warning MAZDA 626 1987 Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 625 of 1865

4C FUEL SYSTEM

^ Pulsation

damper

76G04C-121

Pulsation damper

—

Delivery pipe

76G04C-122

Fuel hose

,Fuel pump

-Intank filter

76G04C-123

Insulator

f f r—

/ 0 DM

•

II r

O - ring

Grommet

Manifold

Delivery pipe

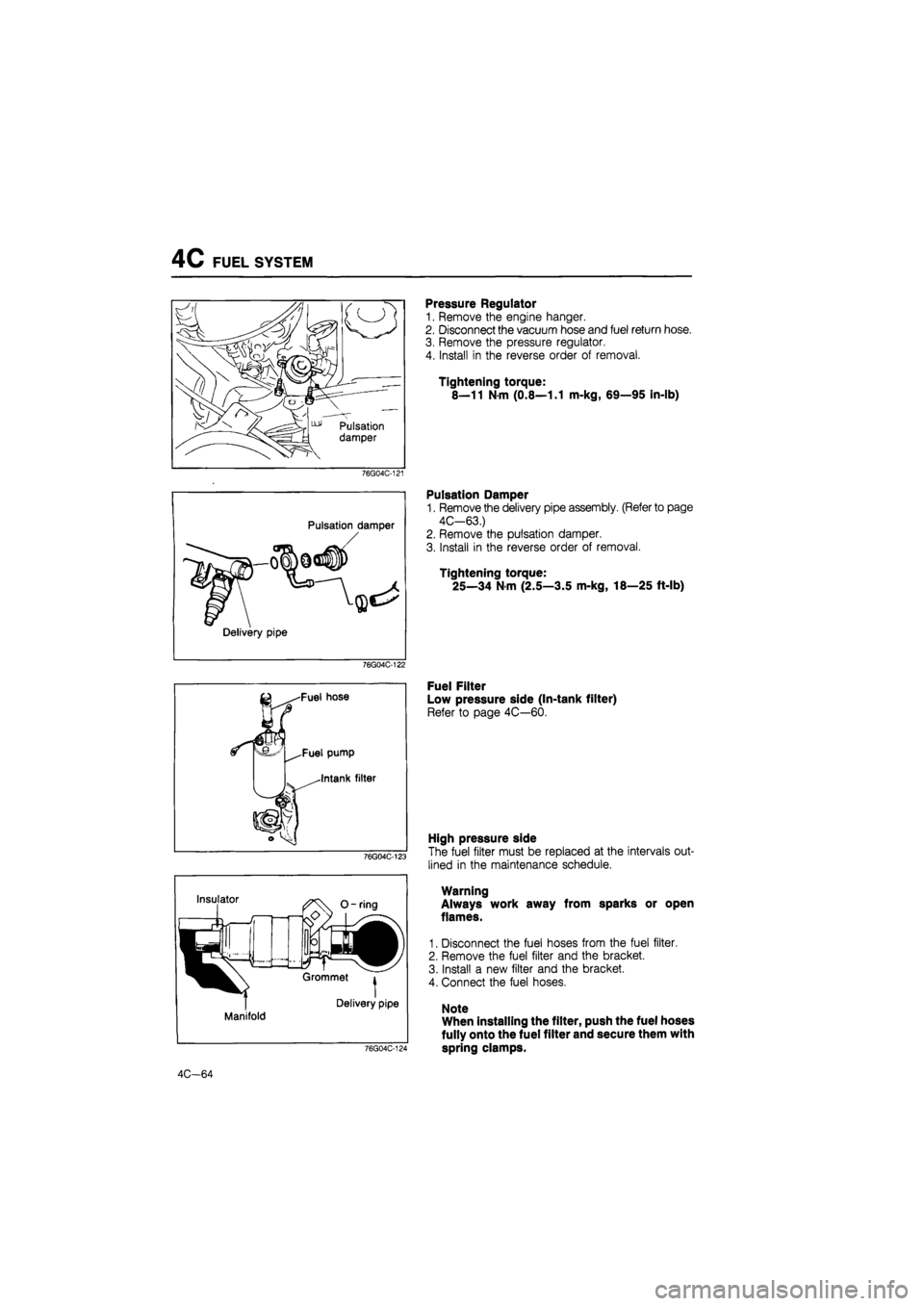

Pressure Regulator

1. Remove the engine hanger.

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the pressure regulator.

