warning MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 731 of 1865

ALTERNATOR 5

Warning

Disconnect the nagative battery terminal when disconnect or reconnect B terminal.

TEST 1

1. Disconnect the alternator connector (2-pin).

2. Connect the SST.

4. Connect the red clip of the adapter harness to the battery

(

+

),

and check that the red

lamp and green lamp illuminate.

5. Start the engine and check that both lamps go off.

86U05X-010

TEST 2

1. Connect an ammeter (75A min.) between the wire and the B terminal.

2. Turn all headlights and accessories on, and depress the brake pedal.

3. Start the engine and check that output current is 70A (RF-CX: 75A) or more at

2,500—3,000 rpm of the engine speed.

Caution

Do not ground the B terminal.

76G05X-029

B terminal

5-25

Page 867 of 1865

7B

AUTOMATIC TRANSAXLE

(Electronically Controlled and 4-Speed)

OUTLINE 7B— 2

SPECIFICATIONS 7B— 2

COMPONENT LOCATION 7B— 3

STRUCTURAL VIEW 7B— 5

OPERATION OF COMPONENTS 7B— 6

FLUID PASSAGE LOCATION 7B— 9

TROUBLESHOOTING (G4A-EL) 7B— 12

GENERAL NOTE 7B— 12

STEP 1

(WARNING CODE RETRIEVAL) 7B— 15

STEP 2

(PRELIMINARY INSPECTION) 7B— 22

STEP 3 (SIGNAL INSPECTION) 7B— 24

STEP 4 (STALL TEST) 7B— 27

STEP 5 (TIME LAG TEST) 7B— 30

STEP 6 (OIL PRESSURE TEST) 7B— 31

STEP 7 (ROAD TEST) 7B— 34

TROUBLESHOOTING (G4A-HL) 7B— 41

GENERAL NOTE 7B— 41

STEP 1

(PRELIMINARY INSPECTION) 7B— 44

STEP 2 (ELECTRICAL

SYSTEM INSPECTION) 7B— 47

STEP 3 (STALL TEST) 7B— 49

STEP 4 (TIME LAG TEST) 7B- 52

STEP 5 (ROAD TEST) 7B— 53

STEP 6 (OIL PRESSURE TEST) 7B— 58

ELECTRICAL SYSTEM

COMPONENTS 7B— 63

MODE SWITCH (G4A-EL) 7B— 63

HOLD SWITCH (G4A-EL) 7B— 63

OD OFF SWITCH (G4A-HL) 7B— 64

INHIBITOR SWITCH 7B- 65

WATER TEMPERATURE SWITCH 7B— 66

FLUID TEMPERATURE SWITCH

(G4A-EL) 7B— 66

BRAKE LIGHT SWITCH

(G4A-EL) 7B— 66

KICK-DOWN SWITCH (G4A-HL) 7B— 67

PULSE GENERATOR (G4A-EL) 7B- 68

VEHICLE SPEED SENSOR

(G4A-EL) 7B— 68

CRUISE CONTROL SWITCH

(CRUISE CONTROL UNIT) 7B— 68

IDLE SWITCH AND THROTTLE

SENSOR (G4A-EL) 7B— 68

OD RELEASE SOLENOID

VALVE (G4A-HL) 7B— 68

SOLENOID VALVES (G4A-EL) 7B— 69

NO LOAD SIGNAL (G4A-EL) 7B— 69

MODE, AND HOLD INDICATOR

LIGHT (G4A-EL) 7B— 69

OD OFF INDICATOR LIGHT

(G4A-HL) 7B— 69

EC-AT CONTROL UNIT

(G4A-EL) 7B— 69

ON-VEHICLE MAINTENANCE 7B— 71

AUTOMATIC TRANSAXLE

FLUID (ATF) 7B— 71

SELECTOR LEVER 7B— 72

THROTTLE CABLE 7B— 73

CONTROL VALVE BODY 7B— 77

OIL STRAINER 7B— 79

ADJUSTMENT OF 2-4 BRAKE

BAND 78— 80

REPLACEMENT OF

DRIVESHAFT OIL SEAL 7B— 80

OIL COOLER 7B— 81

GOVERNOR (G4A-HL) 7B— 82

REMOVAL 7B— 83

PRECAUTION 7B— 83

DISASSEMBLY 7B— 88

DISASSEMBLY-STEP 1 7B— 88

DISASSEMBLY-STEP 2 7B— 94

DISASSEMBLY-STEP 3 7B— 99

DISASSEMBLY-STEP 4 7B—103

INSPECTION AND REPAIR 7B—107

