engine MAZDA 626 1987 Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 69 of 1865

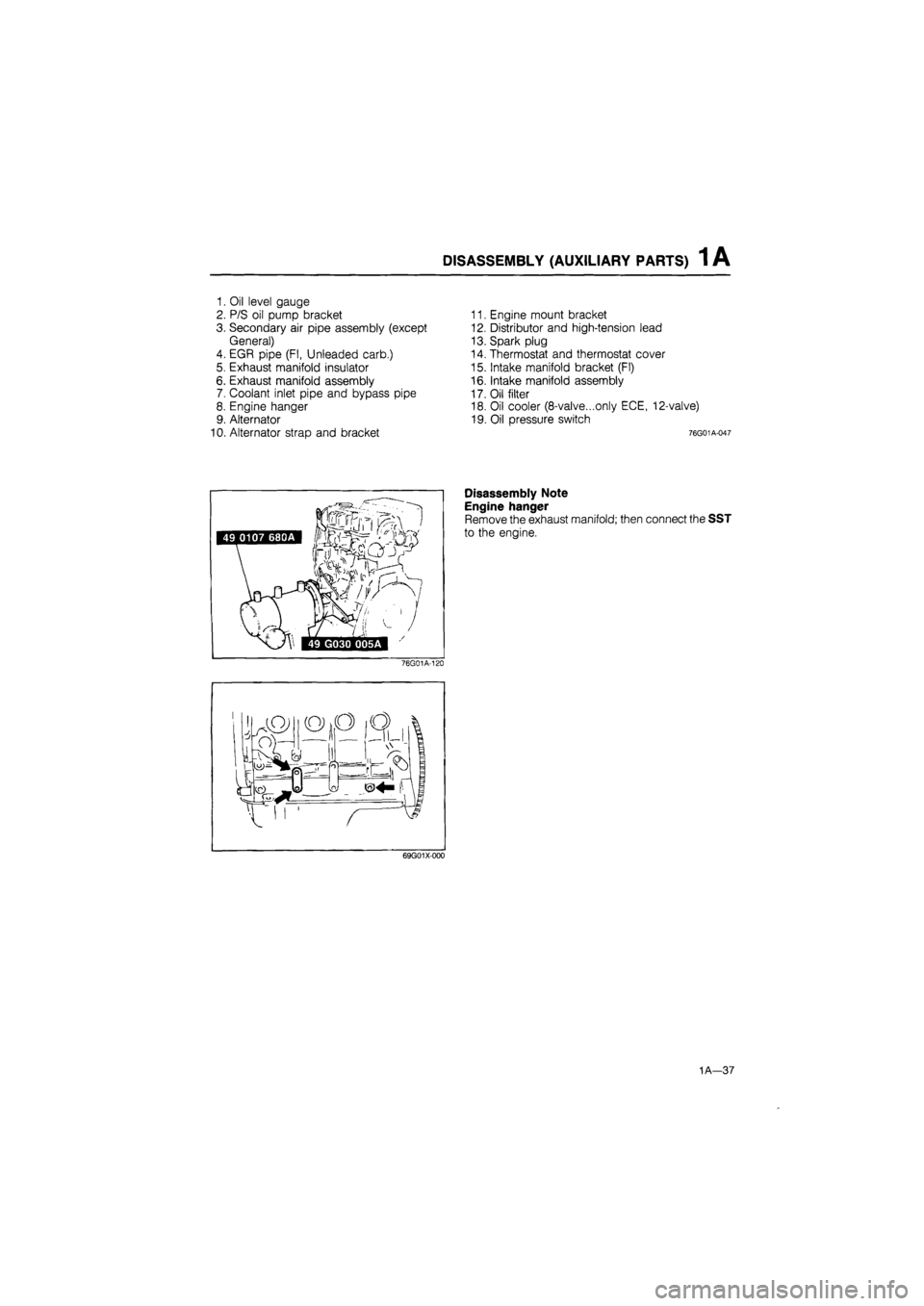

DISASSEMBLY (AUXILIARY PARTS) 1 A

1. Oil level gauge

2. P/S oil pump bracket

3. Secondary air pipe assembly (except

General)

4. EGR pipe (Fl, Unleaded carb.)

5. Exhaust manifold insulator

6. Exhaust manifold assembly

7. Coolant inlet pipe and bypass pipe

8. Engine hanger

9. Alternator

10. Alternator strap and bracket

11. Engine mount bracket

12. Distributor and high-tension lead

13. Spark plug

14. Thermostat and thermostat cover

15. Intake manifold bracket (Fl)

16. Intake manifold assembly

17. Oil filter

18. Oil cooler (8-valve...only ECE, 12-valve)

19. Oil pressure switch

76G01A-047

Disassembly Note

Engine hanger

Remove the exhaust manifold; then connect the SST

to the engine.

