engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 520 of 1865

4B FUEL SYSTEM

76G04B-078

76G04B-079

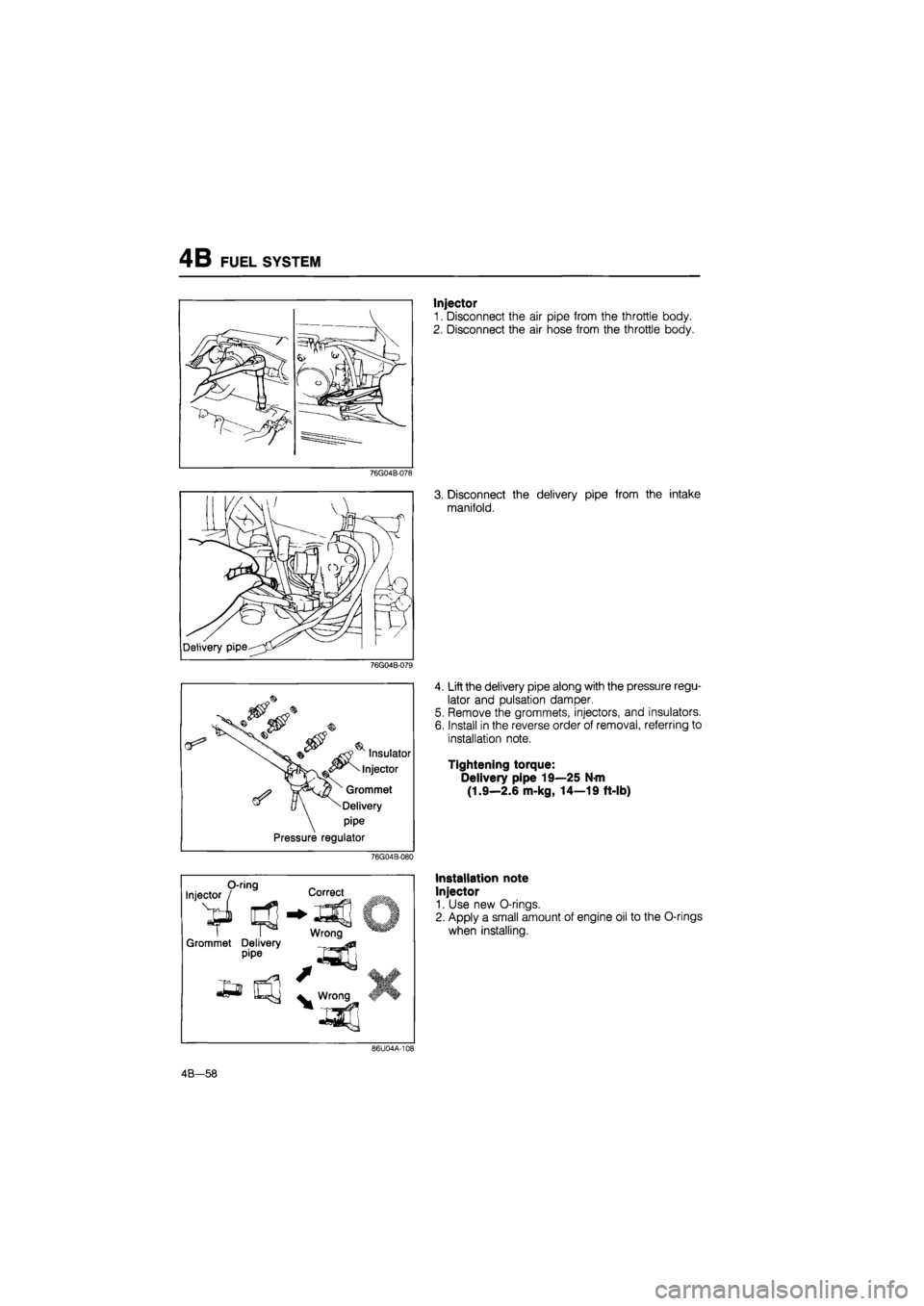

Insulator

Injector

Grommet

Delivery

pipe

Pressure regulator

76G04B-080

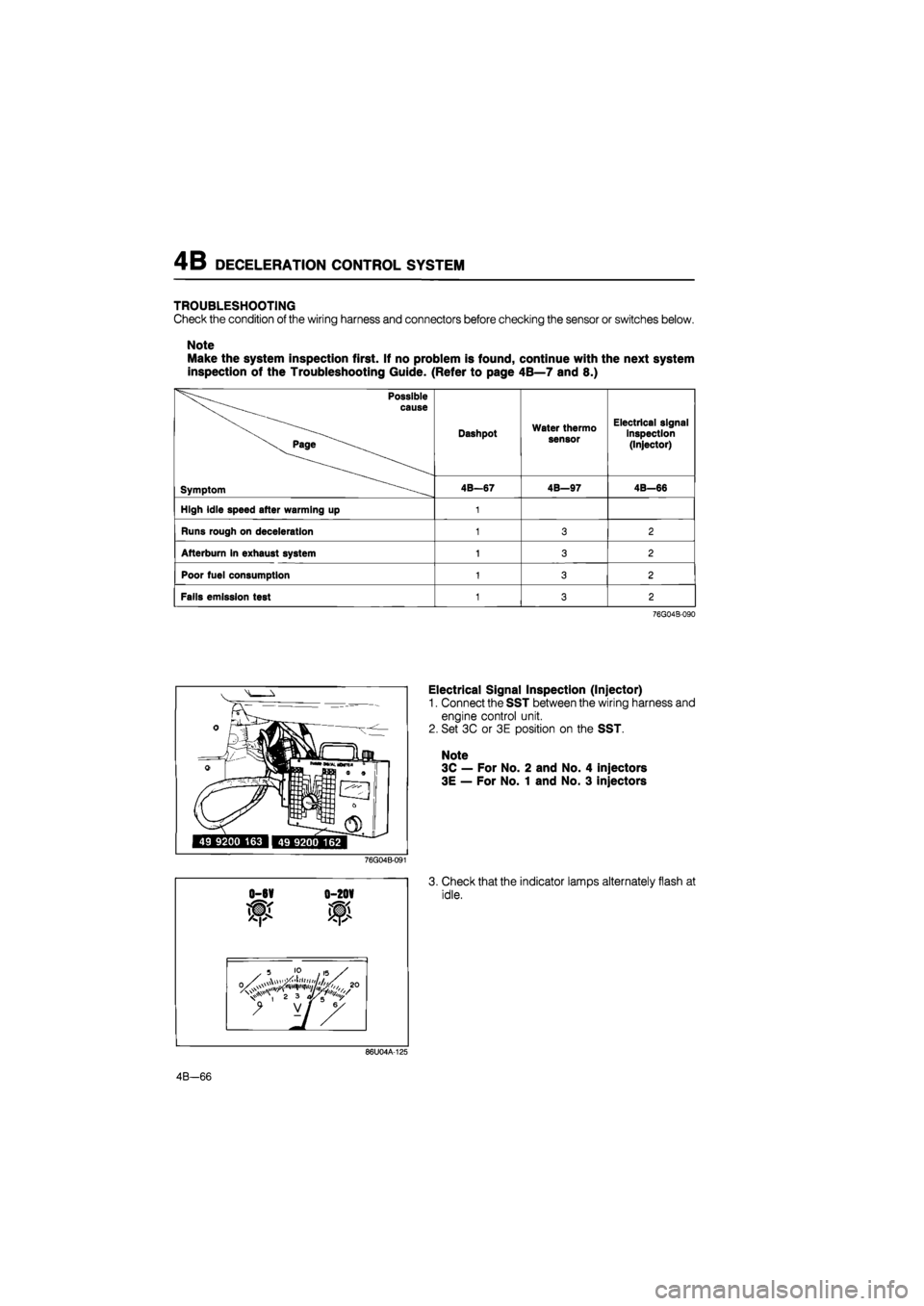

Injector O-ring Correct

1 #J

Grommet Delivery pipe

Wrong

£a

/

^ Wrong IF

Injector

1. Disconnect the air pipe from the throttle body.

2. Disconnect the air hose from the throttle body.

3. Disconnect the delivery pipe from the intake

manifold.

4. Lift the delivery pipe along with the pressure regu-

lator and pulsation damper.

5. Remove the grommets, injectors, and insulators.

6. Install in the reverse order of removal, referring to

installation note.

Tightening torque:

Delivery pipe 19—25 N-m

(1.9—2.6 m-kg, 14—19 ft-lb)

Installation note

Injector

1. Use new O-rings.

2. Apply a small amount of engine oil to the O-rings

when installing.

86U04A-108

4B-58

Page 526 of 1865

4B DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

This system consists of the dashpot and fuel cut system. The dashpot is to prevent after-burn so that

the throttle valve gradually closes during deceleration.

