engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 455 of 1865

4A CONTROL SYSTEM

Terminal

(Wire color) Connected to Condition Voltage

2K

— — —

2L

(BR) Inhibitor switch "P"

or "N"

range Below 1,5V 2L

(BR) Inhibitor switch

Others Battery voltage

2M

(BY)

Ignition switch

(START position)

Ignition switch

ON

Below 1,5V 2M

(BY)

Ignition switch

(START position) Cranking Battery voltage

2N

— — —

76G04A-172

(2M X

2

X

2F 2C

X 2L

2J 2H 2F 2D 2B

fll X >< X

1J 1H

>< X

1B

FE and F8 Engine — MTX (General)

Terminal (Wire color) Connected to Condition Voltage

A

(W)

Headlight switch Headlight switch

ON

Below 1,5V A

(W)

Headlight switch

Headlight switch OFF Battery voltage

B

(B)

Ground

—

Below 1,5V

C

(BL) Rear defroster switch Rear defroster switch

ON

Below 1,5V C

(BL) Rear defroster switch

Rear defroster switch OFF Battery voltage

D

(LG) A/C switch A/C operated Below 1.5V D

(LG) A/C switch

A/C not operated Battery voltage

E

(LB) Solenoid valve (Main

air

bleed control)

Intake manifold vacuum more than 300 mmHg (11.8 inHg), and radiator coolant temperature above 17°C (63 °F)

Battery voltage E

(LB) Solenoid valve (Main

air

bleed control)

Others Below 1.5V

F

(GW)

Water thermo switch

(Radiator)

Radiator coolant temperature below 17°C (63°F) Below 1,5V F

(GW)

Water thermo switch

(Radiator) Radiator coolant temperature above 17°C (63°F) Battery voltage

G (YL)

Ignition coil Ignition switch

ON or

engine running Battery voltage

H

(L)

Water thermo switch (Intake manifold) Engine coolant temperature below 72°C (162°F) Below 1,5V H

(L)

Water thermo switch (Intake manifold) Engine coolant temperature above 72°C (162°F) Battery voltage

I

— — —

J

(BW)

Ignition switch Ignition switch

ON

Battery voltage

K

— —

L

— — —

M

— — —

N

— —

4A-90

Page 456 of 1865

CONTROL SYSTEM 4 A

Terminal (Wire color) Connected to Condition Voltage

0 (BY)

Ignition switch*

(START position) Ignition switch

ON

Below 1.5V 0 (BY)

Ignition switch*

(START position) Cranking Battery voltage

P

(LW) Solenoid valve (A/C) A/C switch

ON

and engine speed below approx.

2,300

rpm

Below 1,5V

Others Battery voltage

Q (YW) Idle-up solenoid valve Headlight switch ON, rear defroster switch ON,

fan

speed control switch

is

3rd

or

4th position, A/C oper-ated,

or

engine coolant temperature below 72°C (162°F)

Below 1,5V

Others Battery voltage

R

(LB)

Fan speed control switch Fan speed control switch

in

3rd

or

4th position Below 1,5V R

(LB) Fan speed control switch OFF Battery voltage

*

Not

used

76G04A-173

{

Q

0

><

K

X

G E C A

^

R P

R X

J H F D B

FE 8Valve — Unleaded Fuel

Terminal (Wire color) Connected to Condition Voltage

A

(L)

Coast enrichment solenoid valve Engine speed approx. 1,500—2,300 rpm and idle switch

ON

Below 1,5V A

(L)

Coast enrichment solenoid valve

Others Battery voltage

B

(B)

Ground

—

Below 1,5V

C (LB)

Air bypass solenoid valve Engine speed above approx. 3,500 rpm and idle

switch

ON

Below 1,5V C (LB)

Air bypass solenoid valve

Others Battery voltage

D

(YL)

Ignition coil Ignition switch

ON or

engine running Battery voltage

E

— — —

F

(BW)

Ignition switch Ignition switch

ON

Battery voltage

G (YW) Slow fuel cut solenoid valve Engine speed above approx. 2,300 rpm and idle

switch

ON

Battery voltage G (YW) Slow fuel cut solenoid valve

Others Below 1.5V

H

(LW) A/C switch A/C operated and engine speed above approx.

1,500 rpm

Battery voltage H

(LW) A/C switch

A/C not operated

or

engine speed below approx.

