engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 506 of 1865

4B FUEL SYSTEM

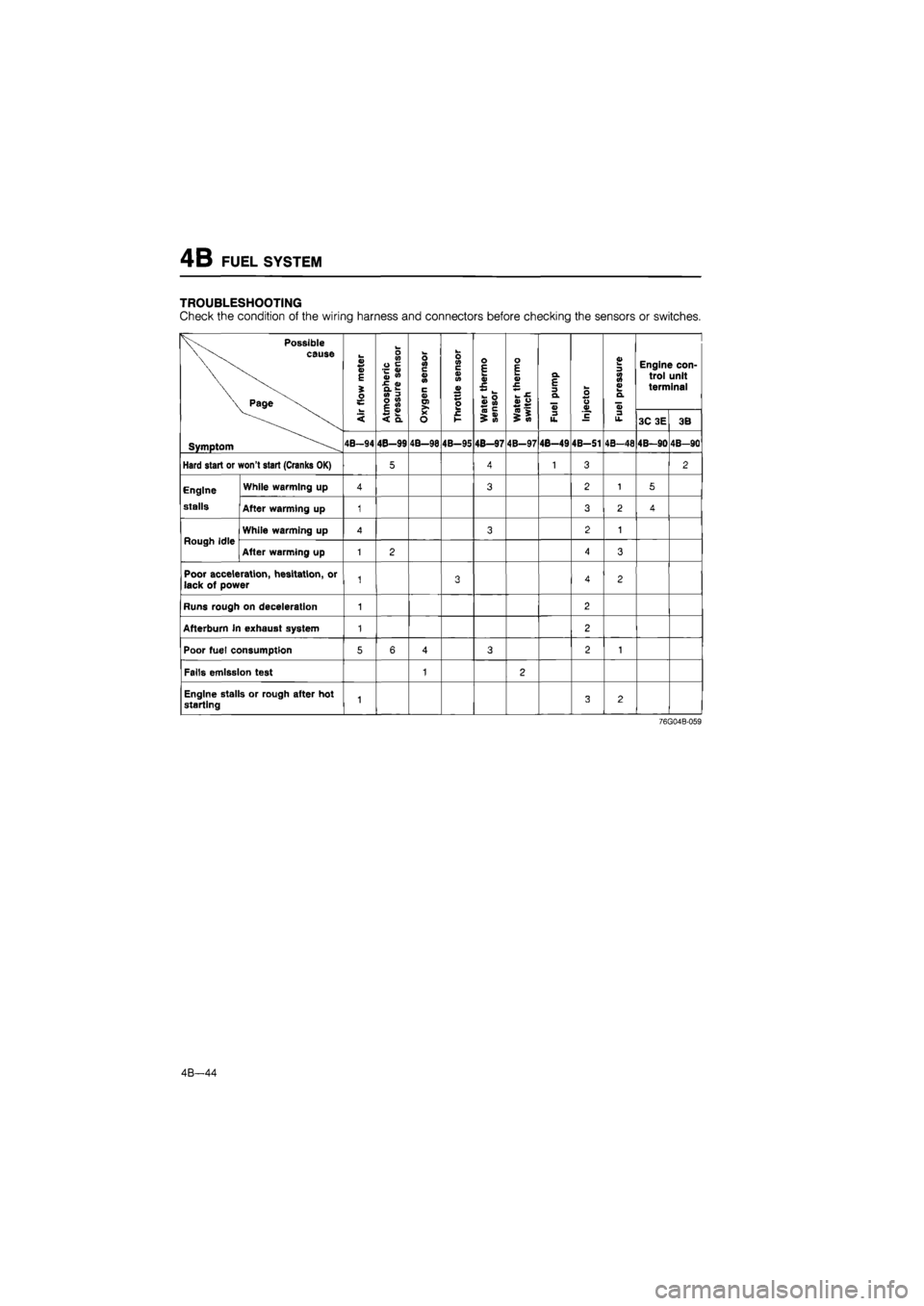

TROUBLESHOOTING

Check

the

condition

of

the wiring harness and connectors before checking

the

sensors

or

switches.

Possible

cause

Page

V

S E

i

o

o V)

0

e

~

0)

Ju

»

•E

<»

CL

01

3

0

<0

1

£

Oxygen

sensor

s c V

in

V

P

o E k_

•E **

l_

h

O

v

w

Water

thermo

switch

Q.

E

3 Q.

u

Injector

£ 3 3 o d

aj

Engine

con-

trol unit terminal

< £

8

<

Q. Oxygen

sensor

£ t->

0)

>

M Water

thermo

switch

3

u.

Injector

3

u. 3C

3E

3B

Symptom 4B-94 4B-99 4B—98 4B-95 48—97 4B-97 4B-49 4B-S1 4B-48 4B-90 4B-90

Hard start

or

won't start (Cranks

OK)