PRECAUTION 7B—107

TORQUE CONVERTER 7B—107

OIL PUMP 7B—108

CLUTCH ASSEMBLY 7B—113

SMALL SUN GEAR AND

ONE-WAY CLUTCH 7B—122

ONE-WAY CLUTCH AND

CARRIER HUB ASSEMBLY 7B-126

3-4 CLUTCH 7B—128

2-3 ACCUMULATOR 7B—132

GOVERNOR ASSEMBLY

(G4A-HL) 7B-133

LOW AND REVERSE BRAKE 7B—134

2-4 BRAKE BAND 7B—135

BAND SERVO 7B—135

OTHER INSPECTION 7B—135

CONTROL VALVE BODY

(G4A-EL) 7B-136

CONTROL VALVE BODY

(G4A-HL) 7B-155

DIFFERENTIAL 7B—177

OUTPUT GEAR 7B—181

IDLE GEAR 7B—182

BEARING COVER ASSEMBLY 7B—185

BEARING HOUSING 7B—186

ASSEMBLY 7B-187

PRECATION 7B—187

ASSEMBLY-STEP 1 7B—187

ASSEMBLY-STEP 2 7B—197

ASSEMBLY-STEP 3 7B—202

ASSEMBLY-STEP 4 7B—208

INSTALLATION 7B—215

TORQUE SPECIFICATIONS 7B—215

HYDRAULIC CIRCUIT (G4A-EL) 7B—221

HYDRAULIC CIRCUIT (G4A-HL) 7B—239

76G07B-001

Page 881 of 1865

TROUBLESHOOTING (G4A-EL) 7B

STEP 1 (WARNING CODE RETRIEVAL)

Self-diagnosis Function

The self-diagnosis system, which is integrated in the EC-AT control unit, diagnoses malfunction of the

main sensors (input) and solenoid valves (output), and the EC-AT control unit.

Malfunctions which have happened or are continuing are memorized in the EC-AT control unit as specific

codes.

The EC-AT Tester is used to retrieve these warning codes. Each malfunction is indicated by a code

number and buzzer as shown the table below.

Code Number

Code number Location of malfunction Buzzer

06 Vehicle speed sensor or circuit JliUli c

12 Throttle sensor or circuit rui r

55 Pulse genelator or circuit nnnnruiii r

60 1-2 shift solenoid valve or circuit jinnnnn r

61 2-3 shift solenoid valve or circuit nnnnnruL_[

62 3-4 shift solenoid valve or circuit nnnnnn nn r

63 Lock-up solenoid valve or circuit

_ 1 0,4 sec

rnnnnn ihi J r1.2sec J | _1.fi sec

76G07B-213

EC-AT Tester

Assembly of EC-AT tester

1. Set the plate (49 G019 912) onto the EC-AT tester

body (49 G019 901 A).

2. Connect the adapter harness (49 G019 911) to

the EC-AT tester body.

3. Select the code select switch to A position.

4. Select the select switch to NEW 626 position.

76G07B-603

7B—15

Page 883 of 1865

TROUBLESHOOTING (G4A-EL) 7B

06 4 second period

55 4 second period

63

-*•

4 second period

Repeats above

General Note

1. If there is more than one malfunction, the code

numbers will be displayed on the tester one by one

in a numerical order. In the case of malfunctions,

55, 06, and 63, the code numbers are displayed

in an order of 06, 55, then 63. The display is as

shown.

86U07B-018

When the service connector

is not grounded

Malfunctions YES

NO

Hold indicator YES

flashing NQ

YES

NO

Memory in control unit

2. The hold indicator flashes to indicate the same pat-

tern as the buzzer of the EC-AT Tester when the

EC-AT service connector is grounded.