1,500 rpm

Below 1,5V

4A—91

Page 457 of 1865

4A CONTROL SYSTEM

Terminal

(Wire color) Connected to Condition Voltage

I

(LgB)

Idle switch Idle switch

ON

Below 1.5 V I

(LgB)

Idle switch

Idle switch OFF Battery voltage

J

— —

76G04A-174

( I

G

X

C

0

X

H F D B

F6 Engine (Singapore)

Terminal

(Wire color) Connected to Condition Voltage

A

— — —

B

(YL) Ignition coil Ignition switch

ON

and engine running Battery voltage

C

(B)

Ground

— —

D

(GB) Relay Engine speed below approx. 2,100

rpm

Below 1,5V D

(GB) Relay

Engine speed above approx. 2,100

rpm

Battery voltage

F

(BW) Ignition switch Ignition switch

ON

Battery voltage

76G04A-175

4A—92

Page 458 of 1865

CONTROL SYSTEM 4 A

76G04A-176

76G04A-177

76G04A-178

Replacement

1. Disconnect the negative battery cable.

2. Remove the front console covers (right or left).

3. Disconnect the connectors from the control unit.

4. Remove and replace the control unit.

INHIBITOR SWITCH

Inspection

1. Verify that the starter operates with the ignition

switch at START position in

P

and N positions only.

2. Check that the back-up lights illuminate when R

position selected and the ignition switch is ON.

3. If not as specified, check the following:

(1) Jack up the vehicle and support it with safety

stands.

(2) Disconnect the inhibitor switch connector.

(3) Check continuity of the switch with an

ohmmeter.

Connecting guide

Position

N

D,1,2

Connector terminal

O -O

O

O

-O

-O

O—O: indicates continuity

4. Replace if necessary.

IDLE SWITCH

Inspection

1. Warm up the engine and run it at idle.

2. Turn all accessories OFF.

3. Connect a tachometer to the engine.

4. Connect a voltmeter to the carburetor connector

F terminal.

76G04A-179

4A-93

Page 459 of 1865

4A CONTROL SYSTEM

Idle switch

Adjust screw

76G04A-180

76G04A-181

5. Increase the engine speed to more than 2,000 rpm

and decelerate gradually.

6. Check the voltage.

Specification

Engine speed

^^^

FE 8Valve—

Unleaded Fuel

& F6 Sin-

gapore

Others

At idle below 1,5V Battery voltage

Above 1,000—1,100 rpm Battery voltage below 1.5V

7. If the voltage is not within specification, turn the ad-

just screw to adjust.

VACUUM SWITCH

On-Vehicle Inspection

1. Run the engine at idle.

2. Connect a voltmeter to the vacuum switch connec-

tor terminal wire (LB).

Voltage: Approx. 12V

3. Disconnect the vacuum hose from the vacuum

switch, and plug it.

4. Check the voltage.

Voltage: Less than 1.5V

Off-Vehicle Inspection

Inspection

1. Remove the vacuum switch.

2. Connect a vacuum pump to the vacuum switch.

3. Connect an ohmmeterto the vacuum switch, and

check the continuity between the switch terminals.

Vacuum Continuity

MTX: More than 300 mmHg (11.8 inHg) No ATX: More than 200 mmHg (7.9 inHg) No

Others Yes

76G04A-182

4A—94

Page 463 of 1865

FUEL AND EMISSION

CONTROL SYSTEMS

(FUEL INJECTION FE)

