warning MAZDA 626 1987 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 317 of 1865

2A OIL FILTER, OIL COOLER

j

F

k

4

4. Install the drain plug and a new gasket.

5. Refill the engine with the specified type and amount

of oil.

6. Refit the oil filler cap.

Oil pan capacity:

3.6 liters (3.8 US qt, 3.2 Imp qt)

7. Recheck the oil level after the engine has been run.

76G02A-006

TbJ

r

86U02X-008

76G02A-007

0

A

if \ lO

/O

f \ 11 • V jJ

VJ f .fa,-

n D

©

76G02A-008

OIL FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface

on the engine.

3. Apply a small amount of engine oil to the rubber

seal of the new filter.

Warning

Be careful that the engine and filter are very

hot.

4. (DOHC)

Install the oil filter until the rubber seal contacts the

base and then tighten the filter

1

and

1

/6 turn with

a wrench.

(SOHC)

Install the oil filter and tighten it by hand only. Do

not use a wrench.

5. Start the engine and inspect around the filter seal

for leaks.

6. Check the oil level and add oil if necessary.

Oil filter capacity:

0.20 liters (0.21 US qt, 0.18 Imp qt)...DOHC

0.30 liters (0.32 US qt, 0.26 Imp qt)...SOHC

OIL

COOLER

(DOHC, 12-valve,

ECE

8-valve)

REMOVAL AND INSTALLATION

Remove in the sequence shown in the figure.

Install in the reverse order of removal.

1. Water hose

2. Oil filter

3. Nut

4. Oil cooler

Nut tightening torque:

29—39

N

m (3.0—4.0 m-kg, 22—29 ft-lb)