76G01A-120

69G01X-000

1A—37

Page 94 of 1865

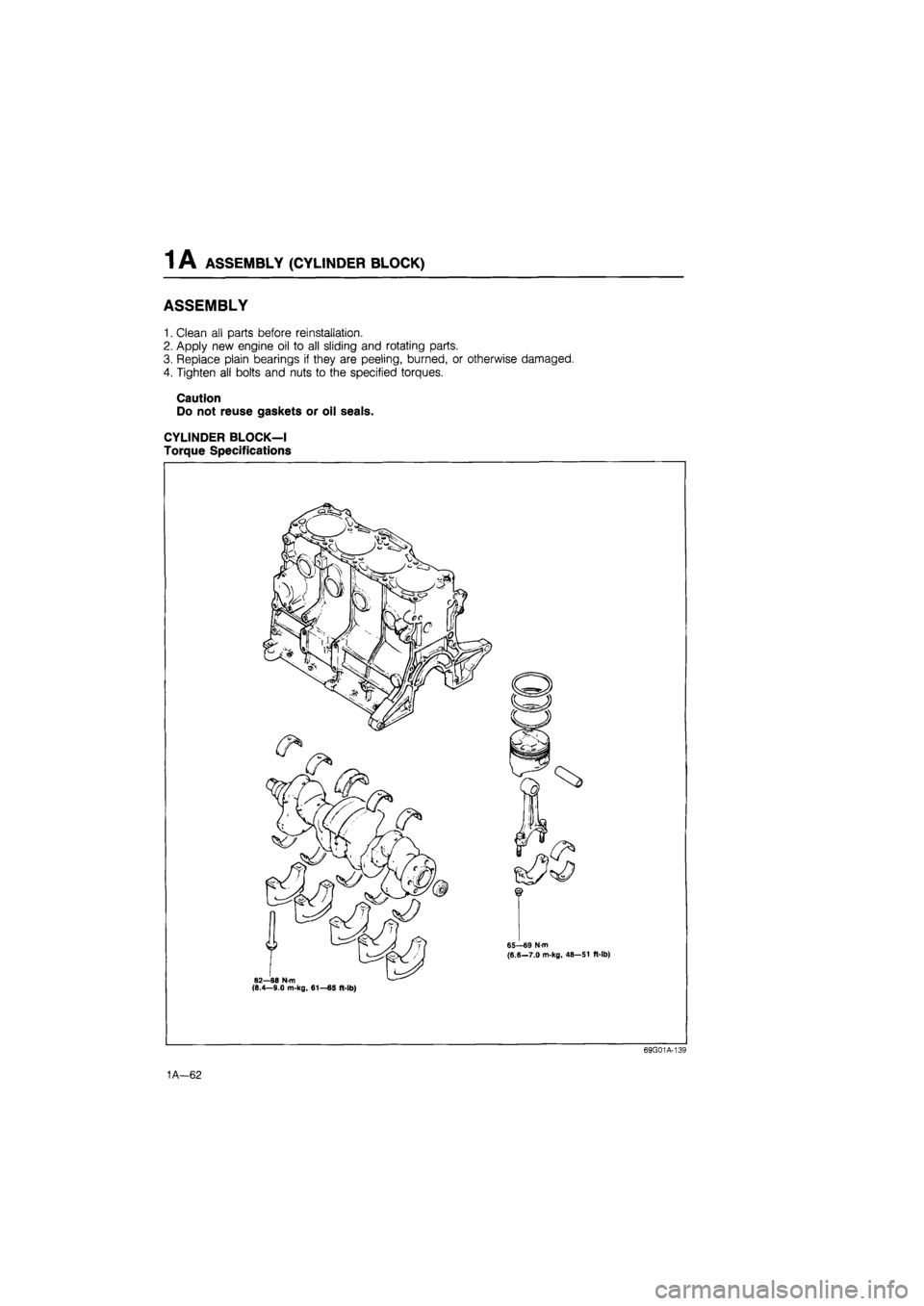

1 A ASSEMBLY (CYLINDER BLOCK)

ASSEMBLY

1. Clean all parts before reinstallation.

2. Apply new engine oil to all sliding and rotating parts.

3. Replace plain bearings if they are peeling, burned, or otherwise damaged.

4. Tighten all bolts and nuts to the specified torques.

Caution

Do not reuse gaskets or oil seals.

