warning MAZDA 626 1987 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 148 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

1. Center cover

2. High-tension lead and spark plug

3. Accelerator cable

4. Air intake pipe assembly

5. Fuel hose

6. Upper radiator hose

7. Heater hose

8. Brake vacuum hose

9. Canister hose (Unleaded fuel)

10. Engine harness connector and ground

11. EGR pipe (Unleaded fuel)

12. A/C compressor and bracket

13. Exhaust manifold insulator

14. Exhaust pipe

15. Exhaust manifold

16. Intake manifold bracket

17. Intake manifold assembly

18. Distributor

19. Engine mount stay

20. Upper timing belt cover

21. Timing belt tensioner spring

22. Timing belt

23. Cylinder head cover

24. Cylinder head and gasket

76G01B-030

Removal note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep sparks and open flame away from the

fuel area.

Plug the disconnected hoses to avoid fuel leakage.

86U01X-032

Timing belt

1. Before removing the timing belt, turn the crankshaft

to align the mating marks of the camshaft pulleys

with the seal plate timing mark.

Note

For intake side camshaft pulley, align "I"

mark.

For exhaust side camshaft pulley, align "E"

mark.

76G01B-031

2. Loosen the timing belt tensioner lock bolt.

3. Shift the tensioner outward as far as possible, then

temporarily tighten it.

76G01B-034

1B—17

Page 153 of 1865

1B REMOVAL

REMOVAL

Warning: Release the fuel pressure. (Refer to Section 4C.)

1. Disconnect the negative battery cable.

2. Drain the engine oil and coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01B-036

1B—22

Page 154 of 1865

REMOVAL 1B

1. Battery and battery carrier

2. Air cleaner assembly

3. High-tension lead

4. Accelerator cable

5. Fuel hose

6. Radiator hose

7. Radiator harness

8. Radiator and electric fan

9. EGI harness

10. Engine harness

11. Brake vacuum hose

12. Canister hose (Unleaded

fuel)

13. Heater hose

14. Transaxle harness

15. Speedometer cable

16. Clutch release cylinder

17. Drive belt

18. A/C compressor and

bracket

19. P/S oil pump

20. Engine side cover

21. Front wheel

22. Tie-rod end

23. Stabilizer control rod

24. Lower arm bushing

25. Driveshaft

26. Change rod

27. Extension bar

28. Exhaust pipe

29. Engine mount

30. Engine and transaxle

31. Transaxle

76G01B-037

Removal Note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep sparks and open flame away from the

fuel area.

Plug the disconnected hoses to avoid fuel leakage.

76G01A-11£

P/S pump, A/C compressor

Remove the P/S pump and A/C compressor with the

hoses still connected to them, secure the pump and

compressor as shown in the figure.

67U01X-029

Driveshaft

Remove the driveshafts. (Refer to Section 9.) Slide

the SST into the transaxle.

86U01X-060

1B—23

Page 205 of 1865

1B INSTALLATION

ENGINE INSTALLATION

Install the engine and transaxle assembly.

Warning: Be sure the vehicle is securely supported.

Torque Specifications

67—93

N m

(6.8—9.5 m-kg, 49—69 ft-lb)

85—117

N m

(8.7—11.9 m-kg, 63—86 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

8-11 N-m (80—110 cm-kg, 69—95 In-lb)

[;> )

16—27

N-m

(1.6—2.8 m-kg, 12—20 ft-lb)

37—63 N-m (3.8—6.4 m-l 27—46 ft-ll

37—52 N-m (3.8—5.3 m-kg 27—38 ft-lb)

64—89 N-m (6.5—9.1 m-kg, 47—66 ft-lb)

36—54 N-m (3.7—5.5 m-kg, 27—40 ft-lb)

-31—46 N-m (3.2—4.7 m-kg, 23—34 ft-lb)

31—46 N-m (3.2-4.7 m-kg, 23—34 ft-lb)

39—59 N-m (4.0—6.0 m-kg, 29—43 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

31—46 N-m (3.2—4.7 m 23—34 ft-lb)