The control unit detects engine deceleration judging from the engine speed and the idle switch, and

signals a fuel cut operation to match the engines need, based on the coolant temperature and the

driving condition.

4B—64

Page 527 of 1865

DECELERATION CONTROL SYSTEM 4B

COMPONENT DESCRIPTIONS

Component Function Remarks

Brake light switch Detects braking operation (deceleration);

sends signal to engine control unit

Clutch switch Detects in-gear condition;

sends signal to engine control unit Switch ON when clutch pedal released

Dashpot (MTX) Prevents sudden closing of throttle valve during deceleration or shifting Adjustment speed: 1,900—2,100 rpm

Engine control unit Detects signals from input sensors and switches; cuts fuel injection

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed in throttle sensor

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Neutral switch Detects in-gear condition; sends signal to engine control unit Switch ON when in-gear

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04B-089

4B—65

Page 528 of 1865

4B DECELERATION CONTROL SYSTEM

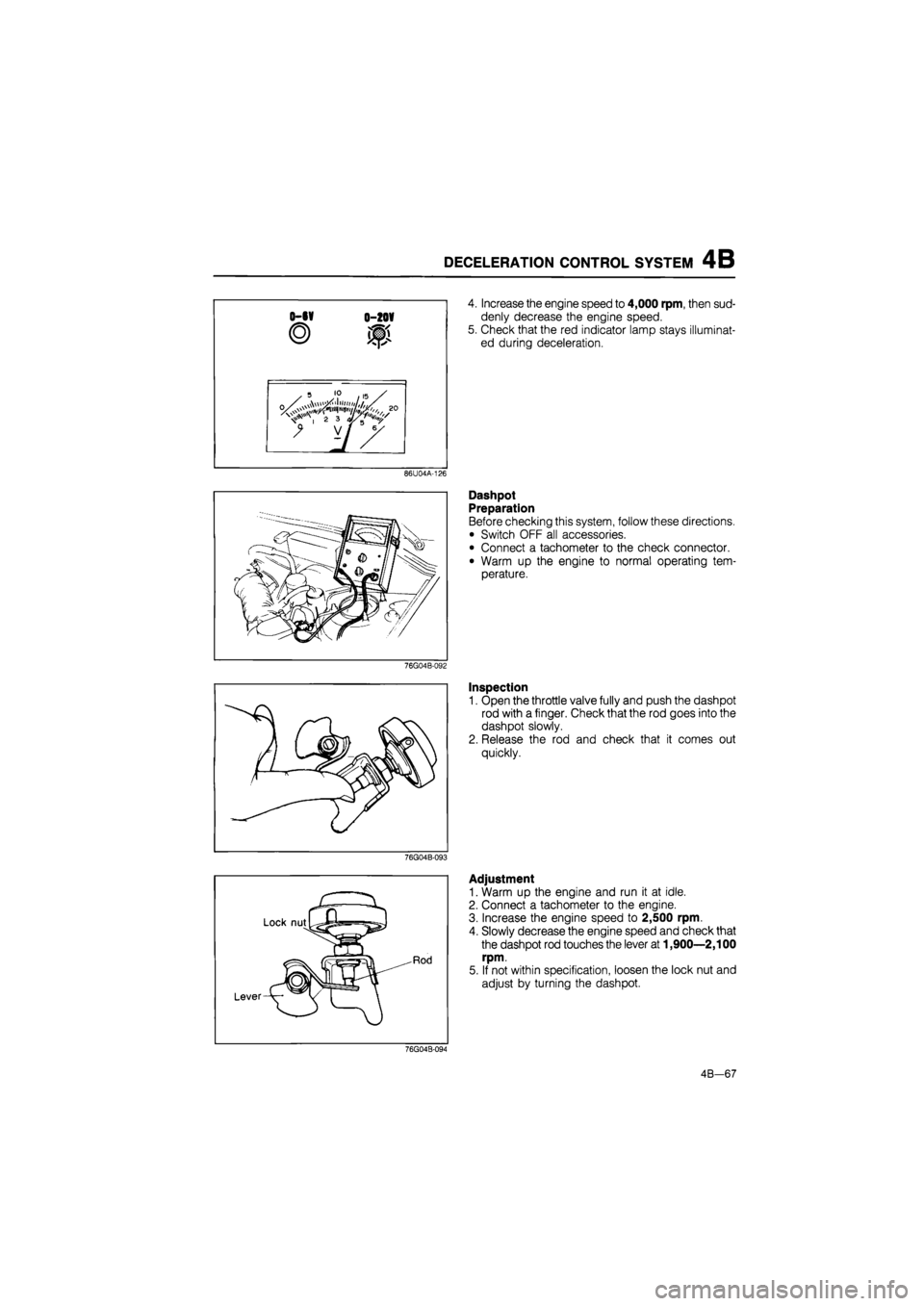

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to page 4B—7 and 8.)