5 4 1 3 2

Engine While warming

up

4 3 2 1 5

stalls After warming

up

1 3 2 4

Rough Idle While warming

up

4 3 2 1

Rough Idle After warming

up

1 2 4 3

Poor acceleration, hesitation,

or

lack

of

power

1 3 4 2

Runs rough

on

deceleration

1 2

Afterburn

in

exhaust system

1 2

Poor fuel consumption

5 6 4 3 2 1

Falls emission test

1 2

Engine stalls

or

rough after

hot

starting

1 3 2

76G04B-059

4B—44

Page 507 of 1865

FUEL SYSTEM 4B

86U04A-068

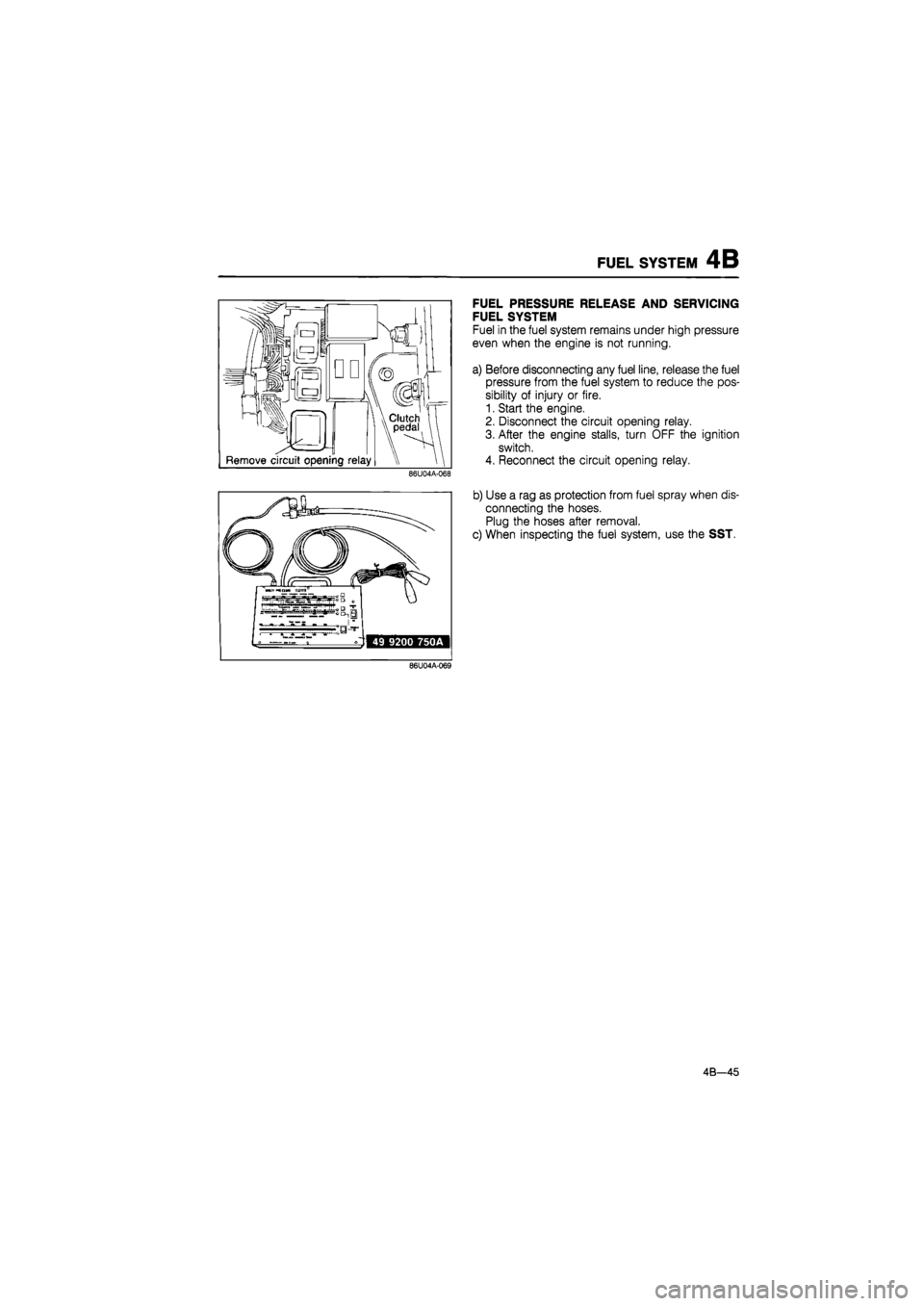

FUEL PRESSURE RELEASE AND SERVICING

FUEL SYSTEM

Fuel in the fuel system remains under high pressure

even when the engine is not running.

a) Before disconnecting any fuel line, release the fuel

pressure from the fuel system to reduce the pos-

sibility of injury or fire.

1. Start the engine.

2. Disconnect the circuit opening relay.

3. After the engine stalls, turn OFF the ignition

switch.

4. Reconnect the circuit opening relay.

b) Use a rag as protection from fuel spray when dis-

connecting the hoses.

Plug the hoses after removal.

c) When inspecting the fuel system, use the SST.

86U04A-069

4B—45

Page 510 of 1865

4B FUEL SYSTEM

76G04B-061

I i. i { 1 t' i 1 I • i i 1 1 "1 —r

1 . . • , 1 ,

EDO 250

86U04A-074

w Test connector

(Yellow)

