engine MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 39 of 1865

1A TUNE-UP PROCEDURE

Coolant Level (Cold engine)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the level in the coolant reservoir is be-

tween the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b) Wrap a thick cloth around the cap and care-

fully remove it.

86U01X-008

When set

When measured

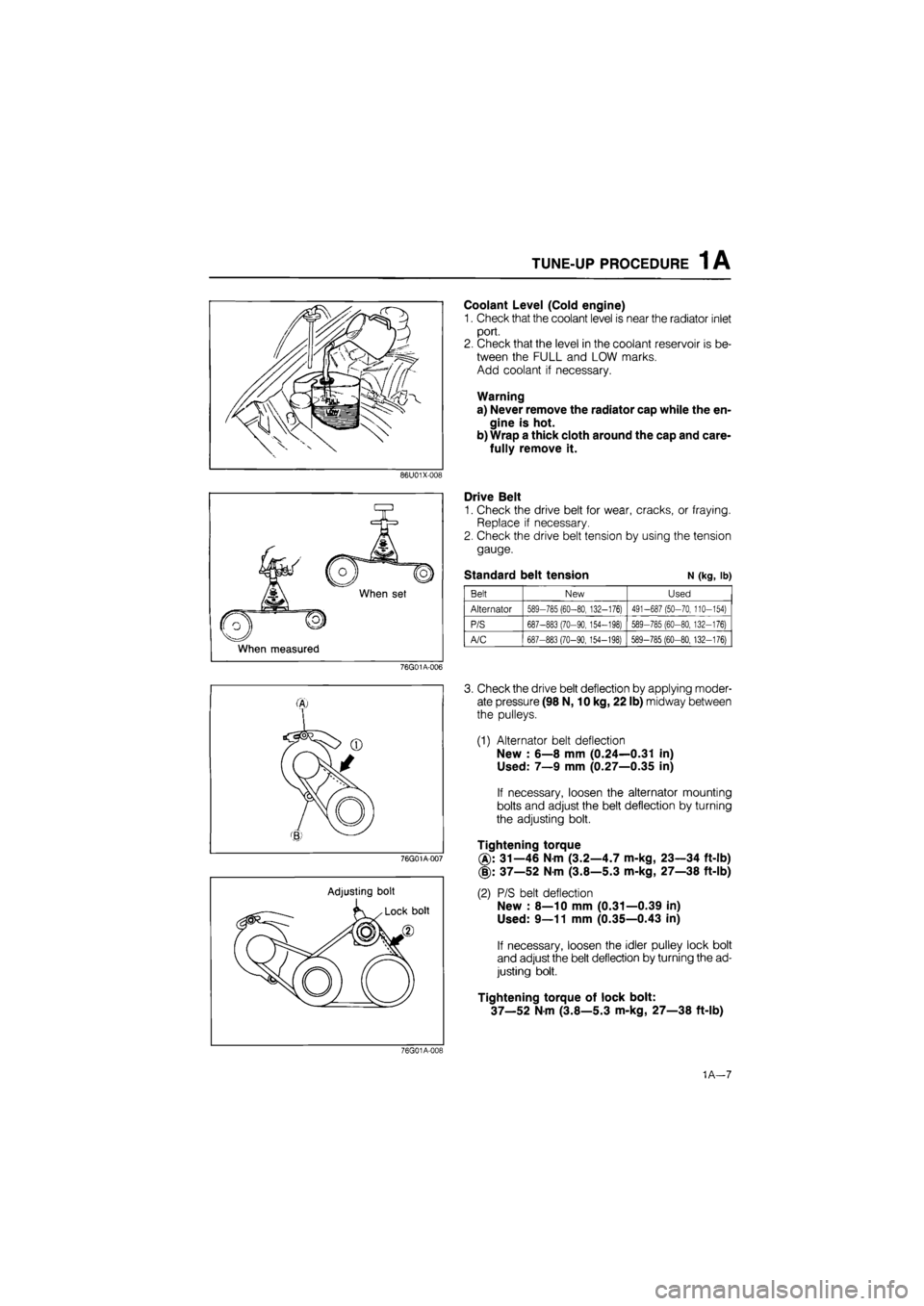

Drive Belt

1. Check the drive belt for wear, cracks, or fraying.

Replace if necessary.