CYLINDER BLOCK—I

Torque Specifications

69G01A-139

1A—62

Page 95 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 A

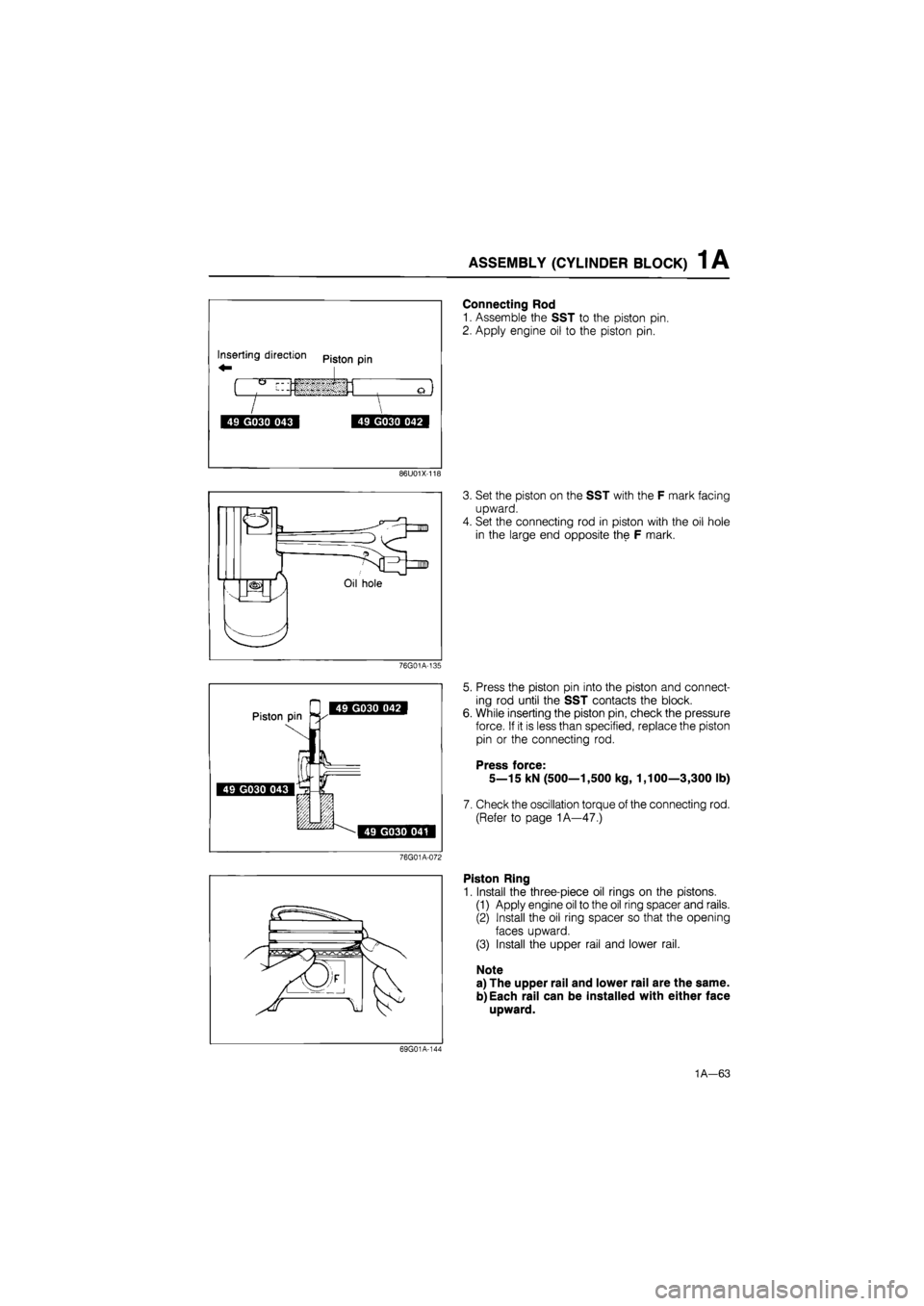

Connecting Rod

1. Assemble the SST to the piston pin.

2. Apply engine oil to the piston pin.

86U01X-118

3. Set the piston on the SST with the F mark facing

upward.

4. Set the connecting rod in piston with the oil hole

in the large end opposite the F mark.

76G01A-135

5. Press the piston pin into the piston and connect-

ing rod until the SST contacts the block.

While inserting the piston pin, check the pressure

force. If it is less than specified, replace the piston

pin or the connecting rod.

Press force:

5—15 kN (500—1,500 kg, 1,100—3,300 lb)

Check the oscillation torque of the connecting rod.

(Refer to page 1A—47.)

76G01A-072

Piston Ring

1. Install the three-piece oil rings on the pistons.

(1) Apply engine oil to the oil ring spacer and rails.

(2) Install the oil ring spacer so that the opening

faces upward.

(3) Install the upper rail and lower rail.

Note

a) The upper rail and lower rail are the same.

b) Each rail can be installed with either face

upward.