86U04A-075

Lever

To fuel pump To pulsation damper

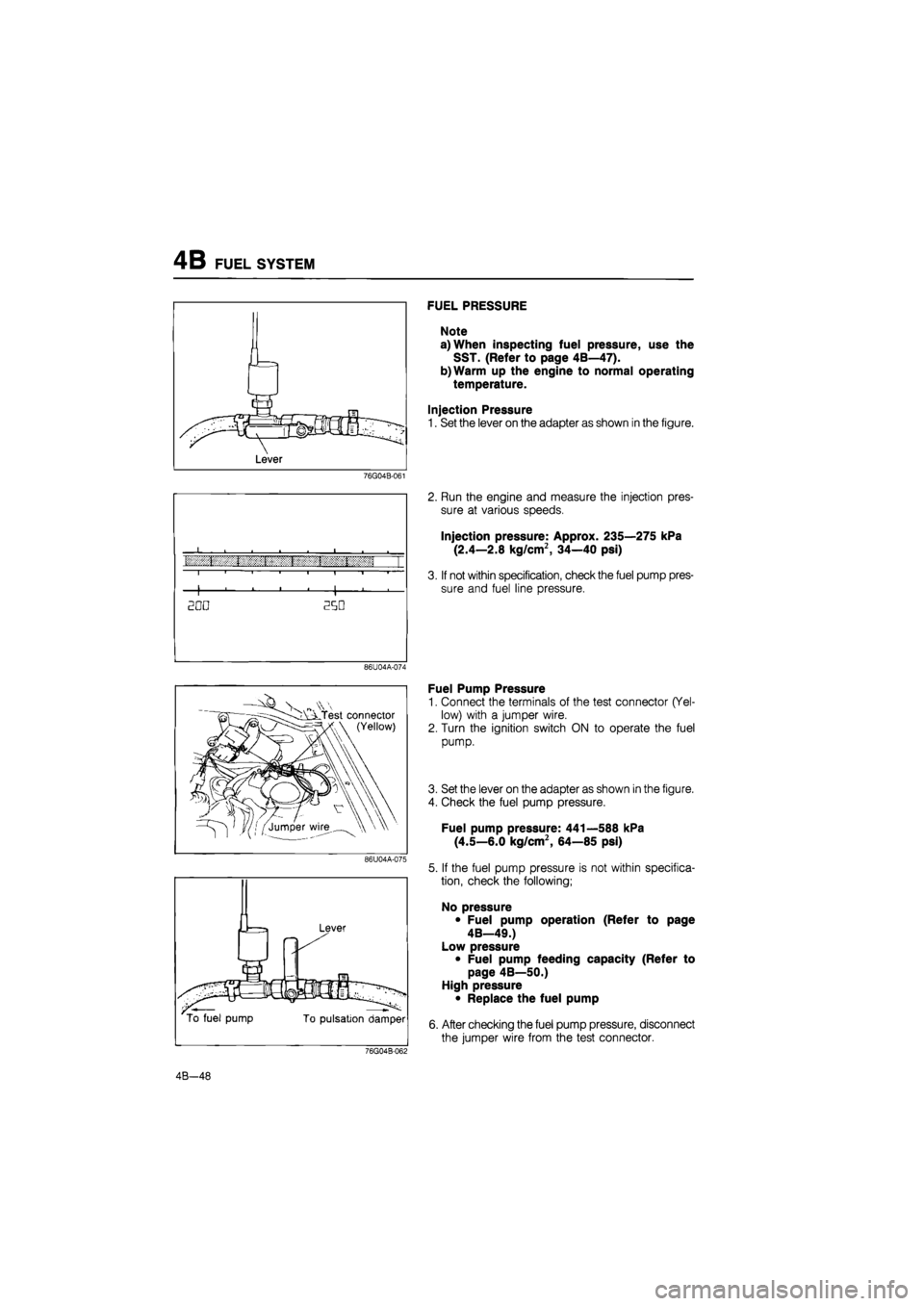

FUEL PRESSURE

Note

a) When inspecting fuel pressure, use the

SST. (Refer to page 4B—47).

b)Warm up the engine to normal operating

temperature.

Injection Pressure

1. Set the lever on the adapter as shown in the figure.

2. Run the engine and measure the injection pres-

sure at various speeds.

Injection pressure: Approx. 235—275 kPa

(2.4—2.8 kg/cm2, 34—40 psi)

3. If not within specification, check the fuel pump pres-

sure and fuel line pressure.

Fuel Pump Pressure

1. Connect the terminals of the test connector (Yel-

low) with a jumper wire.

2. Turn the ignition switch ON to operate the fuel

pump.

3. Set the lever on the adapter as shown in the figure.

4. Check the fuel pump pressure.

Fuel pump pressure: 441—588 kPa

(4.5—6.0 kg/cm2, 64—85 psi)

5. If the fuel pump pressure is not within specifica-

tion, check the following;

No pressure

• Fuel pump operation (Refer to page

4B—49.)

Low pressure

• Fuel pump feeding capacity (Refer to

page 4B—50.)

High pressure

• Replace the fuel pump

6. After checking the fuel pump pressure, disconnect

the jumper wire from the test connector.

76G04B-062

4B—48

Page 511 of 1865

FUEL SYSTEM 4B

76G04B-126

86U04A-078

V^AN.

- Test connector

(Yellow)

