check oil MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 271 of 1865

INSPECTION AND REPAIR 1C

4. Check each connecting rod for bending or twist-

ing. Repair or replace if necessary.

Bend:

0.080 mm (0.0031 in) max.

/50 mm (1.969 in)

Twist:

0.080 mm (0.0031 in) max.

/50 mm (1.969 in)

76G01C-141

Crankshaft

1. Check the journals and pins for damage, scoring,

or oil hole clogging.

2. Set the crankshaft on V-blocks.

3. Check the crankshaft runout at the center journal.

Replace if necessary.

Runout: 0.05 mm (0.002 in) max.

76G01C-142

76G01C-143

Crankpin

Main journal

4. Measure each journal diameter in X and Y direc-

tions at two points.

Main journal

Diameter:

59.937—59.955 mm (2.3597—2.3604 in)

Minimum: 59.89 mm (2.358 in)

Out-of-round: 0.05 mm (0.002 in) max.

Crankpin journal

Diameter:

50.940—50.955 mm (2.0055—2.0061 in)

Minimum: 50.89 mm (2.004 in)

Out-of-round: 0.05 mm (0.002 in) max.

5. If the diameter is less than the minimum, grind the

journals to match undersize bearings.

Undersize bearing: 0.25 mm (0.010 in),

0.50 mm (0.020 in), 0.75 mm (0.030)

Main journal diameter undersize mm (in)

Bearing size Journal diameter

0.25 undersize 59.687-59.705 (2.3499—2.3506)

0.50 undersize 59.437-59.455 (2.3400-2.3407)

0.75 undersize 59.187-59.205 (2.3302-2.3309)

76G01C-144

1C-59

Page 272 of 1865

1C INSPECTION AND REPAIR

Rolled fillet

Crankpin journal diameter undersize mm (in)

Bearing size Journal diameter

0.25 undersize 50.690—50.705 (1.9957-1.9963)

0.50 undersize 50.440—50.455 (1.9858-1.9864)

0.75 undersize 50.190-50.205 (1.9760-1.9766)

Caution

Do not grind the rolled fillet area.

76G01C-145

Main Bearing and Connecting Rod Bearing

Check the main bearings and the connecting rod

bearings for peeling, scoring, or other damage.

79G01C-077

Timing Belt

1. Replace the timing belt if there is any oil or grease

on it.

2. Check the timing belt for damage, wear, peeling,

cracks, or hardening. Replace if necessary.

86U01X-113

Caution

a) Never forcefully twist, turn inside out, or

bend the timing belt.

b) Be careful not to allow oil or grease on the

belt.