69G01A-144

1A—63

Page 96 of 1865

1 A ASSEMBLY (CYLINDER BLOCK)

Spacer iang

Oil ring

spacer ends

Upper rail

Piston

Lower rail

69G01A-145

86U01X-121

Oil ring —

upper rail f .Top ring

Oil ring (

spacer r \30° \ . Pistion

^-^/ao0F pin

Oil ring

lower rail /Second ring

69G01A-147

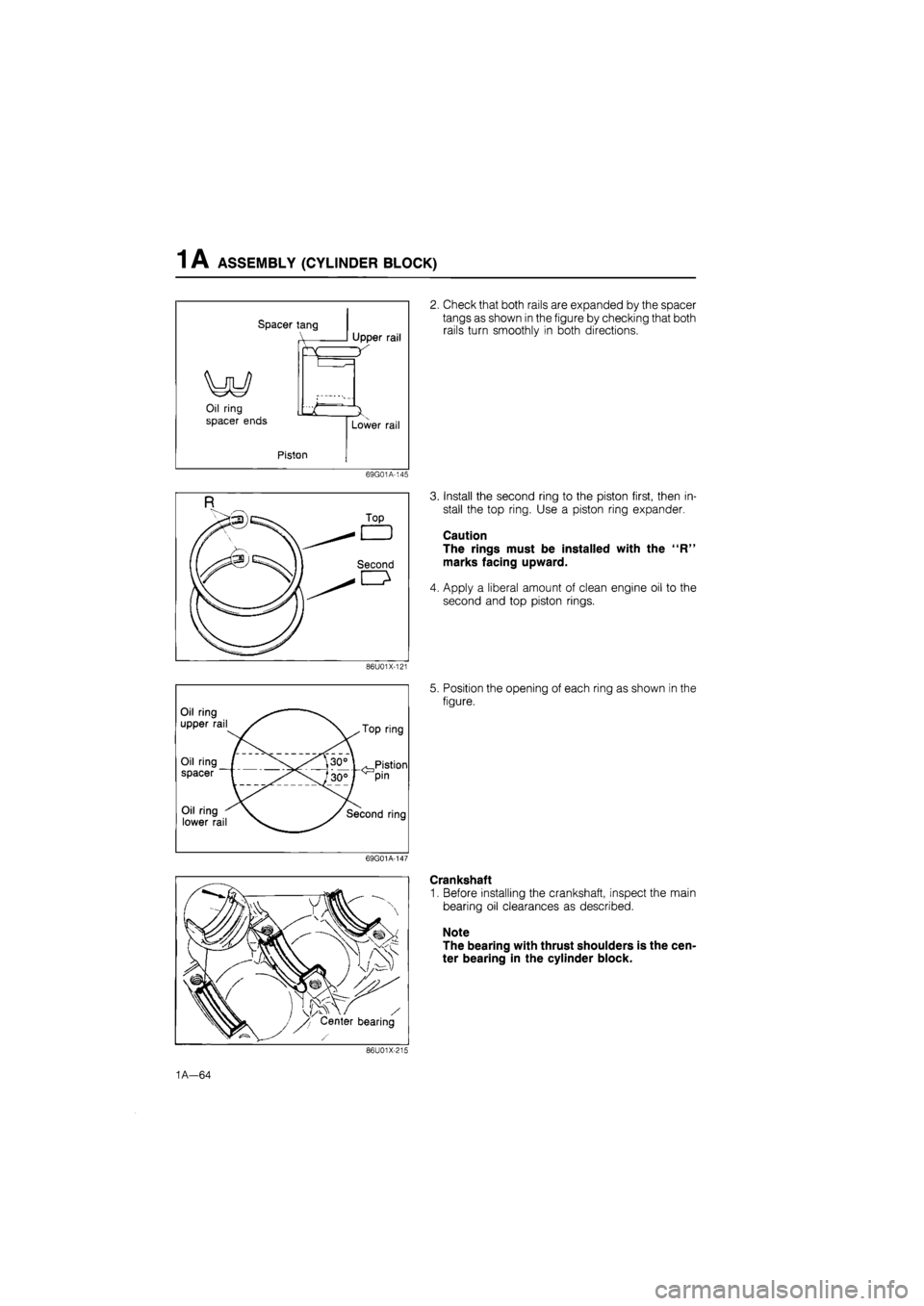

2. Check that both rails are expanded by the spacer

tangs as shown in the figure by checking that both

rails turn smoothly in both directions.

3. Install the second ring to the piston first, then in-

stall the top ring. Use a piston ring expander.

Caution

The rings must be installed with the "R"

marks facing upward.

4. Apply a liberal amount of clean engine oil to the

second and top piston rings.

5. Position the opening of each ring as shown in the

figure.

Crankshaft

1. Before installing the crankshaft, inspect the main

bearing oil clearances as described.

Note

The bearing with thrust shoulders is the cen-

ter bearing in the cylinder block.

