check engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1457 of 1865

PARKING BRAKE 1 1

86U11X-130

86U11X-131

PARKING BRAKE

ON-VEHICLE MAINTENANCE

Parking Brake Lever Stroke

Inspection

Check that the stroke is within specification when the

parking brake lever is pulled with a force of 98N

(10kg, 22lb).

Stroke: 5—7 notches

Adjustment

1. Before adjustment, start the engine and depress

the brake pedal several times.

2. Stop the engine.

3. Remove the adjust nut clip and turn the adjust nut

at the front of the parking cable.

4. After adjustment, check the following points:

(1) Turn the ignition switch ON, pull the parking

brake lever one notch, and check that the park-

ing brake warning lamp illuminates.

(2) Check that the rear brakes do not drag.

11—65

Page 1465 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

TROUBLESHOOTING

Precaution

Conditions that are not malfunctions

1. It may happen that vibration is felt in the steering wheel, body, and/or brake pedal when the ABS

is functioning; such vibration is simply an indication that the system is functioning.

2. Sound of the pump motor operating, accumulator pressure being released, or the relay operating

may be heard from the engine compartment when the engine is started as the system is being auto-

matically checked.

3. The ABS pump motor may be automatically activated even though the ABS is not operating.

4. The ABS warning light may illuminate under any of the following conditions:

• When the vehicle is traveling on snow or ice with the parking brake activated or a brake dragging

at one wheel.

• When different-sized tires are used.

• When tires of different gripping performance are used.

• When (while the vehicle is jacked up or stuck) only the front wheels are spun for 20 seconds or more.

• When there is insufficient battery voltage.

Note

Under the above conditions, the warning light will not illuminate a second time when the

ignition is switched OFF then back ON, and there will be no memory entry to the control

unit of a problem.

Troubleshooting notes

The ABS is composed of electrical components, mechanical components (hydraulic unit), and the com-

ponents of the standard brake system.

Fundamentally, malfunction of the ABS electrical or mechanical components is judged by the self-

diagnosis function within the ABS control unit. And malfunctions are indicated by the warning light

in the instrument panel.

The location

of

a malfunction is indicated by the technician switching the system to the diagnosis-indication

mode.

The self-diagnosis and indication functions must be used when malfunctions of the ABS are being

diagnosed.

76G11X-091

11—73

Page 1466 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

Troubleshooting Main Flow Chart

Check that the ABS warning light operates.

• Turn ignition switch OFF

to

ON, and check that ABS warning light illuminates constantly.

Flashing (Past failure)

OK

Check the ABS for failure.

• Start engine, and observe flashing

of

warning light.

Does not

illuminate

constantly

Warning light Possible cause

Does

not il-

luminate

at all

Refer

to

page 11—86.

ON

Alternator

L

ter-minal output Wiring harness (ALT-control unit) Control unit

OFF

1 sec

Alternator

L

ter-minal output Wiring harness (ALT-control unit) Control unit

ON

Relay box wiring harness (warning light-control unit) Control unit

OFF

1 sec

Relay box wiring harness (warning light-control unit) Control unit

No illumination

(Not diagnosed)

Illuminates constantly

(Present failure)

ABS is usually operating cor-rectly.

Consult table below when ABS failure

is

still suspected.

System Possible cause

ABS Brake light switch

Both rear wheel speed sensors

Control unit Proportioning

valve

in hy-

draulic unit

Other than Refer

to

ABS troubleshoot-ing guide

on

page 11—5.

Repair failures with flow

chart. (Refer to page

11—76.)

76G11X-054

11-74

Page 1467 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

Diagnosis Table

Note

Flashing of the warning light shows past failure, and its illumination shows present failure.

Diagnosis indication Possible failure Flow chart

No. Warning light Voltmeter Possible failure Flow chart

No.

