steering wheel MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 569 of 1865

4C OUTLINE

SPECIFICATIONS

Item Engine type Unleaded Fuel Leaded Fuel

Idle speed rpm 750 ± 50

Throttle body

Type Horizontal draft (2-barrel)

Throat diameter mm (in) No. 1 46 (1.8) Throat diameter mm (in) No. 2 40 (1.6)

Fuel pump

Type Impeller (in tank)

Output pressure kPa (kg/cm2, psi) Main pump: 441-588 (4.5—6.0, 64—85) Transfer pump: 20—25 (0.20—0.25, 2.8—3.6)

Feeding capacity cc (cu in)/10 sec. Main pump: More than 220 (13.4) Transfer pump: More than 190 (11.6)

Fuel filter

Type Low pressure side Nylon element Type High pressure side Paper element

Pressure regulator

Type Diaphragm

Regulating pressure kPa (kg/cm2, psi) 235-275 (2.4 -2.8, 34-40)

Injector

Type High-ohmic

Type of drive Voltage

Resistance G 12--16

Injection amount cc (cu in)/15 sec. 66-91 (4.03-5.55)

Idle speed control valve

Solenoid resistance a 6.3--9.9

Fuel tank

Capacity liters (US gal, Imp gal) 60 (15.9, 13.2), 57 (15.0, 12.5): 4-wheel steering vehicle

Air cleaner

Element type Dry

Fuel

Specification Unleaded (95 RON or more) Leaded or unleaded fuel

(95 RON or more)

76G04C-008

4C-8

Page 606 of 1865

ISC SYSTEM 4C

COMPONENT DESCRIPTION

Component Function Remark

A/C switch Detects air conditioner operation; sends

signal to engine control unit Switch ON when air conditioner

operating

Air valve When cold, supplies bypass air into dy-namic chamber • Engine speed increased to shorten warm-up period • Thermo wax type

• Installed in BAC valve

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

E/L control unit Detects that E/L is being applied; sends

signal to engine control unit

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Idle speed control)

Idle switch Detects when throttle valve fully closed;

sends signal to engine control unit

Installed on throttle body

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

P/S pressure switch Detects P/S operation; sends signal to engine control unit Switch ON when steering wheel turned right or left

Solenoid valve (Idle speed control) Controls bypass air amount • Controlled by duty signal from engine control unit • Installed in BAC valve

• Operates idle-up

Test connector For initial idle speed adjustment • Gerrn, 1-pin

• Idle speed feedback control cancelled when connector grounded

Water thermo sensor Detects coolant temperature; sends

signal to engine control unit

76G04C-078

4C—45

Page 610 of 1865

FUEL SYSTEM 4C

FUEL SYSTEM

76G04C-087

This system supplies the necessary fuel for combustion at a constant pressure to the injectors. Fuel

is metered and injected into the intake manifold according to the injection control signals from the en-

gine control unit. It consists of the fuel pump, fuel filters, delivery pipe, pulsation damper, pressure

regulator, injectors, fuel pump control unit, and the control relay.

The fuel pump is mounted in the fuel tank to minimize the operating noise of the fuel pump. The injec-

tors directly supplied with battery voltage through the control relay. The connector of the injectors is

white to distinguish the injectors for FE DOHC from those of other engines.

Due to the installation of the steering angle transfer shaft for the 4-wheel steering (4WS) the fuel tank

of 4WS vehicles is designed with separate right and left sections. A transfer pump is used to pump

fuel from the left side to the right side.

4C—49

Page 620 of 1865

FUEL SYSTEM 4C

5. Connect the SST to the battery and injector.

6. Check the injection volume with a graduated con-

tainer.

Injection volume:

Approx. 66—91 cc (4.03—5.55 cu in) /15 sec.

Caution

When using the SST, make sure of the SST

number and use correct one.

7. If not correct, replace the injector.

76G04C-107

Rear seat Cushion Release Button -

76G04C-108

TRANSFER PUMP CONTROL SYSTEM (4 WHEEL

STEERING)

1. Remove the rear seat. (Refer to 14 section.)

2. Remove the fuel filler cap.

3. Turn the ignition switch ON.

Note

a) The tank should be more than 1/3 full.

b) Due to the delay timer, transfer pump oper-

ation begins approx. 10 sec. after the igni-

tion switch is turned ON.

4. Listen for the operational sound of the transfer

pump.