19—25 N-m (1.9—2.6 m-kg, 14-

19—25 N-m (1.9—2.6 m

16—23 N-m (1.6—2.3 m-l

5—7 N-m (50—70 cm-kg, 43—61 in-lb)

-16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

9—13 N-m (90—130 cm-kg, 78—113 In-lb)

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

,68—118 N-m .0—12.0 m-kg 65—87 ft-lb)

43-54 N-m (4.4—5.5 m-kg, 32-40 tl-lb)

8—11

N-m

(80—110 cm-kg, 69—95 In-lb)

86U01X-180

1B—74

Page 218 of 1865

1C TUNE-UP PROCEDURE

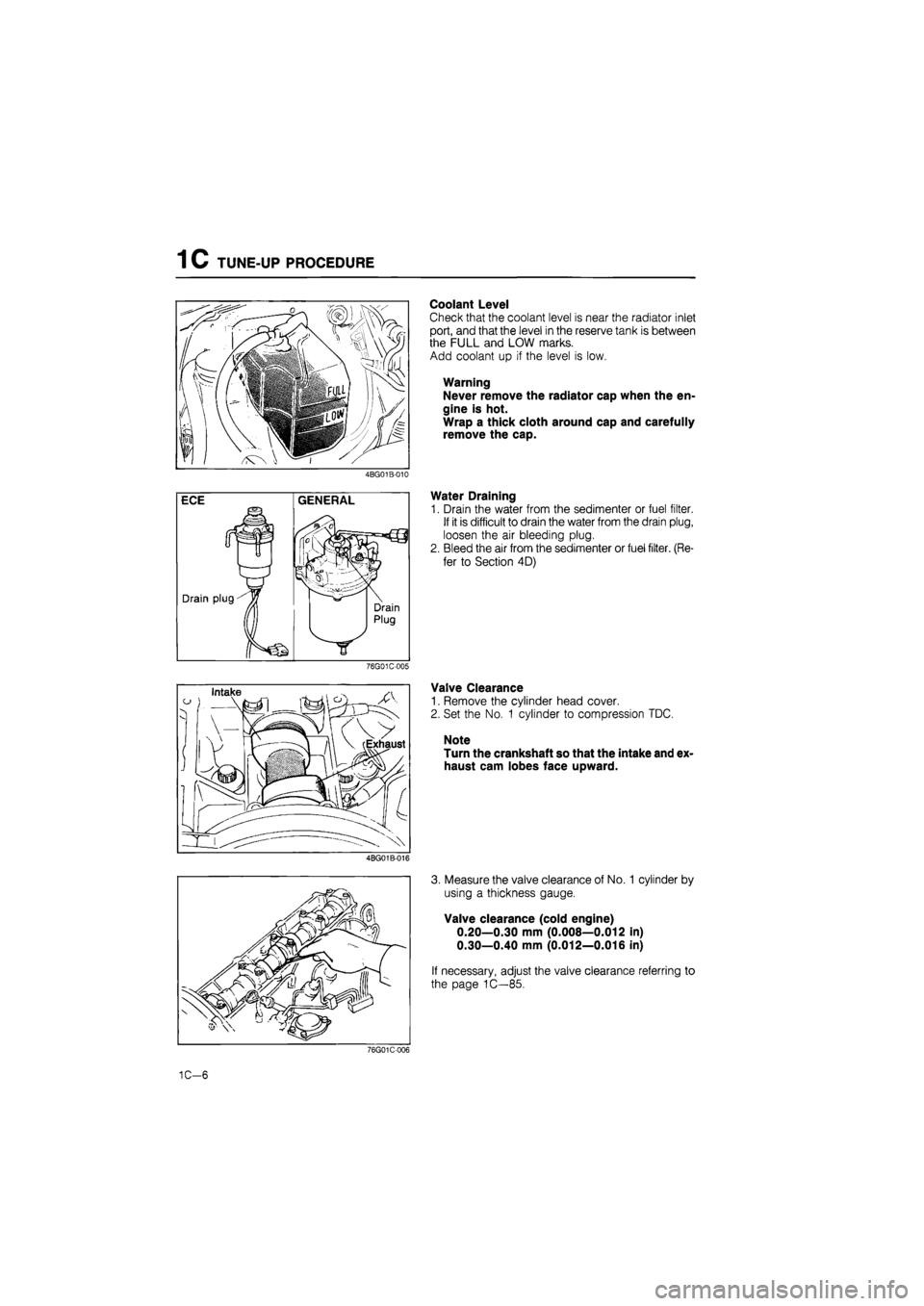

Coolant Level

Check that the coolant level is near the radiator inlet

port, and that the level in the reserve tank is between

the FULL and LOW marks.