ON

n

i2vn

OV

Hydraulic unit Harness

Right front wheel speed

sensor ABS-1

ON

n nn

Hydraulic unit Harness Left front wheel speed sensor ABS-2

OFF

Hydraulic unit Harness Left front wheel speed sensor ABS-2

OFF

nnn

Hydraulic unit Harness

Rear wheel speed sensor ABS-3

n

nnnn

Right front sensor rotor ABS-4

n

nnnnn

Left front sensor rotor ABS-5

JLilTUITLTL

Right rear sensor rotor ABS-6

jirLruiJum

Left rear sensor rotor ABS-7

J n

Hydraulic unit Harness

Control unit connector (11-pin)

ABS-8

nnnn

Hydraulic unit Harness

Control unit connector (11-pin)

ABS-8

J nn

Relay box

Hydraulic unit

Harness

ABS-9

jumruiTL

Relay box

Hydraulic unit

Harness

ABS-10

j nnn

Relay box

Hydraulic unit

Harness

ABS-11

jinnjuuL

Relay box

Hydraulic unit

Harness ABS-12

j nnnn

Relay box

Hydraulic unit

Harness

ABS-13

jiruuirirL

Relay box

Hydraulic unit

Harness

ABS-14

j nnnnn

Hydraulic unit Harness Control unit

ABS-15

juuuiruL

Hydraulic unit Harness Control unit ABS-16

j JinjiruifL.

Control unit

ABS-17

jiruinjiri—

JinjiruifL.

Control unit

ABS-18

j

No signal; failure condi-tions not stored

in

memory

Control unit Control unit connector (17-pin) Battery capacity Alternator output voltage Wiring harness (warning light-control unit-check connector)

