brake light MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 933 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

Inspection of Continuity

1. Disconnect the brake light switch connector.

2. Check for continuity between the terminals while

depressing the brake pedal.

79G07C-114

76G07B-076

KICK-DOWN SWITCH (G4A-HL)

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage at terminal (V) with a voltmeter.

Depressing stroke Terminal voltage

7/8-8/8 (Full) Approx. 12V

0-7/8 Below 1,5V

3. If not correct, check the wiring harness, switch, or

adjust the switch position.

Inspection of Continuty

1. Disconnect the kick-down switch connector.

2. Check for continuity of the switch with an

ohmmeter.

Switch Continuity

Pushed Yes

Released No

3. If not correct, replace the kick-down switch.

76G07B-077

Adjustment

1. Loosen the kick-down switch locknuts.

2. Depress the accelerator pedal fully.

3. Turn the switch until the threaded case touches the

stopper.

4. Turn the switch counterclockwise by one half revo-

lution.

5. Secure the switch with the locknut.

76G07B-078

7B—67

Page 936 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

Terminal Connected to Voltage Condition

1J — — —

1K — — —

1L (Input) Idle switch Below 1.5V At idle 1L (Input) Idle switch Approx. 12V Other speeds

1M — — —

1N (Input) Brake light switch Approx. 12V Brake pedal depressed 1N (Input) Brake light switch Below 1.5V Brake pedal released

10 (Input) Throttle sensor

Approx. 5V Ignition switch ON 10 (Input) Throttle sensor Below 1,5V Ignition switch OFF

1P (Input)

Throttle sensor

Approx. 0.5—4.3V Throttle valve fully closed to fully open

1Q (Input) Vehicle speed sensor

Approx. 4.5V During driving

1Q (Input) Vehicle speed sensor Approx. 4.5V or below 1.5V Vehicle stopped

1R (Ground) Throttle sensor Below 1,5V —

1S (Input) Pulse generator Approx. 12V Engine running 1S (Input) Pulse generator Below 1,5V Engine stopped

1S (Ground) Pluse generator Below 1.5V —

2A (Battery power) Battery Approx. 12V Ignition switch ON 2A (Battery power) Battery Below 1,5V Ignition switch OFF

2B (Ground) Body ground Below 1,5V —

2C (Memory power) Battery Approx. 12V —

2D (Ground) Body ground Below 1,5V —

2E (Output) 1-2 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2E (Output) 1-2 shift solenoid valve Below 1.5V Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Below 1,5V

Refer to page 7B—26 of solenoid valve

operation table

2G — — —

2H (Output) 3-4 shift solenoid valve Approx. 12V Refer to page 7B—26 of solenoid valve operation table 2H (Output) 3-4 shift solenoid valve Below 1.5V

Refer to page 7B—26 of solenoid valve operation table

21 — — —

2J (Output) Lock-up solenoid valve Approx. 12V Lock-up 2J (Output) Lock-up solenoid valve Below 1,5V Other

2K (Output) Hold indicator Below 1,5V Hold mode 2K (Output) Hold indicator Approx. 12V Other modes

2L (Output) Mode indicator Approx. 12V Hold mode 2L (Output) Mode indicator Below 1,5V Power or economy mode

2M (Output) EC-AT Tester

(malfunction code)

Approx. 12V Normal

2M (Output) EC-AT Tester

(malfunction code) Below 1,5V If malfunction present 2M (Output) EC-AT Tester

(malfunction code) Code signal Self-diagnosis check connector grounded

2N — — —

20 (Input) Fluid temperature switch Below 1,5V Above 150°C (302°F) 20 (Input) Fluid temperature switch Approx. 10—12V Below 143°C (289°F)

2P (Input) EC-AT check connect Approx. 12V —

76G07B-084

7B-70

Page 966 of 1865

7B DISASSEMBLY

1. Remove the bolts; then remove the transaxle case

by tapping lightly with a plastic hammer.

86U07B-153

3. Remove the low and reverse brake piston

(1) Install the SST.

(2) Compress the spring and retainer assembly.

86U07B-154

(3) Remove the snap ring with snap ring pliers;

then remove the spring and retainer assembly.

