brake fluid MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1402 of 1865

1 1 BRAKE HYDRAULIC LINE

Procedure

1. Jack up the vehicle and support it with safety

stands.

2. Fill the reservoir with brake fluid. Be sure that it is

at least half full at all times during the air bleeding

process.

Caution

a) Be careful not to spill brake fluid onto a

painted surface.

b)Use only the specified brake fluid. Do not

mix it with any other type.

3. Remove the bleeder cap; then connect one end

of a transparent vinyl tube to the bleeder screw and

place the other end in a receptacle.

4. Have an assistant depress the brake pedal a few

times, and then hold it in the depressed position.

5. Loosen the bleeder screw, drain out the fluid, and

retighten the bleeder.

Note

a) The two people should stay in voice con-

tact with each other.

b) Be sure the pedal remains depressed until

the bleeder is tightened.

86U11X-014

6. Repeat steps 4 and 5 until no more air is dis-

charged.

7. Tighten the bleeder screw, and check that there

is no fluid leakage.

Bleeder screw tightening torque:

6—9 N-m (60—90 cm-kg, 52—78 in-lb)

Caution

Be sure to clean away any spilled fluid with

rags.

8. Add brake fluid to the reservoir up to the speci-

fied level.

11—10

Page 1406 of 1865

1 1 MASTER CYLINDER

MASTER CYLINDER

REMOVAL

Remove in the sequence shown in the figure, referring to removal note for specially marked parts.

Caution

Brake fluid will damage painted surfaces. If it does get on a painted surface, wipe it off

immediately.

1. Fluid level sensor connector

2. Brake pipe

76G11X-011

3. Master cylinder

4. Clutch pipe holder (LHD MTX ABS)

Removal Note

Brake pipe (Flare nut type)

1. Place rags under the master cylinder to prevent

brake fluid from dripping on painted surfaces.

2. Disconnect the brake pipe from the master cylin-

der with the SST.

76G11X-012

11—14

Page 1407 of 1865

MASTER CYLINDER 1 1

DISASSEMBLY AND ASSEMBLY (EXCEPT RHD DOHC TURBO)

1. Pour out the brake fluid.

2. Disassemble in the sequence shown in the figure, referring to disassembly note for specially marked

parts.

3. Assemble in the reverse order of disassembly, referring to assembly note for specially marked parts.

Caution a) Do not to allow any foreign material into the master cylinder during repairs. b)Do not scratch the inside of the cylinder or the outer surface of the piston.

Note

The primary piston assembly is not repairable. Replace it as an assembly.

76G11X-013

1. Fluid level sensor 5. Secondary piston assembly

2. Stopper screw and O-ring 6. Reservoir assembly

3. Snap ring 7. Bushing

4. Primary piston assembly

11—15

Page 1408 of 1865

1 1 MASTER CYLINDER

86U11X-029

Disassembly Note

Stopper screw

Remove the stopper screw with a Phillips screwdriver.

Note

Prepare a suitable container for the brake fluid

to drain into.

Snap ring

Push the primary piston with a Phillips screwdriver

and remove or install the snap ring with snap-ring

pliers.

Secondary Piston Assembly

Remove the secondary piston assembly by gradual-

ly blowing compressed air into the cylinder.

Caution

Use a rag to catch the secondary piston as-

sembly when applying compressed air.

Assembly Note

Application of brake fluid

Before assembly, apply brake fluid to the following

parts:

1. Cylinder inner surface

2. Piston

3. Piston cups

4. Bushings

rQ^W 1 ..-V ti V^LUl I

IMCHI tWW&EZBlQ

at itt^

86U11X030

11—16

Page 1410 of 1865

1 1 MASTER CYLINDER

DISASSEMBLY AND ASSEMBLY (RHD DOHC TURBO)

1. Pour out the brake fluid.

2. Disassemble in the sequence shown in the figure, referring to disassembly note for specially marked

parts.

3. Assemble in the reverse order of disassembly, referring to assembly note for specially marked parts.

Caution a) Do not to allow any foreign material into the master cylinder during repairs. b)Do not scratch the inside of the cylinder or the outer surface of the piston.

Note

The primary piston assembly is not repairable. Replace it as an assembly.