2. Check the drive belt tension by using the tension

gauge.

Standard belt tension N (kg, lb)

Belt New Used

Alternator 589-785 (60-80, 132-176) 491-687 (50-70, 110-154)

P/S 687-883 (70-90, 154-198) 589-785 (60-80, 132-176)

A/C 687-883 (70-90,154-198) 589-785 (60-80, 132-176)

76G01A-006

76G01A-007

Adjusting bolt

3. Check the drive belt deflection by applying moder-

ate pressure (98 N, 10 kg, 22 lb) midway between

the pulleys.

(1) Alternator belt deflection

New : 6—8 mm (0.24—0.31 in)

Used: 7—9 mm (0.27—0.35 in)

If necessary, loosen the alternator mounting

bolts and adjust the belt deflection by turning

the adjusting bolt.

Tightening torque

31—46 Nm (3.2—4.7 m-kg, 23—34 ft-lb)

(§): 37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(2) P/S belt deflection

New : 8—10 mm (0.31—0.39 in)

Used: 9—11 mm (0.35—0.43 in)

If necessary, loosen the idler pulley lock bolt

and adjust the belt deflection by turning the ad-

justing bolt.

Tightening torque of lock bolt:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

76G01A-019

1A—7

Page 41 of 1865

TUNE-UP PROCEDURE 1A

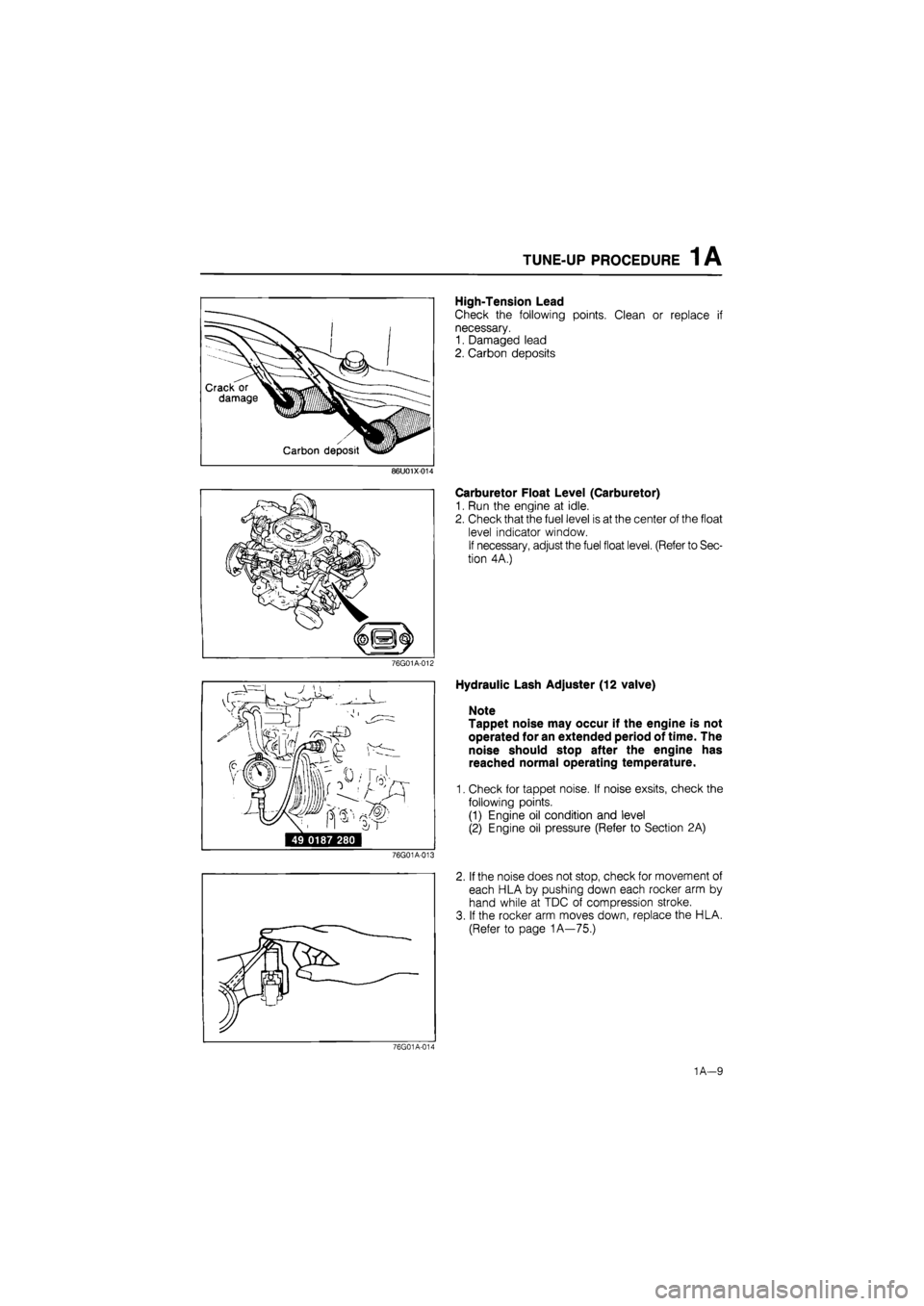

High-Tension Lead

Check the following points. Clean or replace if

necessary.

1. Damaged lead

2. Carbon deposits

86U01X-014

76G01A-012

49 0187 280

76G01A-013

Carburetor Float Level (Carburetor)

1. Run the engine at idle.

2. Check that the fuel level is at the center of the float

level indicator window.

If necessary, adjust the fuel float level. (Refer to Sec-

tion 4A.)

Hydraulic Lash Adjuster (12 valve)

Note

Tappet noise may occur if the engine is not

operated for an extended period of time. The

noise should stop after the engine has

reached normal operating temperature.

1. Check for tappet noise. If noise exsits, check the

following points.

(1) Engine oil condition and level

(2) Engine oil pressure (Refer to Section 2A)

2. If the noise does not stop, check for movement of

each HLA by pushing down each rocker arm by