86U01X-114

1C—60

Page 277 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

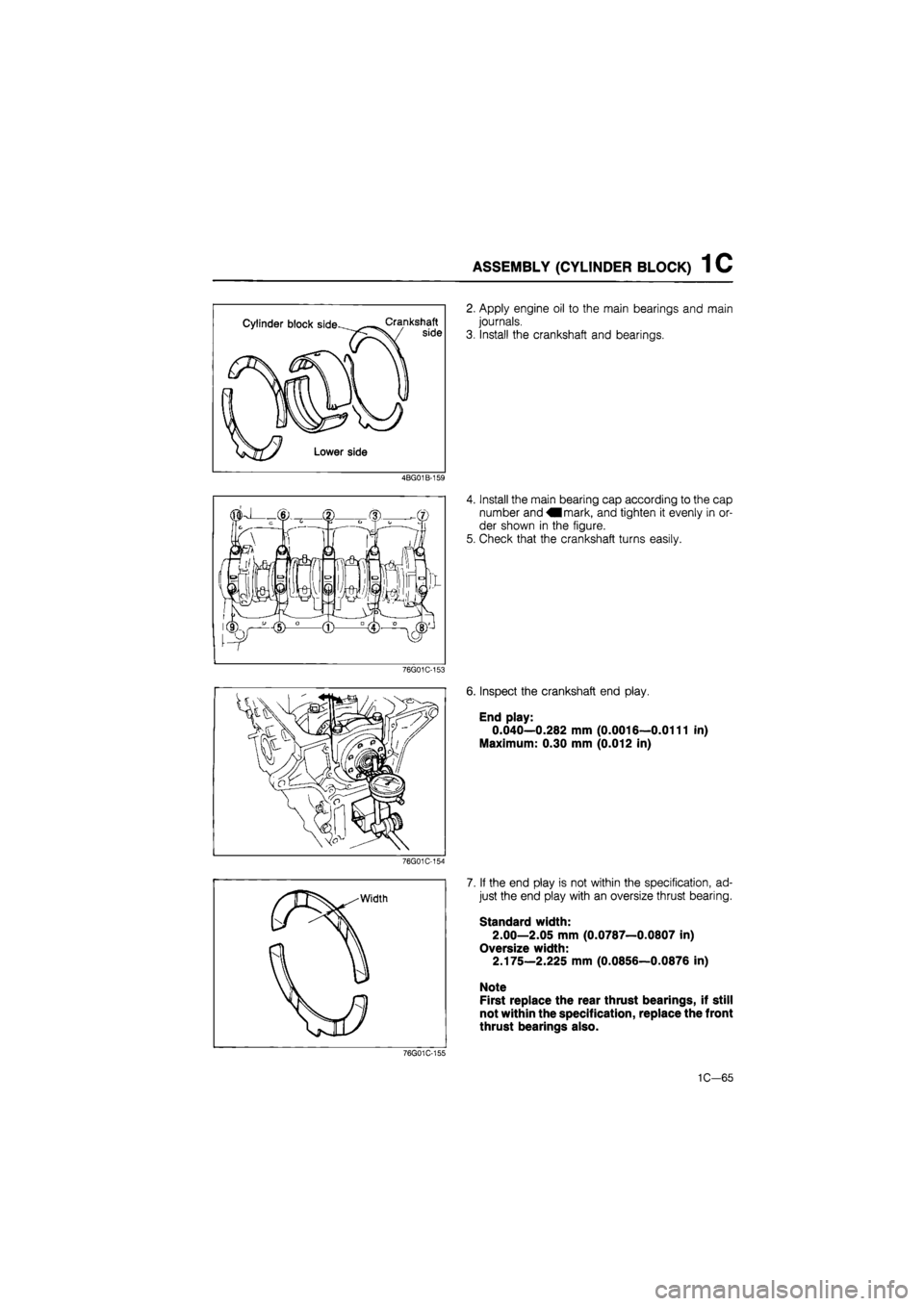

Cylinder block side Crankshaft side

Lower side

4BG01B-159

2. Apply engine oil to the main bearings and main

journals.

3. Install the crankshaft and bearings.

4. Install the main bearing cap according to the cap

number and mark, and tighten it evenly in or-

der shown in the figure.

5. Check that the crankshaft turns easily.

76G01C-153

6. Inspect the crankshaft end play.

End play:

0.040—0.282 mm (0.0016—0.0111 in)

Maximum: 0.30 mm (0.012 in)

76G01C-154

76G01C-155

7. If the end play is not within the specification, ad-

just the end play with an oversize thrust bearing.

Standard width:

2.00—2.05 mm (0.0787—0.0807 in)

Oversize width:

2.175—2.225 mm (0.0856—0.0876 in)

Note

First replace the rear thrust bearings, if still

not within the specification, replace the front

thrust bearings also.

1C-65

Page 278 of 1865

1C ASSEMBLY (CYLINDER BLOCK)