2A-6

Page 327 of 1865

OUTLINE 2B

SPECIFICATIONS

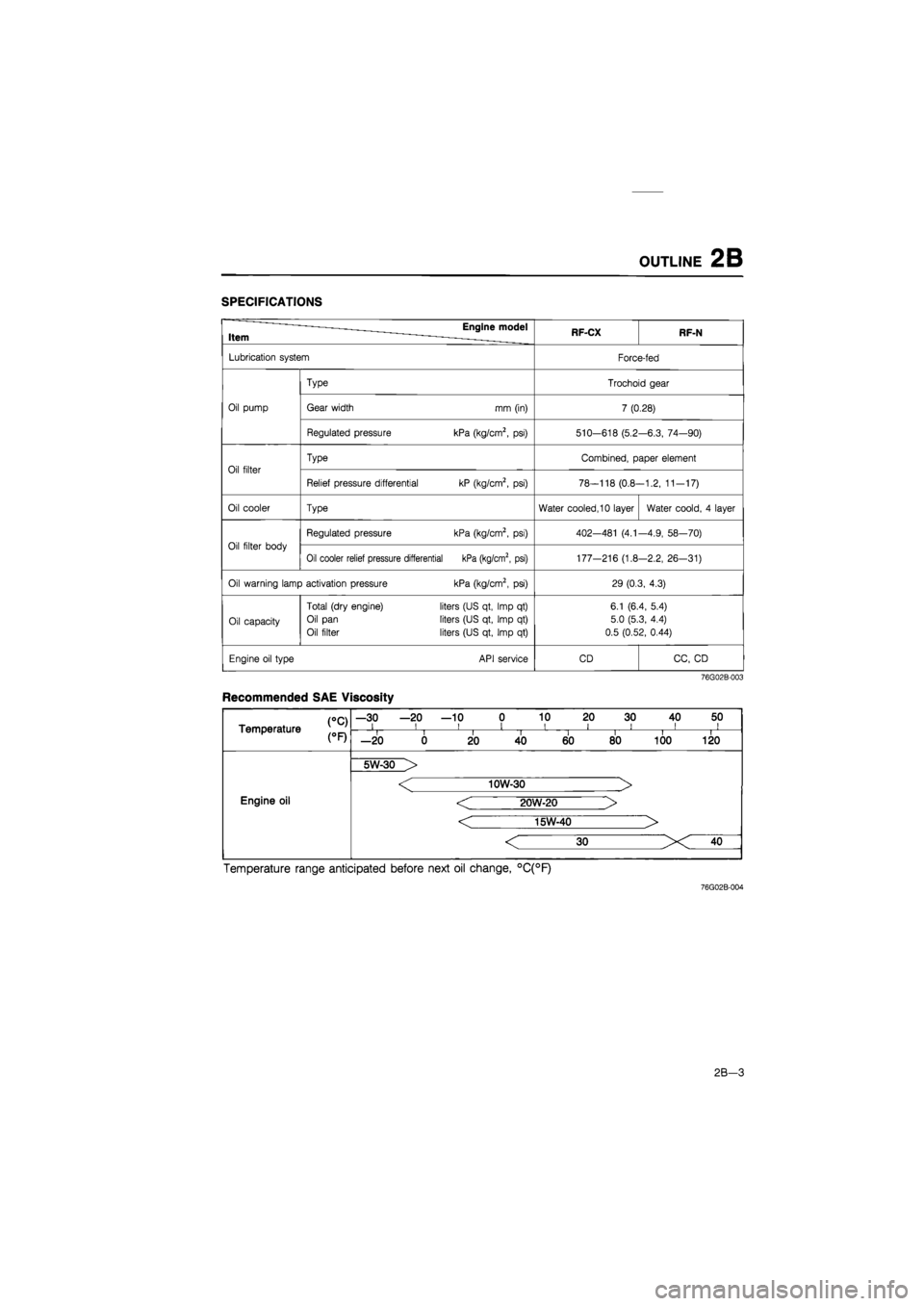

Item Engine model RF-CX RF-N

Lubrication system Force-fed

Type Trochoid gear

Oil pump Gear width mm (in) 7 (0.28)

Regulated pressure kPa (kg/cm2,

psi)

510-618 (5.2 -6.3, 74—90)

Oil filter

Type Combined, paper element

Oil filter

Relief pressure differential kP (kg/cm2,

psi)

78-118 (0.8--1.2, 11-17)

Oil cooler Type Water cooled, 10 layer Water coold,

4

layer

Oil filter body

Regulated pressure kPa (kg/cm2,

psi)

402—481

(4.1

-4.9, 58—70)

Oil filter body

Oil cooler relief pressure differential kPa (kg/cm2, psi) 177-216 (1.8 -2.2, 26-31)

Oil warning lamp activation pressure kPa (kg/cm2,

psi)

29 (0.3, 4.3)

Oil capacity

Total (dry engine)

Oil pan

Oil filter

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

liters (US qt, Imp

qt)

6.1 (6.4, 5.4)

5.0 (5.3, 4.4)

0.5 (0.52, 0.44)

Engine oil type API service CD CC,

CD

76G02B-003

Recommended SAE Viscosity

CC) Temperature

—30 —20 —10 0 10 20 30 40 50 i i i i i i i ii CC) Temperature i i II i i i i —20 0 20 40 60 80 100 120

Engine oil

5W-30 >

Engine oil

< 10W-30 >

< 20W-20 >

< 15W-40 >

Engine oil

Temperature range anticipated before next oil change, °C(°F)

76G02B-004

2B-3

Page 328 of 1865

2B TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine

oil

Insufficient engine

oil

Replace

Add

oil

2B—

6

2B—

5

Excessive oil

consumption

Oil working

up or

working down

Oil leakage

Refer

to

Section

1C

As described below

Oil leakage

Loose drain plug

or

damaged washer

Faulty seal

at oil

pan and cylinder block

Damaged cylinder head cover and

its

seal

Loose

oil

pump body bolt, cylinder head cover bolt,

or

oil pan bolt

Damaged front housing gasket,

or

cylinder head gasket

Faulty

oil

seal(s)