76G04B-063

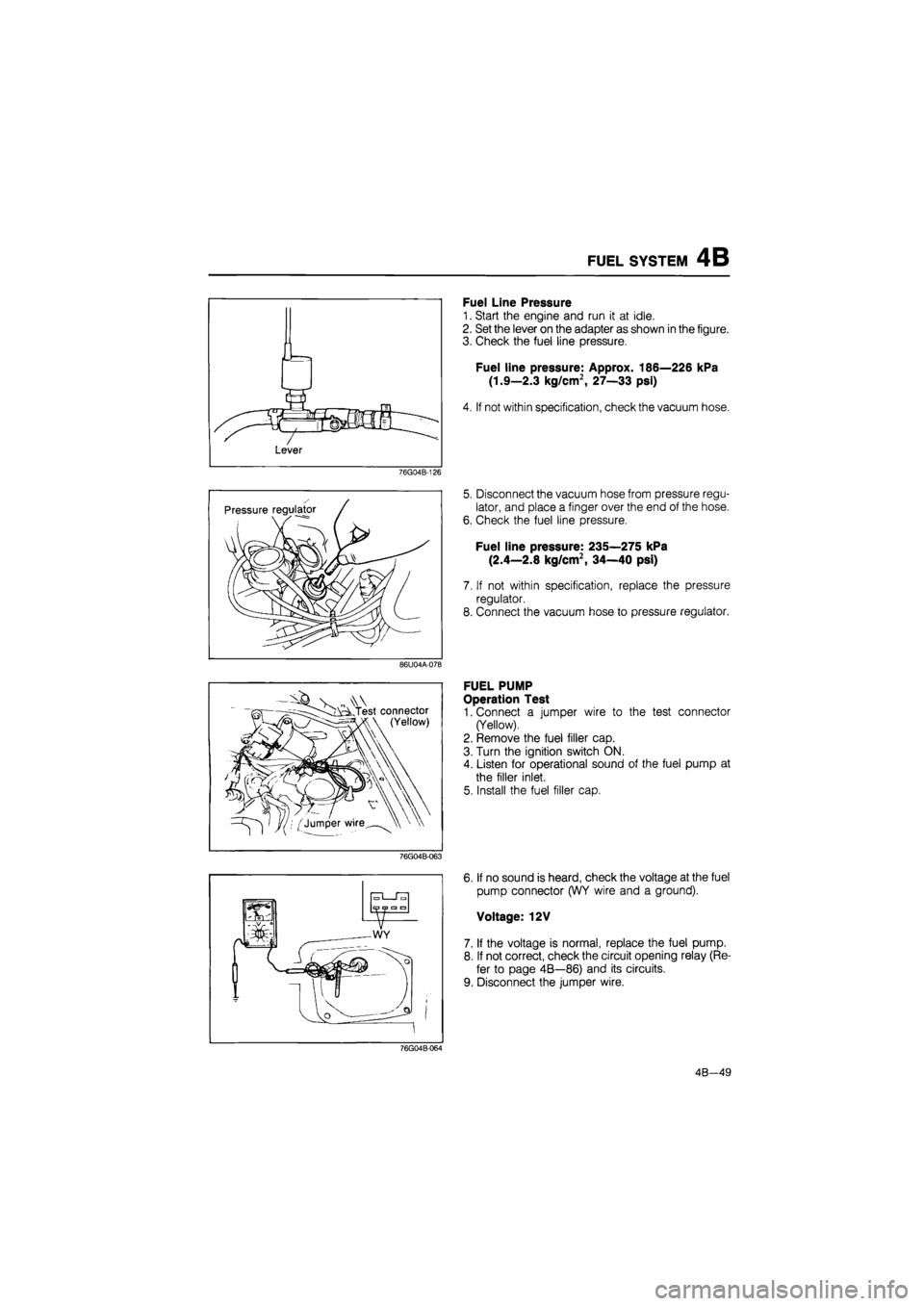

Fuel Line Pressure

1. Start the engine and run it at idle.

2. Set the lever on the adapter as shown in the figure.

3. Check the fuel line pressure.

Fuel line pressure: Approx. 186—226 kPa

(1.9—2.3 kg/cm2, 27—33 psi)

4. If not within specification, check the vacuum hose.

5. Disconnect the vacuum hose from pressure regu-

lator, and place a finger over the end of the hose.

6. Check the fuel line pressure.

Fuel line pressure: 235—275 kPa

(2.4—2.8 kg/cm2, 34—40 psi)

7. If not within specification, replace the pressure

regulator.

8. Connect the vacuum hose to pressure regulator.

FUEL PUMP

Operation Test

1. Connect a jumper wire to the test connector

(Yellow).

2. Remove the fuel filler cap.

3. Turn the ignition switch ON.

4. Listen for operational sound of the fuel pump at

the filler inlet.

5. Install the fuel filler cap.

6. If no sound is heard, check the voltage at the fuel

pump connector (WY wire and a ground).

Voltage: 12V

7. If the voltage is normal, replace the fuel pump.

8. If not correct, check the circuit opening relay (Re-

fer to page 4B—86) and its circuits.

9. Disconnect the jumper wire.

76G04B-064

4B—49

Page 512 of 1865

4B FUEL SYSTEM

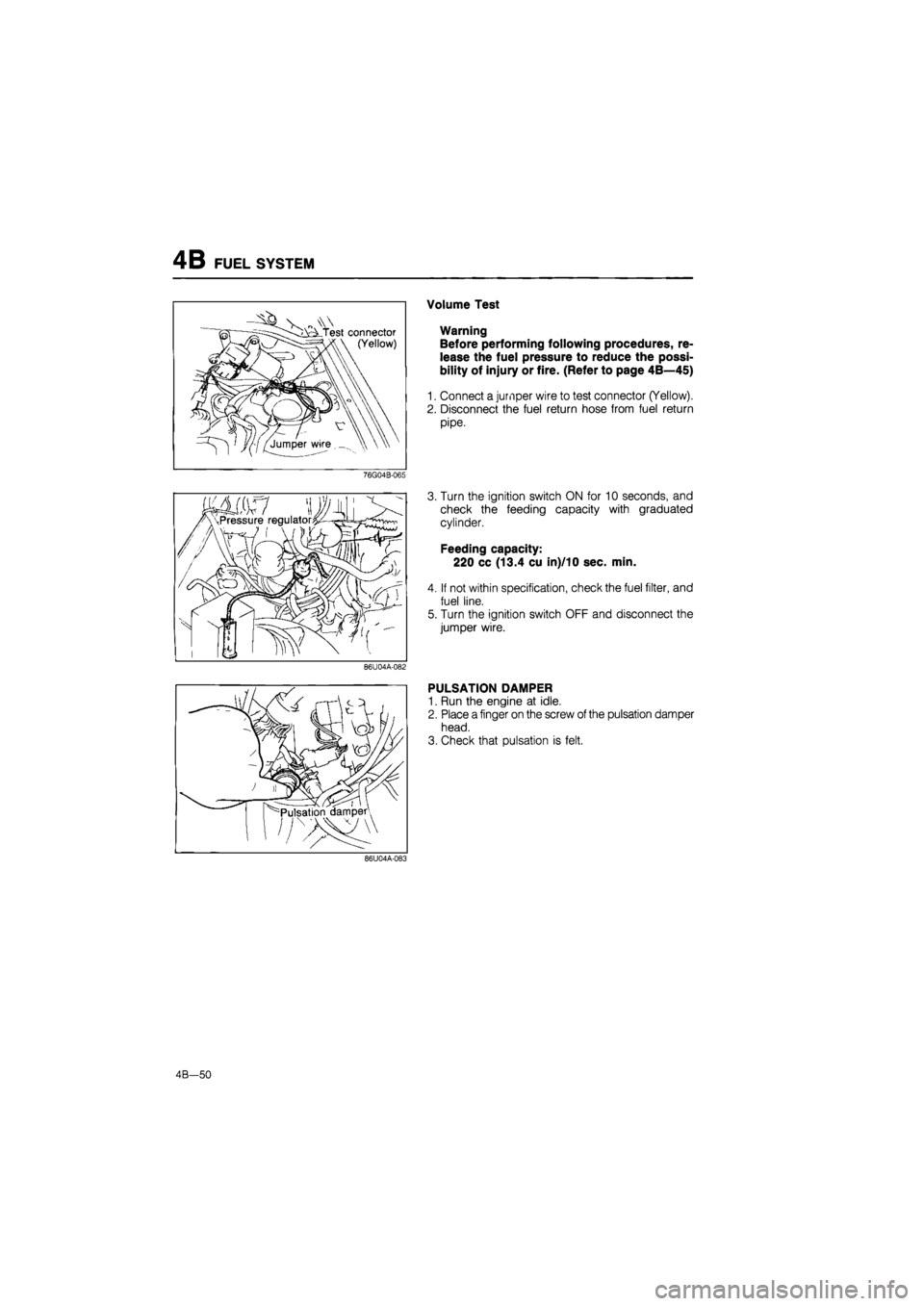

Volume Test

Warning

Before performing following procedures, re-

lease the fuel pressure to reduce the possi-

bility of injury or fire. (Refer to page 4B—45)

1. Connect a jumper wire to test connector (Yellow).

2. Disconnect the fuel return hose from fuel return

pipe.

