lock MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1721 of 1865

15 POWER WINDOW

OK Check power window switch

on

each door. Refer

to

page 15—67.

76G15X-059

INSPECTION

Power Window Driver's Side Switch

(For Sedan and Hatchback)

Check for continuity between terminals of the switch.

Main switch

—Terminal Position -——___ h i

Lock

Unlock

O o

O O:

Indicates continuity

76G15X-016

c f i i 0

b e h k n

a d R J m /

O O:

Indicates continuity

15-66

Page 1722 of 1865

REAR WINDOW 15

9 c a

CD [=• cm

•

h f d b

76G15X-017

g c a

I I I I

cm I I I I

h f d b

86U15X-11E

(For Coupe/MX-6)

Check for continuity between terminals of the switch.

Main switch

-—-—^^Terminal Position

——- ^

a c

Lock

Unlock 0 O

o

-O: Indicates continuity

Switch

'erminal

Position

UP

OFF

DOWN

Driver's side

O

O

o

o-

o

-o

-o

-o

=o

-o

Passenger's side

O

O

O-

O

O

-o

-o

-o

-o

-o

O O:

Indicates continuity

Switch on Each Side

(For Sedan And Hatchback)

Check for continuity between terminals of the switch.

Position Terminal

UP

OFF

DOWN

O-

O-

O-

-0

O-

O-

-o

-o -o

-o

O O:

Indicates continuity

(For Coupe/MX-6)

Check for continuity between terminals of the switch.

Position

~———^

a b d f h

UP O—

O— —0

—o

OFF o—

O—

—o —O

DOWN O—

o—

—0 —o

O

O:

