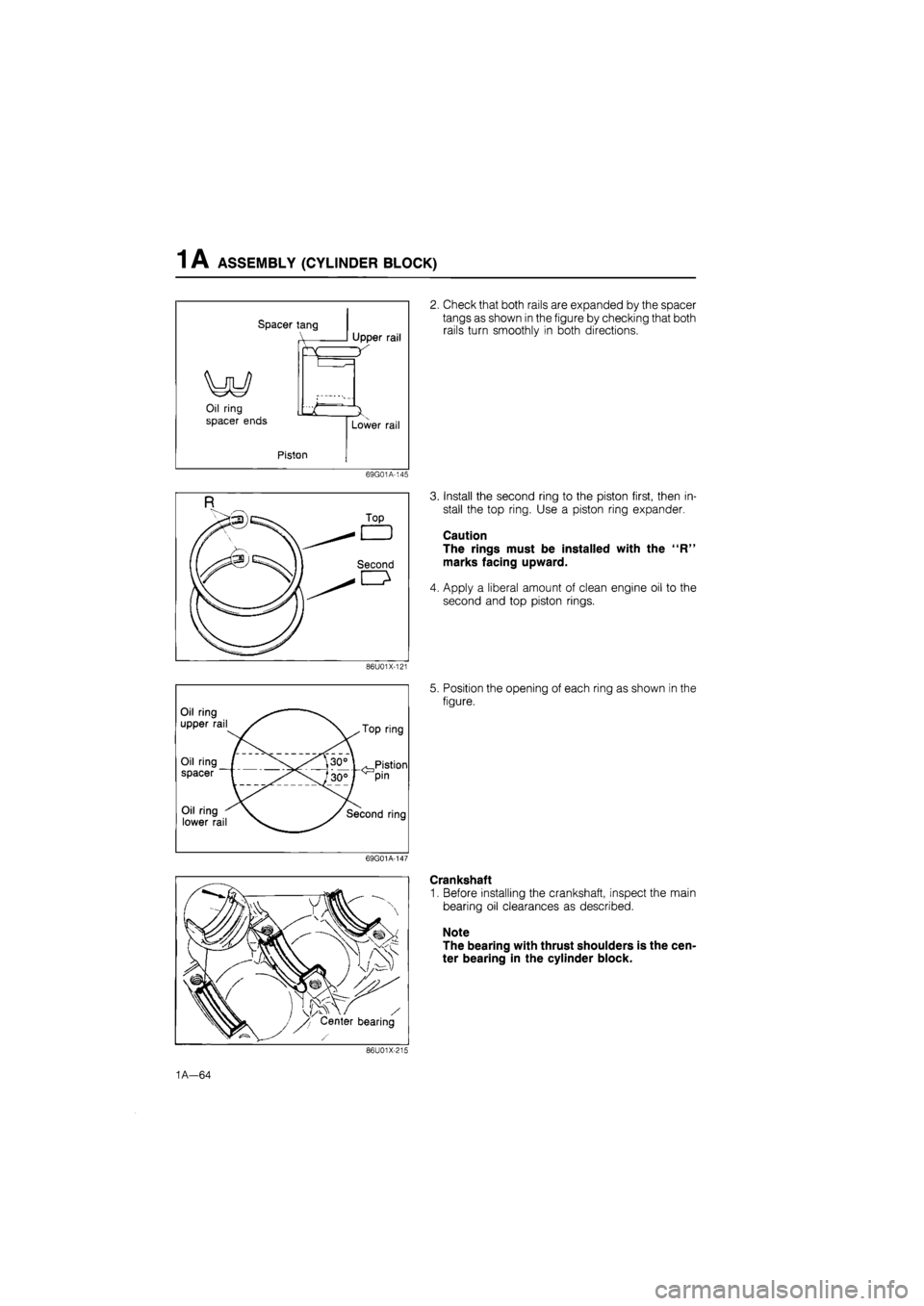

Spacer iang

Oil ring

spacer ends

Upper rail

Piston

Lower rail

69G01A-145

86U01X-121

Oil ring —

upper rail f .Top ring

Oil ring (

spacer r \30° \ . Pistion

^-^/ao0F pin

Oil ring

lower rail /Second ring

69G01A-147

2. Check that both rails are expanded by the spacer

tangs as shown in the figure by checking that both

rails turn smoothly in both directions.

3. Install the second ring to the piston first, then in-

stall the top ring. Use a piston ring expander.

Caution

The rings must be installed with the "R"

marks facing upward.

4. Apply a liberal amount of clean engine oil to the

second and top piston rings.

5. Position the opening of each ring as shown in the

figure.

Crankshaft

1. Before installing the crankshaft, inspect the main

bearing oil clearances as described.

Note

The bearing with thrust shoulders is the cen-

ter bearing in the cylinder block.

86U01X-136

1A—64