5. Install the fuel filler cap.

6. If no sound was heard, check the voltage at the

transfer pump connector.

Terminal (wire) Voltage

A, C (WG) Approx. 12V

I, J (B) OV

86U04B-075

I C A

lb d

cp a • • •

J

76G04C-211

7. If the voltages are correct, replace the transfer

pump.

8. If not correct, disconnect the transfer pump con-

nector.

9. Check the voltage at the terminals below.

Terminal (wire) Voltage

A, C (WG) Approx. 12V

I, J (B) OV

10. If the voltages are correct, replace the transfer

pump.

4C—59

Page 626 of 1865

FUEL SYSTEM 4C

FUEL TANK

Removal

Caution

a) Before performing the following procedure, release the fuel pressure from the fuel sys-

tem to reduce the possibility of injury or fire. (Refer to page 4C—52.)

b)When removing the fuel tank, keep sparks, cigarettes, and open flames away from the

fuel tank.

Remove in the sequence shown in the figure.

76G04C-125

Note

Drain the fuel from the fuel tank before removing the tank.

1. Remove fuel filler cap.

2. Fuel pump connectors

3. Fuel hoses

4. Steering angle transfer shaft (4-wheel

steering)

(Refer to section 10)

5. Cross member (4-wheel steering)

6. Evaporative hoses

7. Fuel filler hose

8. Breather hose

9. Parking cable bracket

10. Fuel tank strap

11. Fuel tank

4C-65

Page 628 of 1865

FUEL SYSTEM 4C

Installation note

Hoses

1. Push the ends of the main fuel hose, fuel return

hose, and evaporation hoses onto the fuel tank fit-

tings at least 25 mm (1.0 in).

2. Push the fuel filler hose onto the fuel tank pipe and

filler pipe at least 35 mm (1.4 in).

Steering angle transfer shaft

(4-wheel steering)