86U07B-155

7B—100

Page 1296 of 1865

1 0 TROUBLESHOOTING GUIDE

POWER STEERING

Problem Possible cause Remedy Page

Hard steering

Loose

or

damaged belt Low fluid level,

or air in

fluid Leakage

of

fluid

Malfunctioning electrical system* Insufficient oil pump pressure Improperly adjusted wheel alignment Malfunctioning steering gear Linkage ball joint not operating smoothly

Adjust

or

replace Add fluid

or

bleed

air

Repair

or

replace Repair

or

replace Repair

or

replace Refer

to

Section

13

Repair

or

replace Replace

10—12 10-11 10-13 10-87 10-16

10—28,

37

10-18

Poor return

Insufficient tire pressure

Improperly adjusted wheel alignment

Ball-joint not operating smoothly

Steering shaft contacting something

Refer

to

Section

12

Refer

to

Section

13

Replace

Repair

10-20 10-21

Excessive play

Loose gear box housing mounting bolts Worn linkage

or

tie-rod ball joint Worn lower ball joint Worn

or

damaged steering joint Worn rack and pinion gear

Tighten Replace

Refer

to

Section

13

Replace

Replace

10—30

10—18

10—21

10-58,

75

Steering wheel

vibrates

Insufficient tire pressure Damaged

or

unbalanced wheel Improperly adjusted wheel alignment Loose gear box housing mounting bolts Incorrect pinion preload adjustment Worn ball joints

