engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 491 of 1865

IDLE ADJUSTMENT 4B

76G04B-034

76G04B-035

Idle mixture

Automatic

Control

Function

Engine Control Unit

IDLE

ADJUSTMENT

IDLE SPEED

Preparation

1) Check the condition of the engine (plugs, leaks in

hoses, etc.).

2) Make sure all accessories are OFF.

3) Warm up the engine and run it for three minutes

at 2,500—3,000 rpm in neutral.

4) Check the initial ignition timing and adjust if

necessary.

Inspection and Adjustment

Caution

Disconnect the air bypass solenoid connec-

tor when checking and adjusting the idle

speed.

1. Check that the idle speed is within specification.

Specification:

MTX—800 +58 rpm

ATX—900 +58 rpm (P range)

2. If the idle speed is not within specification, remove

the blind cap from the throttle body and adjust it

by turning the air adjust screw.

IDLE MIXTURE

Because an automatic compensation function

for air/fuel mixture is built into the engine con-

trol unit, it is not necessary to check and adjust

the idle mixture.

86U04A-049

4B-29

Page 492 of 1865

4B INTAKE AIR SYSTEM

INTAKE AIR SYSTEM

76G04B-036

This system controls the air required by the engine for operation. The system consists of the air duct,

air cleaner, air flow meter, throttle body, dynamic chamber, and intake manifold.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air cleaner

Filters

air

into throttle body

Air flow meter

Detects amount

of

intake air;

sends signal

to

engine control unit Intake

air

thermo sensor and fuel pump

switch are integrated

Throttle body

Controls intake

air

quantity Integrated throttle sensor and idle switch

76G04B-037

4B—30

Page 495 of 1865

INTAKE AIR SYSTEM 4B

76G04B-039

D C B E\\ I I A

p 'V > "

F G

76G04B-040

76G04B-041

1. Check that the throttle valve moves smoothly when

the throttle lever is moved from fully closed to fully

open.

2. Warm up the engine and run at idle.

3. Check the vacuum generated at each port as

shown in the following table.

~ —Condition

Port (Connected to) ——____ Idle Other

A (solenoid valve, EGR) No Yes

B (distributor, advance) No Yes

C (EGR modulator valve) No Yes

D (water thermo valve) No Yes

E (vacuum switch valve

&

charcoal canister) Yes

F (distributor, retard

& air

control valve) Yes

G (distributor, advance) Yes

4. If vacuum is not obtained as in the table, clean the

necessary port.

Dynamic Chamber

1. Visually check the dynamic chamber for damage.

2. Replace, if necessary.

Intake Manifold

1. Visually check the intake manifold for damage.

2. Replace, if necessary.

76G04B-042

4B—33

Page 497 of 1865

IDLE-UP SYSTEM 4B

IDLE-UP SYSTEM

Dynamic chamber

To engine i

lN

Water thermo |ntake air sensor thermo

sensor

E/L control unit

-D

Solenoid A

From air ^^ flow meter ~

Engine

control

unit

Atmospheric pressure sensor

HI

f

"Solenoid B

UJ m

Solenoid C

u

Adjusting screw

| A/C

H-!

relay

IGN switch

-©n

To engine

control

unit

Magnetic clutch

fftf

tr Main relay

r © ©

P/S pressure switch

76G04B-043

Air Valve

This valve is constructed so that the gate valve is opened and closed by means of a bimetal strip and

heat coil. It acts as a fast idle mechanism by opening the gate valve to increase intake air by bypass-

ing the throttle valve while engine is cold, therefore engine speed is increased to shorten the warm

up period.

Air Bypass Solenoid Valve

This valve incorporates three solenoid valves. They operate according to the signal from the engine

control unit or A/C switch in order to achieve idling stability and the optimum idle speed.

The operating conditions of each solenoid valve are as shown below.