Refer to section 10

4C—67

Page 658 of 1865

CONTROL SYSTEM 4C

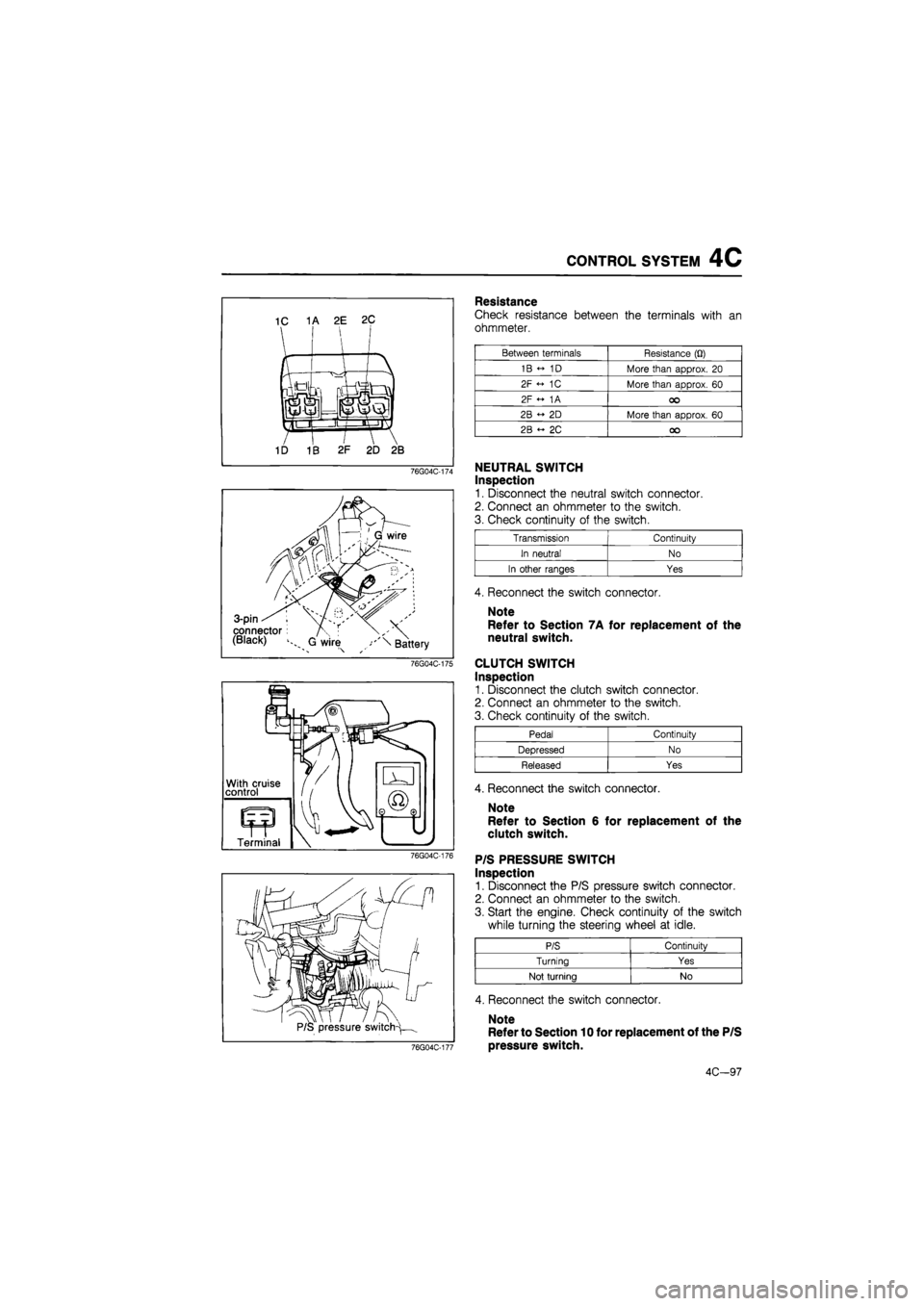

Resistance

Check resistance between the terminals with an

ohmmeter.

Between terminals Resistance (Q)

1B « 1D More than approx. 20

2F <- 1C More than approx. 60

2F « 1A oo

2B « 2D More than approx. 60

2B ~ 2C oo

NEUTRAL SWITCH

Inspection

1. Disconnect the neutral switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Transmission Continuity

In neutral No

In other ranges Yes

4. Reconnect the switch connector.

Note

Refer to Section 7A for replacement of the

neutral switch.

CLUTCH SWITCH

Inspection

1. Disconnect the clutch switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Pedal Continuity

Depressed No

Released Yes

4. Reconnect the switch connector.

Note

Refer to Section 6 for replacement of the

clutch switch.

P/S PRESSURE SWITCH

Inspection

1. Disconnect the P/S pressure switch connector.

2. Connect an ohmmeter to the switch.

3. Start the engine. Check continuity of the switch

while turning the steering wheel at idle.

P/S Continuity

Turning Yes

Not turning No

4. Reconnect the switch connector.

Note

Refer to Section 10 for replacement of the P/S

pressure switch.

4C-97

Page 819 of 1865

REMOVAL 7A

RF-N and RF-CX

1. Battery

2. Air cleaner assembly

3. Vacuum hose

4. Intercooler pipe and hose

(RF-CX)

5. Electric fan

6. Speedometer cable

7. Ground(s)

8. Clutch release cylinder

9. Pressure and return hoses

(power steering)

10. Starter

11. Wheel

12. Splash shield

13. Stabilizer

14. Joint shaft

15. Extension bar

16. Control rod

76G07A-011

17. Exhaust pipe bracket

18. Water pipe

19. Gusset plate (rear)

20. Gusset plate (front)

21. Under cover

22. Engine mount No.4

23. Engine mount No.2

24. Crossmember

7 A—13

Page 1256 of 1865

TROUBLESHOOTING GUIDE 9

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Faulty operation of

driveshaft

Broken ball joint

Broken tri-pod joint

Worn or seized joint

Replace

Replace

Replace

9—31

9—35

9—31, 35

Abnormal noise from driveshaft Insufficient grease in joint or spline Excessive backlash on spline Worn joint

Add or replace

Replace

Replace

9—33, 36 9—31, 35 9-31, 35

Steering wheel pulls. (Steering wheel pulls toward either right or left side)

Bent steering linkage

Fatigued coil spring

Lower arm bushing worn or damaged Bent knuckle Bent lower arm or loose mounting Incorrect toe-in adjustment Improper tire air pressure Unevenly worn tires (left and right tires) Brake dragging

Refer to Section 10 Refer to Section 13 Refer to Section 13 Replace Refer to Section 13 Refer to Section 13 Refer to Section 12 Refer to Section 12 Refer to Section 11