hand while at TDC of compression stroke.

3. If the rocker arm moves down, replace the HLA.

(Refer to page 1A—75.)

76G01A-014

1

A—9

Page 42 of 1865

1A TUNE-UP PROCEDURE

No.1 IN No.2 IN

No.1 EX No.3 EX

76G01A-015

Adjust bolt

^N^^^^^Lock nut

SsKs&b ' Valve

Camshaft >Nw clearance

76G01A-016

76G01A-017

Valve Clearance (8-valve)

1. Warm up the engine to the normal operating tem-

perature.

2. With the piston of the No.1 cylinder at TDC of com-

pression stroke.

Adjust the valve clearance as shown in the figure.

Valve clearance (valve side)

IN : 0.30 mm (0.012 in)

EX: 0.30 mm (0.012 in)

3. Turn the crankshaft one full turn so that the piston

of the No.4 cylinder is at TDC of compression

stroke.

Adjust the clearances of the remaining valves.

Ignition Timing

1. Warm up the engine and run it at idle.

2. Turn all electric loads OFF.

3. Connect a timing light tester.

4. Disconnect the vacuum hose from the vacuum

control, and plug the hose.

5. Check that the ignition timing mark (yellow) on the

crankshaft pulley and the timing mark on the tim-

ing belt cover are aligned.

Ignition timing: 6° ±

1

° BTDC (at idle speed)

6. If necessary adjust the ignition timing by turning

the distributor.

69G01B-518

1A—10

Page 43 of 1865

1A TUNE-UP PROCEDURE

76G01A-105

Idle Speed (Carburetor)

1. Connect a tachometer to the engine.

2. Turn all electric loads OFF.

3. Confirm that the choke valve has fully returned at

idling speed.

4. Check the idle speed. If necessary, turn the throt-

tle adjust screw and adjust the idle speed.

Idle speed

MTX: 800 ±s8 rpm (in neutral)

ATX: 950

Is8

rpm (in "N" range) F6

900 I58 rpm (in "N" range).. FE, F8

Idle Speed (Fl)

1. Connect the tachometer to the engine.

2. Check the idle speed.

Idle speed

MTX: 850 i!°0 rpm (in neutral)

ATX: 850 t55°o rpm (in "N" range)

3. If necessary, remove the blind cap from the throt-

tle body and adjust by turning the air adjust screw.