Indicates continuity

76G15X-019

15-67

Page 1740 of 1865

CRUISE CONTROL SYSTEM 1 5

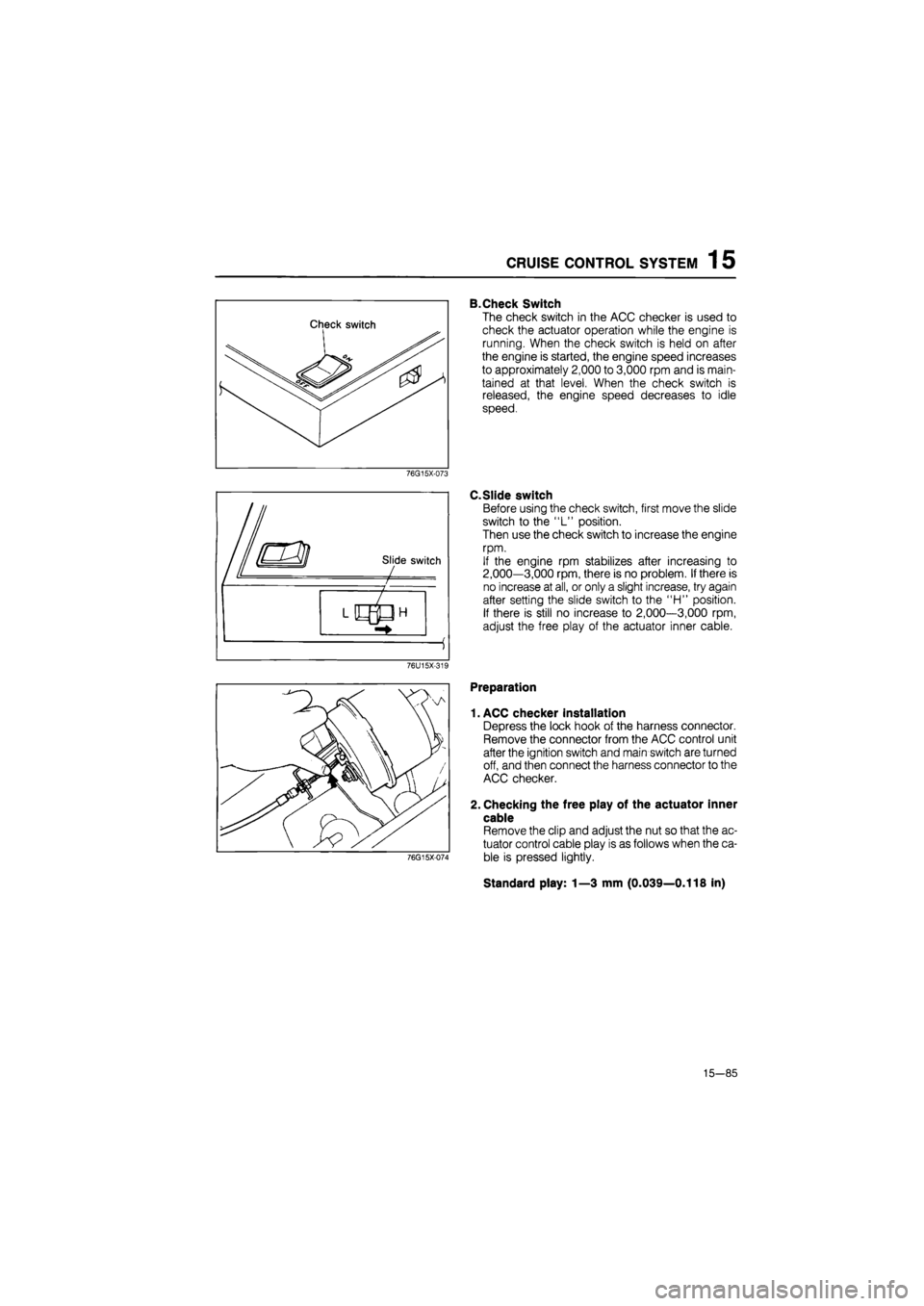

B.Check Switch

The check switch in the ACC checker is used to

check the actuator operation while the engine is

running. When the check switch is held on after

the engine is started, the engine speed increases

to approximately 2,000 to 3,000 rpm and is main-

tained at that level. When the check switch is

released, the engine speed decreases to idle

speed.

76G15X-073

C.Slide switch

Before using the check switch, first move the slide

switch to the "L" position.

Then use the check switch to increase the engine

rpm.

If the engine rpm stabilizes after increasing to

2,000—3,000 rpm, there is no problem. If there is

no increase at all, or only a slight increase, try again

after setting the slide switch to the "H" position.

If there is still no increase to 2,000—3,000 rpm,

adjust the free play of the actuator inner cable.

76U15X-319

76G15X-074

Preparation

1. ACC checker installation

Depress the lock hook of the harness connector.

Remove the connector from the ACC control unit

after the ignition switch and main switch are turned

off, and then connect the harness connector to the

ACC checker.

2. Checking the free play of the actuator inner

cable

Remove the clip and adjust the nut so that the ac-

tuator control cable play is as follows when the ca-

ble is pressed lightly.

Standard play: 1—3 mm (0.039—0.118 in)

15—85

Page 1750 of 1865

AUTO ADJUSTING SUSPENSION (AAS) 1 5

Checking Condition

Note:

Turn the ignition switch OFF to reset the con-

trol unit before each test.

Condition A

1. Turn the ignition switch ON.

2. Set steering wheel in the straight-ahead position,

and check the output pattern.

86U15X-154

Condition B

1. Turn the ignition switch ON.

2. Turn the steering wheel right and left, and check

the output pattern.

86U15X-155

•

/

AUTO ADJUSTING SUSPENSION I- AUTO—i SOFT NORMAL SPORT

Condition C

1. Turn the ignition switch ON.

2. Change the AAS switch from NORMAL to SPORT

or from SPORT to NORMAL, and check the out-

put pattern.

86U15X-156

Condition D

1. Operate the vehicle on a chassis roller.

2. Check the output pattern at above 15 km/h (9.3

mph).

Caution

a) Block the rear wheels.

b) In vehicle equipped with ABS, ABS warn-

ing light may come on, which is not a fail-

ure. The light goes off by turning ignition

switch OFF and again ON.

86U15X-157

15—95

Page 1760 of 1865

POWER DOOR LOCK 1 5

POWER DOOR LOCK

STRUCTURAL VIEW

CIRCUIT DIAGRAM

BATTERY

86U15X-171

15—105

Page 1761 of 1865

1 5 POWER DOOR LOCK

TROUBLESHOOTING

Terminal Voltage

WG 12V

B OV

Check the voltage

at GB

terminal

of

the power door lock relay with each switch condition.

Terminal Condition Voltage

GB Lock 12V GB Unlock OV

OK

Check the voltage

at R

and

G

terminal

of

the power door lock relay with each switch condition.

Terminal Condition Voltaae

R Lock OV R Unlock 12V

G Lock 12V G Unlock OV

Power door lock does not operate.