Possible

^^ cause

Symptom

Dashpot Water thermo

sensor

Electrical signal

inspection

(Injector)

Possible

^^ cause

Symptom 4B—67 4B—97 4B-66

High idle speed after warming up 1

Runs rough on deceleration 1 3 2

Afterburn in exhaust system 1 3 2

Poor fuel consumption 1 3 2

Fails emission test 1 3 2

76G04B-090

Electrical Signal Inspection (Injector)

1. Connect the SST between the wiring harness and

engine control unit.

2. Set 3C or 3E position on the SST.

Note

3C — For No. 2 and No. 4 injectors

3E — For No. 1 and No. 3 injectors

76G04B-091

0-6V 0-20V

3. Check that the indicator lamps alternately flash at

idle.

86U04A-125

4B—66

Page 529 of 1865

DECELERATION CONTROL SYSTEM 4B

86U04A-126

76G04B-092

76G04B-093

Lock nutLg*

rJpM

Lever-V- y"

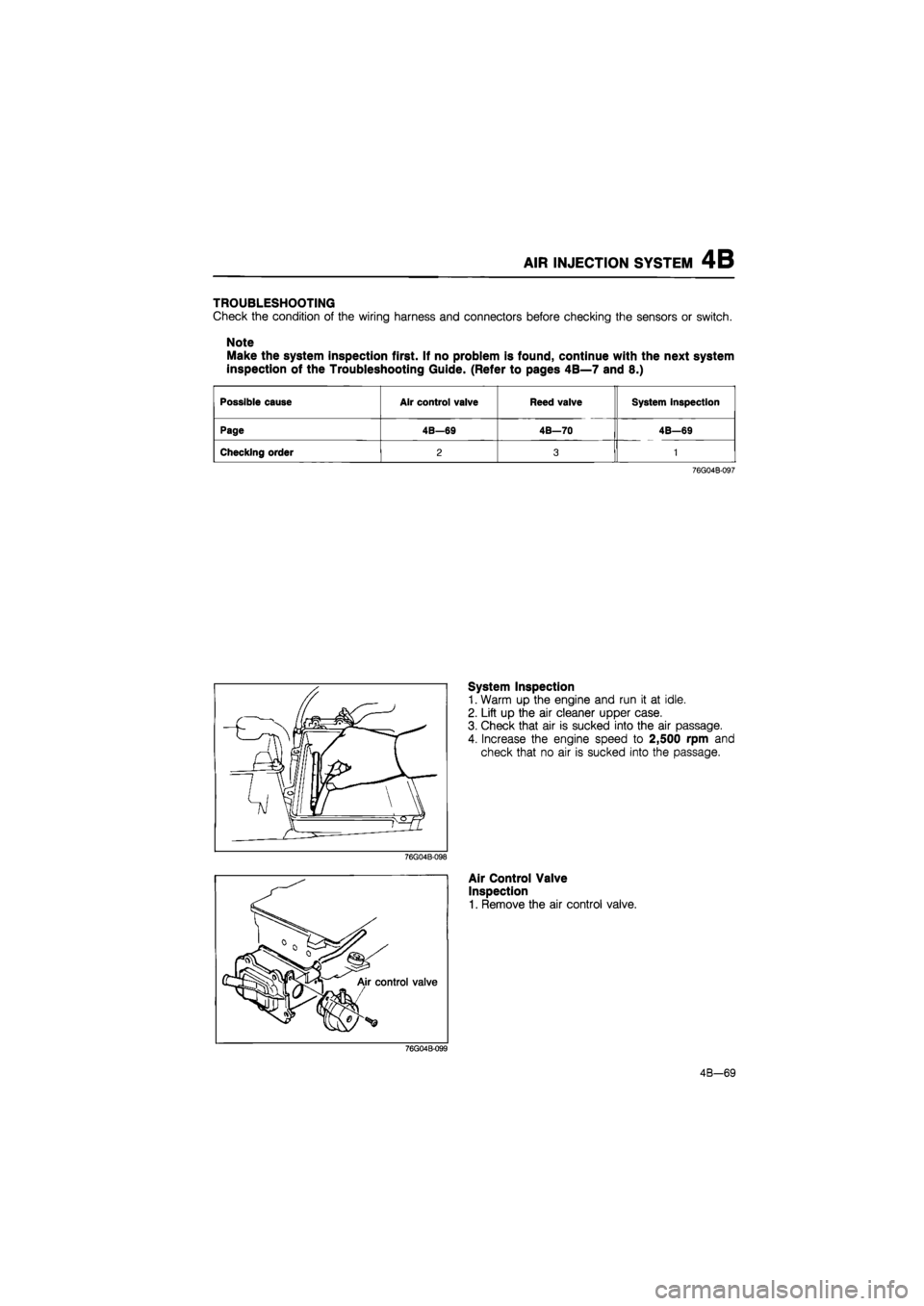

4. Increase the engine speed to 4,000 rpm, then sud-

denly decrease the engine speed.

5. Check that the red indicator lamp stays illuminat-

ed during deceleration.

Dashpot

Preparation

Before checking this system, follow these directions.

• Switch OFF all accessories.

• Connect a tachometer to the check connector.

• Warm up the engine to normal operating tem-

perature.

Inspection

1. Open the throttle valve fully and push the dashpot

rod with a finger. Check that the rod goes into the

dashpot slowly.

2. Release the rod and check that it comes out

quickly.

Adjustment

1. Warm up the engine and run it at idle.

2. Connect a tachometer to the engine.

3. Increase the engine speed to 2,500 rpm.

4. Slowly decrease the engine speed and check that

the dashpot rod touches the lever at 1,900—2,100

rpm.

5. If not within specification, loosen the lock nut and

adjust by turning the dashpot.

76G04B-094

4B-67

Page 531 of 1865

AIR INJECTION SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switch.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause Air control valve Reed valve System inspection

Page 4B—69 4B—70 4B—69

Checking order 2 3 1

76G04B-097

System Inspection

1. Warm up the engine and run it at idle.

2. Lift up the air cleaner upper case.

3. Check that air is sucked into the air passage.

4. Increase the engine speed to 2,500 rpm and

check that no air is sucked into the passage.