Loose

oil

filter

Loose

or

damaged

oil

pressure switch

Tighten

or

replace

Repair

Replace

Tighten

Replace

Replace

Tighten

Tighten

or

replace

2B—10

2B—10

2B-

6

Oil pressure drop

Oil leakage

Insufficient

oil

Worn and/or damaged

oil

pump gear

Worn plunger (inside

oil

pump)

or

weak spring

Clogged

oil

strainer

Excessive

oil

clearance between main bearing

or

con-

necting

rod

bearing

As described above

Add

oil

Replace

Replace

Clean

Refer

to

Section

1C

2B-

5

2B—13

2B—14

Warning lamp il-

luminates while

engine running

Oil pressure drop

Malfunction

of oil

pressure switch

Malfunction

of

electrical system

As described above

Refer

to

Section

15

Refer

to

Section

15

76G02B-005

2B—4

Page 330 of 1865

2B

ENGINE OIL, OIL

FILTER

86U02X-006

76G02B-010

86U02X-008

ENGINE OIL

REPLACEMENT

1. Warm up the engine to the normal operating tem-

perature and stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

Warning

Be careful when draining, the oil is very hot.

4. Install the drain plug and a new gasket.

Tightening torque:

29—41 N-m (3.0—4.2 m-kg, 22—30 ft-lb)

5. Refill the engine with the specified type and amount

of oil.

6. Refit the oil filler cap.

Oil pan capacity:

5.0 liters (5.3 US qt, 4.4 Imp qt)

7. Recheck the oil level after the engine has been run.

OIL

FILTER

REPLACEMENT

1. Remove the oil filter with a suitable wrench.

2. Use a clean rag to wipe off the mounting surface

on the engine.

3. Apply a coat of engine oil to the filter rubber seal.

4. Install the oil filter until the rubber seal contacts the

oil cooler by hand. Then tighten it a 7/6 turn fur-

ther with a band type wrench.

5. Start the engine and inspect around the filter seal

for leaks.

6. Check the oil level and add oil if necessary.

Oil filter capacity:

0.50 liters (0.52 US qt, 0.44 Imp qt)

76G02B-011

2B—6

Page 344 of 1865

COOLANT 3A

76G03A-016

69G03A-006

COOLANT

INSPECTION

Coolant Level (Engine cold)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the coolant level in the coolant reser-

voir is between the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

removing it.

Coolant Quality

1. Check that there is no build-up of rust or scales

around the radiator cap or radiator filler neck.

2. Check that coolant is free from oil.

3. Replace the coolant, if necessary.

Coolant Leakage

1. Connect a tester and SST to the radiator inlet port.

2. Apply 103 kPa (1.05 kg/cm2, 15 psi) pressure

to the system.

3. Check that the pressure is held.

If not, check for coolant leakage.

Warning

When removing either the radiator cap or the

tester, loosen it slowly until the pressure in

the radiator is released, and then remove it.

86U03X-005

REPLACEMENT

1. Remove the radiator cap and loosen the drain plug.

2. Drain the coolant into a suitable container.

Warning

a) Never open the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

loosening.

c) Use caution when draining hot coolant.

86U03X-006

3A-5

Page 357 of 1865

3B COOLANT

86U03X-004

69G03A-006

COOLANT

INSPECTION

Coolant Level (Engine cold)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the coolant level in the coolant reser-

voir is between the FULL and Low marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

removing it.

Coolant Quality

1. Check that there is no build-up of rust or scales

around the radiator cap or radiator filler neck.

2. Check that coolant is free from oil.

3. Replace the coolant, if necessary.

Coolant Leakage

1. Connect a tester and SST to the radiator inlet port.

2. Apply 103 kPa (1.05 kg/cm2, 15 psi) pressure

to the system.

3. Check that the pressure is held.

If not, check for coolant leakage.

Warning

When removing either the radiator cap or the

tester, loosen it slowly until the pressure in

the radiator is released, and then remove it.