Solenoid valve Operating condition

A A/C operated

B Intake air temp, above 55°C (131 °F)

or

vehicle

at

above 1,000

m

(3,280

ft)

C P/S operated, E/L applied, intake

air

temp, above 55°C (131 °F), pressure regulator solenoid ON

or

vehicle

at

above 1,900

m

(6,232

ft)

4B-35

Page 498 of 1865

4B IDLE-UP SYSTEM

COMPONENT DESCRIPTIONS

Component Function Remarks

Air bypass solenoid

valve

Controls bypass

air

amount Operates A: A/C

: ON

B: Intake

air

temp, high

or at

high

al-

titude C: P/S

:

ON, E/L applied

or

hot start

Air valve

When cold, supplies bypass

air

into

dy-

namic chamber

• Engine speed increased

to

shorten

warm-up period

• Bimetal type

Atmospheric pressure sensor

Detects atmospheric pressure; sends sig-

nal

to

engine control unit

E/L control unit

Detects electrical load applied; sends sig-nal

to

engine control unit

Engine control unit

Detects signals from input sensors and switches; controls

air

bypass solenoid valve

Intake air thermo sensor

Detects intake

air

temperature; sends sig-

nal

to

engine control unit

Installed

in air

flow meter

P/S pressure switch

Detects P/S operation; sends signal

to

engine control unit P/S:

ON

when steering wheel turnefl right

or

left

76g04b-044

4B-36

Page 499 of 1865

IDLE-UP SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switch.

Possible

cause

\ Page

Symptom

Air valve

Air bypass solenoid valve Engine control unit

terminal

Possible

cause

\ Page

Symptom

Air valve

Idle-up singal Adjustment

Engine control unit

terminal

Possible

cause

\ Page

Symptom

Air valve

Idle-up singal Adjustment

1S 20

Possible

cause

\ Page

Symptom 4B—38 4B—39 4B—40 4B—89 4B—90

Engine

stalls

While warming up

1 2 3 4 5

Engine

stalls After warming up

1 2 3 4

Rough Idle

While warming up

1 2 3 4 5

Rough Idle After warming up

1 2 3 4

High idle speed after warming up

1 2 3 4 5

Runs rough on deceleration

1 2 3 4

Afterburn in exhaust system

1 2 3 4 5

Fails emission test

1 2 3 4 5

76G04B-045

4B-37

Page 500 of 1865

4B IDLE-UP SYSTEM

AIR VALVE

Pre-inspection

1. Start the engine and run it at idle.

2. Pinch the bypass air hose and check that the en-

gine rpm drops.

When engine still cool RPM reduced

After warming-up RPM drop within

200 rpm

3. If the speed is not reduced when cold, check the

air valve, or check for vacuum leaks at the bypass

air hose.

4. If the speed drop is more than 200 rpm when

warm, check the air valve and current to the valve.

Inspection of Terminal Voltage

1. Disconnect the connector from the valve.

2. Remove the rubber boot from the connector.

3. Start the engine and run it at idle.

4. Check that there is battery voltage at terminal (WY),

using a voltmeter.

5. If not correct, check the circuit opening relay and

wiring harness.

76G04B-046

Inspection of Air Valve

1. Check the valve for operation.

Temperature 20°C (68°F) Valve open

(When engine cool)

