engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 779 of 1865

STATRER (DIESEL ENGINE, 2.2 KW TYPE) 5

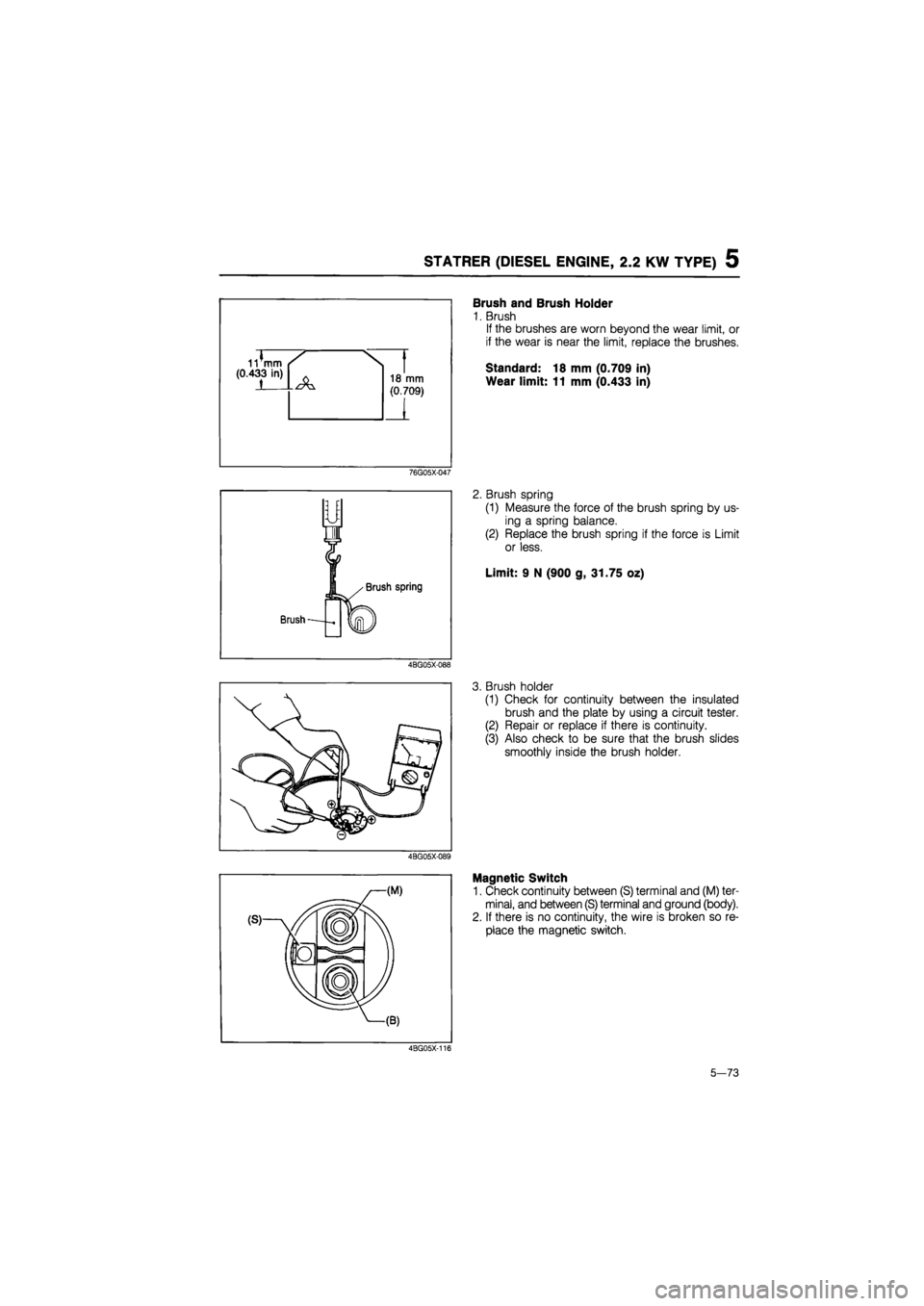

11*mm S (0.433 in)

A

A 18 mm

(0,709)

Brush and Brush Holder

1. Brush

If the brushes are worn beyond the wear limit, or

if the wear is near the limit, replace the brushes.

Standard: 18 mm (0.709 in)

Wear limit: 11 mm (0.433 in)

76G05X-047

2. Brush spring

(1) Measure the force of the brush spring by us-

ing a spring balance.

(2) Replace the brush spring if the force is Limit

or less.

Limit: 9 N (900 g, 31.75 oz)

4BG05X-088

3. Brush holder

(1) Check for continuity between the insulated

brush and the plate by using a circuit tester.

(2) Repair or replace if there is continuity.

(3) Also check to be sure that the brush slides

smoothly inside the brush holder.

4BG05X-089

Magnetic Switch

1. Check continuity between (S) terminal and (M) ter-

minal, and between (S) terminal and ground (body).

2. If there is no continuity, the wire is broken so re-

place the magnetic switch.

4BG05X-116

5-73

Page 780 of 1865

5 STARTER (DIESEL ENGINE, 2.2 KW TYPE)

Gear

Wear and damage

Bearing

Replace the bearing when it is noisy or does not ro-

tate smoothly.

4BG05X-117

4BG05X-118

Over-running Clutch

1. Replace the pinion when a worn pinion or

damaged pinion are found.

2.

If

the pinion does not rotate in both directions when

rotating the pinion by hand, replace it.

Note

Do not wash the over-running clutch in gas

or kerosene, this will destroy the grease

packing.