OUTLINE 4B— 2

SYSTEM DIAGRAM 4B— 2

COMPONENT LOCATION 4B— 3

VACUUM HOSE ROUTING

DIAGRAM 4B— 5

SPECIFICATIONS 4B— 6

TROUBLESHOOTING GUIDE 4B— 7

TROUBLESHOOTING

PROCEDURE 4B— 7

TROUBLESHOOTING WITH SST.... 4B— 9

INSPECTION PROCEDURE 4B—10

AFTER-REPAIR PROCEDURE 4B—10

PRINCIPLE OF CODE CYCLE 4B—12

CODE NUMBER 4B—13

SWITCH MONITOR FUNCTION 4B—25

INSPECTION PROCEDURE 4B—26

IDLE SPEED 4B—29

IDLE MIXTURE 4B—29

INTAKE AIR SYSTEM 4B—30

COMPONENT DESCRIPTIONS 4B—30

REMOVAL 4B—31

PARTS INSPECTION 4B—32

INSTALLATION 4B—34

IDLE-UP SYSTEM 4B—35

COMPONENT DESCRIPTIONS 4B—36

TROUBLESHOOTING 4B—37

AIR VALVE 4B—38

AIR BYPASS SOLENOID VALVE ... 4B—39

FUEL SYSTEM 4B—42

COMPONENT DESCRIPTIONS 4B—43

TROUBLESHOOTING 4B—44

FUEL PRESSURE RELEASE AND

SERVICING FUEL SYSTEM 4B—45

MULTI-PRESSURE TESTER 4B—46

FUEL PRESSURE 4B—48

FUEL PUMP 4B—49

PULSATION DAMPER 4B—50

INJECTOR 4B—51

PRESSURE REGULATOR

CONTROL SYSTEM 4B—53

COMPONENT DESCRIPTIONS 4B—54

TROUBLESHOOTING 4B—55

REPLACEMENT 4B—57

FUEL TANK 4B—61

DECELERATION CONTROL

SYSTEM 4B—64

COMPONENT DESCRIPTIONS 4B—65

TROUBLESHOOTING 4B—66

AIR INJECTION SYSTEM 4B—68

COMPONENT DESCRIPTIONS 4B—68

TROUBLESHOOTING 4B—69

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM 4B—71

COMPONENT DESCRIPTIONS 4B—71

TROUBLESHOOTING 4B—72

EVAPORATIVE EMISSION

CONTROL (EEC) SYSTEM 4B—74

COMPONENT DESCRIPTIONS 4B—74

TROUBLESHOOTING 4B—75

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM 4B—80

COMPONENT DESCRIPTION 4B—80

EXHAUST SYSTEM 4B—81

REMOVAL AND INSTALLATION ... 4B—82

INSPECTION 4B—82

CONTROL SYSTEM 4B—83

RELATIONSHIP CHART 4B—84

EGI MAIN FUSE 4B—86

MAIN RELAY 4B—86

CIRCUIT OPENING RELAY 4B—86

ENGINE CONTROL UNIT 4B—87

NEUTRAL SWITCH 4B—91

CLUTCH SWITCH 4B—91

BRAKE LIGHT SWITCH 4B—91

P/S PRESSURE SWITCH 4B—92

INHIBITOR SWITCH 4B—92

E/L CONTROL UNIT 4B—93

AIR FLOW METER 4B—94

THROTTLE SENSOR 4B—95

WATER THERMO SENSOR 4B—97

WATER THERMO SWITCH 4B—97

OXYGEN SENSOR 4B—98

ATMOSPHERIC PRESSUFfE

SENSOR 4B—99

76G04B-001

Page 469 of 1865

TROUBLESHOOTING GUIDE 4B

TROUBLESHOOTING GUIDE

This troubleshooting guide shows the malfunction numbers and the symptoms of various failures.

Perform troubleshooting as described below.

Possible cause

Symptom

Input sensors and switches

o>

C

0

Jh c 01

4B-14

a> 4)

E

o

4B-1S

o in c « m o E k_ 0) c.

0 <0 £

4B-16

o CO c a> 0) o E

a>

.x

co

4B-17

o 10 c a) co

4B-18

o in c a> (0

o> o> a>

a) £ a VI o E

4B-19

0 <0 c a> 0) c a> 01

S? o

4B-20

E a> in (0

o 10 A •o 0) 0> u.

4B-21

Output solenoid valves

o «

3 O) 0)

0) 0) 01

0> > 10 >

•o o c V o tt)

4B-22

0)

OI

0> > CO >

TJ

O c 0> o CO

4B-23

oc O u

o> > 75 >

•o o c a> o 05

4B-23

0 a. 3 1

2

0) > (0 >

"D O

o 0> in in a a >. £

4B-23

ffl a 3 • a>

2

a> > 10 >

"O o c a> o

CO Q. >. JO

4B-24

Fault Indicated by SST

Code No. 01 08 09 10 12 14 15 17 25 26 28 34 35

Hard start or won't start

(Cranks OK)

Engine stalls

Rough

idle

While warming up

After warming up

While warming up

After warming up

High idle speed after

warming up

TROUBLESHOOTING PROCEDURE

Note

Step 1 under symptom is to quickly determine what system or unit may be at fault by use of the SST. (Self-Diagnosis Checker 49 H018 9A1)

1st:

Check input sensors and output solenoid valves with the

SST.

(Refer

to

page 4B—10.)

2nd:

Check other switches with the

SST.

(Refer

to

page 4B—26.)