When the EC-AT service connector is not ground-

ed, the indicator flashes in a constant frequency

while a malfunction is occurring and goes out

if

the

malfunction recovers. However, the warning code

is memorized in the EC-AT control unit.

76G07B-015

Sensors-

Solenoid-valve

Fail-safe program Proces--\Out sing -v puts

The EC-AT control unit has a built-in fail-safe func-

tion for the throttle sensor, the pulse generator, and

the 1-2, 2-3, and 3-4 shift solenoid valves.

If a malfunction occurs, the EC-AT control unit will

control operation of the remaining components ac-

cording to a preset fail-safe program.

The vehicle may still be driven, although the driv-

ing performance will be slightly affected.

79G07C-062

4. The memory of warning codes is canceled by dis-

connecting the negative battery terminal for ap-

prox. five seconds.

79G07C-063

7B-17

Page 956 of 1865

7B DISASSEMBLY

4. Assemble the SST.

86U07B-121

5. Lift the transaxle and mount it on the SST.

86U07B-122

Note

Attach the suitable hanger to the oil pump as

shown.

86U07B-123

Warning

Avoid leaning the transaxle to one side dur-

ing disassembly, it may turn quickly and cause

injury.

76U07B-453

7B-90

Page 1151 of 1865

DISASSEMBLY 7C

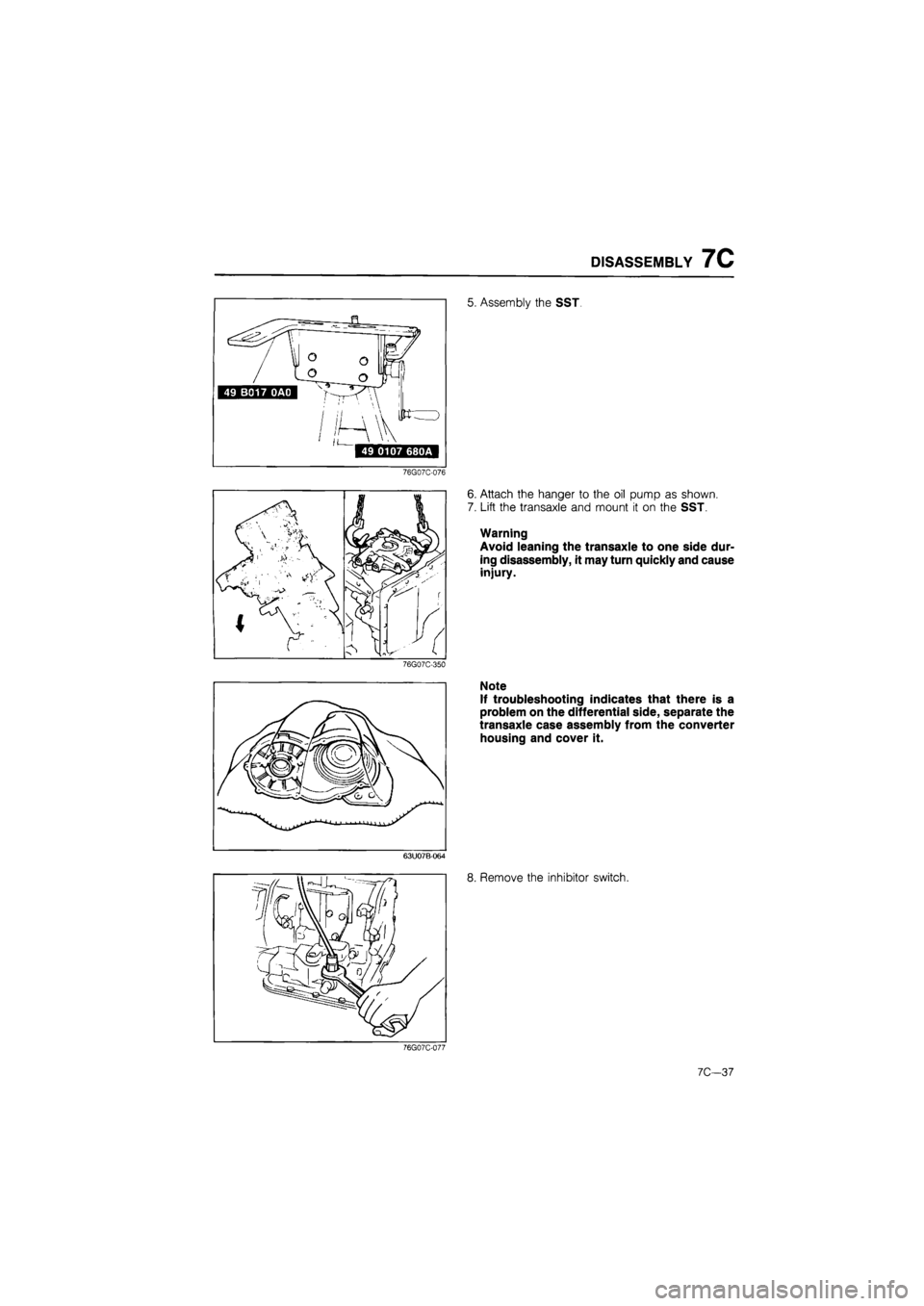

5. Assembly the SST.

76G07C-076

76G07C-350

6. Attach the hanger to the oil pump as shown.

7. Lift the transaxle and mount it on the SST.

Warning

Avoid leaning the transaxle to one side dur-

ing disassembly, it may turn quickly and cause

injury.

Note

If troubleshooting indicates that there is a

problem on the differential side, separate the

transaxle case assembly from the converter

housing and cover it.