86U03X-005

REPLACEMENT

1. Remove the radiator cap and loosen the drain plug.

2. Drain the coolant into a suitable container.

Warning

a) Never open the radiator cap while the en-

gine is hot.

b)Wrap a thick cloth around the cap when

loosening.

c) Use caution when draining hot coolant.

86U03X-006

3B—4

Page 401 of 1865

4A FUEL SYSTEM

FUEL TANK

Removal

1. Remove the rear seat cushion.

2. Remove the cover and disconnect the fuel tank

gauge unit connector.

3. Disconnect the fuel main and return hoses.

4. Raise the vehicle and support it with safety stands.

5. Remove the fuel level gauge unit assembly.

Warning

a) When repairing the fuel tank, clean it

thoroughly with steam to remove all explo-

sive gasoline and fumes.

b) Use of fire is strictly prohibited while work-

ing on the fuel tank.

6. Drain the fuel.

7. Disconnect the remaining hoses.

8. Remove the fuel tank.

Inspection

1. Check the fuel tank for cracks and corrosion.

2. If any defect is found, repair or replace the tank.

3. Check for leaks.

Torque Specifications

76G04A-054

4A—36

ft

—^tjf 5

/vfC(l

I

\ 1c

r 1 / |J

tl/y#

t

^ fcfVii

76G04A-052

76G04A-053

Installation

Install in the reverse order of removal.

Page 430 of 1865

EGR SYSTEM 4A

TROUBLESHOOTING

Note

Make the system inspection first. If no problem is found, continue with the next inspec-

tion of the Troubleshooting Guide. (Refer to pages 4A—22.)

Possible cause System inspection EGR control valve Water thermo valve

Page 4A—65 4A—65 4A—66

Checking order 1 2 3

76G04A-123

76G04A-124

76G04A-125

System Inspection

1. Start the engine.

2. Accelerate the engine while it is still cold and check

that the diaphragm of the EGR control valve does

not move.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve, the surrounding area is very hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves.

EGR Control Valve (ATX)

(No. 1)

1. Manually actuate the valves by pushing on the di-

aphragm with finger.

2. Check that the spring resistance is present and the

diaphragm moves freely with no sticking or

binding.

3. Warm up the engine and run it at idle.

4. Connect a vacuum pump to the valve and apply

vacuum.

5. Check that the engine runs roughly or stalls at more

than the specified vacuum.

Specification:

70—90 mmHg (2.8—3.5 inHg)

6. If not correct, replace the EGR control valve.

76G04A-126

4A—65

Page 490 of 1865

4B SWITCH MONITOR FUNCTION

Headlight switch

76G04B-030

Rear defroster switch

76G04B-031

Inhibitor switch

76G04B-032

Water thermo switch circuit (not included in switch inspection)

Warning

4B—28

Page 509 of 1865

FUEL SYSTEM 4B

Pressure .