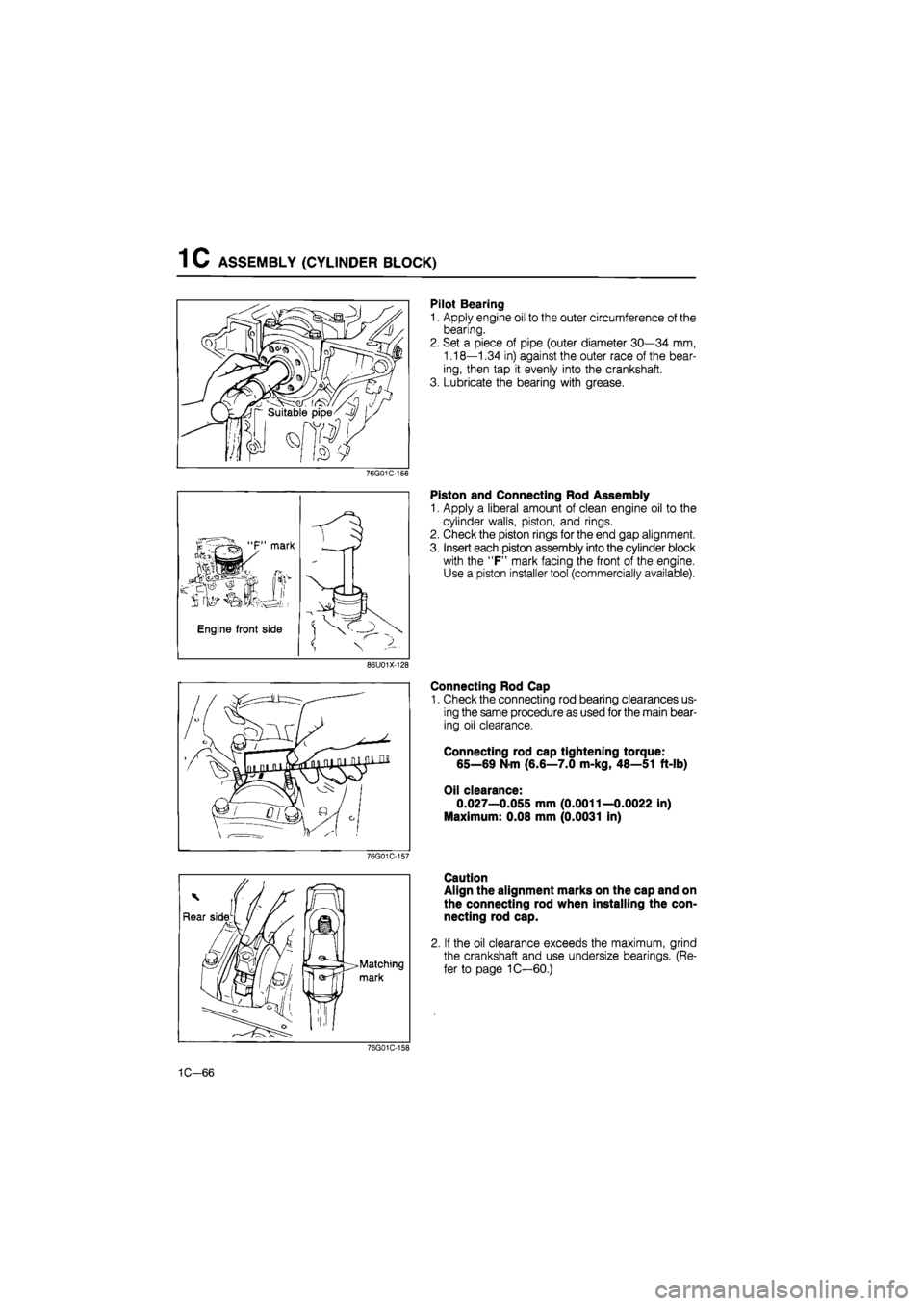

Pilot Bearing

1. Apply engine oil to the outer circumference of the

bearing.

2. Set a piece of pipe (outer diameter 30—34 mm,

1.18—1.34 in) against the outer race of the bear-

ing, then tap it evenly into the crankshaft.

3. Lubricate the bearing with grease.

76G01C-156

Piston and Connecting Rod Assembly

1. Apply a liberal amount of clean engine oil to the

cylinder walls, piston, and rings.

2. Check the piston rings for the end gap alignment.

3. Insert each piston assembly into the cylinder block

with the "F" mark facing the front of the engine.

Use a piston installer tool (commercially available).

86U01X-128

Connecting Rod Cap

1. Check the connecting rod bearing clearances us-

ing the same procedure as used for the main bear-

ing oil clearance.

Connecting rod cap tightening torque:

65—69 N-m (6.6—7.0 m-kg, 48—51 ft-lb)

Oil clearance:

0.027—0.055 mm (0.0011—0.0022 in)

Maximum: 0.08 mm (0.0031 in)

76G01C-157

Caution

Align the alignment marks on the cap and on

the connecting rod when installing the con-

necting rod cap.

If the oil clearance exceeds the maximum, grind

the crankshaft and use undersize bearings. (Re-

fer to page 1C—60.)

76G01C-158

1C-66

Page 279 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 C

3. Check the side clearance of each connecting rod

without the cap installed.

Side clearance:

0.11—0.262 mm (0.0043—0.0103 in)

Maximum: 0.30 mm (0.012 in)

If the clearance exceeds the maximum, replace the

connecting rod.

76G01C-159

4. Apply a liberal amount of engine oil to the crank-

pin journal and connecting rod bearing.

5. Install the connecting rod cap with the alignment

marks aligned.

Tightening torque:

65—69 Nm (6.6—7.0 m-kg, 48—51 ft-lb)

86U01X-130

Oil jet

Install the oil jet into the cylinder block.

Tightening torque: 12—18 N-m

(1.2—1.8 m-kg, 104—156 in-lb)

76G01C-160

1C-67

Page 295 of 1865

ASSEMBLY (TIMING BELT) 1 C

63G01D-431

76G01C-191

76G01C-192

Timing Belt Tensioner

1. Install the tensioner spring onto the tensioner.

2. Install the tensioner assembly.

3. Temporarily secure it so the tensioner is shifted

outward.

Timing Belt

1. Return the crankshaft about 45° to the timing mark

on the oil pump housing.

2. Check that the timing marks of the camshaft pul-

ley and the injection pump pulley align with the tim-

ing marks on the seal plate.

3. Install the timing belt in the sequence shown in the

figure.

Caution

The timing belt must be reinstalled in the same

direction of rotation for continued durability.