76G04B-065

3. Turn the ignition switch ON for 10 seconds, and

check the feeding capacity with graduated

cylinder.

Feeding capacity:

220 cc (13.4 cu in)/10 sec. min.

4. If not within specification, check the fuel filter, and

fuel line.

5. Turn the ignition switch OFF and disconnect the

jumper wire.

86U04A-082

PULSATION DAMPER

1. Run the engine at idle.

2. Place a finger on the screw of the pulsation damper

head.

3. Check that pulsation is felt.

86U04A-083

4B—50

Page 513 of 1865

FUEL SYSTEM 4B

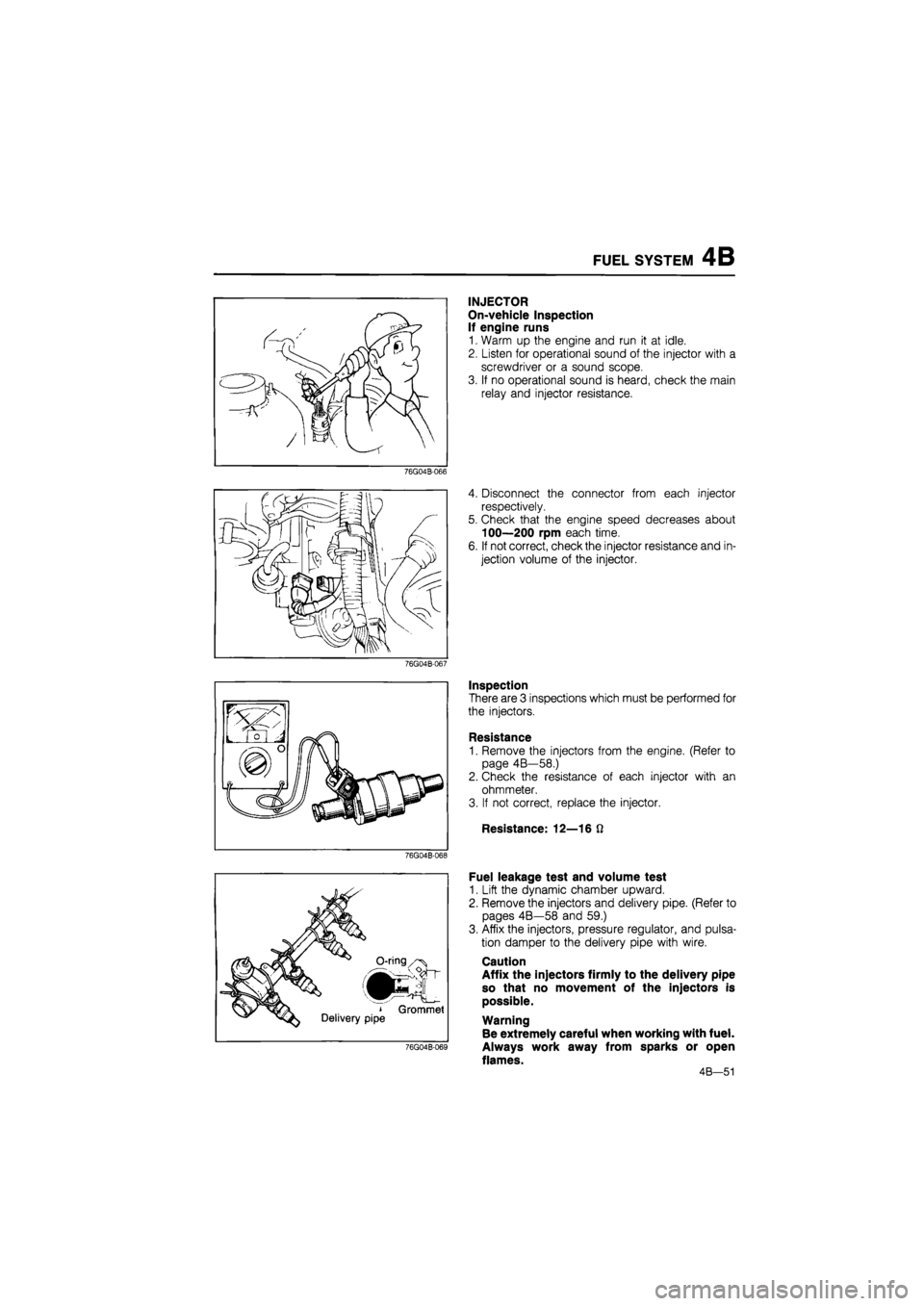

INJECTOR

On-vehicle Inspection

If engine runs

1. Warm up the engine and run it at idle.

2. Listen for operational sound of the injector with a

screwdriver or a sound scope.

3. If no operational sound is heard, check the main

relay and injector resistance.

76G04B-066

4. Disconnect the connector from each injector

respectively.

5. Check that the engine speed decreases about

100—200 rpm each time.

6. If not correct, check the injector resistance and in-

jection volume of the injector.

76G04B-067

Inspection

There are 3 inspections which must be performed for

the injectors.

Resistance

1. Remove the injectors from the engine. (Refer to

page 4B—58.)

2. Check the resistance of each injector with an

ohmmeter.

3. If not correct, replace the injector.

Resistance: 12—16 ft

76G04B-068

' Grommet Delivery pipe

76G04B-069

Fuel leakage test and volume test

1. Lift the dynamic chamber upward.

2. Remove the injectors and delivery pipe. (Refer to

pages 4B—58 and 59.)

3. Affix the injectors, pressure regulator, and pulsa-

tion damper to the delivery pipe with wire.

Caution

Affix the injectors firmly to the delivery pipe

so that no movement of the injectors is

possible.

Warning

Be extremely careful when working with fuel.