4BG05X-119

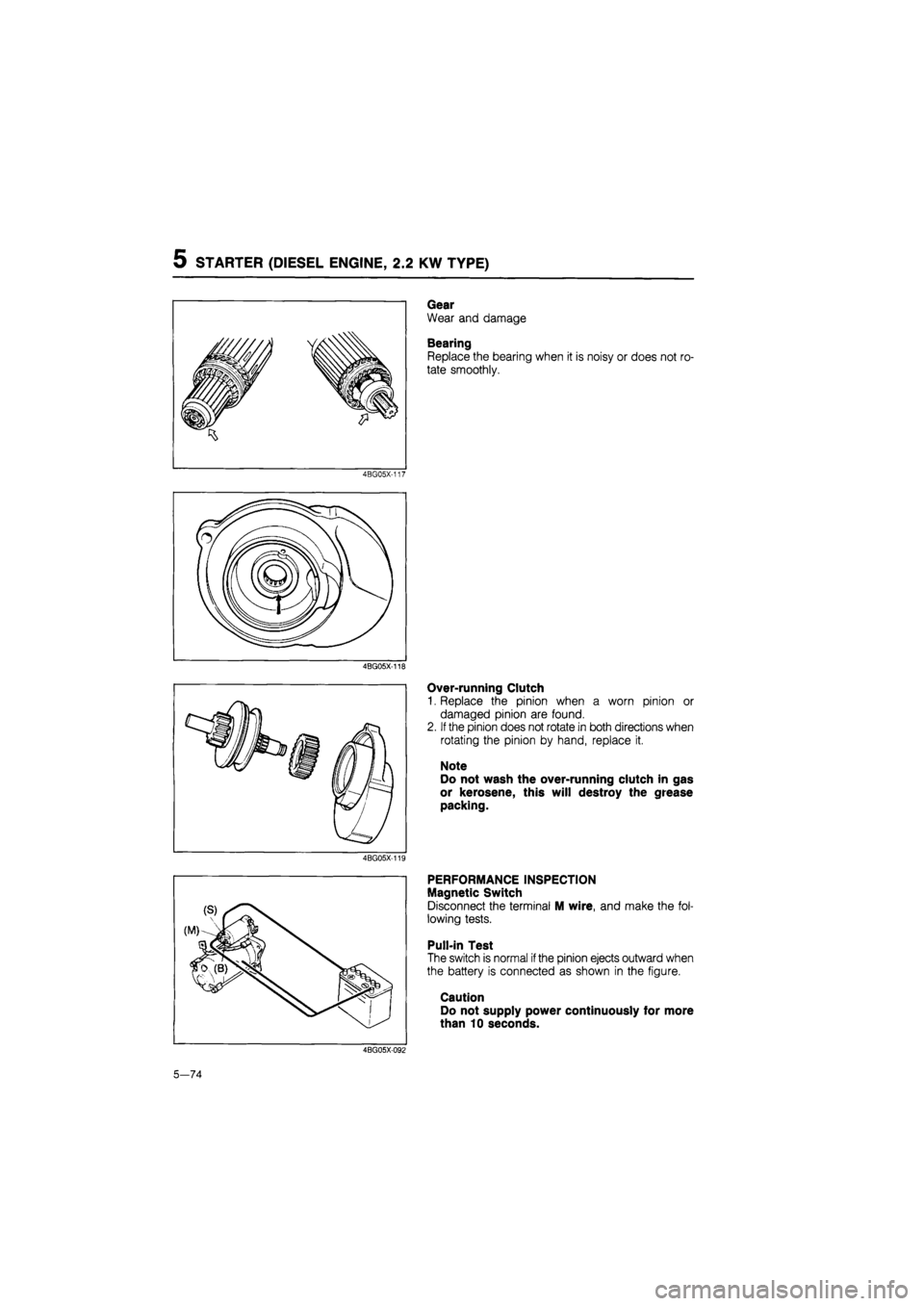

PERFORMANCE INSPECTION

Magnetic Switch

Disconnect the terminal M wire, and make the fol-

lowing tests.

Pull-in Test

The switch is normal

if

the pinion ejects outward when

the battery is connected as shown in the figure.

Caution

Do not supply power continuously for more

than 10 seconds.

4BG05X-092

5—74

Page 781 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

Hold-in Test

1. After completing the pull-in test, disconnect the wire

from terminal M (with the pinion left ejected).

2. The hold-in coil is functioning properly if the pin-

ion does not return.

4BG05X-093

Return Test

1. Connect the battery between terminal M of the

magnetic switch and the body, as shown in the

figure.

2. Pull the pinion out manually to the pinion stopper

position.

3. The pinion should immediately return to its origi-

nal position when it is released.