Air Control Valve

Inspection

1. Remove the air control valve.

4B-69

Page 532 of 1865

4B AIR INJECTION SYSTEM

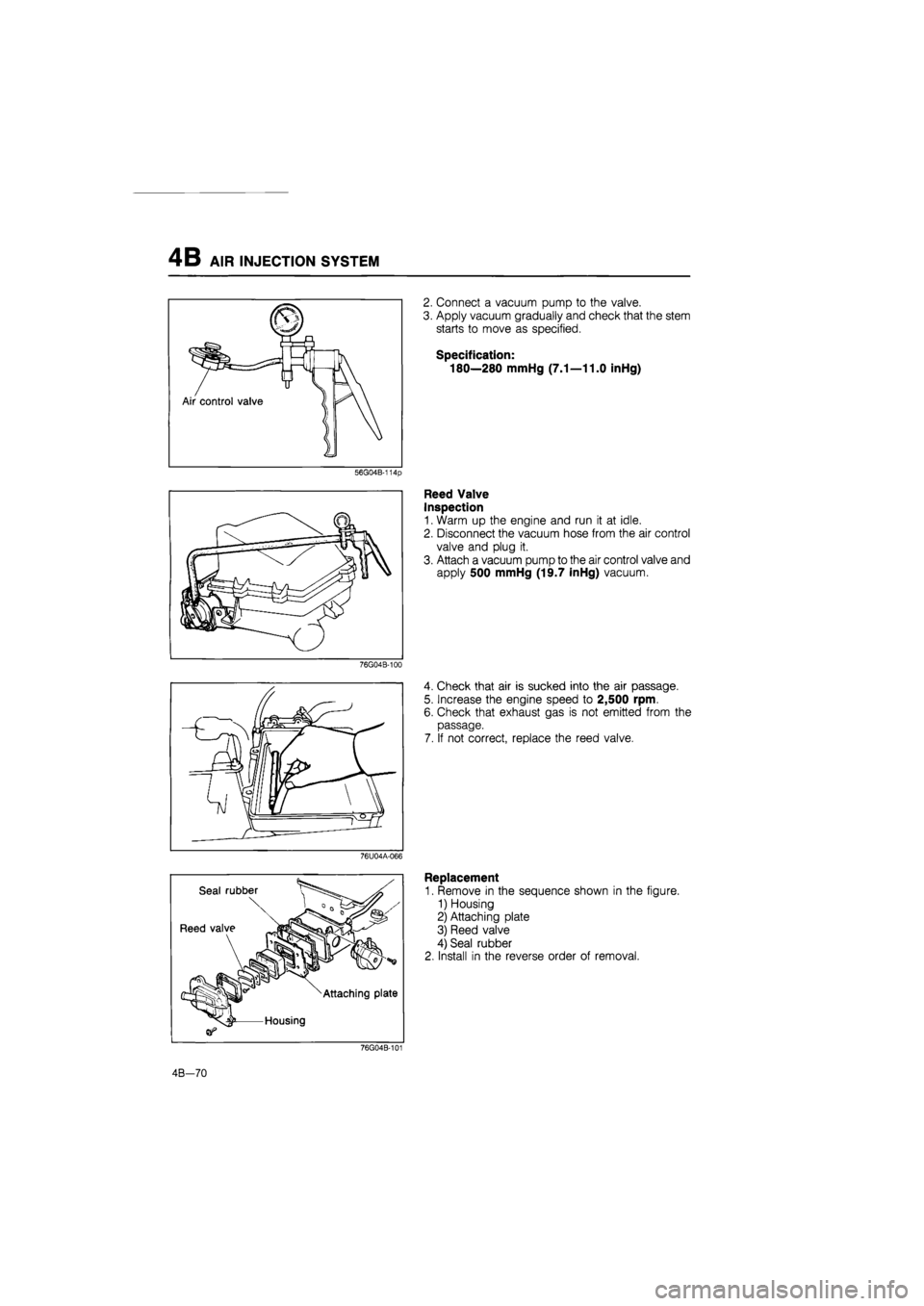

56G04B-114p

76G04B-100

76U04A-066

2. Connect a vacuum pump to the valve.

3. Apply vacuum gradually and check that the stem

starts to move as specified.

Specification:

180—280 mmHg (7.1—11.0 inHg)

Reed Valve

Inspection

1. Warm up the engine and run it at idle.

2. Disconnect the vacuum hose from the air control

valve and plug it.

3. Attach a vacuum pump to the air control valve and

apply 500 mmHg (19.7 inHg) vacuum.

4. Check that air is sucked into the air passage.

5. Increase the engine speed to 2,500 rpm.

6. Check that exhaust gas is not emitted from the

passage.

7. If not correct, replace the reed valve.

Replacement

1. Remove in the sequence shown in the figure.

1) Housing

2) Attaching plate

3) Reed valve

4) Seal rubber

2. Install in the reverse order of removal.

76G04B-101

4B—70

Page 533 of 1865

EGR SYSTEM 4B

EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM

EGR modulator valve Solenoid valve (EGR)

86U04A-127

This system introduces exhaust gas into the intake manifold to reduce NOx in the exhaust gas. It oper-

ates depending on the engine load, engine speed (above 1,500 rpm), engine coolant temperature

(above 70°C, 158°F), and radiator coolant temperature (above 17°C, 63°F).

COMPONENT DESCRIPTIONS

Component Function Remarks

EGR control valve Recirculates portion of exhaust gas

EGR modulator valve Controls vacuum acting on EGR control

valve

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (EGR)

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Solenoid valve (EGR) Controls vacuum line to EGR control

valve

Throttle sensor Detects throttle valve opening angle; sends signal to engine control unit Integrated idle switch

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit

ON: above 17°C (63°F)