Always work away from sparks or open

flames.

4B—51

Page 515 of 1865

FUEL SYSTEM 4B

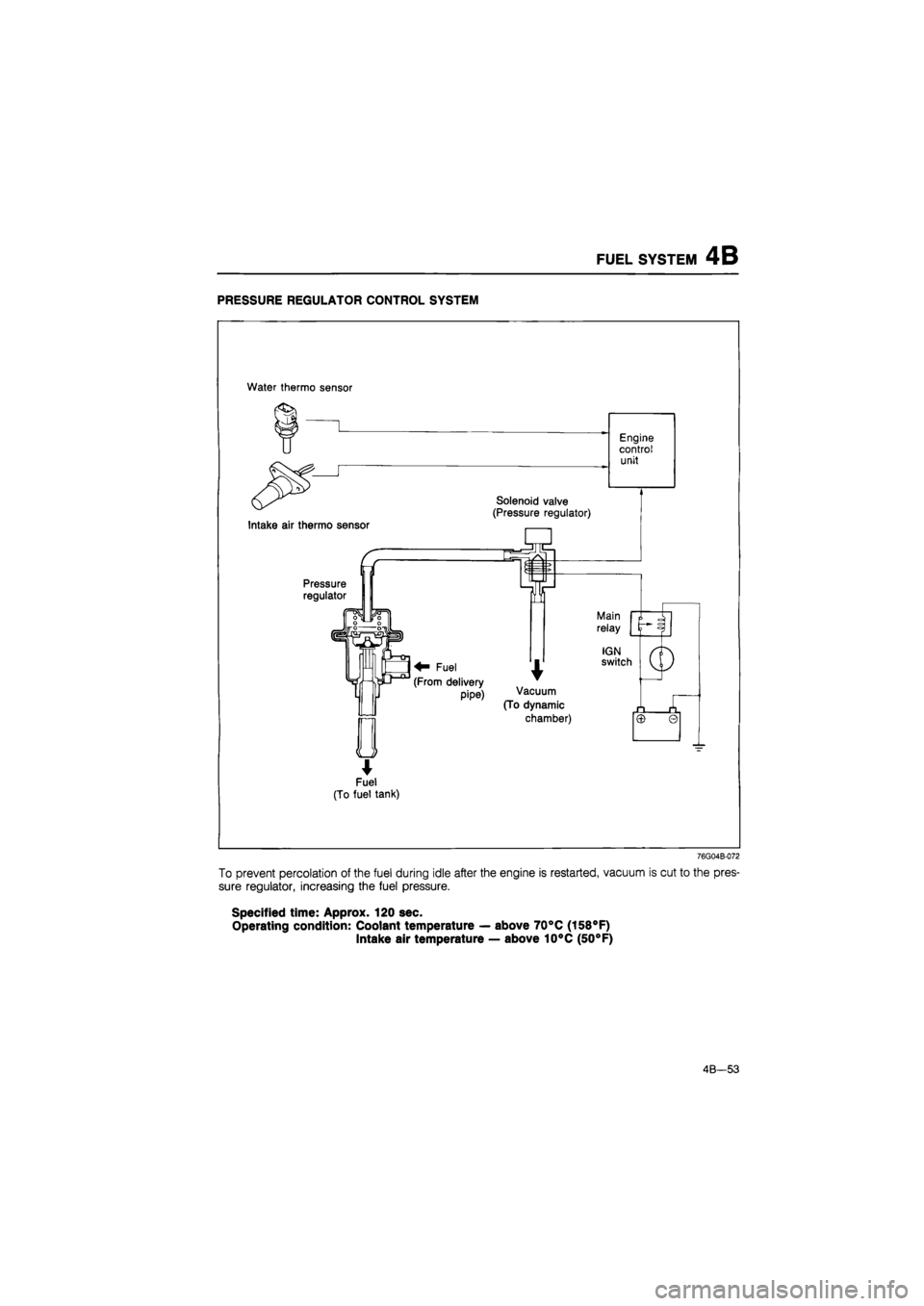

PRESSURE REGULATOR CONTROL SYSTEM

Water thermo sensor

*

Fuel

(To fuel tank)

76G04B-072

To prevent percolation of the fuel during idle after the engine is restarted, vacuum is cut to the pres-

sure regulator, increasing the fuel pressure.

Specified time: Approx. 120 sec.

Operating condition: Coolant temperature — above 70°C (158°F)

Intake air temperature — above 10°C (50°F)