4BG05X-094

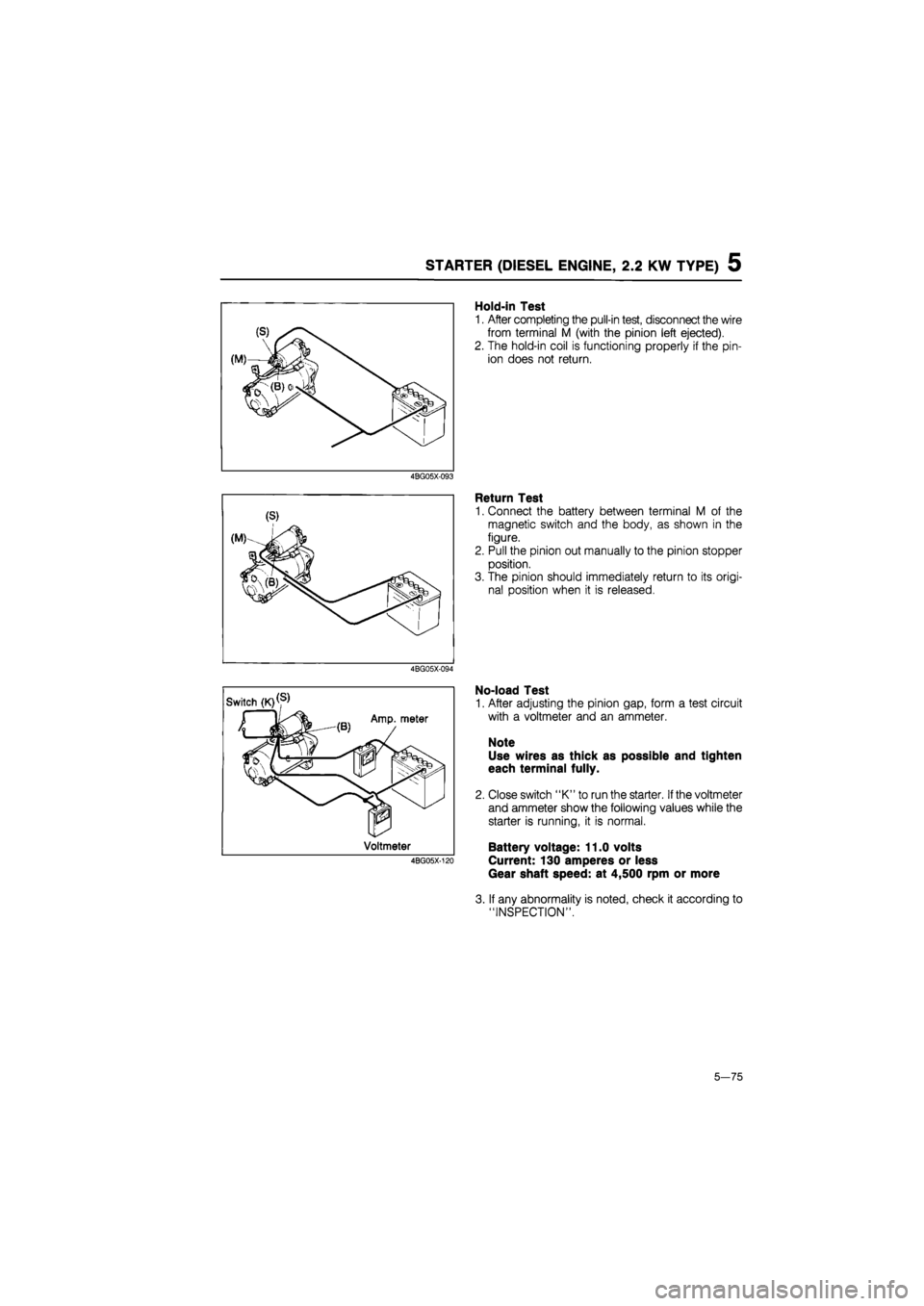

No-load Test

1. After adjusting the pinion gap, form a test circuit

with a voltmeter and an ammeter.

Note

Use wires as thick as possible and tighten

each terminal fully.

2. Close switch "K" to run the starter.

If

the voltmeter

and ammeter show the following values while the

starter is running, it is normal.

Battery voltage: 11.0 volts

Current: 130 amperes or less

Gear shaft speed: at 4,500 rpm or more

3. If any abnormality is noted, check it according to

"INSPECTION".

5—75

Page 783 of 1865

QUICK START SYSTEM (QSS) 5

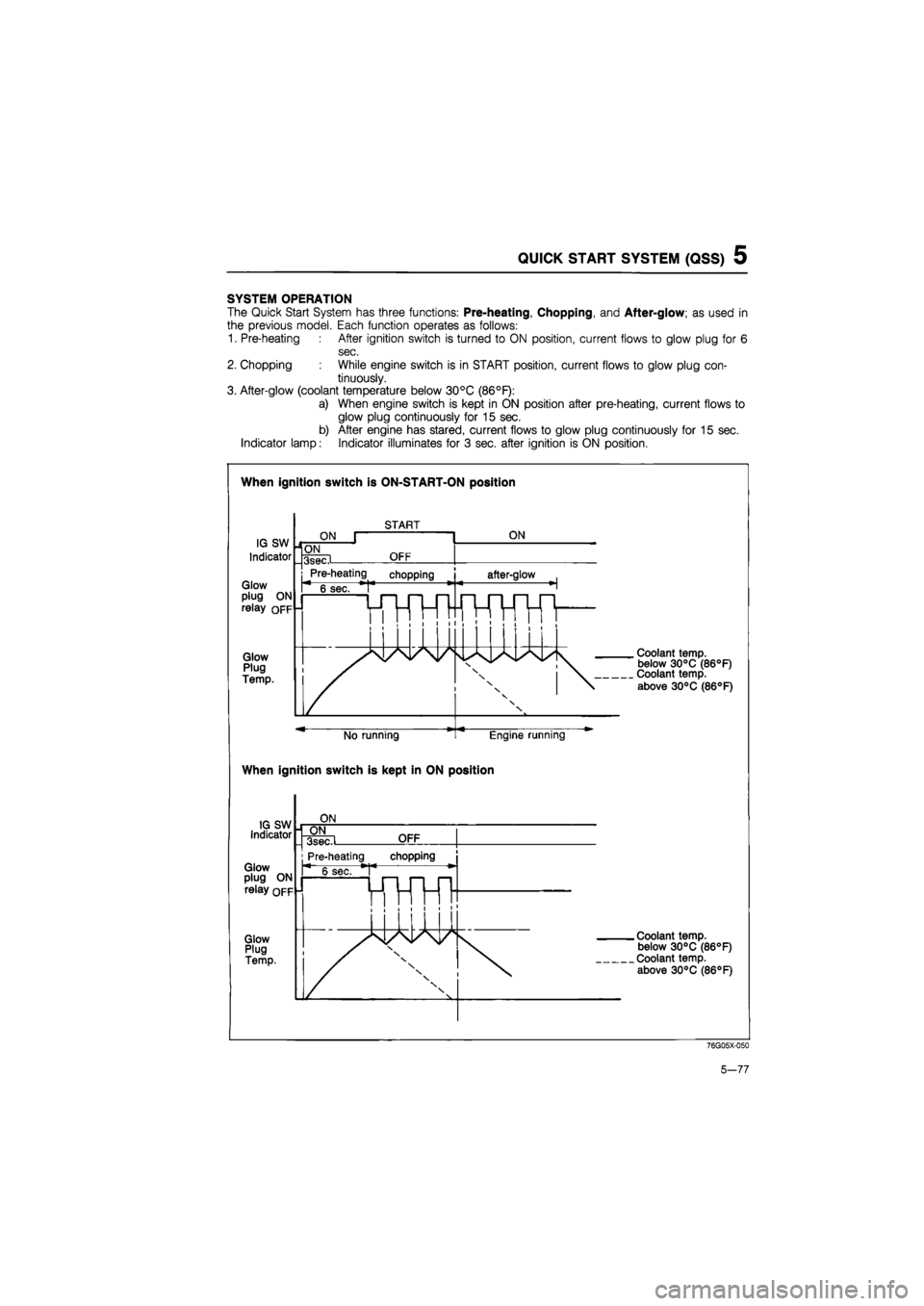

SYSTEM OPERATION

The Quick Start System has three functions: Pre-heating, Chopping, and After-glow; as used in

the previous model. Each function operates as follows:

1. Pre-heating After ignition switch is turned to ON position, current flows to glow plug for 6

sec.

2. Chopping While engine switch is in START position, current flows to glow plug con-

tinuously.

3. After-glow (coolant temperature below 30°C (86°F):

a) When engine switch is kept in ON position after pre-heating, current flows to

glow plug continuously for 15 sec.

b) After engine has stared, current flows to glow plug continuously for 15 sec.

Indicator lamp: Indicator illuminates for 3 sec. after ignition is ON position.