Add coolant up if the level is low.

Warning

Never remove the radiator cap when the en-

gine is hot.

Wrap a thick cloth around cap and carefully

remove the cap.

4BG01B-010

Water Draining

1. Drain the water from the sedimenter or fuel filter.

If it is difficult to drain the water from the drain plug,

loosen the air bleeding plug.

2. Bleed the air from the sedimenter or fuel filter. (Re-

fer to Section 4D)

76G01C-005

Valve Clearance

1. Remove the cylinder head cover.

2. Set the No. 1 cylinder to compression TDC.

Note

Turn the crankshaft so that the intake and ex-

haust cam lobes face upward.

4BG01B-016

3. Measure the valve clearance of No. 1 cylinder by

using a thickness gauge.

Valve clearance (cold engine)

0.20—0.30 mm (0.008—0.012 in)

0.30—0.40 mm (0.012—0.016 in)

If necessary, adjust the valve clearance referring to

the page 1C—85.

76G01C-006

1C-6

Page 229 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 C

Removal note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep fire and open flame away from the fuel

area.

Plug the disconnected hoses to avoid fuel leakage.

76G01C-033

2. Hold the camshaft with a wrench (29 mm, 1.14 in)

and loosen the camshaft pulley lock bolt.

Caution

Do not damage the cylinder head edge with

the wrench.

4BG01B-044

3. Separate the camshaft pulley from the camshaft

with the SST.

Caution

Do not hit the camshaft pulley with a hammer.

Rear camshaft pulley

Remove the rear camshaft pulley in the same man-

ner used for camshaft pulley.

76G01C-044

1C—17

Page 244 of 1865

1C REMOVAL

76G01C-244

76G01C-072

67U01X-029

Removal Note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep fire and open flame away from the fuel

area.

After disconnecting the fuel hoses, plug them to avoid

fuel leakage.

Clutch release cylinder

Remove the clutch release cylinder with the pipe still

connected; then avoid the cylinder.

P/S pump, A/C compressor

Remove the P/S pump and A/C compressor with the

hoses still connected to them, secure the pump and

compressor as shown in the figure.

Driveshaft

Remove the driveshafts. (Refer to Section 9.) Slide

the SST into the transaxle.

86U01X-060

1C-32

Page 304 of 1865

1C INSTALLATION

ENGINE INSTALLATION

Install the engine and transaxle assembly.

Warning: Be sure the vehicle is securely supported.

Torque Specifications

67-93 N-m {6.6—9.5 m-kg, 49—69 ft-Sb)

8—11 Nm (80—110 cm-kg,„ 69—95 in-lb)

85—117 N m (8.7—11.9 m-kg, 63—G6 ft-lb) S—11 N-m (80—110em-kg, 69—95 In-lb)

5—7 N-m (50—70 cm-kg, 43—61 in-lb)

67—93 N-m (6,8—9,5 m-kg, 49—69 ft-lb)

55—80 N-m (5.6—8.2 m-kg, 41—59 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

43—62 N-m (4.3—6.3 m-kg, 14—22 ft-lb)

7—10 N-m (70—100 cm-kg, 60—86 in-lb)

37—52 N-m (3.6—5.3 m-kg, 27—38 ft-lb)

34—49 N-m (3.5—5.0 m-kg, 25—36 ft-lb)

31—40 N-m 9 (3.2-4.1 m-kg, 23—30 ft-lb)

'8—11 N-m (80—110 cm-kg, 69—95 in-lb)