Inspect, and repair or replace as necessary

j

No signal; failure condi-tions not stored

in

memory

No problem When warning light does

not

illuminate with engine running and

no

jumper wire

76G11X092

11-75

Page 1468 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

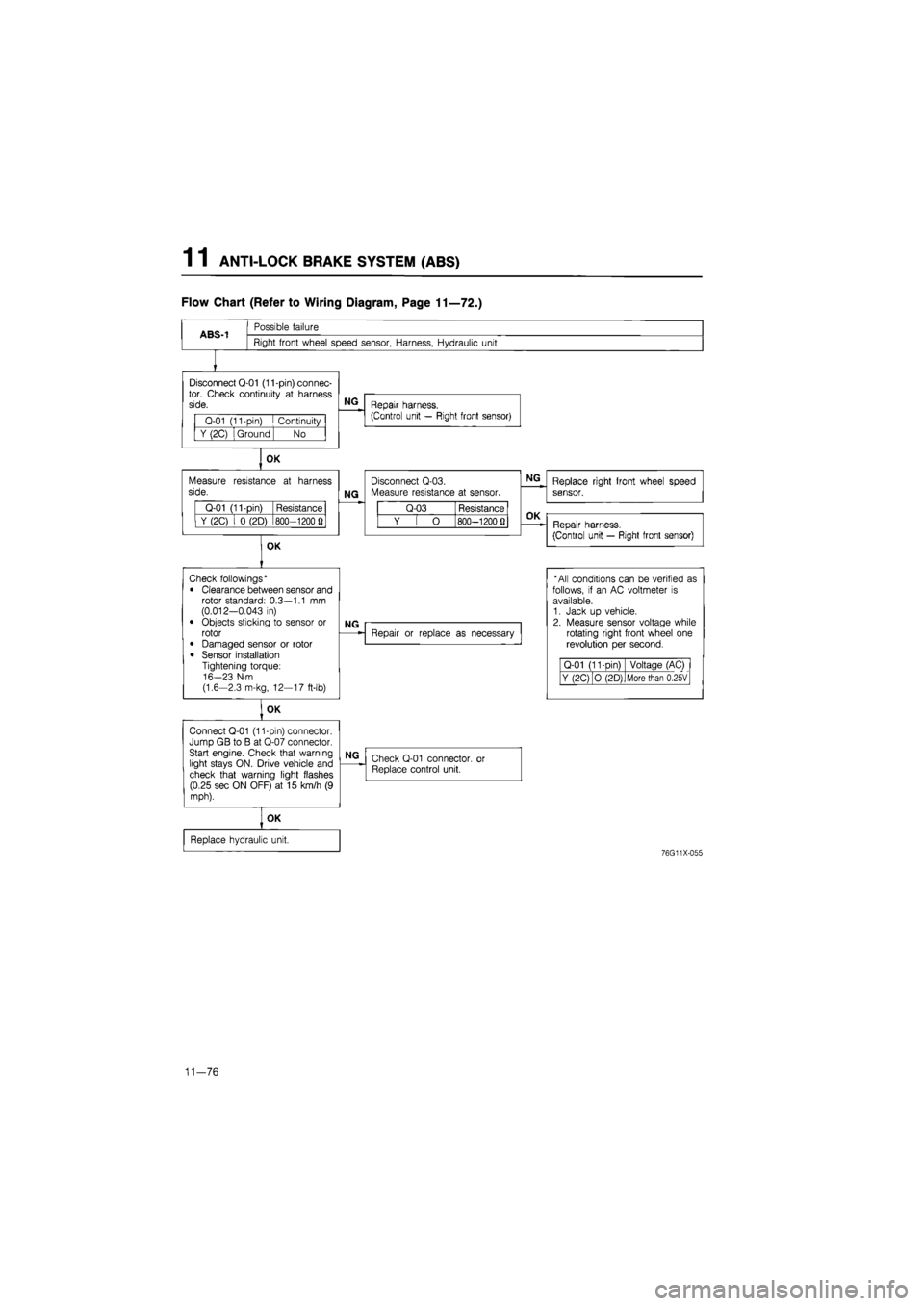

Flow Chart (Refer to Wiring Diagram, Page 11—72.)

ABS-1

Possible failure

Right front wheel speed sensor, Harness, Hydraulic unit

Disconnect Q-01 (11-pin) connec-tor. Check continuity

at

harness side.

Q-01 (11-pin)

I

Continuity

Y (2C) Ground No

OK

Measure resistance

at

harness side.

Q-01 (11-pin) Resistance

Y (2C)

i 0

(2D) 800—1200

Q

OK

NG

Repair harness.

(Control unit — Right front sensor)

NG

Disconnect Q-03. Measure resistance

at

sensor.

Q-03 Resistance

Y

[ O

800—1200 Q

NG

Replace right front wheel speed sensor.

OK

Repair harness.

(Control unit — Right front sensor)

Check followings*

• Clearance between sensor and rotor standard: 0.3—1.1

mm

(0.012-0.043

in)

• Objects sticking

to

sensor

or

rotor

• Damaged sensor

or

rotor

• Sensor installation Tightening torque: 16-23 N-m (1.6-2.3 m-kg, 12—17 ft-lb)

OK

Connect Q-01 (11-pin) connector. Jump GB

to B at

Q-07 connector. Start engine. Check that warning light stays ON. Drive vehicle and check that warning light flashes (0.25 sec ON OFF)

at 15

km/h

(9

mph).

NG

Repair

or

replace

as

necessary

* All conditions can

be

verified

as

follows,

if an AC

voltmeter

is

available. 1. Jack

up

vehicle. 2. Measure sensor voltage while rotating right front wheel

one

revolution

per

second.

Q-01 (11-Din) Voltage (AC)

Y (2C) O (2D) More than 0.25V

NG

Check Q-01 connector,

or

Replace control unit.

OK

Replace hydraulic unit.