When ignition switch is ON-START-ON position

When ignition switch is kept in ON position

76G05X-050

5-77

Page 784 of 1865

QUICK START SYSTEM (QSS) 5

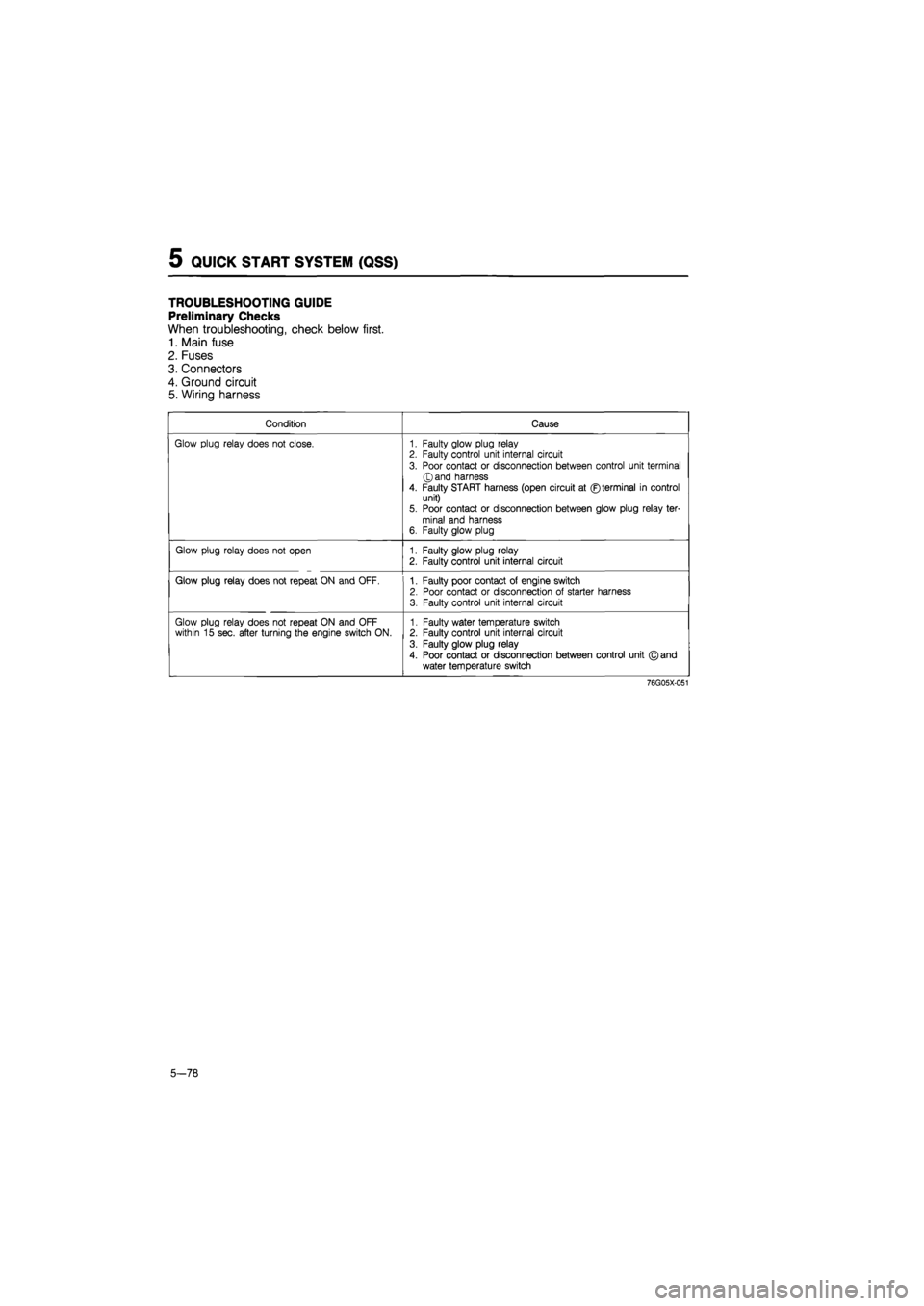

TROUBLESHOOTING GUIDE

Preliminary Checks

When troubleshooting, check below first.

1. Main fuse

2. Fuses

3. Connectors

4. Ground circuit

5. Wiring harness

Condition Cause

Glow plug relay does not close. 1. Faulty glow plug relay 2. Faulty control unit internal circuit

3. Poor contact or disconnection between control unit terminal ©and harness

4. Faulty START harness (open circuit at ©terminal in control unit) 5. Poor contact or disconnection between glow plug relay ter-minal and harness 6. Faulty glow plug

Glow plug relay does not open 1. Faulty glow plug relay 2. Faulty control unit internal circuit

Glow plug relay does not repeat ON and OFF. 1. Faulty poor contact of engine switch 2. Poor contact or disconnection of starter harness 3. Faulty control unit internal circuit

Glow plug relay does not repeat ON and OFF within 15 sec. after turning the engine switch ON. 1. Faulty water temperature switch 2. Faulty control unit internal circuit