86U01X-136

1A—64

Page 97 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 A

86U01X-122

UJlJt^LM

.•I

86U01X-123

76G01A-073

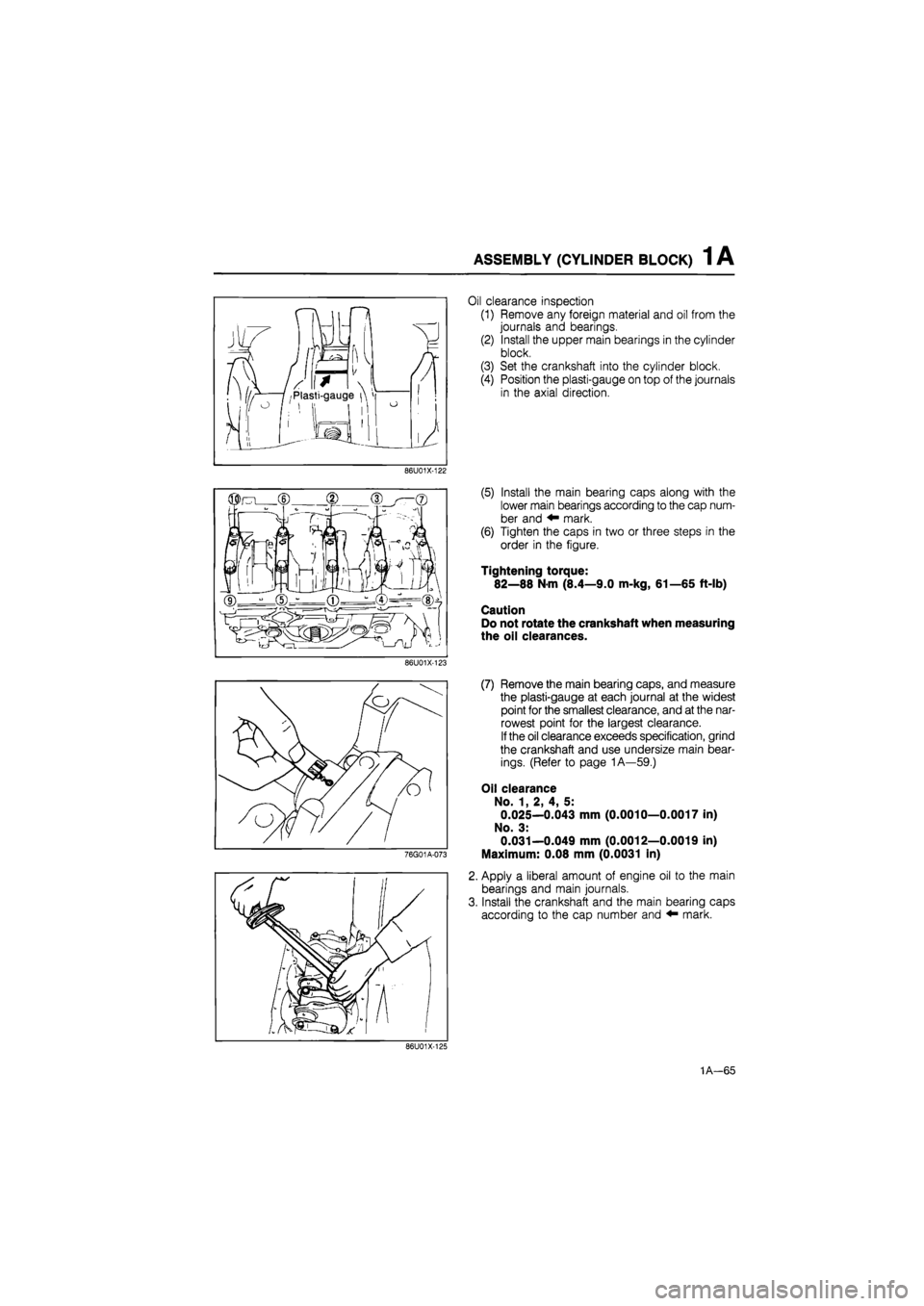

Oil clearance inspection

(1) Remove any foreign material and oil from the

journals and bearings.

(2) Install the upper main bearings in the cylinder

block.

(3) Set the crankshaft into the cylinder block.

(4) Position the plasti-gauge on top of the journals

in the axial direction.

(5) Install the main bearing caps along with the

lower main bearings according to the cap num-

ber and ^ mark.

(6) Tighten the caps in two or three steps in the

order in the figure.

Tightening torque:

82—88 N-m (8.4—9.0 m-kg, 61—65 ft-lb)

Caution

Do not rotate the crankshaft when measuring

the oil clearances.

(7) Remove the main bearing caps, and measure

the plasti-gauge at each journal at the widest

point for the smallest clearance, and at the nar-

rowest point for the largest clearance.

If the oil clearance exceeds specification, grind

the crankshaft and use undersize main bear-

ings. (Refer to page 1A—59.)

Oil clearance

No. 1, 2, 4, 5:

0.025—0.043 mm (0.0010—0.0017 in)

No. 3:

0.031—0.049 mm (0.0012—0.0019 in)

Maximum: 0.08 mm (0.0031 in)

2. Apply a liberal amount of engine oil to the main

bearings and main journals.

3. Install the crankshaft and the main bearing caps

according to the cap number and mark.