regulator ^^ \ To multi-pressure tester

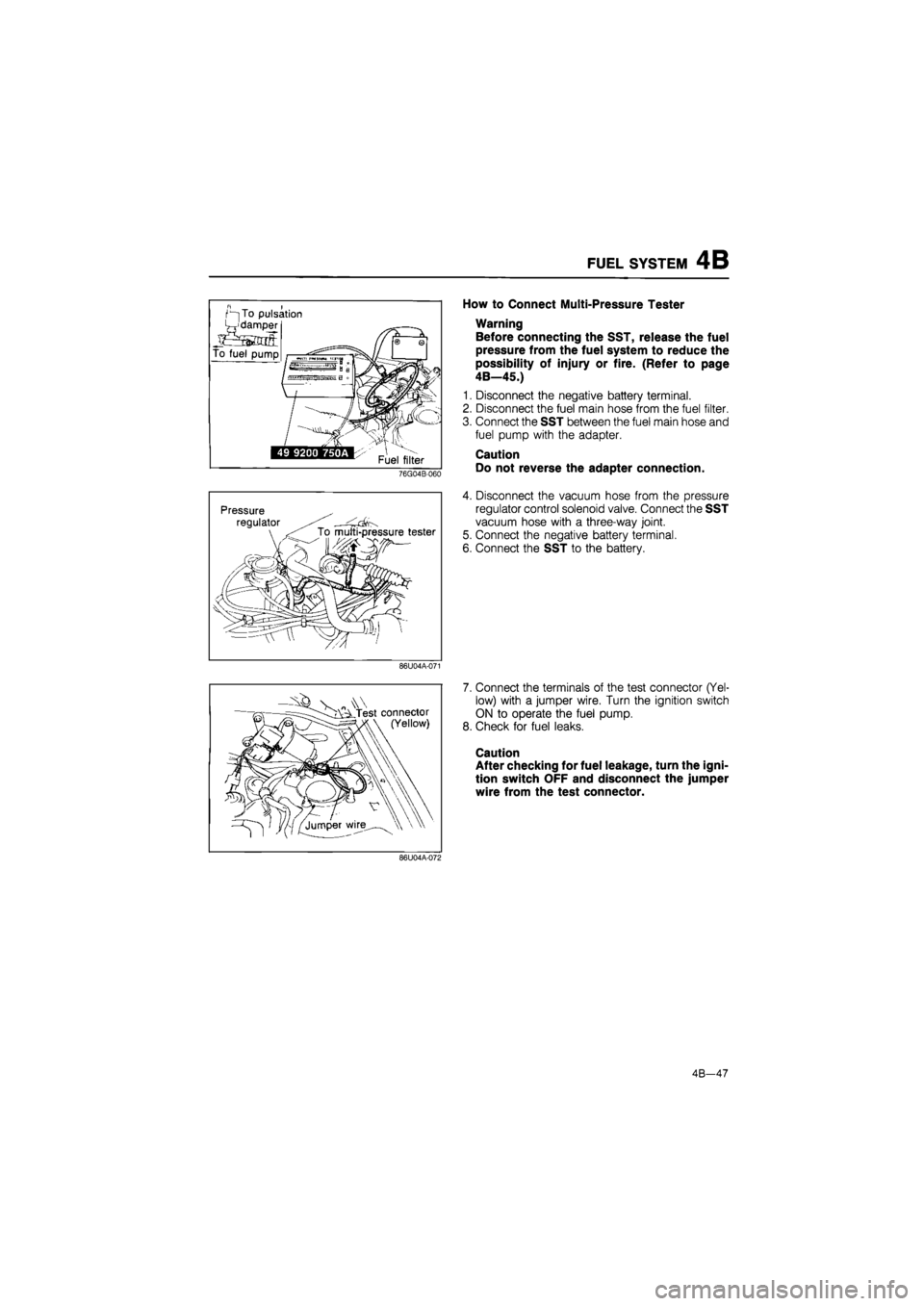

How to Connect Multi-Pressure Tester

Warning

Before connecting the SST, release the fuel

pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page

4B—45.)

1. Disconnect the negative battery terminal.

2. Disconnect the fuel main hose from the fuel filter.

3. Connect the SST between the fuel main hose and

fuel pump with the adapter.

Caution

Do not reverse the adapter connection.

4. Disconnect the vacuum hose from the pressure

regulator control solenoid valve. Connect the SST

vacuum hose with a three-way joint.

5. Connect the negative battery terminal.

6. Connect the SST to the battery.

86U04A-071

v *

- i\zLTest connector (Yellow)

7. Connect the terminals of the test connector (Yel-

low) with a jumper wire. Turn the ignition switch

ON to operate the fuel pump.

8. Check for fuel leaks.

Caution

After checking for fuel leakage, turn the igni-

tion switch OFF and disconnect the jumper

wire from the test connector.

86U04A-072

4B—47