3. Faulty glow plug relay

4. Poor contact or disconnection between control unit © and water temperature switch

76G05X-051

5-78

Page 785 of 1865

QUICK START SYSTEM (QSS) 5

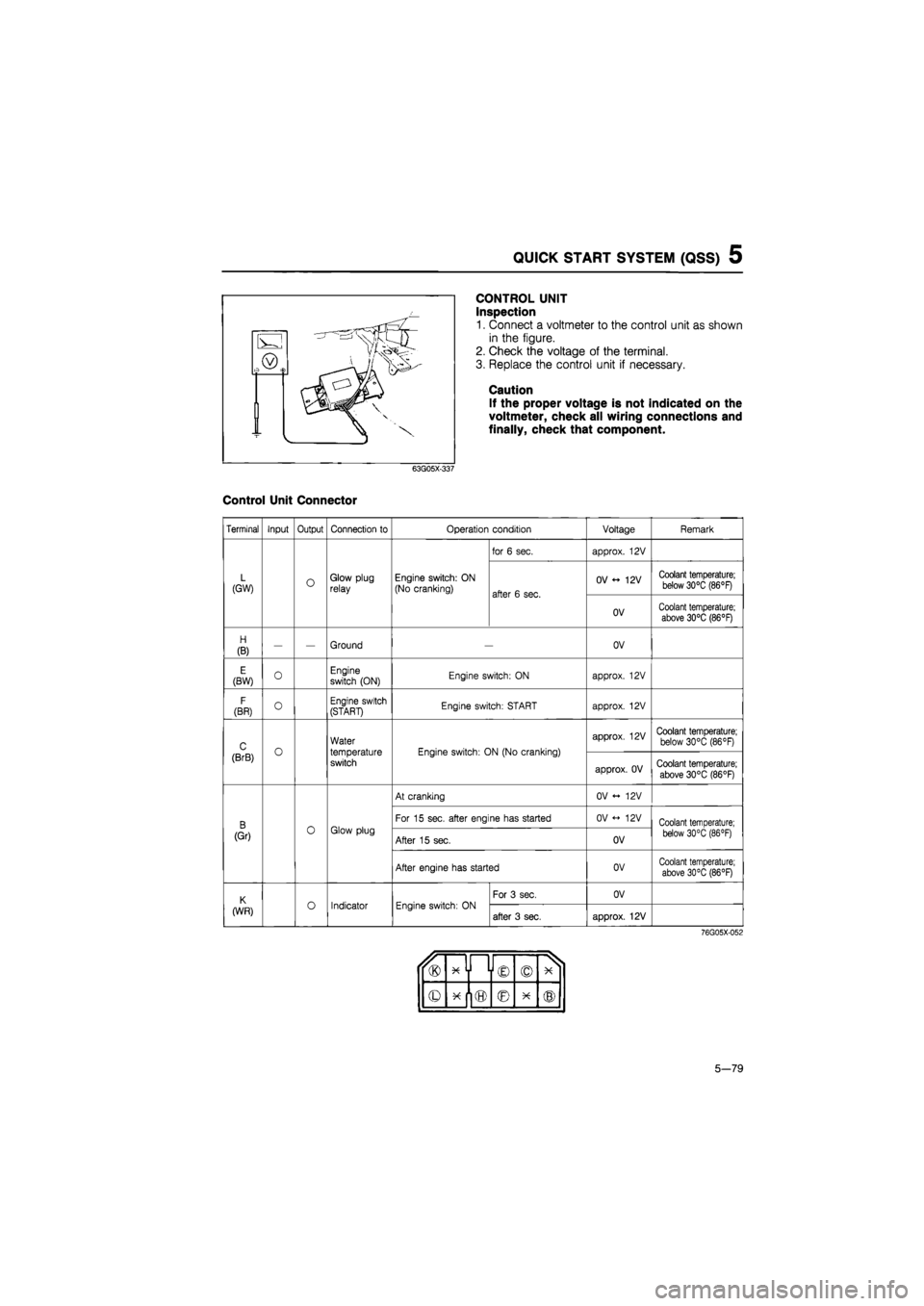

CONTROL UNIT

Inspection

1. Connect a voltmeter to the control unit as shown

in the figure.

2. Check the voltage of the terminal.

3. Replace the control unit if necessary.

Caution

If the proper voltage is not indicated on the

voltmeter, check all wiring connections and

finally, check that component.

63G05X-337

Control Unit Connector

Terminal Input Output Connection to Operation condition Voltage Remark

for 6 sec. approx. 12V

L (GW) O Glow plug relay Engine switch: ON (No cranking) after 6 sec.

OV 12V Coolant temperature; below 30°C (86°F) after 6 sec.

OV Coolant temperature; above 30°C (86°F)

H

(B) — — Ground OV

E (BW) 0 Engine switch (ON) Engine switch: ON approx. 12V

F

(BR) O Engine switch (START) Engine switch: START approx. 12V

C o

Water

temperature switch

Engine switch: ON (No cranking)

approx. 12V Coolant temperature; below 30°C (86°F)

(BrB) o

Water

temperature switch

Engine switch: ON (No cranking)

approx. OV Coolant temperature;

above 30°C (86°F)

At cranking OV <- 12V

B 0 Glow plug

For 15 sec. after engine has started OV <-> 12V Coolant temperature;

(Gr) 0 Glow plug After 15 sec. OV below 30°C (86 °F)

After engine has started OV Coolant temperature; above 30°C (86°F)