4. Install in the reverse order of removal.

Tightening torque:

8—11 Nm (0.8—1.1 m-kg, 69—95 in-lb)

Pulsation Damper

1. Remove the delivery pipe assembly. (Refer to page

4C-63.)

2. Remove the pulsation damper.

3. Install in the reverse order of removal.

Tightening torque:

25—34 N m (2.5—3.5 m-kg, 18—25 ft-lb)

Fuel Filter

Low pressure side (In-tank filter)

Refer to page 4C—60.

76G04C-124

High pressure side

The fuel filter must be replaced at the intervals out-

lined in the maintenance schedule.

Warning

Always work away from sparks or open

flames.

1. Disconnect the fuel hoses from the fuel filter.

2. Remove the fuel filter and the bracket.

3. Install a new filter and the bracket.

4. Connect the fuel hoses.

Note

When installing the filter, push the fuel hoses

fully onto the fuel filter and secure them with

spring clamps.

4C-64

Page 627 of 1865

4C FUEL SYSTEM

Inspection

1. Check the fuel tank for cracks and corrosion.

2. If any defect is found, repair or replace the tank.

Warning

Before repairing, clean the fuel tank thorough-

ly with steam to remove all explosive fuel and

fumes.

Installation

Install in the reverse order of removal, referring to the installation note.

Torque Specifications

4C-66

76G04C-126

Page 631 of 1865

4C PRC SYSTEM

System Inspection

1. Connect the SST to the engine. (Refer to page

4C-53.)

2. Start the engine.

76G04C-131

Hi?

Jpll ssil

Water thermo sensor ^^^Tta^e air thermo sensor

76G04C-132

Operating time Fuel line pressure kPa (kg/cm2, psi)

After starting: for 120 sec. 235-275 (2.4-2.8, 34-40)

After 120 sec. 186-226 (1.9-2.3, 27-33)

3. Warm up the engine to normal operating temper-

ature and stop the engine.

Warning

Be careful when disconnecting the water ther-

mo sensor connector because the surround-

ing area is very hot.

4. Disconnect the water thermo sensor connector.

Connect a resistor (200 fl) to the sensor connector.

5. Heat the intake air thermo sensor to above specifi-

cation.

Specification: 30°C (86°F)....unleaded fuel

50°C (122°F)....leaded fuel

6. Restart the engine.

7. Check the fuel line pressure and operating times

as shown in the chart.

76G04C-133

Solenoid Valve (Pressure Regulator Control)

Inspection

1. Disconnect the vacuum hose from the vacuum

pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

76G04C-134

4C—70

Page 639 of 1865

4C EGR SYSTEM (UNLEADED FUEL)