Check DOOR LOCK 30A fuse.

OK

NG

Short circuit.

Check the voltage

at

each terminal

of

the power door lock relay connector.

NG

Repair the harness. (Fuse box

to

relay, Relay

to

ground)

OK

Check the power door lock switch. Refer

to

page 15-107.

OK

NG

Replace the switch.

NG

Repair the harness. (Door lock switch

to

relay)

NG

Replace the door lock relay.

OK

Check the power door lock motor. Refer

to

page

15-107.

OK

Repair the harness. (Relay

to

each motors)

NG

Replace the door lock motor.

76G15X086

15—106

Page 1762 of 1865

POWER DOOR LOCK 1 5

86U15X-173

INSPECTION

Power Door Lock Switch

1. Check for continuity of the switch with an

ohmmeter.

WG GB B

Lock

o O

Unlock

o O

O

O:

indicates continuity

2. If continuity is not as specified, replace the switch.

Power Door Lock Motor

1. Check operation of the door lock actuator when

the battery voltage is applied to the terminal.

Connecting

to

Door lock motor 12V ground Door lock motor

G R LOCK (Pull)

R G UNLOCK (Release)

2. If not, replace the door lock motor.

86U15X-174

15—107

Page 1793 of 1865

16 OUTLINE

Safety Precautions

1. The R-12 liquid refrigerant is highly volatile. A drop

of it on the skin of your hand could result in local-

ized frostbite. When handling the refrigerant, be

sure to wear gloves.

2. If the refrigerant splashes into your eyes, wash

them with clean water immediately. It is standard

practice to wear goggles or glasses to protect your

eyes, and gloves to protect your hands.

3. The R-12 container is a highly pressurized vessel.

Never leave it in a hot place, and check to be sure

that the temperature where it is stored is below

52°C (126°F).

4. A halide leak detector is often used to check the

system for refrigerant leakage. Remember that

R-12, upon coming into contact with flame (this de-

tector burns like propane to produce a small flame),

produces phosgene, a toxic gas.

69G16X020

V/^V

Connection

LZl

jvmi

Refrigerant Container Service Valve

1. Before connecting the valve to the refrigerant con-

tainer, turn the handle fully counterclockwise.

2. Turn the disc counterclockwise until it reaches its

highest position.

3. Connect the center hose to the valve fitting. Turn

the disc fully clockwise by hand.

4. Turn the handle clockwise to make a hole in the

sealed tap.

5. Turn the handle fully counterclockwise to fill the

center hose with air. Do not open the high- and

low-pressure manual valves.

6. Loosen the center hose nut connected to the cen-

ter fitting of the manifold gauge.

Allow air to escape for a few seconds, then tight-

en the nut.