4B—53

Page 516 of 1865

4B FUEL SYSTEM

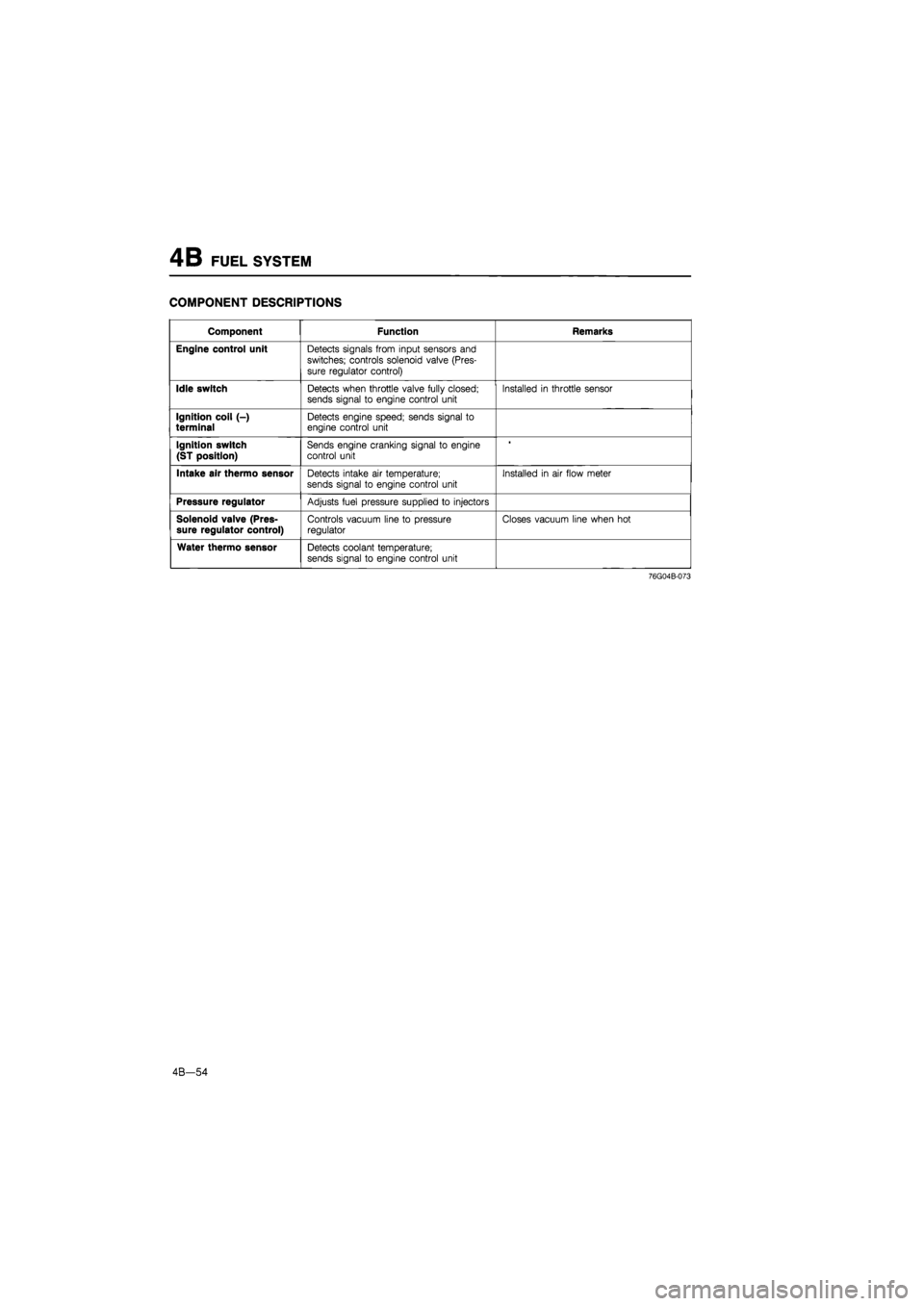

COMPONENT DESCRIPTIONS

Component Function Remarks

Engine control unit Detects signals from input sensors and

switches; controls solenoid valve (Pres-

sure regulator control)

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed in throttle sensor

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Ignition switch

(ST position)

Sends engine cranking signal to engine control unit

Intake air thermo sensor Detects intake air temperature; sends signal to engine control unit

Installed in air flow meter

Pressure regulator Adjusts fuel pressure supplied to injectors

Solenoid valve (Pres-sure regulator control) Controls vacuum line to pressure regulator Closes vacuum line when hot

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

76G04B-073

4B—54

Page 517 of 1865

FUEL SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connections before checking the sensors or switches

below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible \ cause

\ Page

Solenoid valve (Pres-sure regula-tor control)