K o Indicator Engine switch: ON

For 3 sec. OV

(WR) o Indicator Engine switch: ON after 3 sec. approx. 12V

76G05X-052

u® x y i © © X 1

© © X ®

5-79

Page 789 of 1865

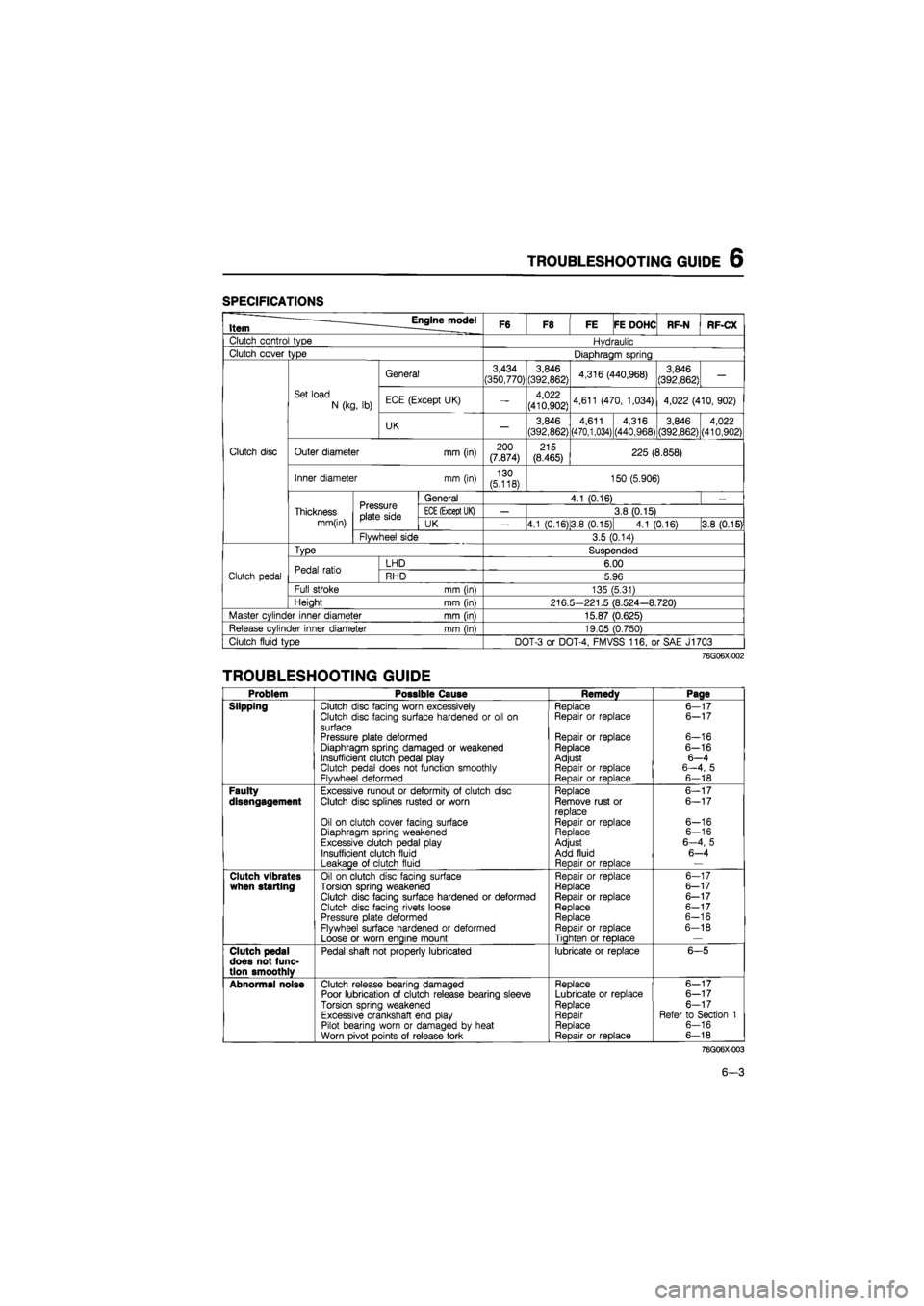

TROUBLESHOOTING GUIDE 6

SPECIFICATIONS

Item Engine model F6 F8 FE FE DOHC RF-N RF-CX

Clutch control type Hydraulic

Clutch cover type Diaphragm spring

General 3,434

(350,770) 3,846

(392,862) 4,316 (440,968) 3,846

(392,862) —

Set load

N (kg, lb) ECE (Except UK) — 4,022

(410,902) 4,611 (470, 1,034) 4,022 (410, 902)

UK — 3,846

(392,862)

4,611 (470,1,034) 4,316

(440,968)

3,846 (392,862) 4,022 (410,902)

Clutch disc Outer diameter mm (in) 200 (7.874) 215 (8.465) 225 (8.858)

Inner diameter mm (in) 130 (5.118) 150 (5.906)

Pressure plate side

General 4.1 (0.16) —

Thickness Pressure plate side

ECE

(Except UK) — 3.8 (0.15)

mm(in)

Pressure plate side UK 4.1 (0.16)13.8 (0.15) 4.1 (0.16) 3.8 (0.15)

Flywheel side 3.5 (0.14)

Type Suspended

Pedal ratio LHD 6.00

Clutch pedal Pedal ratio RHD 5.96

Full stroke mm (in) 135 (5.31)

Height mm (in) 216.5-221.5 (8.524-8.720)

Master cylinder inner diameter mm (in) 15.87 (0.625)

Release cylinder inner diameter mm (in) 19.05 (0.750)

Clutch fluid type DOT-3 or DOT-4, FMVSS 116, or SAE J1703

76G06X-002

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Slipping Clutch disc facing worn excessively Replace 6—17 Clutch disc facing surface hardened or oil on Repair or replace 6-17

surface Pressure plate deformed Repair or replace 6-16 Diaphragm spring damaged or weakened Replace 6-16 Insufficient clutch pedal play Adjust 6—4 Clutch pedal does not function smoothly Repair or replace 6—4, 5 Flywheel deformed Repair or replace 6-18

Faulty Excessive runout or deformity of clutch disc Replace 6-17 disengagement Clutch disc splines rusted or worn Remove rust or 6—17 replace Oil on clutch cover facing surface Repair or replace 6-16 Diaphragm spring weakened Replace 6-16

Excessive clutch pedal play Adjust 6—4, 5

Insufficient clutch fluid Add fluid 6-4

Leakage of clutch fluid Reoair or reDlace —

Clutch vibrates Oil on clutch disc facing surface Repair or replace 6-17 when starting Torsion spring weakened Replace 6-17 Clutch disc facing surface hardened or deformed Repair or replace 6-17

Clutch disc facing rivets loose Replace 6-17 Pressure plate deformed Replace 6-16

Flywheel surface hardened or deformed Repair or replace 6-18

Loose or worn engine mount Tighten or replace —

Clutch pedal Pedal shaft not properly lubricated lubricate or replace 6-5 does not func-tion smoothlv

Abnormal noise Clutch release bearing damaged Replace 6—17 Poor lubrication of clutch release bearing sleeve Lubricate or replace 6-17

Torsion spring weakened Replace 6-17

Excessive crankshaft end play Repair Refer to Section 1 Pilot bearing worn or damaged by heat Replace 6-16