Loose shock absorber mounting Malfunctioning shock absorber

Refer

to

Section

12

Refer

to

Section

13

Refer

to

Section

13

Tighten Adjust

Replace Refer

to

Section

13

Refer

to

Section

13

10-30 10-72,

81

10—18

Steering wheel

pulls

Unevenly worn tires

Incorrect tire pressure

Dragging brake

Improperly adjusted wheel alignment

Refer

to

Section

12

Refer

to

Section

12

Refer

to

Section

11

Refer

to

Section

13 —

Excessively light

steering at high

speed*

Malfunctioning electrical system Repair

or

replace 10-87

*... Only

for

electronically

-

controlled type

76G10X-002

10—8

Page 1393 of 1865

11

BRAKING SYSTEM

OUTLINE 11—2

STRUCTURAL VIEW 11—2

SPECIFICATIONS 11— 4

TROUBLESHOOTING GUIDE 11— 5

ON-VEHICLE MAINTENANCE 11—6

BRAKE FLUID LEVEL IN MASTER

CYLINDER RESERVOIR 11— 6

BRAKE HYDRAULIC LINE 11—6

STRUCTURAL VIEW 11—6

ON-VEHICLE INSPECTION OF

BRAKE LINES 11— 8

REMOVAL AND INSTALLATION OF

BRAKE LINES 11— 9

REPLACEMENT OF BRAKE

FLUID 11— 9

AIR BLEEDING 11— 9

BRAKE PEDAL 11—11

ON-VEHICLE INSPECTION 11—11

REMOVAL 11—12

INSPECTION 11—13

INSTALLATION 11—13

MASTER CYLINDER 11—14

REMOVAL 11—15

DISASSEMBLY AND ASSEMBLY

(EXCEPT RHD DOHC TURBO).... 11—14

INSPECTION 11—17

DISASSEMBLY AND ASSEMBLY

(RHD DOHC TURBO) 11—18

INSPECTION 11—21

INSTALLATION 11—22

POWER BRAKE UNIT 11—27

FUNCTION CHECK 11—27

INSPECTION OF CHECK VALVE... 11—29

REMOVAL 11—29

DISASSEMBLY AND ASSEMBLY... 11—30

INSPECTION 11—32

INSTALLATION 11—33

VACUUM PUMP 11—35

ON-VEHICLE INSPECTION 11—35

REMOVAL AND INSTALLATION.... 11—35

DISASSEMBLY AND ASSEMBLY... 11—36

INSPECTION 11—37

DUAL PROPORTIONING VALVE 11—38

FUNCTION CHECK 11—38

REMOVAL AND INSTALLATION.... 11—39

FRONT DISC BRAKE 11—40

SIMPLE INSPECTION OF DISC

PAD WEAR 11—40

REPLACEMENT OF DISC PAD 11—40

REMOVAL 11—42

DISASSEMBLY AND ASSEMBLY... 11—43

INSPECTION 11—44

INSTALLATION 11—45

REAR DISC BRAKE 11—46

SIMPLE INSPECTION OF DISC

PAD WEAR 11—46

REPLACEMENT OF DISC PAD 11—46

REMOVAL 11—49

DISASSEMBLY AND ASSEMBLY... 11—50

INSPECTION 11—54

INSTALLATION 11—55

REAR DRUM BRAKE 11—56

REMOVAL 11—56

DISASSEMBLY AND ASSEMBLY

OF WHEEL CYLINDER 11—59

INSPECTION 11—60

INSTALLATION 11—61

PARKING BRAKE 11—65

ON-VEHICLE MAINTENANCE 11—65

REMOVAL AND INSTALLATION

OF PARKING BRAKE LEVER 11—66

REMOVAL OF PARKING BRAKE

CABLE 11—68

INSTALLATION OF PARKING

BRAKE CABLE 11—69

ANTI-LOCK BRAKE SYSTEM

(ABS) 11—71

STRUCTURAL VIEW 11—71

WIRING DIAGRAM 11—72

TROUBLESHOOTING 11—73

DIAGNOSIS INDICATION MODE ... 11—86

MEMORY CANCEL 11—86

ABS WARNING LIGHT 11—87

RELAY BOX 11—87

WHEEL SPEED SENSOR 11—87

SENSOR ROTOR 11—90

HYDRAULIC UNIT FLUID 11—94

HYDRAULIC UNIT 11—94

CONTROL UNIT CIRCUIT 11—99

76G11X-001

Page 1403 of 1865

BRAKE PEDAL 1 1

Pedal height

"tt^

Pedal-to-floor clearance

76G11X-008

BRAKE PEDAL

ON-VEHICLE INSPECTION

Pedal Height

Inspection

Check that the distance from the center of the upper

surface of the pedal pad to the firewall is as specified.

LHD and RHD

Pedal height: 222 mm (8.74 +0-200 in)

Adjustment

1. Disconnect the stop light switch connector.

2. Loosen locknut B and turn switch A until it does

not contact the pedal.

3. Loosen locknut D and turn rod C to adjust the

height.

4. Adjust the pedal free play and tighten locknut D.

5. Turn the stop light switch until it contacts the ped-

al; then turn an additional 1/2 turn. Tighten lock-

nut B.

Locknut B tightening torque:

14—18 N m (1.4—1.8 m-kg, 10—13 ft-lb)

Locknut D tightening torque:

24—34 Nm (2.4—3.5 m-kg, 17—25 ft-lb)

Pedal Play

Inspection

1. Depress the pedal a few times to eliminate the

vacuum in the system.

2. Gently depress the pedal again by hand, and

check the free play. (Until the valve plunger con-

tacts the stopper plate = until the power piston be-

gins to move.)

Pedal play: 4—7 mm (0.16—0.28 in)

76G11X-099

Adjustment

Loosen the locknut D of the operating rod C; then

turn the rod to adjust the free play.

Locknut D tightening torque:

24—34 Nm (2.4—3.5 m-kg, 17—25 ft-lb)