69G16X-021

16-10

Page 1807 of 1865

16 CONDENSER

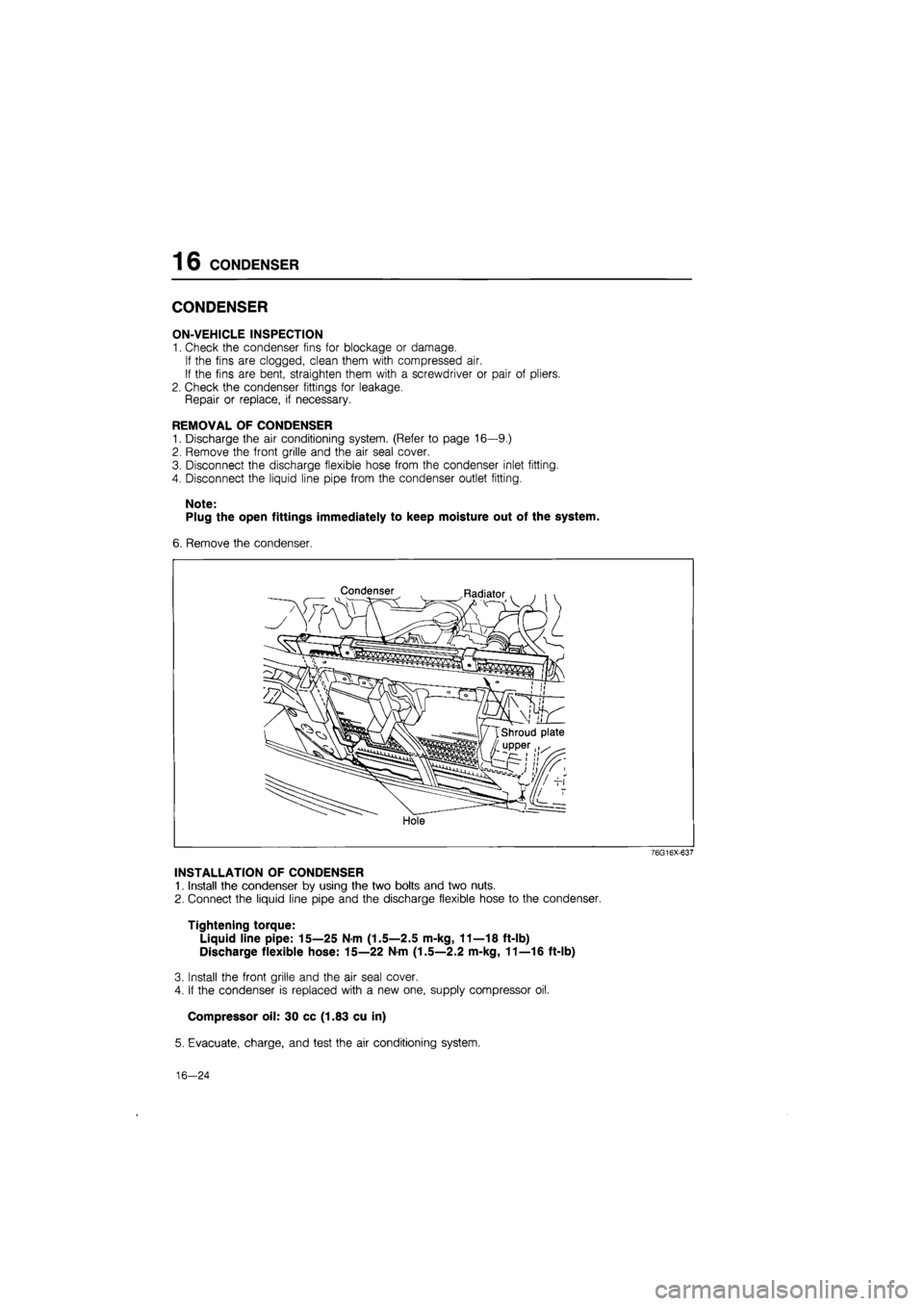

CONDENSER

ON-VEHICLE INSPECTION

1. Check the condenser fins for blockage or damage.

If the fins are clogged, clean them with compressed air.

If the fins are bent, straighten them with a screwdriver or pair of pliers.

2. Check the condenser fittings for leakage.

Repair or replace, if necessary.

REMOVAL OF CONDENSER

1. Discharge the air conditioning system. (Refer to page 16—9.)

2. Remove the front grille and the air seal cover.

3. Disconnect the discharge flexible hose from the condenser inlet fitting.

4. Disconnect the liquid line pipe from the condenser outlet fitting.

Note:

Plug the open fittings immediately to keep moisture out of the system.

6. Remove the condenser.

Condenser Radiator

Hole

76G16X-637

INSTALLATION OF CONDENSER

1. Install the condenser by using the two bolts and two nuts.

2. Connect the liquid line pipe and the discharge flexible hose to the condenser.

Tightening torque:

Liquid line pipe: 15—25 Nm (1.5—2.5 m-kg, 11—18 ft-lb)

Discharge flexible hose: 15—22 N-m (1.5—2.2 m-kg, 11—16 ft-lb)

3. Install the front grille and the air seal cover.

4. If the condenser is replaced with a new one, supply compressor oil.

Compressor oil: 30 cc (1.83 cu in)