76G11X-014

1. Stopper screw and O-ring

2. Snap ring

3. Spacer

4. Piston guide assembly

5. Primary piston assembly

6. Stopper

7. O-ring

8. Piston guide cup

9. Piston guide

10. Secondary piston assembly

11. Stopper

12. Piston cup

13. Washer

14. Secondary piston

15. Spring

16. O-ring

17. Screw

18. Bushing

19. Reservoir assembly

20. Fluid level sensor

21. Master cylinder body

11—18

Page 1411 of 1865

MASTER CYLINDER 1 1

76G11X-015

76G11X-016

76G11X-017

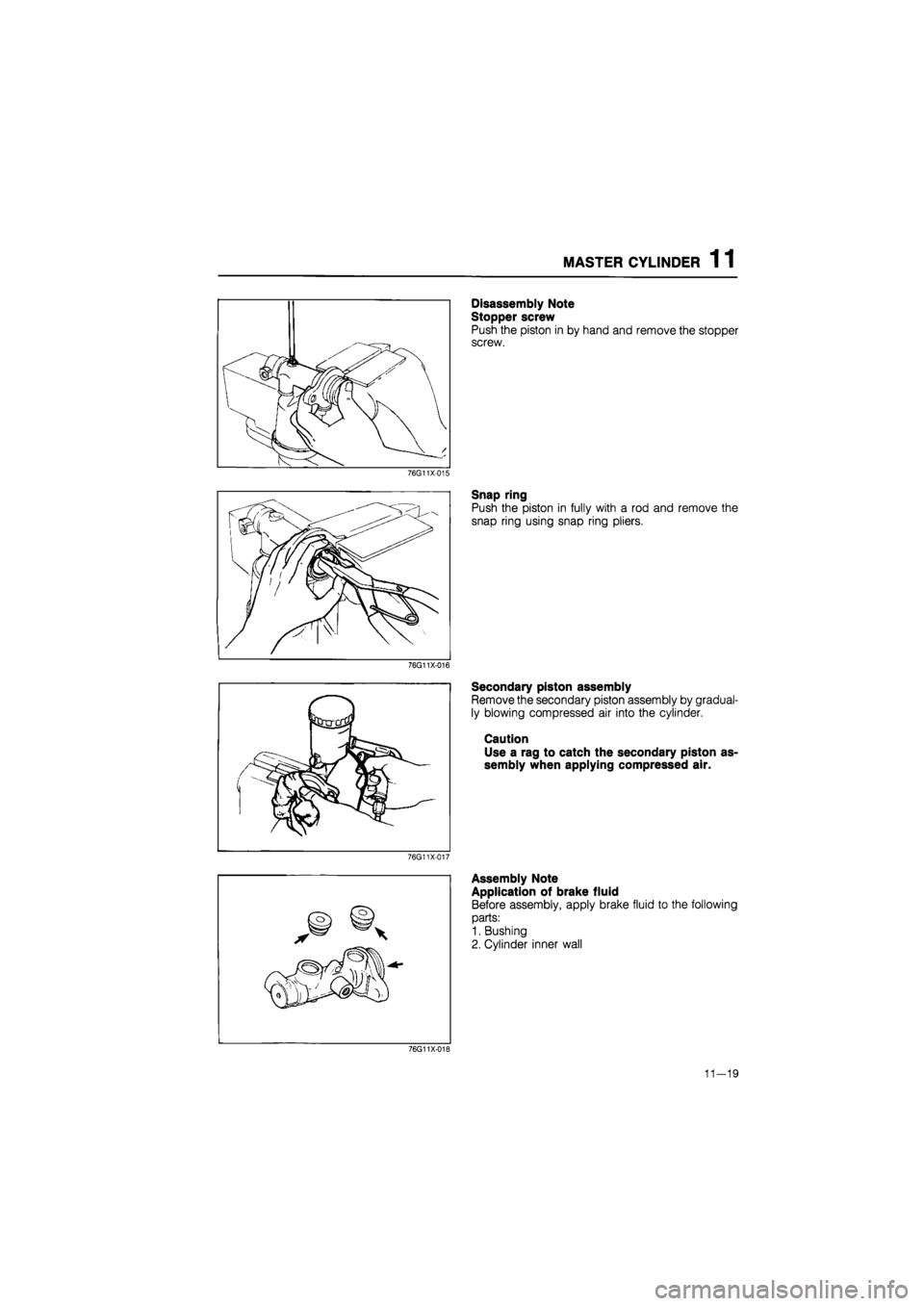

Disassembly Note

Stopper screw

Push the piston in by hand and remove the stopper

screw.

Snap ring

Push the piston in fully with a rod and remove the

snap ring using snap ring pliers.

Secondary piston assembly

Remove the secondary piston assembly by gradual-

ly blowing compressed air into the cylinder.

Caution

Use a rag to catch the secondary piston as-

sembly when applying compressed air.