76G11X-055

11—76

Page 1469 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

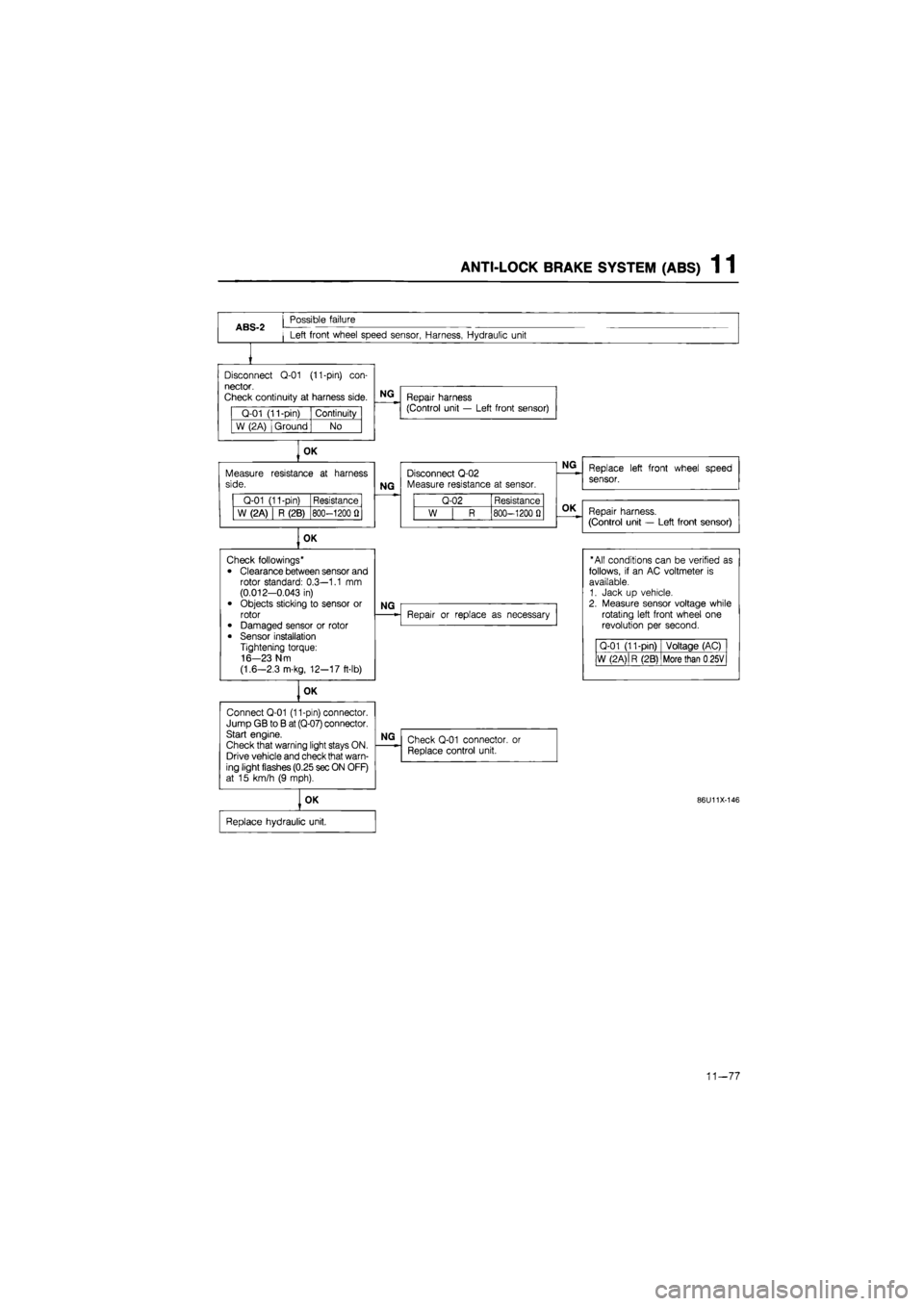

ABS-2

Possible failure

Left front wheel speed sensor, Harness, Hydraulic unit

Disconnect

Q-01

(11-pin)

con-

nector.

Check continuity

at

harness side.

Q-01 (11-pin) Continuity

W (2A) Ground No

OK

Measure side.

Q-01 (11-pin) Resistance

W (2A) R (2B) 800-1200

fl

OK

Connect Q-01 (11-pin) connector. Jump GB

to B

at (Q-07) connector. Start engine.

Check that warning light stays ON. Drive vehicle and check that warn-ing light flashes (0.25 sec ON OFF) at

15

km/h

(9

mph).

NG

Repair harness (Control unit

—

Left front sensor)

resistance

at

harness

NG

Disconnect Q-02 Measure resistance

at

sensor.

Q-02 Resistance

W

| R

800-1200

0

OK

Check followings*

• Clearance between sensor and rotor standard: 0.3—1.1

mm

(0.012-0.043

in)

• Objects sticking

to

sensor

or

rotor • Damaged sensor

or

rotor

• Sensor installation Tightening torque: 16-23 N m

(1.6—2.3 m-kg, 12-17 ft-lb)

NG

OK

NG

Repair

or

replace

as

necessary

NG

Check Q-01 connector,

or

Replace control unit.

OK

Replace hydraulic unit.

Replace left front wheel speed

sensor.

Repair harness.

(Control unit

—

Left front sensor)

"All conditions can

be

verified

as

follows,

if an AC

voltmeter

is

available. 1. Jack

up

vehicle. 2. Measure sensor voltage while rotating left front wheel

one

revolution

per

second.

Q-01 (11-pin) Voltage (AC)