After warming-up Valve closed

2. Replace valve if faulty.

76G04B-047

4B—38 expert22 Arm http://rutracker.org

Page 501 of 1865

IDLE-UP SYSTEM 4B

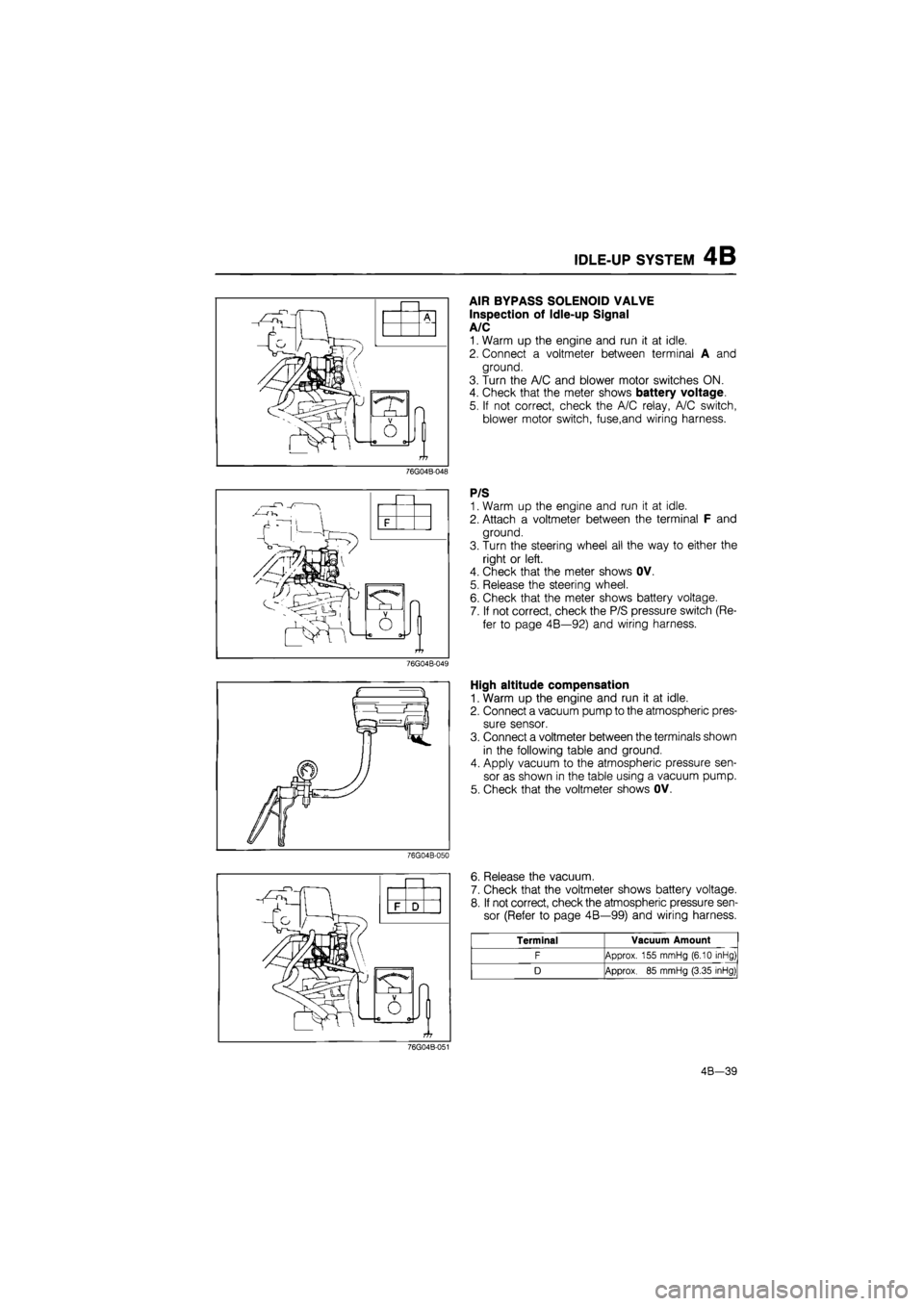

AIR BYPASS SOLENOID VALVE

Inspection of Idle-up Signal

A/C

1. Warm up the engine and run it at idle.

2. Connect a voltmeter between terminal A and

ground.

3. Turn the A/C and blower motor switches ON.

4. Check that the meter shows battery voltage.

5. If not correct, check the A/C relay, A/C switch,

blower motor switch, fuse,and wiring harness.

76G04B-048

P/S

1. Warm up the engine and run it at idle.

2. Attach a voltmeter between the terminal F and

ground.

3. Turn the steering wheel all the way to either the

right or left.

4. Check that the meter shows OV.

5. Release the steering wheel.

6. Check that the meter shows battery voltage.

7. If not correct, check the P/S pressure switch (Re-

fer to page 4B—92) and wiring harness.

76G04B-049

High altitude compensation

1. Warm up the engine and run it at idle.

2. Connect a vacuum pump to the atmospheric pres-

sure sensor.