Worn pivot points of release fork • Reoair or replace 6-18

76G06X-003

6-3

Page 801 of 1865

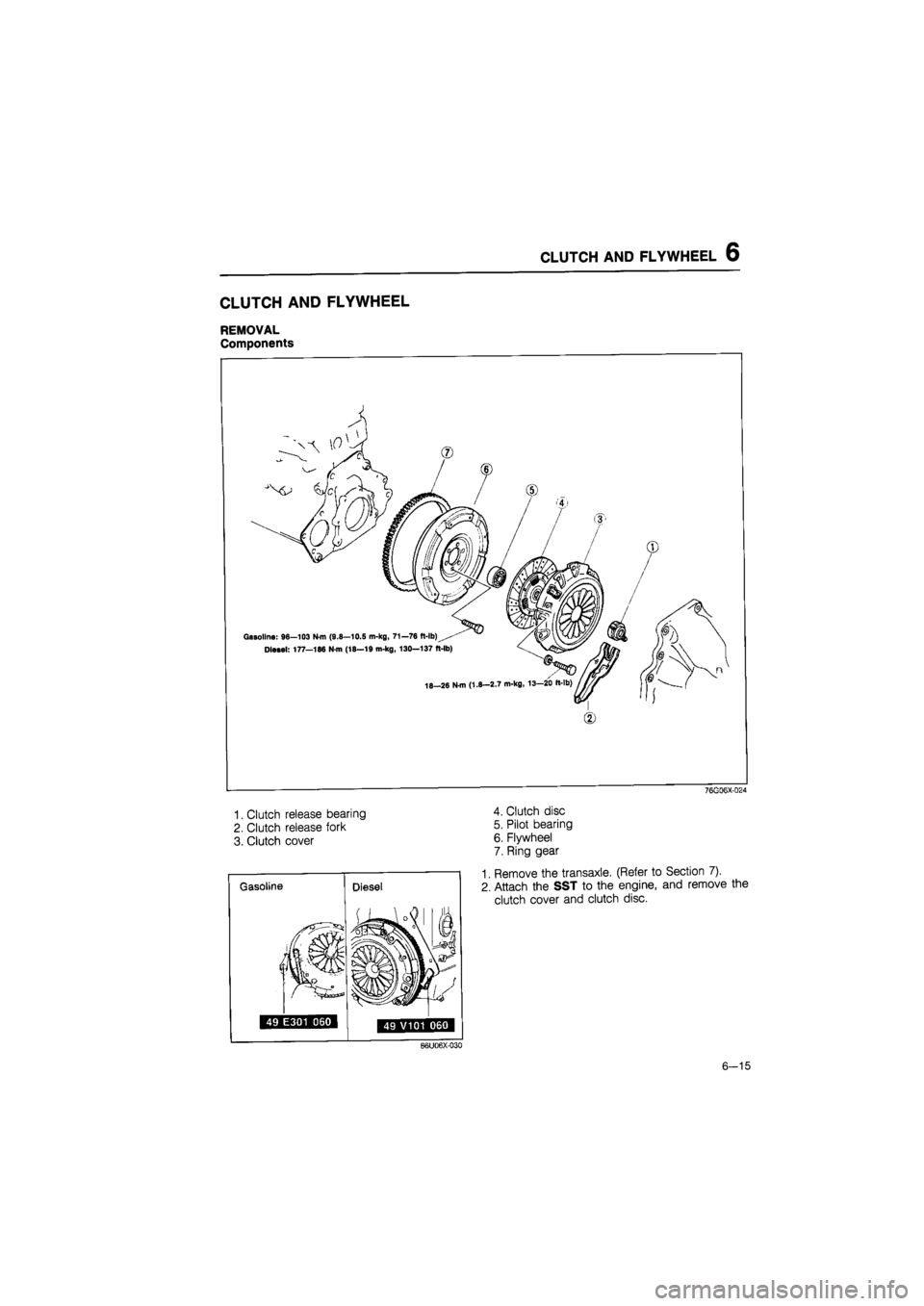

CLUTCH AND FLYWHEEL 6

CLUTCH AND FLYWHEEL

REMOVAL

Components

Gasoline: 96—103 N-m (9.8—10.5 m-kg, 71—76 ft-lb)

Diesel: 177—186 N-m (18—19 m-kg, 130—137 ft-lb)

18-26 N-m (1.8—2.7 m-kg, 13—20 ft-lb)

1. Clutch release bearing

2. Clutch release fork

3. Clutch cover

76G06X-024

4. Clutch disc

5. Pilot bearing

6. Flywheel

7. Ring gear

1. Remove the transaxle. (Refer to Section 7).

2. Attach the SST to the engine, and remove the

clutch cover and clutch disc.

B6U06X-030

6-15

Page 804 of 1865

6 CLUTCH AND FLYWHEEL

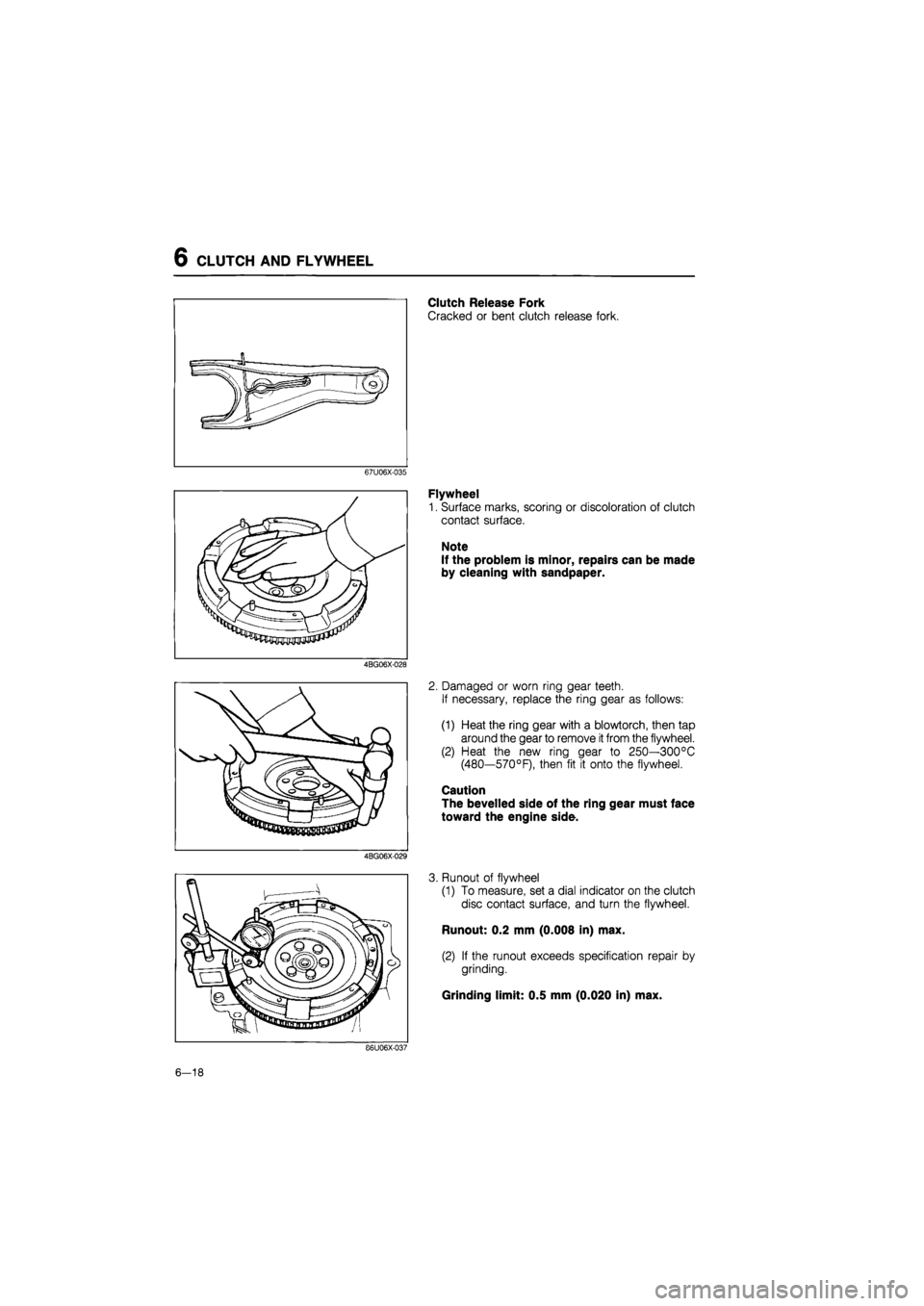

Clutch Release Fork

Cracked or bent clutch release fork.