W (2 A)

|

R (2B) More than

0

25V

86U11X-146

11-77

Page 1470 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

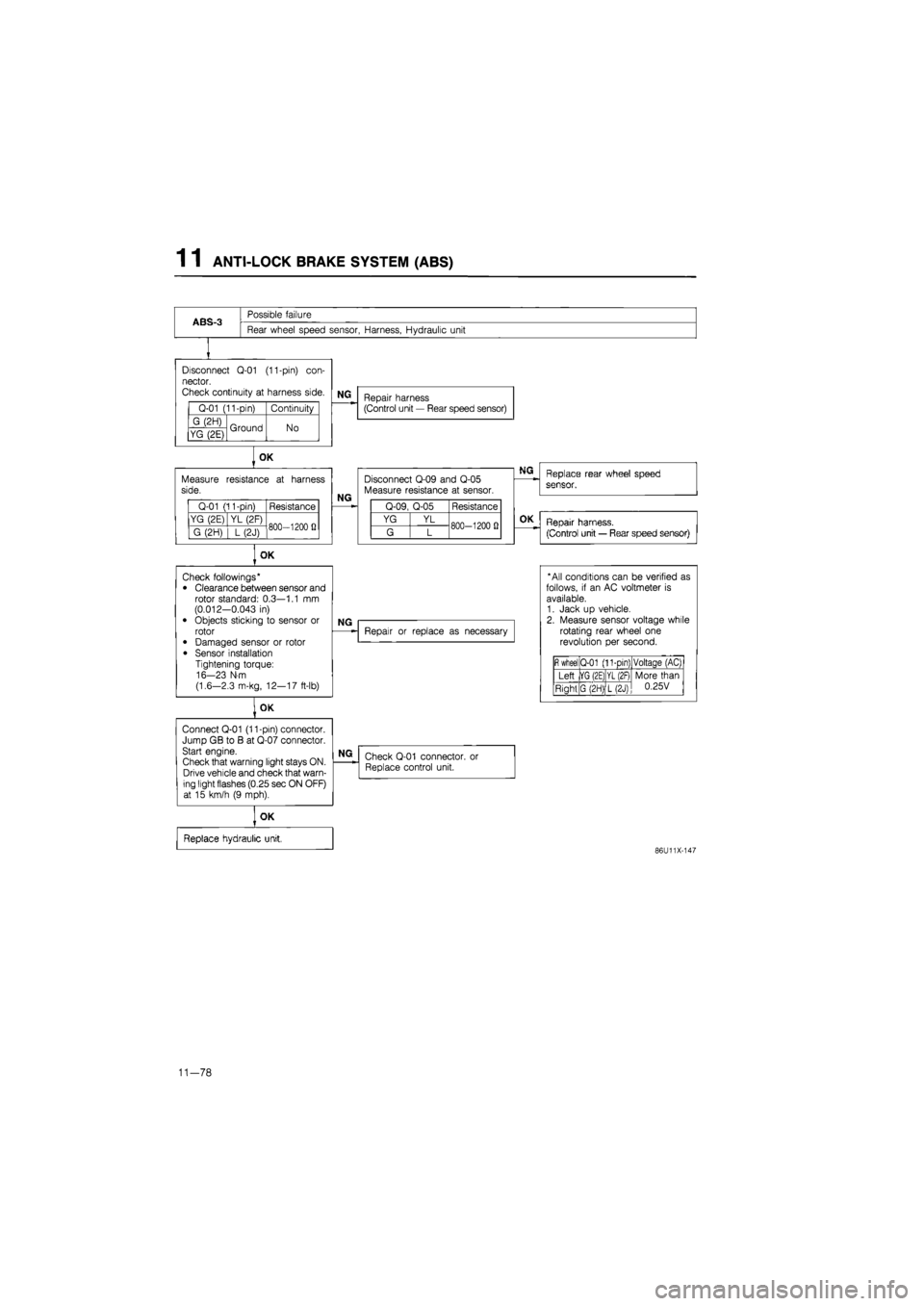

ABS-3

Possible failure

Rear wheel speed sensor, Harness, Hydraulic unit

Disconnect

Q-01

(11-pin)

con-

nector.

Check continuity

at

harness side.

Q-01 (11-pin) Continuity

G (2H) Ground No YG (2E) Ground No

Measure side.

Q-01 (11-pin) Resistance

YG (2E) YL (2F) 800—1200

fi

G (2H)

] L

(2J) 800—1200

fi

OK

Connect Q-01 (11-pin) connector. Jump GB

to B at

Q-07 connector. Start engine.

Check that warning light stays ON. Drive vehicle and check that warn-ing light flashes (0.25 sec ON OFF) at

15

km/h

(9

mph).

NG

Repair harness (Control unit

—

Rear speed sensor)

OK

resistance

at

harness

NG

Disconnect Q-09 and Q-05 Measure resistance

at

sensor.