9-11

Unstable handling Bent steering linkage

Joint in steering system worn or damaged

Incorrect steering pinion preload adjustment Fatigued coil spring

Faulty shock absorber(s) Lower arm bushing worn or damaged Incorrect toe-in adjustment (front or rear) Improper tire air pressure Wheel(s) bent or unbalanced

Refer to Section 10 Refer to Section 10 Refer to Section 10 Refer to Section 13 Refer to Section 13 Refer to Section 13 Refer to Section 13 Refer to Section 12 Refer to Section 12

—

Excessive steering wheel play Faulty front wheel bearing Incorrect steering pinion preload adjustment Rack and pinion worn Joint in steering system worn or damaged Lower arm bushing worn or damaged

Adjust Refer to Section 10 Refer to Section 10 Refer to Section 10 Refer to Section 13

9-11

Tires excessively worn or worn un-evenly

Incorrect toe-in adjustment Improper tire air pressure Unbalanced wheel(s)

Refer to Section 13 Refer to Section 12 Refer to Section 12 —

Abnormal noise

from axle

Faulty wheel bearing Replace 9-11,18,23

86U09X-006

9—7

Page 1289 of 1865

10

STEERING SYSTEM

OUTLINE 10— 2

STRUCTURAL VIEW 10— 2 SPECIFICATIONS 10— 6

TROUBLESHOOTING GUIDE 10— 7

MANUAL STEERING 10— 7

POWER STEERING 10— 8

4WS 10— 9

ON-VEHICLE MAINTENANCE 10— 10

STEERING WHEEL PLAY 10— 10

LOOSENESS OR PLAY OF THE

STEERING WHEEL 10— 10

STEERING WHEEL EFFORT 10— 10

POWER STEERING FLUID LEVEL 1 fl-11

LOOSE OR DAMAGED

OIL PUMP BELT IC— 12

REAR STEERING GEAR OIL 10— 12 LEAKAGE OF POWER STEERING

FLUID 10— 13

INSPECTION AND ADJUSTMENT. 10— 15

BLEEDING OF POWER STEERING

SYSTEM 10— 15

POWER STEERING PRESSURE ... 10— 16

TIE-ROD END BOOTS 10— 18

REMOVAL AND INSTALLATION .. 10— 18

STEERING WHEEL AND COLUMN 10— 21

STRUCTURAL VIEW 10— 21

REMOVAL 10— 22

DISASSEMBLY AND ASSEMBLY.. 10— 24

INSPECTION 10— 25

INSTALLATION 1 fl-27

STEERING GEAR AND LINKAGE .. IC— 28

STRUCTURAL VIEW 10— 28

REMOVAL 10— 29

INSTALLATION 10— 30

4-WHEEL STEERING GEAR AND

LINKAGE 10— 31

STRUCTURAL VIEW 10— 31 4WS PERFORMANCE INSPECTION 10— 32

ADJUSTMENT OF STEERING

ANGLE TRASFER SHAFT 10— 35

REMOVAL AND INSTALLATION .. 10— 37

INSPECTION 10— 44

MANUAL STEERING 10— 48

DISASSEMBLY 10— 48

INSPECTION 10— 51

ASSEMBLY 10— 52

ENGINE SPEED SENSING POWER

STEERING 10— 58

DISASSEMBLY 10— 58

INSPECTION 10— 62

ASSEMBLY 10— 64

ELECTRONICALLY-CONTROLLED

POWER STEERING 10— 75

DISASSEMBLY 10— 75

INSPECTION 10— 78

ASSEMBLY 10— 79

OIL PUMP 10— 83

REMOVAL AND INSTALLATION .. 10— 83

ELECTRICAL COMPONENTS OF

ELECTRONICALLY-CONTROLLED

POWER STEERING 10— 87

CIRCUIT DIAGRAM 10— 87

TROUBLESHOOTING GUIDE 10— 87

TROUBLESHOOTING 10— 87

ELECTRICAL COMPONENTS OF

4 WHEEL STEERING 10— 94

CIRCUIT DIAGRAM 10— 94

TROUBLESHOOTING GUIDE 10— 95

TROUBLESHOOTING 10— 95

4WS WARNING LIGHT 10—102

SPEED SENSOR (IN METER) 10—103

SPEED SENSOR (AT TRANSAXLE) 10—103

REAR-TO-FRONT STEERING

RATIO SENSOR 10—103

OIL LEVEL SWITCH

(IN P/S RESERVOIR) 10—103

RELAY AND TIMER 10—104 76G10X-001