86U11X-018

11—11

Page 1418 of 1865

1 1 MASTER CYLINDER

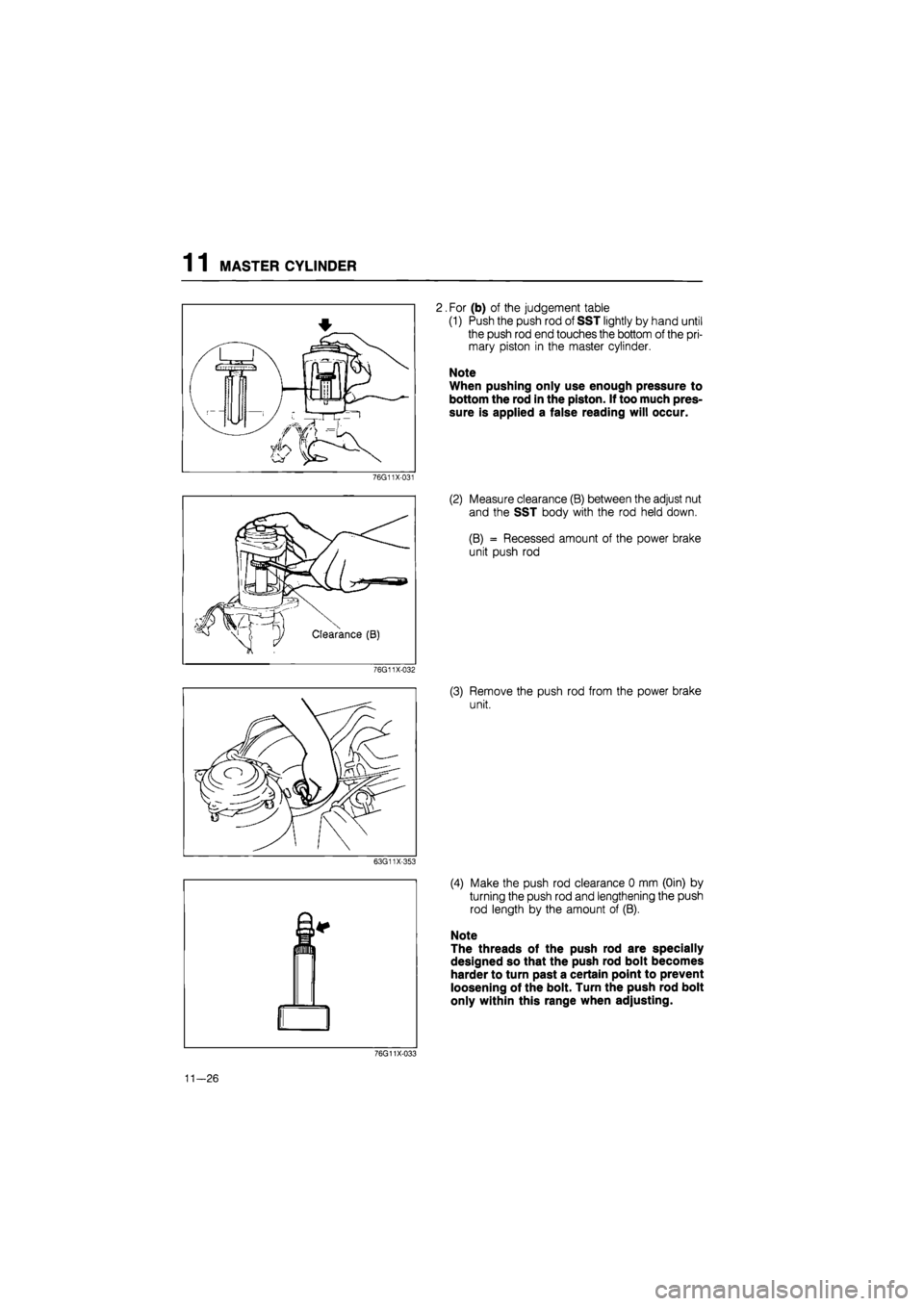

2. For (b) of the judgement table

(1) Push the push rod of SST lightly by hand until

the push rod end touches the bottom of the pri-

mary piston in the master cylinder.

Note

When pushing only use enough pressure to

bottom the rod in the piston. If too much pres-

sure is applied a false reading will occur.

76G11X-031

(2) Measure clearance (B) between the adjust nut

and the SST body with the rod held down.

(B) = Recessed amount of the power brake

unit push rod

76G11X-032

(3) Remove the push rod from the power brake

unit.

63G11X-353

(4) Make the push rod clearance 0 mm (Oin) by

turning the push rod and lengthening the push

rod length by the amount of (B).

Note

The threads of the push rod are specially

designed so that the push rod bolt becomes

harder to turn past a certain point to prevent

loosening of the bolt. Turn the push rod bolt

only within this range when adjusting.

76G11X-033

11—26

Page 1419 of 1865

POWER BRAKE UNIT 1 1

86U11X-038

0

o

X

\ V^ Third

Second

^ First

86U11X-039

O X

fiSy

V

86U11X-040

Pedal-depression Pre!tur!9au9e

force gauge

^Intake manifold

86U11X-041

POWER BRAKE UNIT

FUNCTION CHECK

Simple Method

First step

1. With the engine stopped, depress the pedal a few

times.