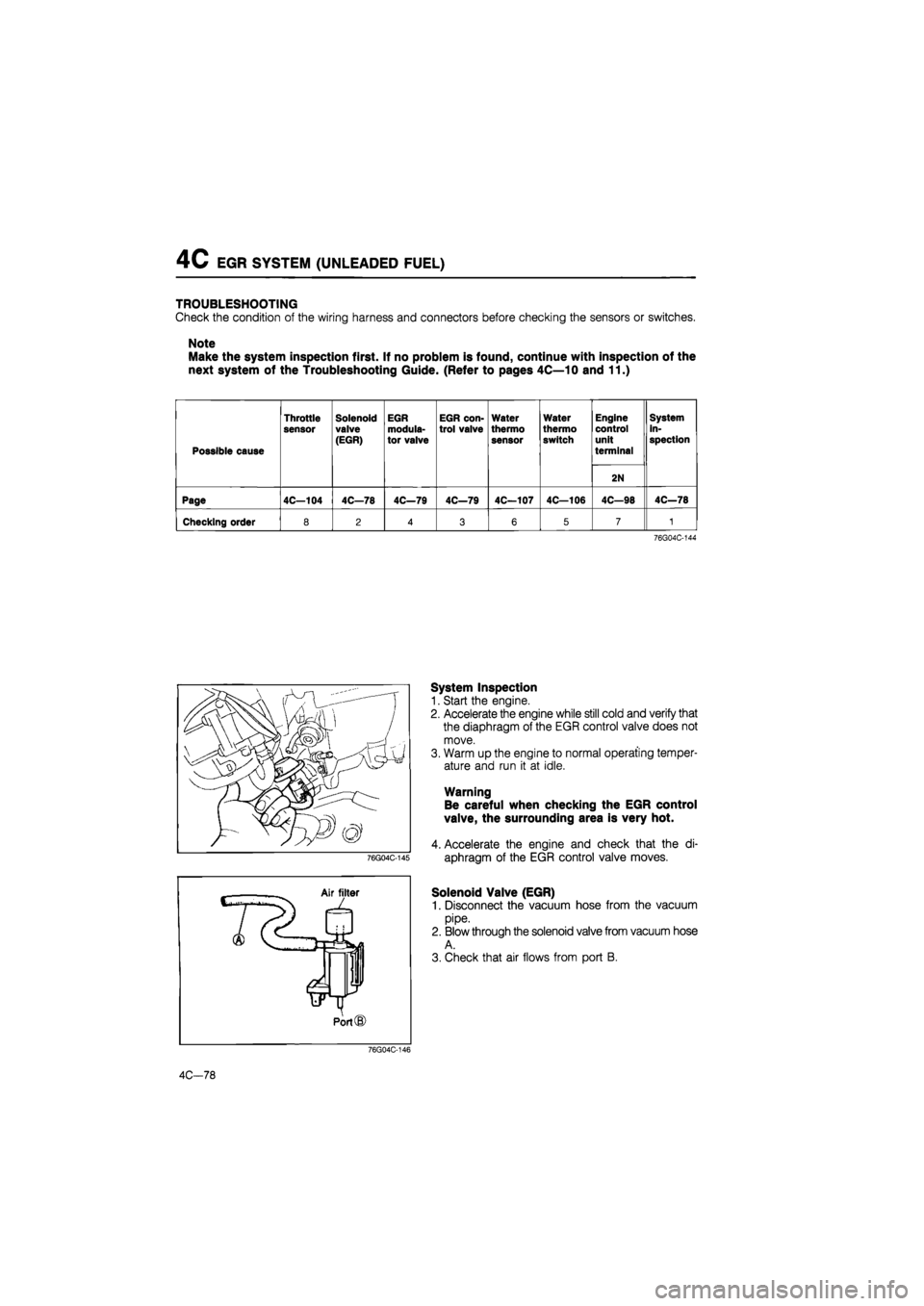

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible cause

Throttle

sensor

Solenoid valve

(EGR)

EGR

modula-

tor valve

EGR con-trol valve

Water

thermo

sensor

Water

thermo switch

Engine control unit

terminal

System in-spection

2N

Page 4C—104 4C—78 4C—79 4C—79 4C—107 4C—106 4C—98 4C—78

Checking order 8 2 4 3 6 5 7 1

76G04C-144

System Inspection

1. Start the engine.

2. Accelerate the engine while still cold and verify that

the diaphragm of the EGR control valve does not

move.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve, the surrounding area is very hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves.

Solenoid Valve (EGR)

1. Disconnect the vacuum hose from the vacuum

pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

76G04C-146

4C-78

Page 693 of 1865

4D FUEL SYSTEM

76G04D-047

76G04D-048

76G04D-049

FUEL FILTER

On-Vehicle Inspection

Check for water in the fuel filter. If present drain the

water. (Refer to page 4D—4.)

Replacement

Removal

1. Disconnect the water level sensor connector (ECE).

2. Remove the water level sensor. (ECE).

3. Remove the fuel filter cartridge.

Warning

Keep fire and open flame away from the fuel

area.

Installation

1. Apply fuel to the O-ring of the fuel filter cartridge

and install it onto the filter body.

2. Install the water level sensor (ECE).

3. Connect the water level sensor connector (ECE).

4. Bleed air from fuel filter. (Refer to page 4D—4.)

5. Check for fuel leakage.

SEDIMENTER (GENERAL)

On-Vehicle Inspection

Check for water in the sedimenter. If present, drain

the water. (Refer to page 4D—4.)