86U01X-130

1A—65

Page 98 of 1865

1 A ASSEMBLY (CYLINDER BLOCK)

76G01A-074

86U01X-216

86U01X-127

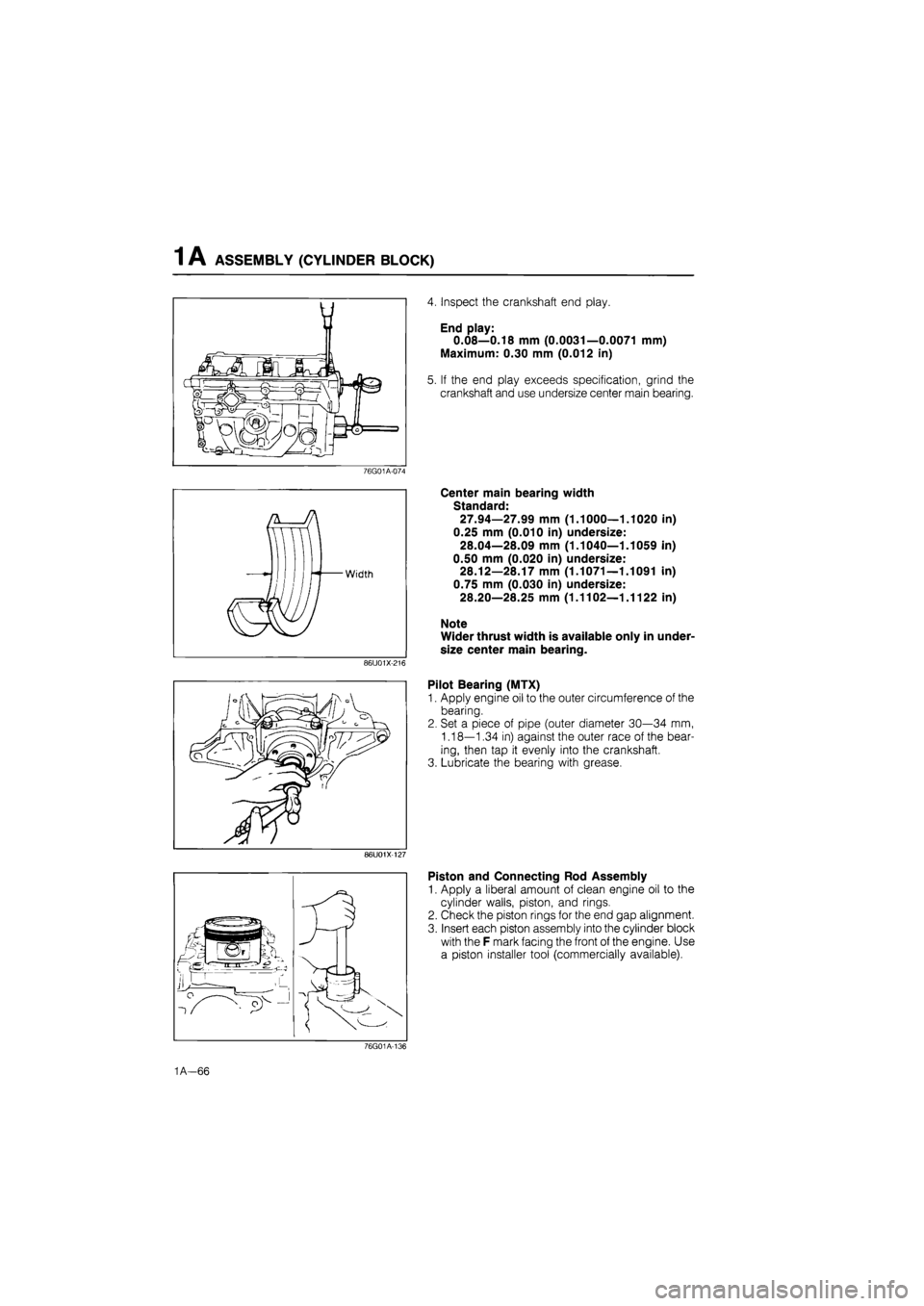

4. Inspect the crankshaft end play.

End play:

0.08—0.18 mm (0.0031—0.0071 mm)

Maximum: 0.30 mm (0.012 in)

5. If the end play exceeds specification, grind the

crankshaft and use undersize center main bearing.

Center main bearing width

Standard:

27.94—27.99 mm (1.1000—1.1020 in)

0.25 mm (0.010 in) undersize:

28.04—28.09 mm (1.1040—1.1059 in)

0.50 mm (0.020 in) undersize:

28.12—28.17 mm (1.1071—1.1091 in)

0.75 mm (0.030 in) undersize:

28.20—28.25 mm (1.1102—1.1122 in)

Note

Wider thrust width is available only in under-

size center main bearing.

Pilot Bearing (MTX)

1. Apply engine oil to the outer circumference of the

bearing.

2. Set a piece of pipe (outer diameter 30—34 mm,

1.18—1.34 in) against the outer race of the bear-

ing, then tap it evenly into the crankshaft.

3. Lubricate the bearing with grease.

Piston and Connecting Rod Assembly

1. Apply a liberal amount of clean engine oil to the

cylinder walls, piston, and rings.

2. Check the piston rings for the end gap alignment.

3. Insert each piston assembly into the cylinder block

with the F mark facing the front of the engine. Use

a piston installer tool (commercially available).