3. Connect a voltmeter between the terminals shown

in the following table and ground.

4. Apply vacuum to the atmospheric pressure sen-

sor as shown in the table using a vacuum pump.

5. Check that the voltmeter shows OV.

76G04B-050

J

O

6. Release the vacuum.

7. Check that the voltmeter shows battery voltage.

8. If not correct, check the atmospheric pressure sen-

sor (Refer to page 4B—99) and wiring harness.

Terminal Vacuum Amount

F Approx. 155 mmHg (6.10 inHg)

D Approx.

85

mmHg (3.35 inHg)

76G04B-051

4B-39

Page 502 of 1865

4B IDLE-UP SYSTEM

76G04B-052

76G04B-053

76G04B-054

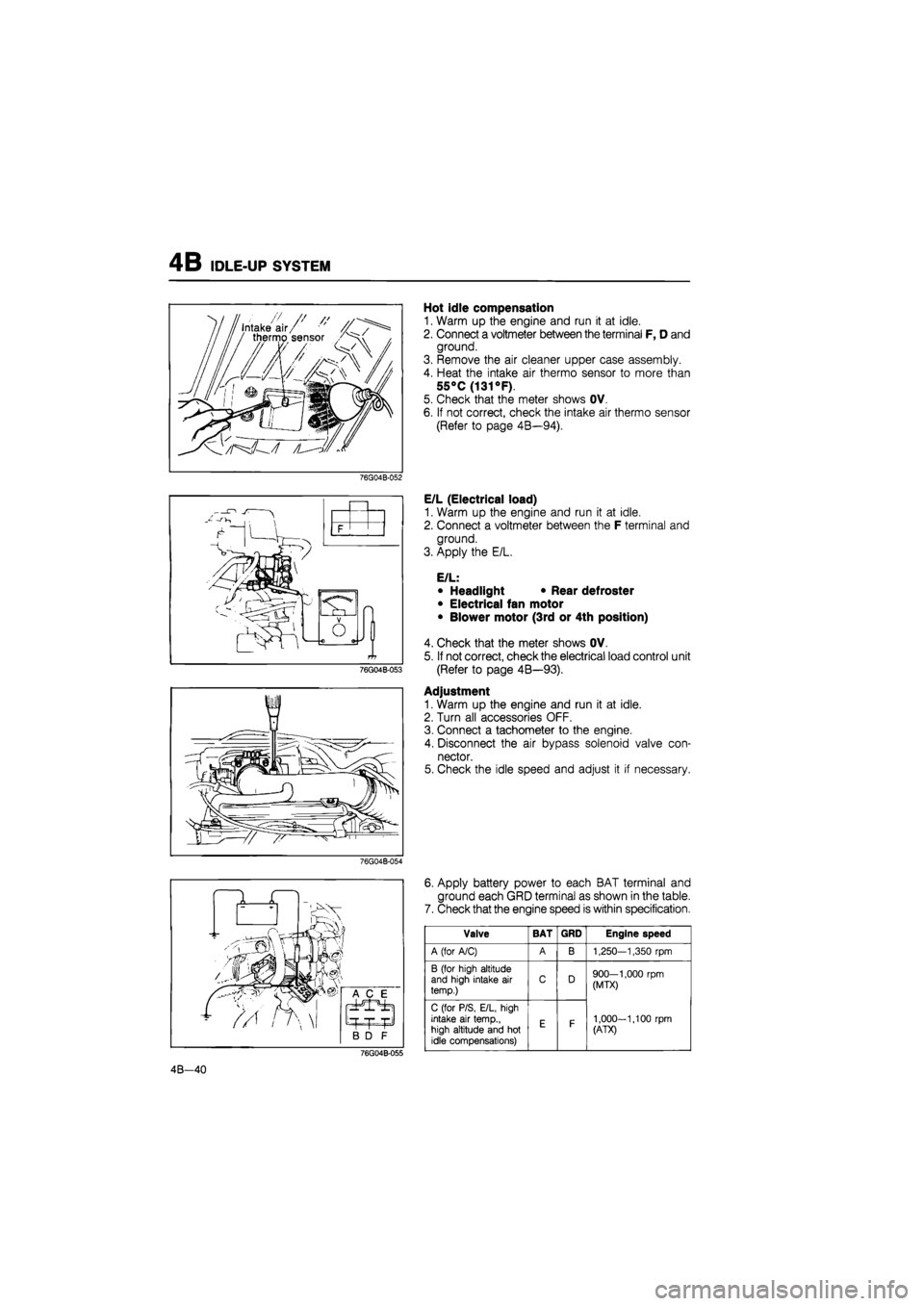

Hot idle compensation

1. Warm up the engine and run it at idle.

2. Connect a voltmeter between the terminal F, D and

ground.

3. Remove the air cleaner upper case assembly.

4. Heat the intake air thermo sensor to more than

55°C

(131

°F).

5. Check that the meter shows OV.

6. If not correct, check the intake air thermo sensor

(Refer to page 4B—94).

E/L (Electrical load)

1. Warm up the engine and run it at idle.

2. Connect a voltmeter between the F terminal and

ground.

3. Apply the E/L.

E/L:

• Headlight • Rear defroster

• Electrical fan motor

• Blower motor (3rd or 4th position)

4. Check that the meter shows OV.

5. If not correct, check the electrical load control unit

(Refer to page 4B—93).

Adjustment

1. Warm up the engine and run it at idle.

2. Turn all accessories OFF.

3. Connect a tachometer to the engine.

4. Disconnect the air bypass solenoid valve con-

nector.

5. Check the idle speed and adjust it if necessary.

6. Apply battery power to each BAT terminal and

ground each GRD terminal as shown in the table.

7. Check that the engine speed is within specification.

76G04B-055

Valve BAT GRD Engine speed

A (for A/C) A B 1,250—1,350

rpm

B (for high altitude and high intake

air

temp.) C D 900—1,000

rpm

(MTX)

1,000-1,100

rpm

(ATX)

C (for P/S, E/L, high intake

air

temp., high altitude and

hot

idle compensations)

E F

900—1,000

rpm

(MTX)

1,000-1,100

rpm

(ATX)