76G04B-102

4B-71

Page 534 of 1865

4B EGR SYSTEM

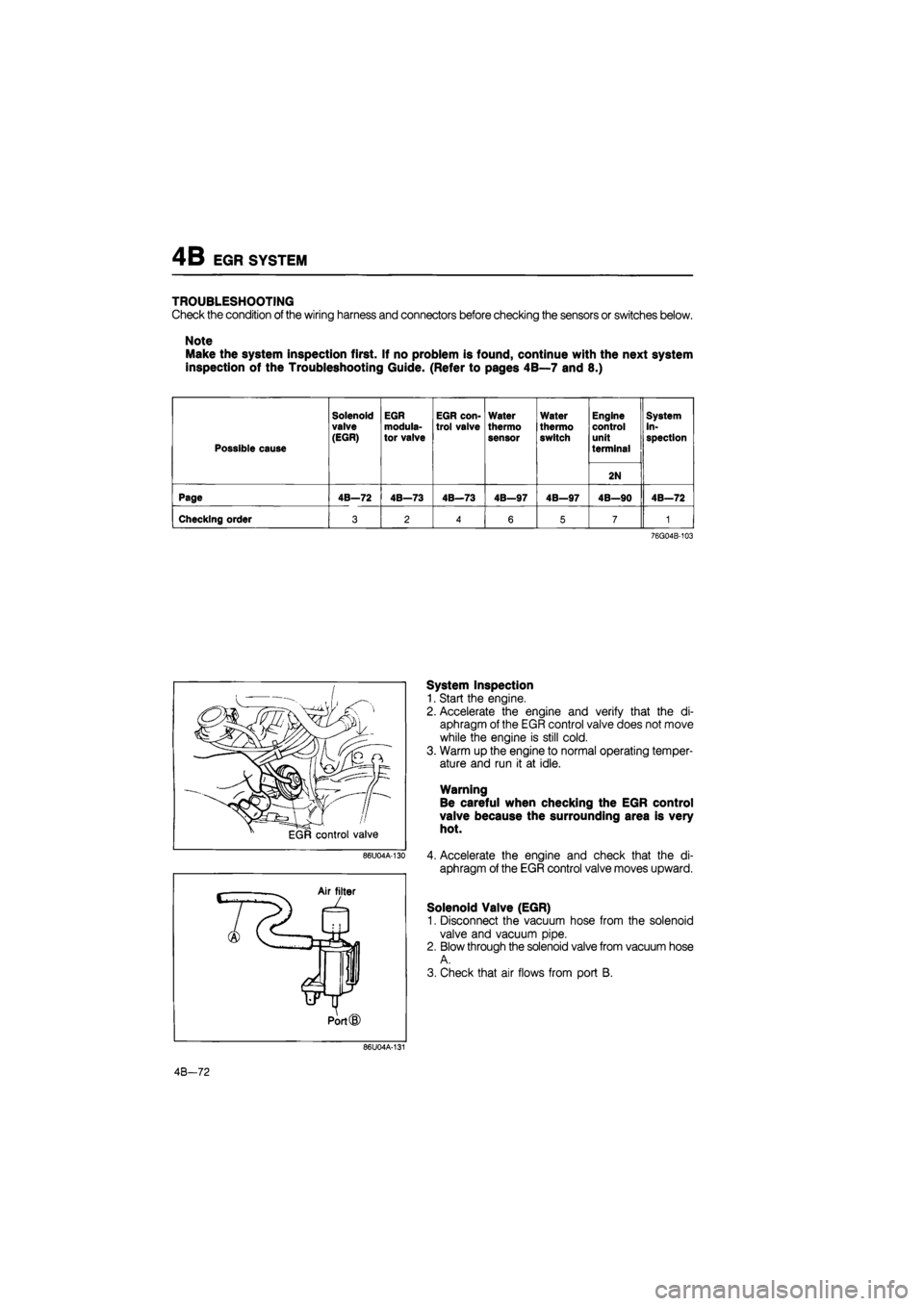

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause

Solenoid

valve (EGR)