Q-09, Q-05 Resistance

YG YL 800-1200

0

G L 800-1200

0

OK

Check followings* • Clearance between sensor and rotor standard: 0.3—1.1

mm

(0.012-0.043

in)

• Objects sticking

to

sensor

or

rotor

• Damaged sensor

or

rotor

• Sensor installation Tightening torque: 16-23 N-m

(1.6—2.3 m-kg, 12—17 ft-lb)

NG

Repair

or

replace

as

necessary

NG

Check Q-01 connector. Replace control unit.

or

OK

Replace hydraulic unit,

Replace rear wheel speed

sensor.

OK

Repair harness.

(Control unit

—

Rear speed sensor)

* All conditions can

be

verified

as

follows,

if an AC

voltmeter

is

available. 1. Jack

up

vehicle. 2. Measure sensor voltage while rotating rear wheel

one

revolution

per

second.

fi

wheel Q-01 (11-pin) Voltaqe (AC)

Left |YG (2E) YL (2F) More than 0.25V Right G (2H) L(2J)

More than 0.25V

86U11X-147

11-78

Page 1472 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

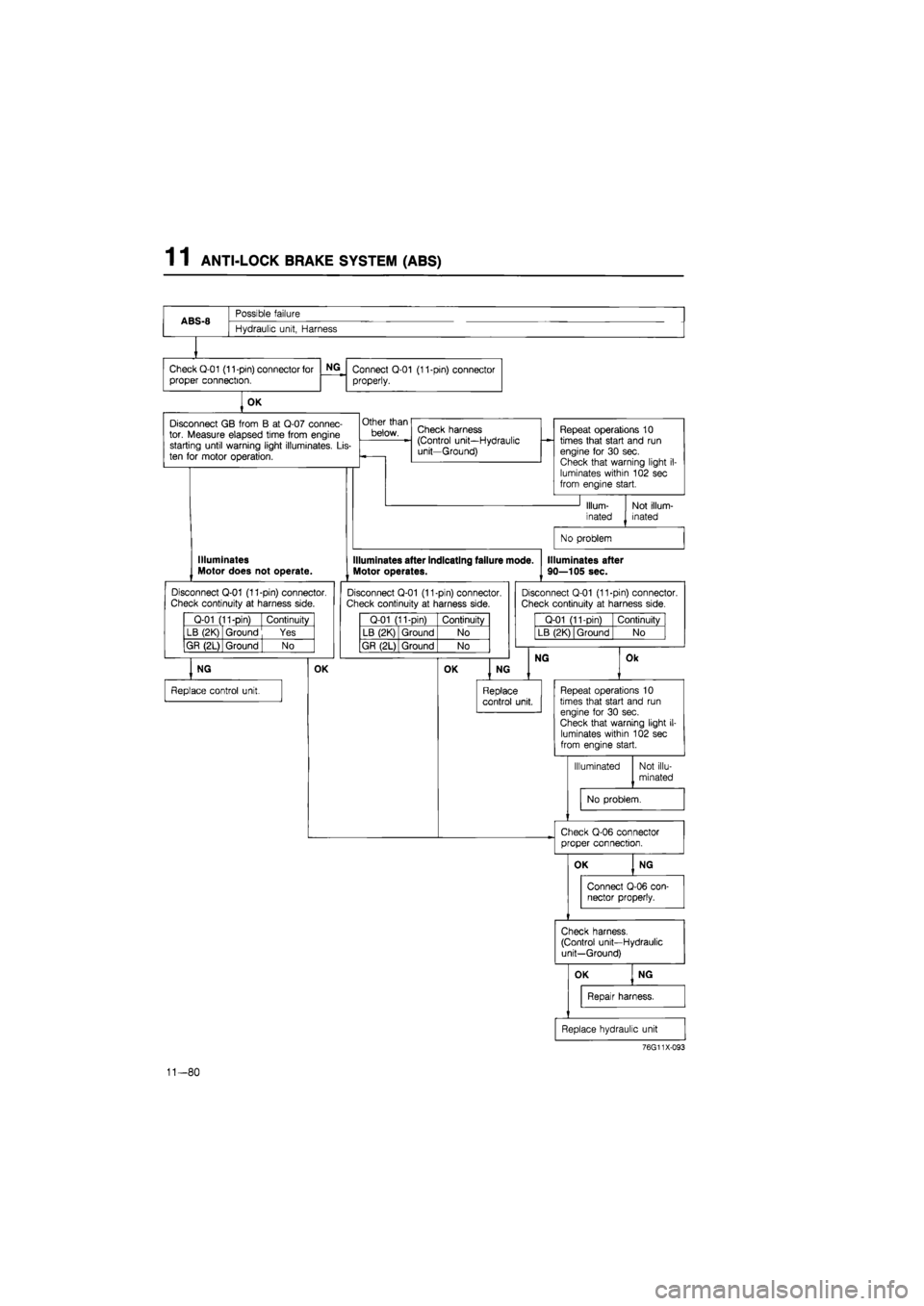

ABS-8

Possible failure

ABS-8

Hydraulic unit, Harness

Check Q-01 (11-pin) connector for

proper connection.