4B—40

Page 505 of 1865

FUEL SYSTEM 4B

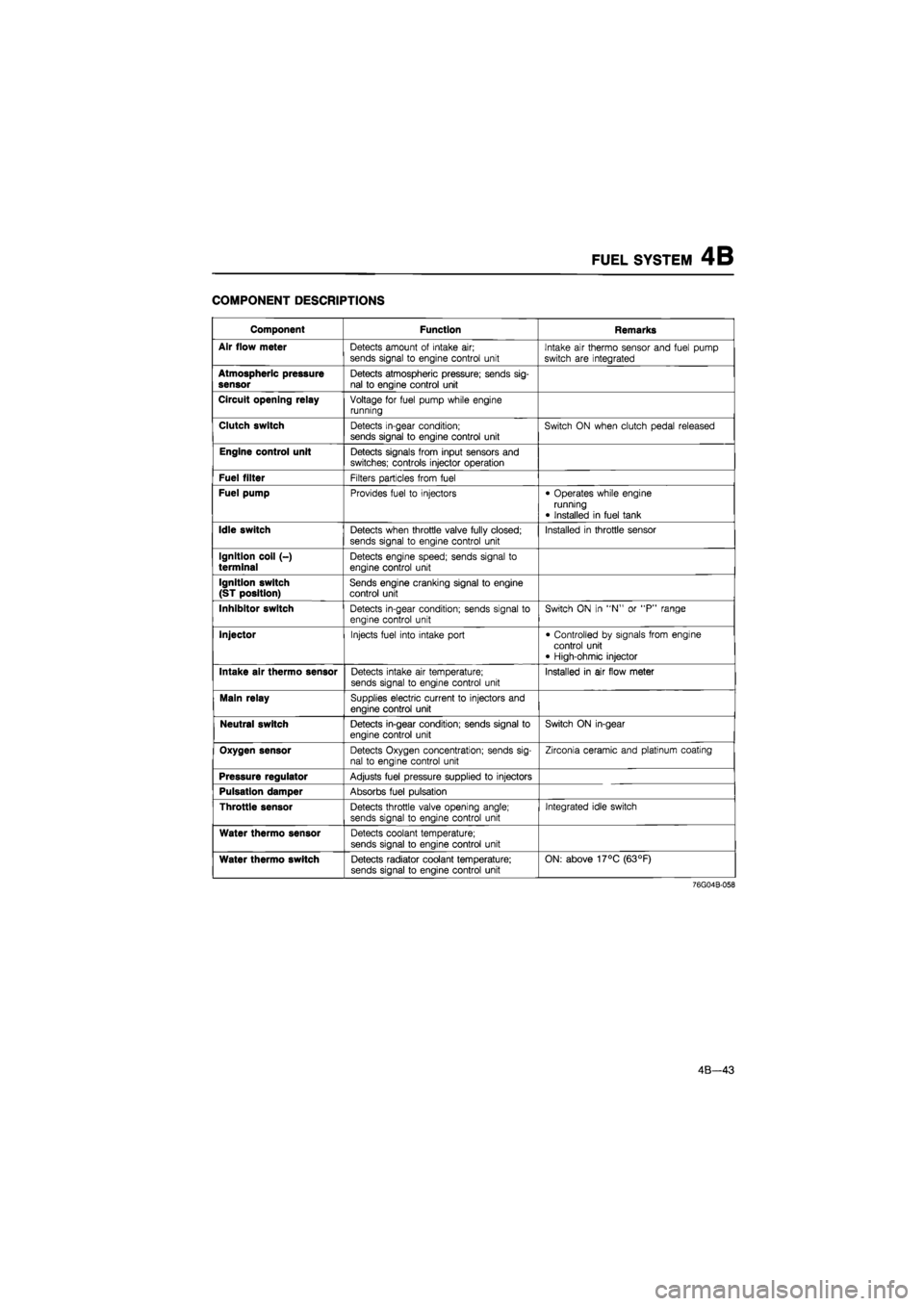

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter

Detects amount

of

intake

air;

sends signal

to

engine control unit Intake

air

thermo sensor and fuel pump

switch

are

integrated

Atmospheric pressure sensor

Detects atmospheric pressure; sends sig-nal

to

engine control unit

Circuit opening relay

Voltage

for

fuel pump while engine running

Clutch switch

Detects in-gear condition; sends signal

to

engine control unit Switch

ON

when clutch pedal released

Engine control unit

Detects signals from input sensors and switches; controls injector operation

Fuel filter

Filters particles from fuel

Fuel pump

Provides fuel

to

injectors • Operates while engine running

• Installed

in

fuel tank

Idle switch

Detects when throttle valve fully closed;

sends signal

to

engine control unit

Installed

in

throttle sensor

Ignition coil (-) terminal

Detects engine speed; sends signal

to

engine control unit

Ignition switch (ST position)

Sends engine cranking signal

to

engine control unit

Inhibitor switch

Detects in-gear condition; sends signal

to

engine control unit

Switch

ON in "N" or "P"

range

Injector

Injects fuel into intake port • Controlled

by

signals from engine control unit • High-ohmic injector

Intake air thermo sensor

Detects intake

air

temperature;

sends signal

to

engine control unit Installed

in air

flow meter

Main relay

Supplies electric current

to

injectors and engine control unit

Neutral switch

Detects in-gear condition; sends signal

to

engine control unit

Switch

ON

in-gear

Oxygen sensor

Detects Oxygen concentration; sends sig-nal

to

engine control unit

Zirconia ceramic and platinum coating

Pressure regulator

Adjusts fuel pressure supplied

to

injectors

Pulsation damper

Absorbs fuel pulsation

Throttle sensor

Detects throttle valve opening angle; sends signal

to

engine control unit

Integrated idle switch

Water thermo sensor

Detects coolant temperature;

sends signal

to

engine control unit

Water thermo switch

Detects radiator coolant temperature; sends signal

to

engine control unit ON: above 17°C (63°F)

76G04B-058

4B—43