76G01A-136

1A—66

Page 99 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 A

69G01B-137

Matin

76G01A-075

69G01B-139

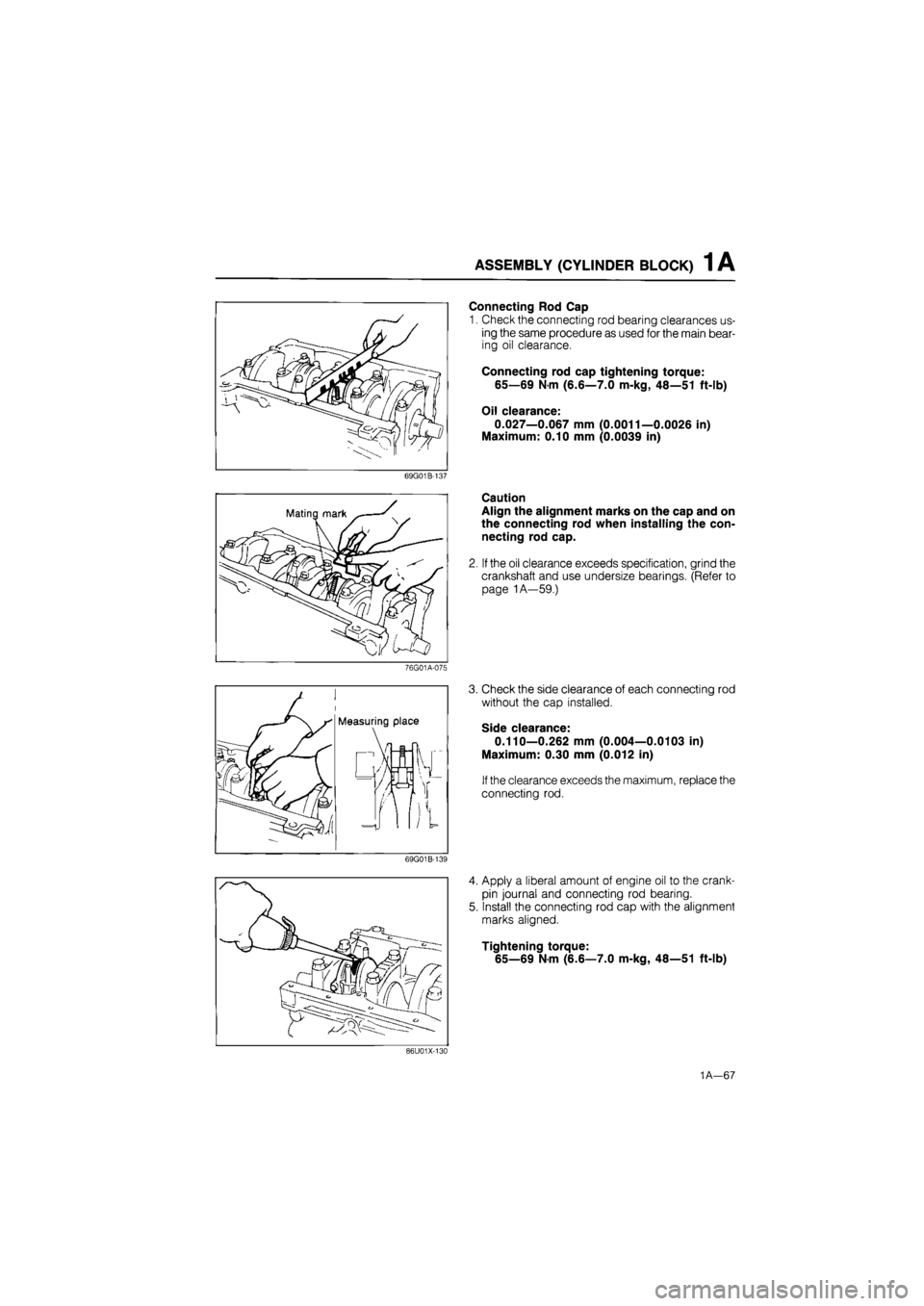

Connecting Rod Cap

1. Check the connecting rod bearing clearances us-

ing the same procedure as used for the main bear-

ing oil clearance.

Connecting rod cap tightening torque:

65—69 Nm (6.6—7.0 m-kg, 48—51 ft-lb)

Oil clearance:

0.027—0.067 mm (0.0011—0.0026 in)

Maximum: 0.10 mm (0.0039 in)

Caution

Align the alignment marks on the cap and on

the connecting rod when installing the con-

necting rod cap.

If the oil clearance exceeds specification, grind the

crankshaft and use undersize bearings. (Refer to

page 1A—59.)

3. Check the side clearance of each connecting rod

without the cap installed.

Side clearance:

0.110—0.262 mm (0.004—0.0103 in)

Maximum: 0.30 mm (0.012 in)

If the clearance exceeds the maximum, replace the

connecting rod.

4. Apply a liberal amount of engine oil to the crank-

pin journal and connecting rod bearing.

5. Install the connecting rod cap with the alignment

marks aligned.

Tightening torque:

65—69 Nm (6.6—7.0 m-kg, 48—51 ft-lb)