Water thermo

sensor Intake air

thermo sensor

Engine con-trol unit terminal

2K

System inspection

Symptom 4B—56 4B—97 4B—94 4B—89 4B—55

Engine stalls or rough after hot starting 2 3

A

5 1

76G04B-074

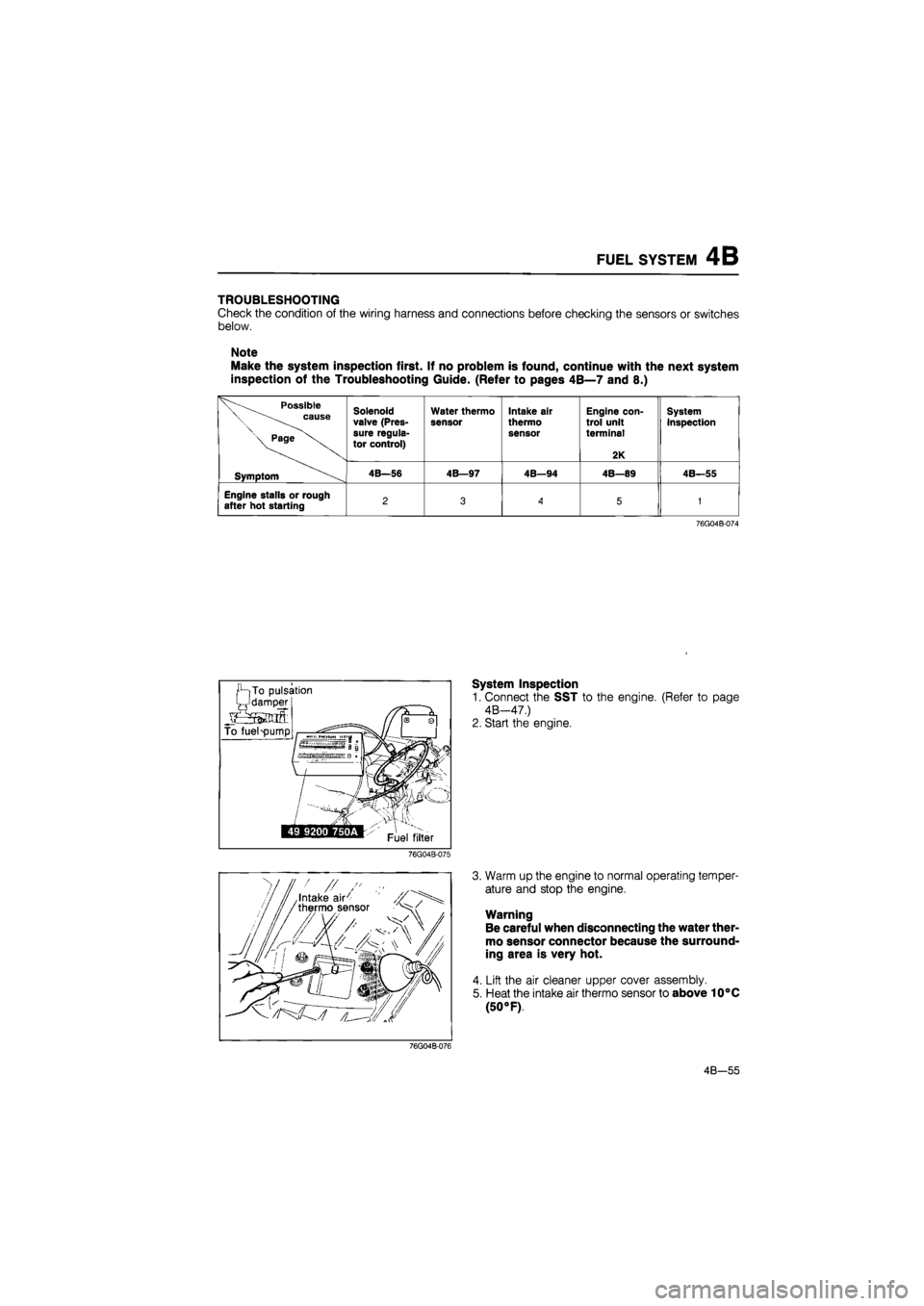

System Inspection

1. Connect the SST to the engine. (Refer to page

4B—47.)

2. Start the engine.

76G04B-075

3. Warm up the engine to normal operating temper-

ature and stop the engine.

Warning

Be careful when disconnecting the water ther-

mo sensor connector because the surround-

ing area is very hot.

4. Lift the air cleaner upper cover assembly.

5. Heat the intake air thermo sensor to above 10°C

(50 °F).

76G04B-076

4B—55

Page 518 of 1865

4B FUEL SYSTEM

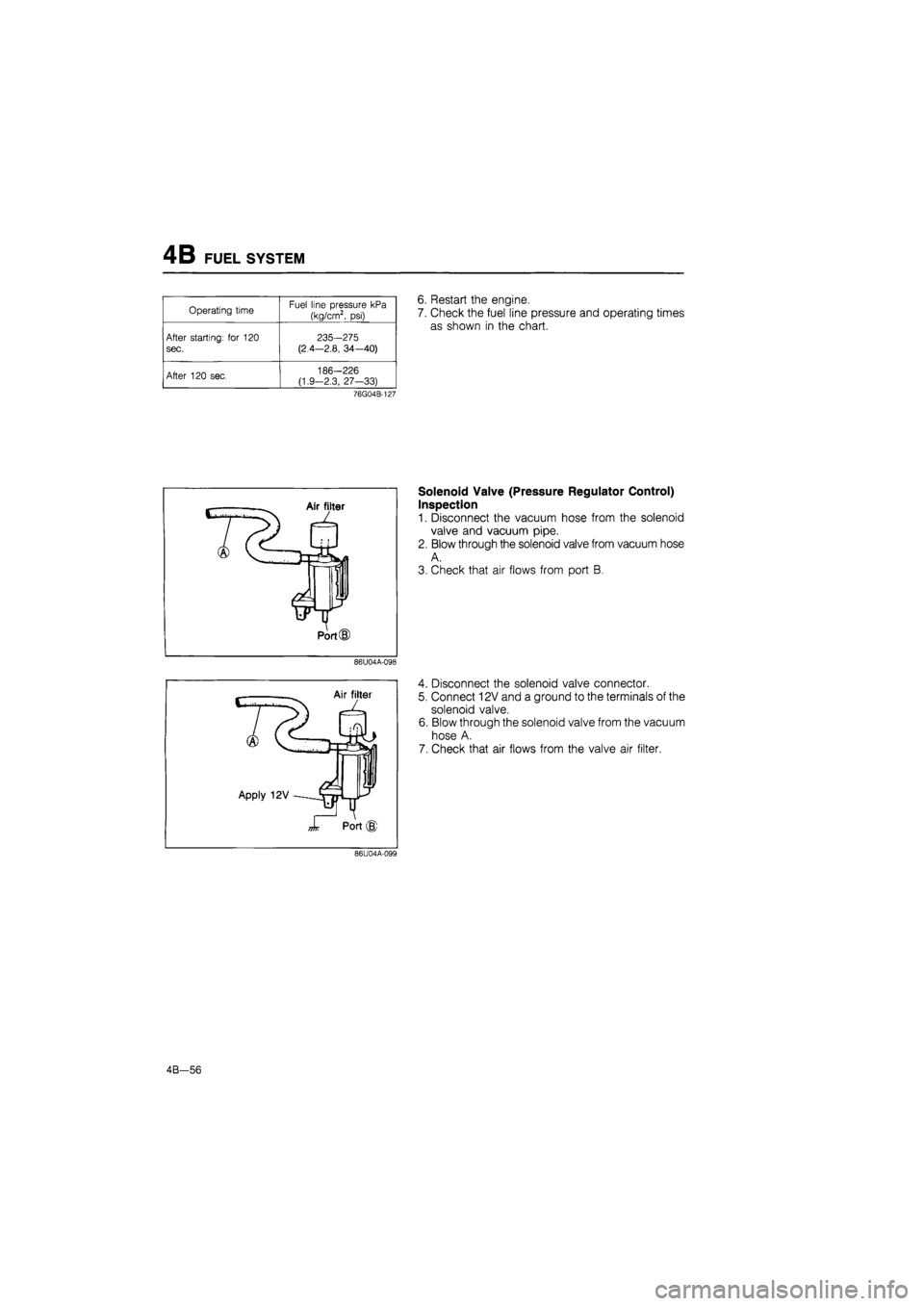

Operating time Fuel line pressure kPa

(kg/cm2, psi)

After starting: for 120

sec.

235-275

(2.4—2.8, 34—40)

After 120 sec, 186-226 (1.9-2.3, 27-33)

6. Restart the engine.

7. Check the fuel line pressure and operating times

as shown in the chart.

76G04B-127

Solenoid Valve (Pressure Regulator Control)

Inspection

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-098

Air filter

Apply 12V

Port (J)

4. Disconnect the solenoid valve connector.

5. Connect 12V and a ground to the terminals of the

solenoid valve.

6. Blow through the solenoid valve from the vacuum

hose A.

7. Check that air flows from the valve air filter.

86U04A-099

4B-56