3rd:

Check the following items:

11

Poor acceleration, hesita-

tion or lack of power

Runs rough on deceleration

Afterburn in exhaust system

Poor fuel consumption

Engine stalls or rough after hot starting

Electrical system

1) Battery condition

2) Fuses

Fuel system

1) Fuel level 2) Fuel leakage

3) Fuel filter 4) Idle speed

Engine

1) Compression 2) Overheating

Ignition system

1) Ignition spark 2) Ignition timing

Intake air system

1)

Air

cleaner element 2) Vacuum

or air

leakage 3) Vacuum hose routing

4) Accelerator cable

Others

1) Clutch slippage 2) Brake dragging

Fails emission test 4th:

Check Fuel and Emission Control Systems. (Refer

to

page 4B—8.)

76G04B-003

4B—7

Page 472 of 1865

4B TROUBLESHOOTING WITH SST

INSPECTION PROCEDURE

1. Connect the SST to the check connector, (Green,

6-pin) and the negative battery terminal.

2. Set the select switch to position A.

Note

The check connector is located at the rear of

the left side wheel housing.

86U04A-011

Test connector: Green (1 pin)

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

Note

The test connector is located near the Self-

Diagnosis Checker check connector.

86U04A-012

OO

uu

SELF-DIAGNOSIS CHECKER

(WPUTOft

SELECT

S*

5

o n==ru

o o o o 49 HO 18 9AI

76G04B-005

4. Turn the ignition switch ON.

5. Verify that 88 flashes on the digital display and that

the buzzer sounds for three seconds after turn-

ing the ignition switch ON.

6. If 88 does not flash, check the main relay (Refer

to page 4B—86), power supply circuit, and check

connector wiring.

7. If 88 flashes and the buzzer sounds continuously

for more than 20 seconds, replace the engine con-

trol unit and perform steps 3 and 4 again.

8. Note the code numbers and check for the causes

by referring to the check sequences shown on

pages from 4B—14 to 4B—24. Repair as

necessary.

Note

Cancel the code numbers by performing the

after-repair procedure after repairing.

AFTER-REPAIR PROCEDURE

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery cable and depressing the

brake pedal for at least 2 seconds; then recon-

nect the negative battery cable.