5. Evacuate, charge, and test the air conditioning system.

16—24

Page 1810 of 1865

COOLING UNIT 1 6

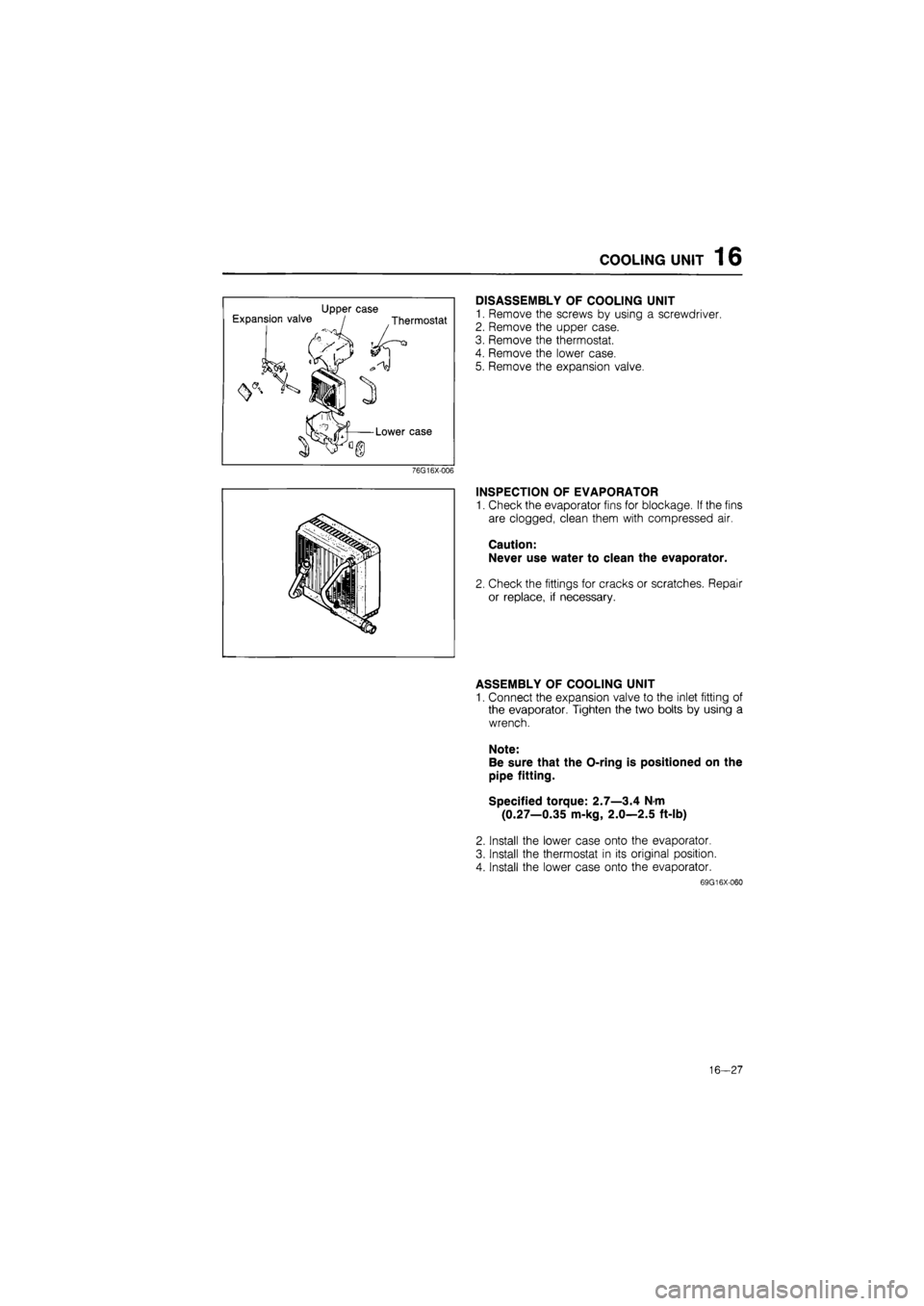

Upper case Expansion valve / Thermostat

Lower case

76G16X-006

DISASSEMBLY OF COOLING UNIT

1. Remove the screws by using a screwdriver.

2. Remove the upper case.

3. Remove the thermostat.

4. Remove the lower case.

5. Remove the expansion valve.

INSPECTION OF EVAPORATOR

1. Check the evaporator fins for blockage. If the fins

are clogged, clean them with compressed air.

Caution:

Never use water to clean the evaporator.

2. Check the fittings for cracks or scratches. Repair

or replace, if necessary.

ASSEMBLY OF COOLING UNIT

1. Connect the expansion valve to the inlet fitting of

the evaporator. Tighten the two bolts by using a

wrench.

Note:

Be sure that the O-ring is positioned on the

pipe fitting.

Specified torque: 2.7—3.4 N-m

(0.27—0.35 m-kg, 2.0—2.5 ft-lb)

2. Install the lower case onto the evaporator.

3. Install the thermostat in its original position.

4. Install the lower case onto the evaporator.

69G16X-060

16—27