19—26 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

-IS* 88—118 N-m ^-(9.0—12.0 m-kg, 65—87 ft-lb) 8—11 N-m (80—110 cm-kg, 69—95 In-lb)

86U01X-180

1C—92

Page 315 of 1865

2 A TROUBLESHOOTING GUIDE

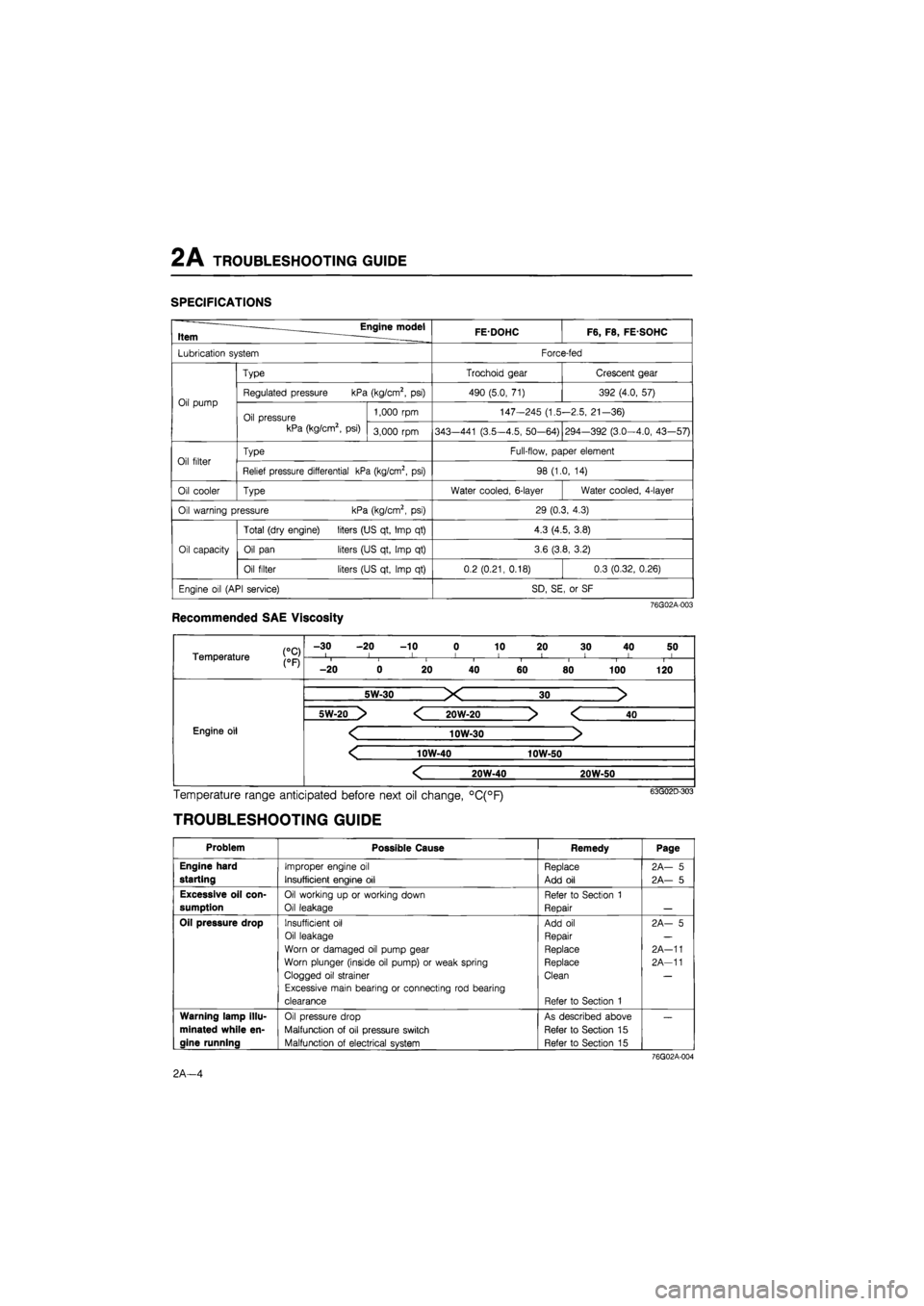

SPECIFICATIONS

Engine model Item . FEDOHC F6, F8, FE SOHC

Lubrication system Force-fed

Oil pump

Type Trochoid gear Crescent gear

Oil pump Regulated pressure kPa (kg/cm2, psi) 490 (5.0, 71) 392 (4.0, 57) Oil pump