NG

Connect Q-01 (11-pin) connector

properly.

OK

Disconnect

GB

from

B at

Q-07 connec-tor. Measure elapsed time from engine starting until warning light illuminates.

Lis-

ten

for

motor operation.

Other than

below. Check harness (Control unit—Hydraulic unit—Ground)

Repeat operations

10

times that start and

run

engine

for 30

sec. Check that warning light

i

luminates within 102 sec from engine start.

Illum-

inated

Not illum-inated

No problem

Illuminates Motor does not operate.

Disconnect Q-01 (11-pin) connector.

Check continuity

at

harness side.

Q-01 (11-pin) Continuity

LB (2K) Ground Yes

GR (2L) Ground

| No

NG

Replace control unit.

OK

Illuminates after indicating failure mode.

Motor operates.

Disconnect Q-01 (11-pin) connector. Check continuity

at

harness side.

Q-01 (11-pin) Continuity

LB (2K) Ground No

GR (2L) Ground No

OK

Illuminates after

90—105 sec.

Disconnect Q-01 (11-pin) connector.

Check continuity

at

harness side.

Q-01 (11-pin) Continuity

LB (2K) Ground No

NG

NG

Replace control unit.

Ok

Repeat operations

10

times that start and

run

engine

for 30

sec. Check that warning light

il-

luminates within 102 sec from engine start.

Illuminated Not illu-

minated

No problem.

Check Q-06 connector proper connection.