63U07B-064

8. Remove the inhibitor switch.

76G07C-077

7C—37

Page 1164 of 1865

7C DISASSEMBLY

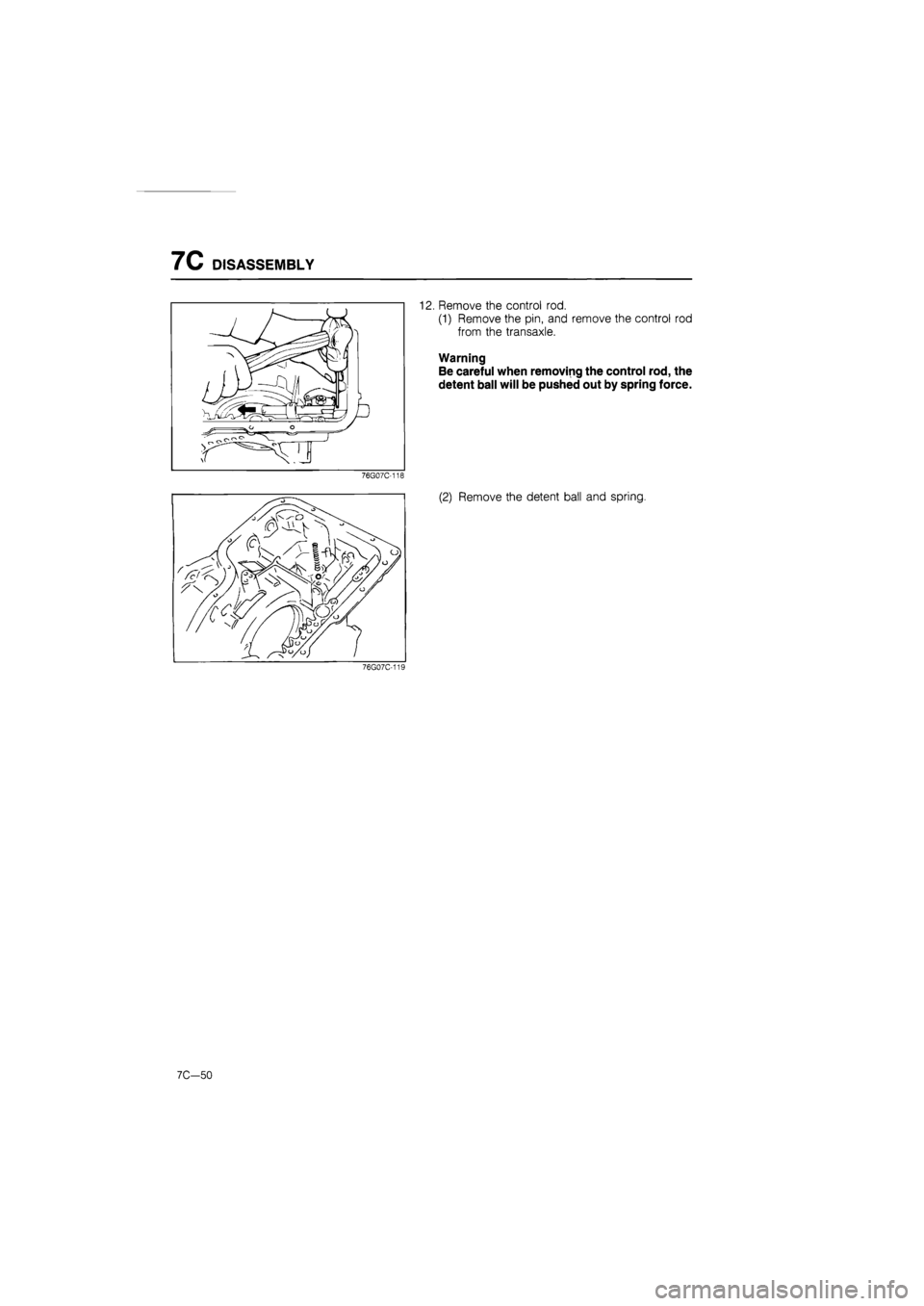

12. Remove the control rod.

(1) Remove the pin, and remove the control rod

from the transaxle.

Warning

Be careful when removing the control rod, the

detent ball will be pushed out by spring force.

(2) Remove the detent ball and spring.