Oil pressure kPa (kg/cm2, psi)

1,000 rpm 147-245 (1.5-2.5, 21-36) Oil pump

Oil pressure kPa (kg/cm2, psi) 3,000 rpm 343—441 (3.5-4.5, 50-64) 294-392 (3.0-4.0, 43—57)

Oil filter Type Full-flow, paper element Oil filter Relief pressure differential kPa (kg/cm2, psi) 98 (1.0, 14)

Oil cooler Type Water cooled, 6-layer Water cooled, 4-layer

Oil warning pressure kPa (kg/cm2, psi) 29 (0.3, 4.3)

Oil capacity

Total (dry engine) liters (US qt, Imp qt) 4.3 (4.5, 3.8)

Oil capacity Oil pan liters (US qt, Imp qt) 3.6 (3.8, 3.2) Oil capacity

Oil filter liters (US qt, Imp qt) 0.2 (0.21, 0.18) 0.3 (0.32, 0.26)

Engine oil (API service) SD, SE, or SF

76G02A-003

Recommended SAE Viscosity

Temperature j0pj

-30 -20 -10 0 10 20 30 40 50 I l I I 1 < ! I I Temperature j0pj i i i i I i 1 1

-20 0 20 40 60 80 100 120

Engine oil Engine oil

5W-30 X 30 >

Engine oil Engine oil

5W-20 > < 20W-20 > < 40

Engine oil < 10W-30 > Engine oil

< 10W-40 10W-50

Engine oil Engine oil

< 20W-40 20W-50

Engine oil

Temperature range anticipated before next oil change, °C(°F)

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Engine hard

starting

Improper engine oil

Insufficient engine oil

Replace

Add oil

2A— 5

2A— 5

Excessive oil con-

sumption

Oil working up or working down

Oil leakage

Refer to Section 1

Repair

Oil pressure drop Insufficient oil

Oil leakage

Worn or damaged oil pump gear

Worn plunger (inside oil pump) or weak spring

Clogged oil strainer

Excessive main bearing or connecting rod bearing

clearance

Add oil

Repair

Replace

Replace

Clean

Refer to Section 1

2A- 5

2A-11

2A-11

Warning lamp illu-

minated while en-

gine running

Oil pressure drop

Malfunction of oil pressure switch

Malfunction of electrical system

As described above

Refer to Section 15

Refer to Section 15

76G02A-004

2A—4

Page 316 of 1865

INSPECTION, ENGINE OIL 2A

86U02X-004

INSPECTION

ENGINE OIL

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temper-

ature and stop it.

3. Wait for five minutes.

4. Remove the oil level gauge and check the oil lev-

el and condition.

5. Add or replace oil if necessary.

Note

The distance between the L and F marks on

the level gauge represents 1.0 liter (1.06 US

qt, 0.88 Imp qt).

OIL PRESSURE

1. Remove the oil pressure switch.

69G02A-006

76G02A-005

86U02X-006

2. Screw the SST into the pressure switch installa-

tion hole.

3. Warm up the engine to normal operating tem-

perature.

4. Run the engine at 3,000 rpm, and note the gauge

reading.

Oil pressure:

343—441 kPa

(3.5—4.5 kg/cm2, 50—64 psi)...DOHC 2g4 392 kPa

(3.0—4.0 kg/cm2, 43—57 psi)...SOHC

5. If the pressure is not as specified, check for the

cause, and repair if necessary.

(Refer to Troubleshooting Guide.)

ENGINE OIL

REPLACEMENT

1. Warm up the engine to the normal operating tem-

perature and stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

Warning

Be careful when draining, the oil is very hot.

2A-5