2. With the pedal depressed, start the engine

3. If immediately after the engine starts the pedal

moves down slightly, the unit is operating.

Second step

1. Start the engine.

2. Stop the engine after it has run for

1

or 2 minutes.

3. Depress the pedal with the usual force.

4.

If

the first pedal stroke is long and becomes short-

er with subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the

check valve or vacuum hose, and examine the in-

stallation condition. Repair if necessary, and inspect

it once again.

Third step

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal still depressed.

4. Hold the pedal down for about 30 seconds.

5. If the pedal height does not change, the unit is

operating.

6. If there is a problem, check for damage to the

check valve or vacuum hose, and check the con-

nection. Repair if necessary, and check once

again.

If the nature of the problem is still not clear after fol-

lowing the 3 steps above, follow the more detailed

check described in "Method using tester".

Method Using Tester

Connect a pressure gauge, vacuum gauge, and ped-

al depression force gauge as shown in the figure. Af-

ter bleeding the air from the pressure gauge, conduct

the test as described in the 3 steps below.

Note

Use commercially available gauges and ped-

al depression force gauge.

11—27

Page 1465 of 1865

ANTI-LOCK BRAKE SYSTEM (ABS) 1 1

TROUBLESHOOTING

Precaution

Conditions that are not malfunctions

1. It may happen that vibration is felt in the steering wheel, body, and/or brake pedal when the ABS

is functioning; such vibration is simply an indication that the system is functioning.

2. Sound of the pump motor operating, accumulator pressure being released, or the relay operating

may be heard from the engine compartment when the engine is started as the system is being auto-

matically checked.

3. The ABS pump motor may be automatically activated even though the ABS is not operating.

4. The ABS warning light may illuminate under any of the following conditions:

• When the vehicle is traveling on snow or ice with the parking brake activated or a brake dragging

at one wheel.

• When different-sized tires are used.

• When tires of different gripping performance are used.

• When (while the vehicle is jacked up or stuck) only the front wheels are spun for 20 seconds or more.

• When there is insufficient battery voltage.

Note

Under the above conditions, the warning light will not illuminate a second time when the

ignition is switched OFF then back ON, and there will be no memory entry to the control

unit of a problem.

Troubleshooting notes

The ABS is composed of electrical components, mechanical components (hydraulic unit), and the com-

ponents of the standard brake system.

Fundamentally, malfunction of the ABS electrical or mechanical components is judged by the self-

diagnosis function within the ABS control unit. And malfunctions are indicated by the warning light

in the instrument panel.

The location

of

a malfunction is indicated by the technician switching the system to the diagnosis-indication

mode.

The self-diagnosis and indication functions must be used when malfunctions of the ABS are being

diagnosed.

76G11X-091

11—73

Page 1466 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

Troubleshooting Main Flow Chart

Check that the ABS warning light operates.

• Turn ignition switch OFF

to

ON, and check that ABS warning light illuminates constantly.

Flashing (Past failure)

OK

Check the ABS for failure.

• Start engine, and observe flashing

of

warning light.

Does not

illuminate

constantly

Warning light Possible cause

Does

not il-

luminate

at all

Refer

to

page 11—86.

ON

Alternator

L

ter-minal output Wiring harness (ALT-control unit) Control unit

OFF

1 sec

Alternator

L

ter-minal output Wiring harness (ALT-control unit) Control unit

ON

Relay box wiring harness (warning light-control unit) Control unit

OFF

1 sec

Relay box wiring harness (warning light-control unit) Control unit

No illumination

(Not diagnosed)

Illuminates constantly

(Present failure)

ABS is usually operating cor-rectly.

Consult table below when ABS failure

is

still suspected.

System Possible cause

ABS Brake light switch

Both rear wheel speed sensors

Control unit Proportioning

valve

in hy-

draulic unit

Other than Refer

to

ABS troubleshoot-ing guide

on

page 11—5.

Repair failures with flow

chart. (Refer to page

11—76.)

76G11X-054

11-74