EGR modula-tor valve

EGR con-trol valve

Water

thermo sensor

Water

thermo switch

Engine control unit

terminal

System in-spection

2N

Page 4B—72 4B—73 4B—73 4B—97 4B—97 4B—90 4B—72

Checking order 3 2 4 6 5 7 1

76G04B-103

86U04A-130

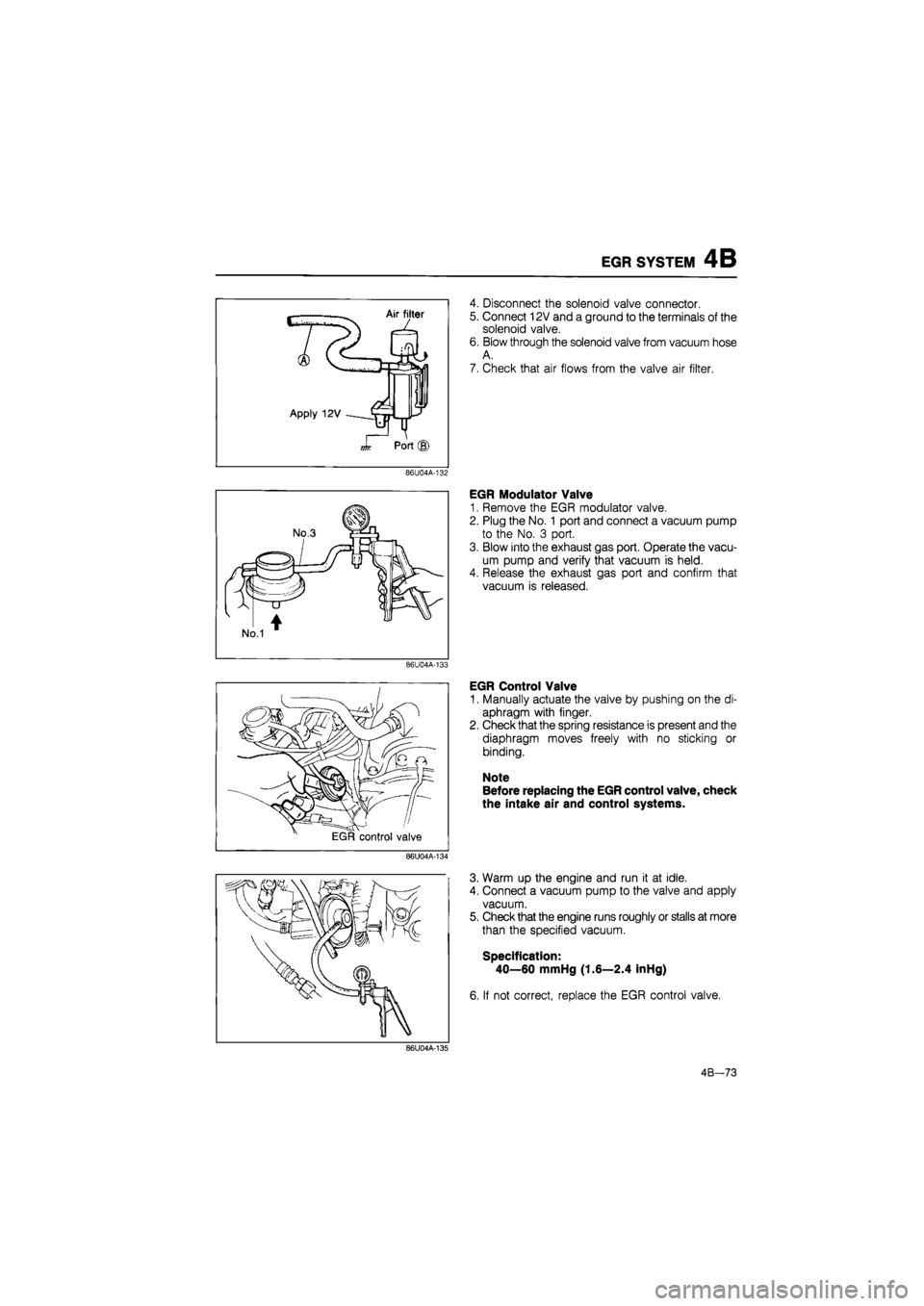

System Inspection

1. Start the engine.

2. Accelerate the engine and verify that the di-

aphragm of the EGR control valve does not move

while the engine is still cold.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve because the surrounding area is very

hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves upward.

Solenoid Valve (EGR)

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-131

4B-72

Page 535 of 1865

EGR SYSTEM 4B

Apply 12V

Air filter

L

Jt Port

4. Disconnect the solenoid valve connector.

5. Connect 12V and a ground to the terminals of the

solenoid valve.

6. Blow through the solenoid valve from vacuum hose

A.

7. Check that air flows from the valve air filter.

86U04A-132

86U04A-133

86U04A-134

EGR Modulator Valve

1. Remove the EGR modulator valve.

2. Plug the No. 1 port and connect a vacuum pump

to the No. 3 port.

3. Blow into the exhaust gas port. Operate the vacu-

um pump and verify that vacuum is held.

4. Release the exhaust gas port and confirm that

vacuum is released.

EGR Control Valve

1. Manually actuate the valve by pushing on the di-

aphragm with finger.

2. Check that the spring resistance is present and the

diaphragm moves freely with no sticking or

binding.

Note

Before replacing the EGR control valve, check

the intake air and control systems.

3. Warm up the engine and run it at idle.

4. Connect a vacuum pump to the valve and apply

vacuum.

5. Check that the engine runs roughly or stalls at more

than the specified vacuum.

Specification:

40—60 mmHg (1.6—2.4 inHg)

6. If not correct, replace the EGR control valve.

86U04A-135

4B-73