76G04B-134

4B—10

Page 473 of 1865

TROUBLESHOOTING WITH SST 4B

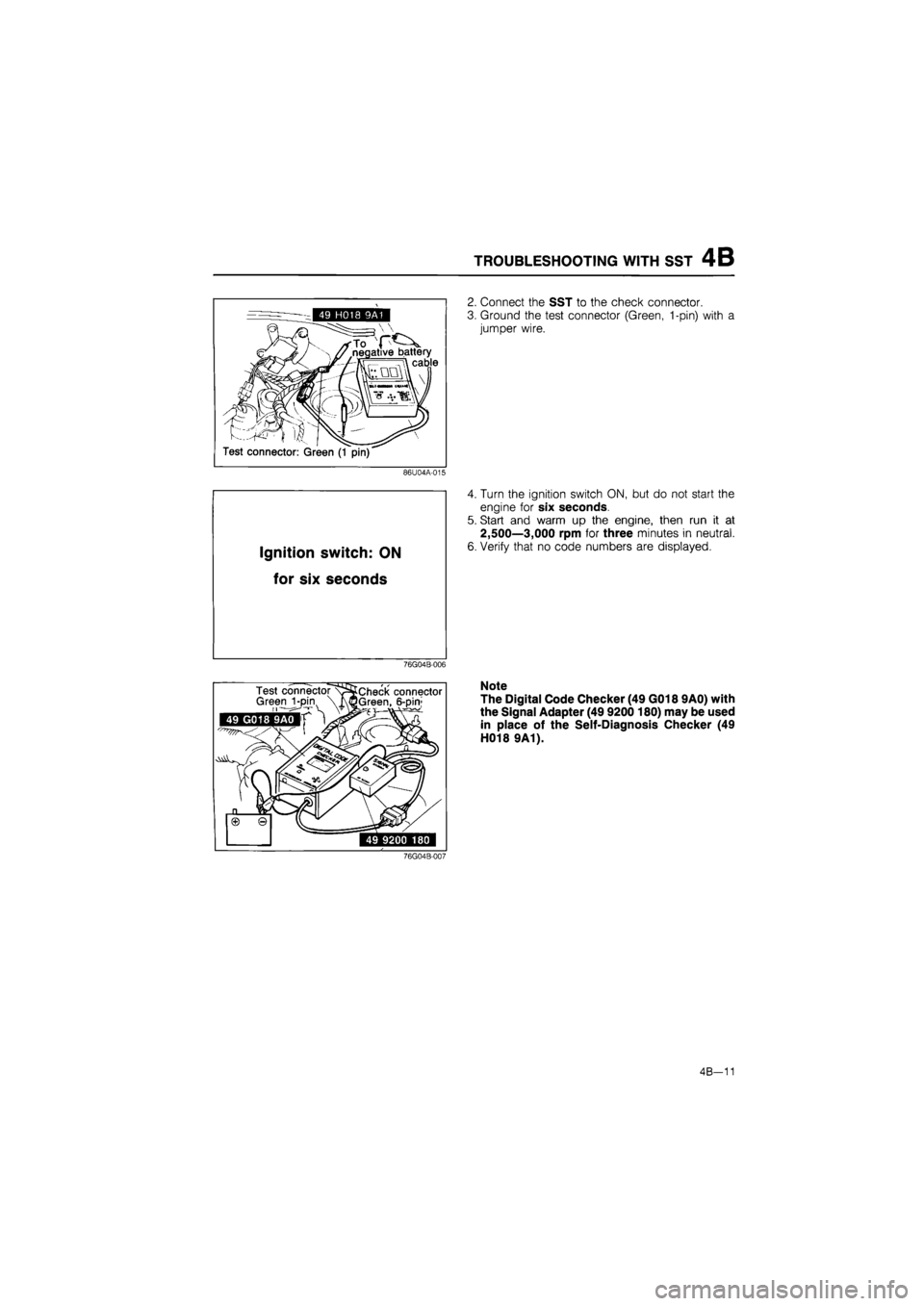

2. Connect the SST to the check connector.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

86U04A-015

Ignition switch:

ON

for six

seconds

4. Turn the ignition switch ON, but do not start the

engine for six seconds.

5. Start and warm up the engine, then run it at

2,500—3,000 rpm for three minutes in neutral.

6. Verify that no code numbers are displayed.

76G04B-006

76G04B-007

Note

The Digital Code Checker (49 G018 9A0) with

the Signal Adapter (49 9200 180) may be used

in place of the Self-Diagnosis Checker (49

H018 9A1).

4B-11

Page 475 of 1865

TROUBLESHOOTING WITH SST 4B

CODE NUMBER

Malfunction display

Self-diagnosis Fail-safe Code

No. Output signal pattern subsystem Self-diagnosis Fail-safe

01

ON

OFF

Ignition pulse

No ignition signal

08

Air flow meter

Open

or

short circuit

Maintains basic sig-

nal

at

preset value

09

1 111

Water thermo sensor

Open

or

short circuit

Maintains constant command 35°C (95 °F)

10

Intake

air

thermo sensor (air flow meter) Open

or

short circuit

Maintains constant 20°C (68°F) command

12

£_IUILJIIL

Throttle sensor

Open

or

short circuit

Maintains constant

command

of

throttle

valve fully open

14

OFF

TL

I I nil

Atmospheric pres-

sure sensor Open

or

short circuit

Maintains constant command

of

sea level pressure

15

oTp m 11 [U

Oxygen sensor Sensor output con-tinues less than 0.55V 120 sec. after engine starts (1,500 rpm)

Cancels EG

I

feed-

back operation

17

SLJlMJl

Feedback system Sensor output

not

changed

20

sec.

af-

ter engine exceeds 1,500 rpm

Cancels EGI feed-back operation

25

^JMLJl

Solenoid valve (pres-

sure regulator)

Open

or

short circuit

26

SUUBUIL

Solenoid valve (purge control)

Open

or

short circuit 28

£ mi in nr

Solenoid valve

(EGR) Open

or

short circuit

34

^jmiUTT

Air bypass solenoid

valve (Idle-up

C)

Open

or

short circuit

35

0Nnnnj OFFU u UUU

"fin nnr

Air bypass solenoid

valve (Idle-up

B)

Open

or

short circuit

76G04B-008

Caution

a) If there is more than one failure present, the lowest number malfunction code is dis-

played first, the remaining codes are displayed sequentially.

b) After repairing a failure, turn off the ignition switch and disconnect the negative battery

cable and depress the brake pedal for at least 2 seconds to erase the memory of a mal-

function code.

4B-13