67U06X-035

4BG06X-028

4BG06X-029

Flywheel

1. Surface marks, scoring or discoloration of clutch

contact surface.

Note

If the problem is minor, repairs can be made

by cleaning with sandpaper.

2. Damaged or worn ring gear teeth.

If necessary, replace the ring gear as follows:

(1) Heat the ring gear with a blowtorch, then tap

around the gear to remove

it

from the flywheel.

(2) Heat the new ring gear to 250—300°C

(480—570°F), then fit it onto the flywheel.

Caution

The bevelled side of the ring gear must face

toward the engine side.

3. Runout of flywheel

(1) To measure, set a dial indicator on the clutch

disc contact surface, and turn the flywheel.

Runout: 0.2 mm (0.008 in) max.

(2) If the runout exceeds specification repair by

grinding.

Grinding limit: 0.5 mm (0.020 in) max.

86U06X-037

6-18

Page 810 of 1865

7A OUTLINE

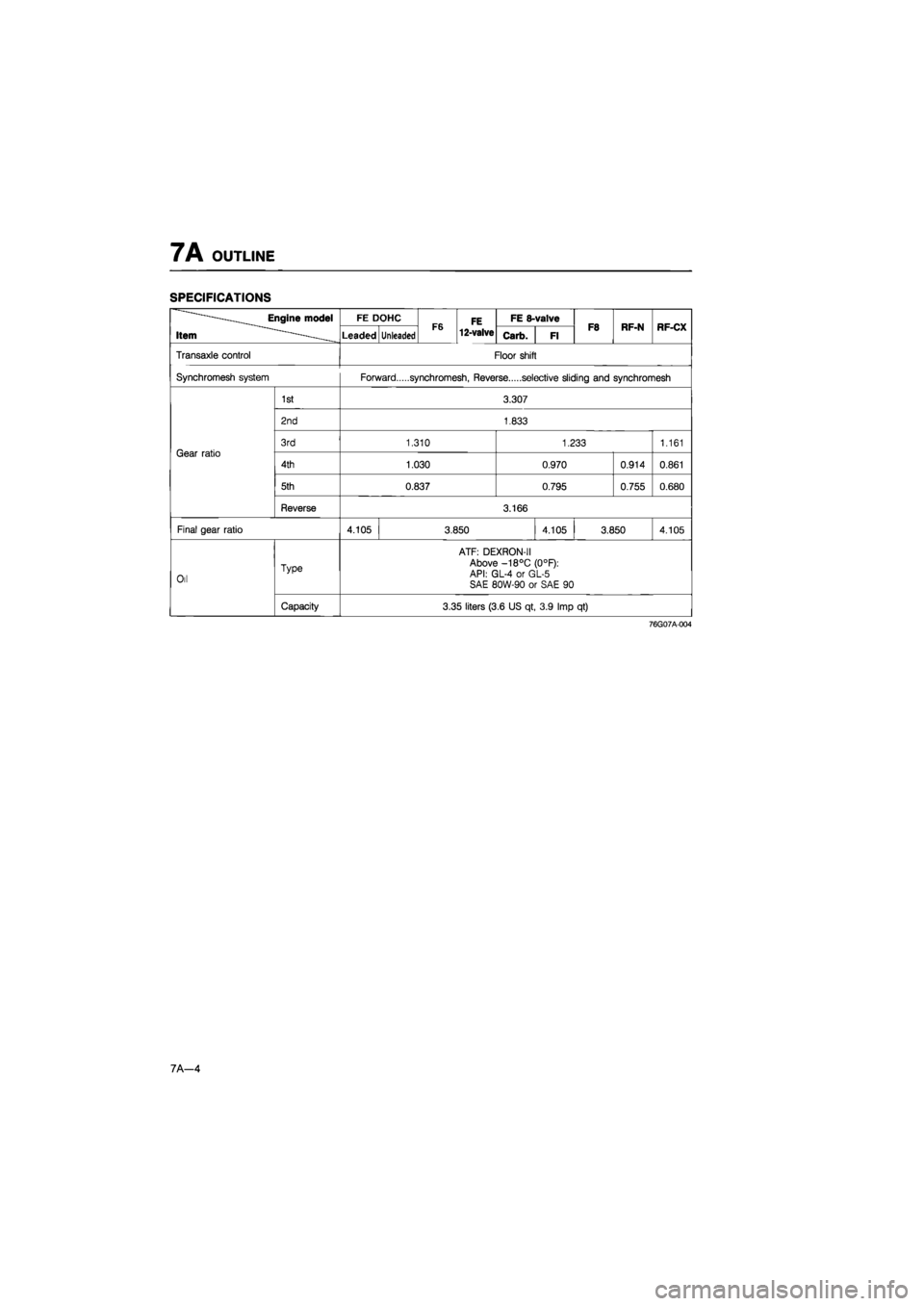

SPECIFICATIONS

•Engine model

Item ——

FE DOHC F6 FE 12-valve

FE 8-valve F8 RF-N RF-CX •Engine model

Item —— Leaded Unleaded F6 FE 12-valve Carb. Fl F8 RF-N RF-CX

Transaxle control Floor shift

Synchromesh system Forward synchromesh, Reverse selective sliding and synchromesh

Gear ratio

1st 3.307

Gear ratio

2nd 1.833

Gear ratio 3rd 1.310 1.233 1.161 Gear ratio

4th 1.030 0.970 0.914 0.861

Gear ratio

5th 0.837 0.795 0.755 0.680

Gear ratio

Reverse 3.166

Final gear ratio 4.105 3.850 4.105 3.850 4.105

Oil Type

ATF: DEXRON-II Above -18°C (0°F): API: GL-4 or GL-5 SAE 80W-90 or SAE 90 Oil

Capacity 3.35 liters (3.6 US qt, 3.9 Imp qt)

76G07A-004

7A—4