4D—22

Page 697 of 1865

4D FUEL SYSTEM

Removal and Installation

1. Remove in the sequence shown in the figure, referring to the removal note for specially marked parts.

2. Install in the reverse order of removal.

59—69 N-m

(6.0—7.0 m-kg, 43-51 ft-lb)

19—26

N m

(1.9—2.6

m-kg,

14—19 ft-lb) 25—29

N-m .5—3.0 m-kg, 18—22

ft-lb)

19—26 N-m

(1.9—2.6

m-kg,

14—19 ft-lb)

76G04D-063

1. Accelerator cable

2. Injection pipe

3. Fuel hose

4. Water hose

5. Fuel cut solenoid valve con-

nector

6. Pick-up coil connector

7. Boost air hose (RF-CX)

8. Injection pump pulley lock

nut

9. Injection pump

Removal note

Injection pipe

Warning

a) Catch leaking fuel with a rag when remov-

ing the injection pipes.

b) Keep fire and open flame away from the fuel

area.

Remove the injection pipes.

76G04D-064

4D—26

Page 702 of 1865

FUEL SYSTEM 4D

INJECTION NOZZLE

Removal

Remove in the sequence shown in the figure, referring to the removal note for the specially marked parts.

Removal note

Injection pipe

Warning

a) Catch leaking fuel leakage with a rag when

removing the injection pipes.

b) Keep fire and open flame away from the fuel

area.

Remove the injection pipes.

1. Injection pipe bracket

2. Injection pipe

3. Fuel leak pipe

4. Fuel injection nozzle

76G04D-072

4D—31

Page 705 of 1865

4D FUEL SYSTEM

FUEL TANK

Removal and Installation

1. Drain the fuel from the fuel tank.

2. Remove in the sequence shown in the figure, referring to the removal note for the specially marked

parts.

76G04D-081

1. Fuel level gauge connector 4. Joint hose 7. Fuel tank

2. Fuel main hose 5. Ventilation hose 8. Fuel tank pad

3. Fuel return hose 6. Breather hose

Removal note

Fuel main and return hoses

1. Remove the service hole cover from the body.

2. Disconnect the fuel main and return hoses and

plug them.

Warning

Keep fire and open flame away from the fuel

area.

4D—34

Page 729 of 1865

ALTERNATOR 5

TROUBLESHOOTING

Preliminary Check

1. Turn the ignition switch ON, and check that

the alternator warning light illuminates.

2. Start the engine, and check that the alternator warning light goes off.

76G05X-024

1. Alternator warning light always not illuminate

76G05X-025

2. Alternator warning light illuminates when engine running

76G05X-026

5-23

Page 730 of 1865

5 ALTERNATOR

3. Alternator warning light operates properly, but battery discharged

OK

NG OK

1

a) Poor connection between B terminal and positive battery cable

b) Poor connection of negative battery cable c) Poor connection between alternator connector (2-pin) and positive battery terminal d) Stator coil or diodes malfunction (Refer to page 5—32 or 5—34.)

Perform TEST 2. (Refer to page 5--25.)

NG

Perform TEST 3. (Refer to Dage 5--26.)

I OK

Perfrom TEST 4. (Refer to page 5--26.)

NG

Perform TEST 5 (F Refer to page 5—26)

OK

Alternator normal.

Check other electrical components.

NG

Alternator normal.

Check other electrical components.

Perform TEST 5. (Refer to page 5—26.)

OK

Stator coil, diode, main fuse, or wiring har-ness between B ternimal and battery mal-function.

(Refer to page 5—32 or 5—34.)

IC regulator, bush, or rotor coil malfunction. (Refer to page 5—32 or 5—33)

NG

76G05X-027

4. Battery overcharged

Less than 14.1V

(At 20°C, 68°F)

More than 14.7V

(At 20oC,68°F)

IC regulator malfunction,

Perform TES T 6. (Refer to page 5—27.)

NG OK

Wiring harness malfunction.

76G05X-028

5—24