76G01C-200

1C—83

Page 311 of 1865

INSTALLATION 1C

Accelerator Cable

Install the accelerator cable.

76G01C-235

76G01C-236

Engine Oil

Add the specified amount and type of engine oil. (Re-

fer to Section 2B)

Coolant

Close the drain plug, fill the radiator and reservoir tank

with the specified amount and type of coolant. (Re-

fer to Section 3B)

Check Engine Condition

1. Check for leaks.

2. Perform engine adjustments if necessary.

3. Perform a road test.

4. Recheck the oil and coolant levels.

1C—99

Page 316 of 1865

INSPECTION, ENGINE OIL 2A

86U02X-004

INSPECTION

ENGINE OIL

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temper-

ature and stop it.

3. Wait for five minutes.

4. Remove the oil level gauge and check the oil lev-

el and condition.

5. Add or replace oil if necessary.

Note

The distance between the L and F marks on

the level gauge represents 1.0 liter (1.06 US

qt, 0.88 Imp qt).

OIL PRESSURE

1. Remove the oil pressure switch.

69G02A-006

76G02A-005

86U02X-006

2. Screw the SST into the pressure switch installa-

tion hole.

3. Warm up the engine to normal operating tem-

perature.

4. Run the engine at 3,000 rpm, and note the gauge

reading.

Oil pressure:

343—441 kPa

(3.5—4.5 kg/cm2, 50—64 psi)...DOHC 2g4 392 kPa

(3.0—4.0 kg/cm2, 43—57 psi)...SOHC

5. If the pressure is not as specified, check for the

cause, and repair if necessary.

(Refer to Troubleshooting Guide.)

ENGINE OIL

REPLACEMENT

1. Warm up the engine to the normal operating tem-

perature and stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

Warning

Be careful when draining, the oil is very hot.

2A-5

Page 317 of 1865

2A OIL FILTER, OIL COOLER

j

F

k

4

4. Install the drain plug and a new gasket.

5. Refill the engine with the specified type and amount

of oil.

6. Refit the oil filler cap.

Oil pan capacity:

3.6 liters (3.8 US qt, 3.2 Imp qt)

7. Recheck the oil level after the engine has been run.

76G02A-006

TbJ

r

86U02X-008

76G02A-007

0

A

if \ lO

/O

f \ 11 • V jJ

VJ f .fa,-

n D

©

76G02A-008

OIL FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface

on the engine.

3. Apply a small amount of engine oil to the rubber

seal of the new filter.

Warning

Be careful that the engine and filter are very

hot.

4. (DOHC)

Install the oil filter until the rubber seal contacts the

base and then tighten the filter

1

and

1

/6 turn with

a wrench.

(SOHC)

Install the oil filter and tighten it by hand only. Do

not use a wrench.

5. Start the engine and inspect around the filter seal

for leaks.

6. Check the oil level and add oil if necessary.

Oil filter capacity:

0.20 liters (0.21 US qt, 0.18 Imp qt)...DOHC

0.30 liters (0.32 US qt, 0.26 Imp qt)...SOHC

OIL

COOLER

(DOHC, 12-valve,

ECE

8-valve)

REMOVAL AND INSTALLATION

Remove in the sequence shown in the figure.

Install in the reverse order of removal.

1. Water hose

2. Oil filter

3. Nut

4. Oil cooler

Nut tightening torque:

29—39

N

m (3.0—4.0 m-kg, 22—29 ft-lb)

2A-6

Page 319 of 1865

2A OIL PAN

4BG02X-037

76G02A-013

76G02A-014

(SOHC)

1. Remove the oil pan mounting bolts.

2. Insert a scraper or a suitable tool between the oil

pan and the stiffener or the cylinder block to sep-

arate them.

3. Remove the oil pan.

Caution

Do not bend the oil pan when prying loose.

INSPECTION

Check the following points. Repair or replace if

necessary.

1. Cracks, deformation, damage

2. Damaged drain plug threads

INSTALLATION

Install in the reverse order of removal referring to the

installation note.

Installation Note

Stiffener (FE 8-valve...only ECE, 12-valve)

1. Remove any dirt or other material from the con-

tact surface.

2. Apply silicon sealant to the stiffener around inside

of the bolt holes and overlap the ends.

3. Install the stiffener.

Tightening torque:

7—12 Nm (70—120 cm-kg, 61—104 in-lb)

Oil pan

1. Apply silicon sealant to the oil pan around inside

of the bolt holes and overlap the ends.

2. Install the oil pan.

Tightening torque:

7—12 Nm (70—120 cm-kg, 61—104 in-lb)

Caution (DOHC)

Oil pan projection and recession from the end

of the cylinder block must not be more than

1.5 mm (0.06 in).

2A—8