76G11X-093

11-80

Page 1478 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

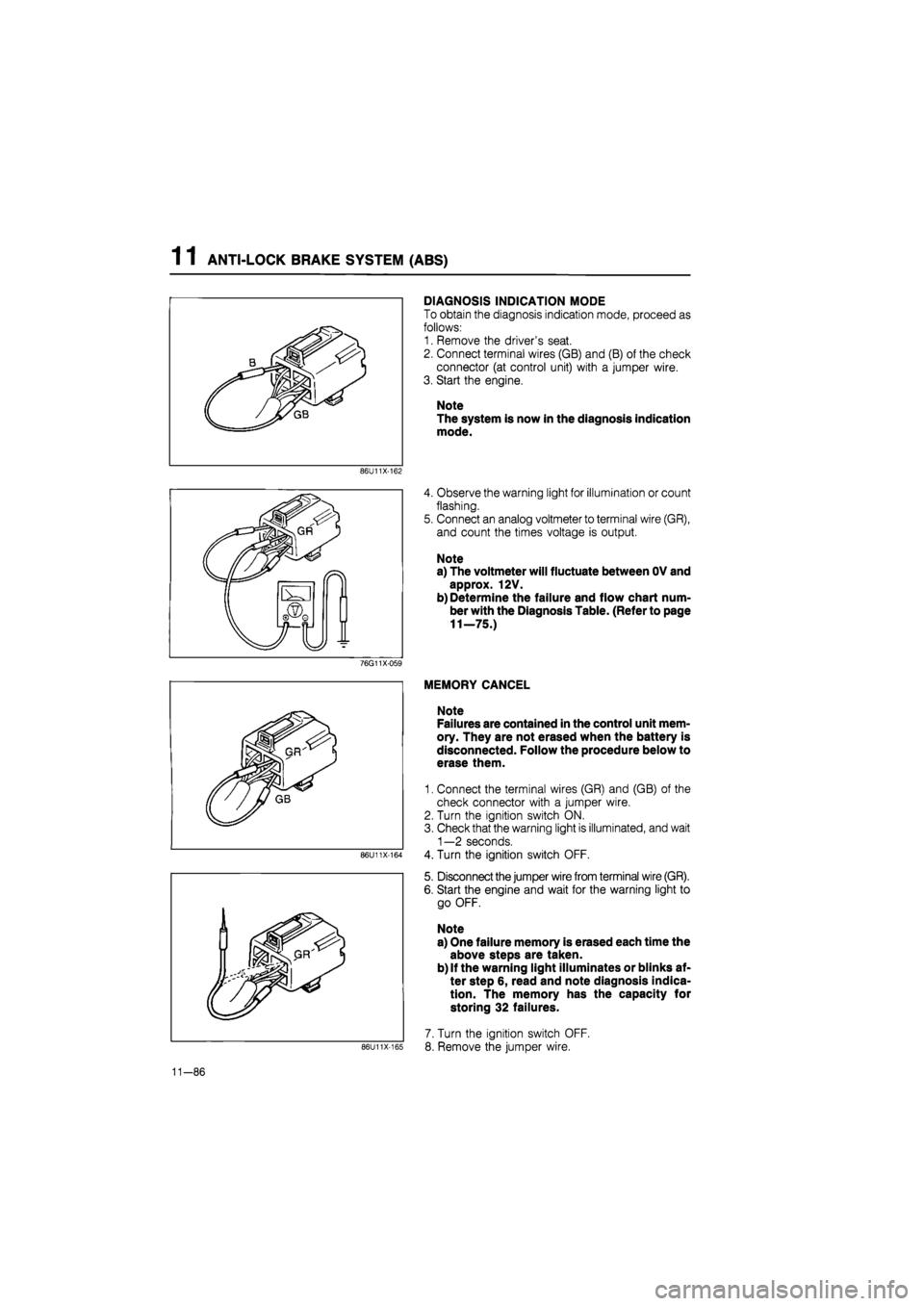

DIAGNOSIS INDICATION MODE

To obtain the diagnosis indication mode, proceed as

follows:

1. Remove the driver's seat.

2. Connect terminal wires (GB) and (B) of the check

connector (at control unit) with a jumper wire.

3. Start the engine.

Note

The system is now in the diagnosis indication

mode.

86U11X-162

4. Observe the warning light for illumination or count

flashing.

5. Connect an analog voltmeter to terminal wire (GR),

and count the times voltage is output.

Note

a) The voltmeter will fluctuate between OV and

approx. 12V.

b) Determine the failure and flow chart num-

ber with the Diagnosis Table. (Refer to page

11—75.)

76G11X-059

86U11X-164

86U11X-165

MEMORY CANCEL

Note

Failures are contained in the control unit mem-

ory. They are not erased when the battery is

disconnected. Follow the procedure below to

erase them.

1. Connect the terminal wires (GR) and (GB) of the

check connector with a jumper wire.

2. Turn the ignition switch ON.

3. Check that the warning light is illuminated, and wait

1—2 seconds.

4. Turn the ignition switch OFF.

5. Disconnect the jumper wire from terminal wire (GR).

6. Start the engine and wait for the warning light to

go OFF.

Note

a) One failure memory is erased each time the

above steps are taken.

b) If the warning light illuminates or blinks af-

ter step 6, read and note diagnosis indica-

tion. The memory has the capacity for

storing 32 failures.

7. Turn the ignition switch OFF.

8. Remove the jumper wire.

11-86

Page 1486 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

HYDRAULIC UNIT FLUID

Inspection of Level

1. Run the engine for 10 seconds to let the pump mo-

tor build pressure in the accumulator; then stop the

engine.

2. Check that the fluid level is between the Max and

Min lines of the reservoir.

3. If the level is lower than the Min line and leakage

from cap is not found, replace the hydraulic unit

assembly.

86U11X-187

76G11X-061

Replacement

1. Remove the reservoir cap and retainer.

2. Use a suction pump and a soft vinyl hose to suck

fluid from the reservoir.

Caution

a) A hard hose may damage the filter in the

reservoir.

b)Only the amount of fluid shown can be re-

moved from the reservoir.

3. Fill the reservoir with the specified type and amount

of brake fluid.

Caution

a) Do not allow any foreign material to enter

the reservoir.

b) Do not soak the upper filter with brake flu-

id. Otherwise, pouring fluid may be difficult.

Fluid: DOT-3 or DOT-4 or SAE J1703

4. Check the fluid level as described above.

HYDRAULIC UNIT

Warning

The accumulator contains high-pressure gas;

do not attempt to disassemble it or subject it

to hard shocks or high heat.

When the hydraulic unit is scrapped, the high-

pressure gas must be released. Turn the

screw on the accumulator bottom one full turn

only and allow the gas to escape gradually.

76G11X-097

11—94