76G07C-119

7C-50

Page 1289 of 1865

10

STEERING SYSTEM

OUTLINE 10— 2

STRUCTURAL VIEW 10— 2 SPECIFICATIONS 10— 6

TROUBLESHOOTING GUIDE 10— 7

MANUAL STEERING 10— 7

POWER STEERING 10— 8

4WS 10— 9

ON-VEHICLE MAINTENANCE 10— 10

STEERING WHEEL PLAY 10— 10

LOOSENESS OR PLAY OF THE

STEERING WHEEL 10— 10

STEERING WHEEL EFFORT 10— 10

POWER STEERING FLUID LEVEL 1 fl-11

LOOSE OR DAMAGED

OIL PUMP BELT IC— 12

REAR STEERING GEAR OIL 10— 12 LEAKAGE OF POWER STEERING

FLUID 10— 13

INSPECTION AND ADJUSTMENT. 10— 15

BLEEDING OF POWER STEERING

SYSTEM 10— 15

POWER STEERING PRESSURE ... 10— 16

TIE-ROD END BOOTS 10— 18

REMOVAL AND INSTALLATION .. 10— 18

STEERING WHEEL AND COLUMN 10— 21

STRUCTURAL VIEW 10— 21

REMOVAL 10— 22

DISASSEMBLY AND ASSEMBLY.. 10— 24

INSPECTION 10— 25

INSTALLATION 1 fl-27

STEERING GEAR AND LINKAGE .. IC— 28

STRUCTURAL VIEW 10— 28

REMOVAL 10— 29

INSTALLATION 10— 30

4-WHEEL STEERING GEAR AND

LINKAGE 10— 31

STRUCTURAL VIEW 10— 31 4WS PERFORMANCE INSPECTION 10— 32

ADJUSTMENT OF STEERING

ANGLE TRASFER SHAFT 10— 35

REMOVAL AND INSTALLATION .. 10— 37

INSPECTION 10— 44

MANUAL STEERING 10— 48

DISASSEMBLY 10— 48

INSPECTION 10— 51

ASSEMBLY 10— 52

ENGINE SPEED SENSING POWER

STEERING 10— 58

DISASSEMBLY 10— 58

INSPECTION 10— 62

ASSEMBLY 10— 64

ELECTRONICALLY-CONTROLLED

POWER STEERING 10— 75

DISASSEMBLY 10— 75

INSPECTION 10— 78

ASSEMBLY 10— 79

OIL PUMP 10— 83

REMOVAL AND INSTALLATION .. 10— 83

ELECTRICAL COMPONENTS OF

ELECTRONICALLY-CONTROLLED

POWER STEERING 10— 87

CIRCUIT DIAGRAM 10— 87

TROUBLESHOOTING GUIDE 10— 87

TROUBLESHOOTING 10— 87

ELECTRICAL COMPONENTS OF

4 WHEEL STEERING 10— 94

CIRCUIT DIAGRAM 10— 94

TROUBLESHOOTING GUIDE 10— 95

TROUBLESHOOTING 10— 95

4WS WARNING LIGHT 10—102

SPEED SENSOR (IN METER) 10—103

SPEED SENSOR (AT TRANSAXLE) 10—103

REAR-TO-FRONT STEERING

RATIO SENSOR 10—103

OIL LEVEL SWITCH

(IN P/S RESERVOIR) 10—103

RELAY AND TIMER 10—104 76G10X-001

Page 1304 of 1865

![MAZDA 626 1987 Repair Manual

1 0 INSPECTION AND ADJUSTMENT

86U10X023

2WS

To oil pump

Si£r To gear housing

86U10X-024

86U10X-025

Thermometer [50—60°C (122—140°C)]

ii ^

Gauge

Close valve

completely

POWER STEERIN MAZDA 626 1987 Repair Manual

1 0 INSPECTION AND ADJUSTMENT

86U10X023

2WS

To oil pump

Si£r To gear housing

86U10X-024

86U10X-025

Thermometer [50—60°C (122—140°C)]

ii ^

Gauge

Close valve

completely