4. Install the blind cap.

76G01A-018

Idle Mixture (Carburetor)

1. Disconnect the secondary air hoses from the reed

valves and then plug the hoses (if equipped).

2. Connect an exhaust gas analyzer to the vehicle as

shown in the figure and measure the CO concen-

tration.

76G01A-106

3. Remove the blind cap from the mixture adjust

screw.

Note

The blind cap will be broken when it is re-

moved, do not attempt to reinstall it.

76G01A-019

1A—11

Page 45 of 1865

ON-VEHICLE INSPECTION 1 A

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following points.

1. Ignition system (Refer to Section 5)

2. Compression

3. Fuel system (Refer to Section 4)

COMPRESSION

1. Check that the battery is fully charged. Recharge

if necessary.

76G01A-107

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all spark plugs.

5. Disconnect the primary wire connector from the

ignition coil.

86U01X-020

6. Connect a compression gauge to No.

1

spark plug

hole.

7. Fully depress the accelerator pedal and crank the

engine.

8. Note the maximum gauge reading.

9. Check each cylinder.

Compression pressure kPa (kg/cm2, psi)-rpm

Standard Minimum

F6 1,128 (11.5, 164)—270 790 (8.1, 114)—270

F8-FE 1,275 (13.0, 185)—270 893 (9.1, 129)—270

FE 12-valve 1,422 (14.5, 206)—280 996 (10.2, 144)—280

76G01A-023

Possible Cause

86U01X-022

1A—13

Page 46 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

ON-VEHICLE MAINTENANCE

TIMING BELT

Removal

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01A-108

76G01A-024

1. High-tension lead and spark plug

2. Engine side cover

3. Drive belt

4. Crankshaft pulley

5. Upper timing belt cover

6. Lower timing belt cover

7. Baffle plate

8. Timing belt tensioner

9. Timing belt tensioner spring

10. Timing belt

1A—14

Page 47 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

Removal note

Timing belt tensioner

1. Turn the crankshaft to align the mating mark of the

camshaft pulley with the front housing timing mark.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

2. Remove the tensioner.

76G01A-025

Timing belt

Mark the timing belt rotation for proper reinstallation

if it is reused.

Caution

Be careful not to allow oil, grease, or water

on the belt.

86U01X-024

Inspection

Inspect the following parts.

(Refer to page 1A—60, 61.)

1. Timing belt

2. Timing belt tensioner and spring

3. Timing belt idler pulley

4. Timing belt pulley

5. Camshaft pulley

76G01A-026

1A—15

Page 49 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 A

76G01A-027

76G01B-024

76G01A-028

/Jf

ry.

2. Check that the mating mark of the camshaft pul-

ley is aligned with the timing mark. If it is not

aligned, turn the camshaft to align.

Note

For FE engine, align "2" mark.

For F8, F6 engine, align "3" mark.

3. Install the timing belt tensioner and spring. Tem-

porarily secure it with the spring fully extended.

Caution

Do not damage the pulleys when securing the

tensioner pulley.

4. Install the timing belt. (Keep the tension side of belt

as tight as possible).

Caution

a) If the timing belt is being reused, it must be

reinstalled to rotate in the original direction.

b) Check that there is no oil, grease, or dirt on

the timing belt.

5. Loosen the tensioner lock bolt.

6. Turn the crankshaft twice in the direction of rota-

tion, and align the mating marks.

7. Check that the timing marks are correctly aligned.

If not aligned, remove the timing belt tensioner and

timing belt, and repeat steps 1—6.

69G01B-027

1A-17

Page 51 of 1865

1 A ON-VEHICLE MAINTENANCE (TIMING BELT)

Spark plug

1. Apply anti-seize compound or molybdenum-based

lubricant to the spark plug threads.

2. Install the spark plugs.

Tightening torque:

15—23 N-m (1.5—2.3 m-kg, 11—17 ft-lb)

79G01C-021

Steps After Installation

Perform the necessary engine adjustment. (Refer to

TUNE-UP PROCEDURE.)

86U01X-029

1A—19

Page 52 of 1865

1 A ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

CYLINDER HEAD

Removal

Warning: Release the fuel pressure. (Refer to Section 4.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01A-110

1A—20