86U01X-130

1A—67

Page 100 of 1865

1 A ASSEMBLY (CYLINDER BLOCK)

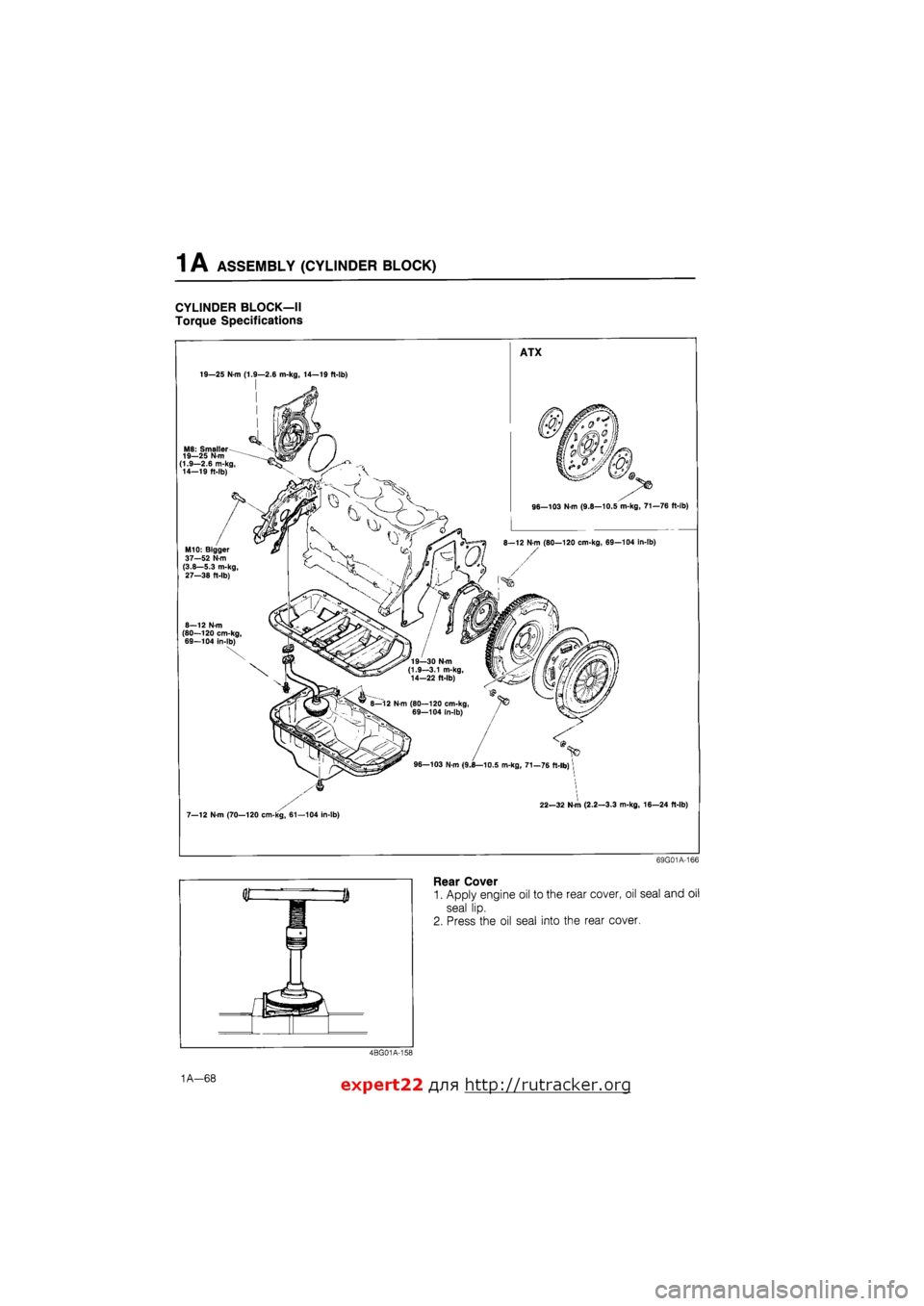

CYLINDER BLOCK—II

Torque Specifications

ATX

MS: Smaller 19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

M10: Bigger 37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

96—103 N-m (9.8—10.5 m-kg, 71—76 ft-lb)

69G01A-166

Rear Cover

1. Apply engine oil to the rear cover, oil seal and oil

seal lip.

2. Press the oil seal into the rear cover.

4BG01A-158

expert22 fl/ifl http://rutracker.org

Page 101 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 A

3. Install the rear cover and a new gasket.

Tightening torque:

8—12 N-m (80—120 cm-kg, 69—104 in-lb)

86U01X-131

4. Cut away the portion of the gasket that projects out

from the rear cover assembly toward the oil pan

side.

Caution

Do not scratch the rear cover assembly.

86U01X-132

End Plate

Install the end plate.

Tightening torque:

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

4BG01A-160

Oil Pump

1. Apply engine oil to a new oil pump oil seal and the

oil pump body.

2. Press the oil seal into the oil pump body.

79G01C-085

1

A—69

Page 102 of 1865

1 A ASSEMBLY (CYLINDER BLOCK)

86U01X-133

76G01A-137

76G01A-076

3. Apply engine oil to the oil seal lip.

4. Remove any dirt or other material from the con-

tact surfaces.

5. Apply a continuos bead of silicon sealant to the

contact surface of the oil pump.

Caution

Do not allow any sealant to get into the oil

hole.

6. Install a new O-ring into the pump body.

7. Install the oil pump.

Tightening torque

(A): 19—25 Nm

(1.9—2.6 m-kg, 14—19 ft-lb)

(§): 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

8. Remove any sealant which has been squeezed

out.

Stiffener (FE 8-valve...only ECE, 12-valve)

1. Remove any dirt or other material from the con-

tact surface.

2. Apply a continuous bead of silicon sealant to the

stiffener along the inside of the bolt holes, and over-

lap the ends.

3. Install the stiffener.

Tightening torque:

7—12

N

m (70—120 cm-kg, 61—104 in-lb)

Oil Strainer

Install the oil strainer and a new gasket.

Tightening torque:

8—12 N-m (80—120 cm-kg, 69—104 in-lb)

86U01X-136

1A—70