POWER STEERIN](/img/28/57059/w960_57059-1303.png)

1 0 INSPECTION AND ADJUSTMENT

86U10X023

2WS

To oil pump

Si£r To gear housing

86U10X-024

86U10X-025

Thermometer [50—60°C (122—140°C)]

ii ^

Gauge

Close valve

completely

POWER STEERING PRESSURE

1. Disconnect the high-pressure hose of the gear

housing side, and attach the SST.

Tightening torque:

39—49 N-m (4.0—5.0 m-kg, 29—36 ft-lb)

2. Bleed air from the system.

3. Open the gauge valve fully, then start the engine

and turn the steering wheel fully left and right to

raise the fluid temperature to 50—60°C

(122—140°F)

4. To measure the fluid pressure generated by the

oil pump, close the gauge valve completely and

increase the engine speed to 1,000—1,500 rpm.

If the fluid pressure is low, replace the oil pump

assembly.

Warning

If the valve is left closed for more than 15 sec-

onds, the fluid temperature will increase ex-

cessively and adversely affect the oil pump.

Oil pump fluid pressure

2WS

7,355—7,846 kPa

(75—80 kg/cm2, 1,066—1,138 psi)

4WS

Front 8,093—8,829 kPa

(82.5—90.0 kg/cm2, 1,173—1,280 psi)

Rear 7,112—7,848 kPa

(72.5—80.0 kg/cm2, 1,031—1,138 psi)

To measure the fluid pressure generated at the

gear housing, first open the gauge valve complete-

ly, increase the engine speed to 1,000—1,500

rpm, and then turn the steering wheel fully to the

left and right.

Warning

If the steering wheel is kept in the fully turned

position for more than 15 seconds, the fluid

temperature will rise excessively.

80U10X-026

10—16

Page 1322 of 1865

1 0 4-WHEEL STEERING GEAR AND LINKAGE

(Example) ^"in)

-I

8 mm (0.31 in)

1 1111111

- ^Center

10 mm (0.39 in)

86U10X-309

(8) The center position can be determined from

the left/right measurements in (5) and (7) above.

Example:

Right rotation.... 10 mm (0.39 in)

Left rotation....8 mm (0.31 in)

Center = Right 1 mm (0.04 in)

(9) Check that the center is within specification.

Specification

= R 5 mm (0.4 in ) to L 5 mm (0.4 in)

(10) If not correct, adjust the steering angle trans-

fer shaft.

2. Steering Inspection

With the vehicle stopped and the engine running,

check that the rear wheels turn in the opposite

direction when the steering wheel is turned and that

there is no abnormal noise.

86U10X-310

3.4WS Electric System Inspection

Drive the vehicle and check that the 4WS warning

light does not come on at over 40 km/h (25mph).

86U10X-311

10—34