Assembly Note

Application of brake fluid

Before assembly, apply brake fluid to the following

parts:

1. Bushing

2. Cylinder inner wall

76G11X-018

11—19

Page 1412 of 1865

1 1 MASTER CYLINDER

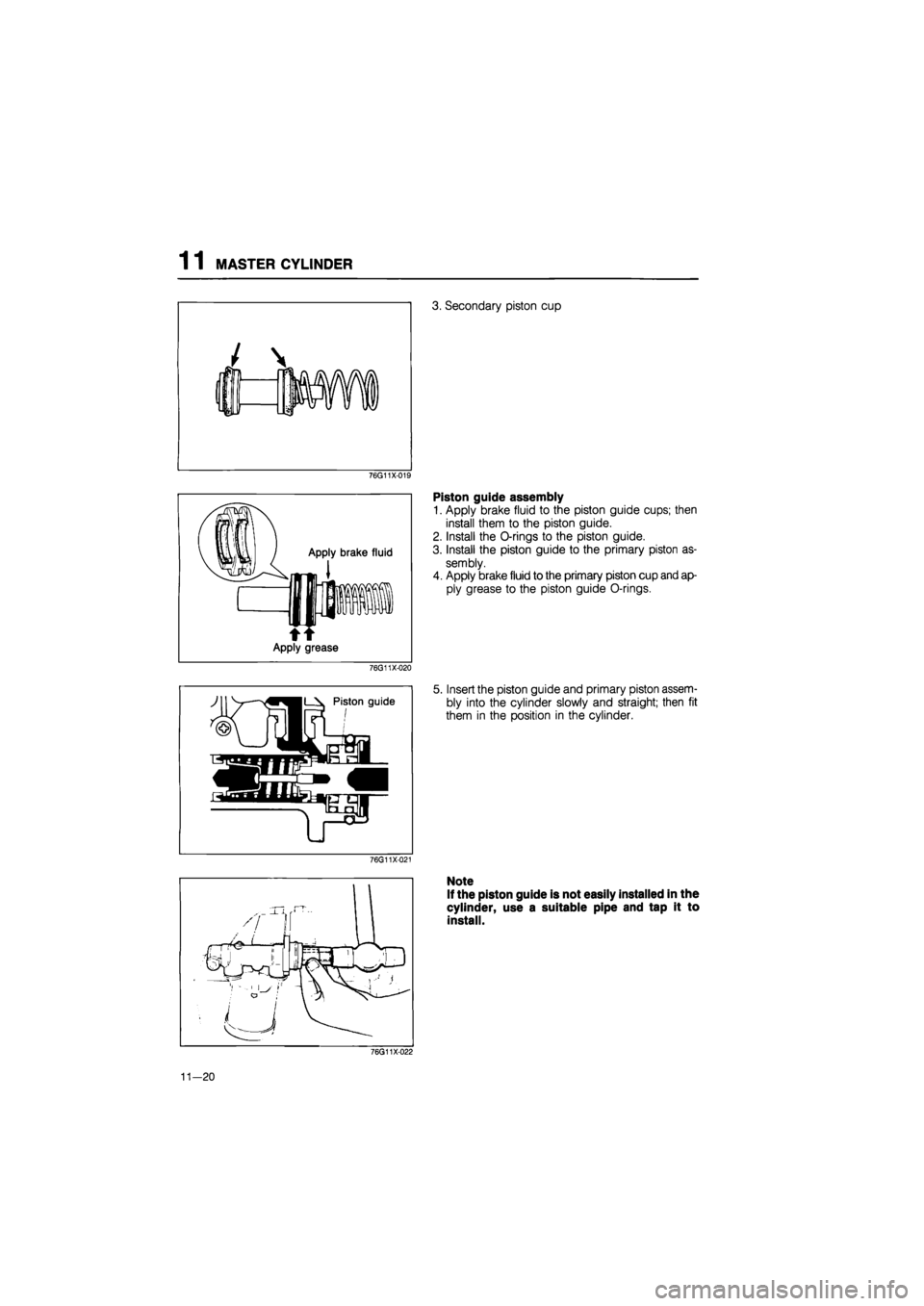

3. Secondary piston cup

76G11X-019

Apply brake fluid

t Apply grease

76G11X-020

Piston guide assembly

1. Apply brake fluid to the piston guide cups; then

install them to the piston guide.

2. Install the O-rings to the piston guide.

3. Install the piston guide to the primary piston as-

sembly.

4. Apply brake fluid to the primary piston cup and ap-

ply grease to the piston guide O-rings.

5. Insert the piston guide and primary piston assem-

bly into the cylinder slowly and straight; then fit

them in the position in the cylinder.

76G11X-021

Note

If the piston guide is not easily installed in the

cylinder, use a suitable pipe and tap it to

install.

76G11X-022

11—20

Page 1420 of 1865

1 1 POWER BRAKE UNIT

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading

reaches 500 mmHg (19.7 inHg).

3. Observe the vacuum gauge for 15 seconds.

If

the

gauge shows 475—500 mmHg (18.7—19.7

inHg), the unit is operating.

76G11X-065

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a force of 196 N (20

kg, 44 lb).

3. With the brake pedal depressed, stop the engine

when the vacuum gauge reading reaches 500

mmHg (19.7 inHg).

4. Observe the vacuum gauge for 15 seconds.

If

the

gauge shows 475—500 mmHg (18.7—19.7

inHg), the unit is operating.

76G11X066

b) Checking for hydraulic pressure

1. If with the engine stopped (when vacuum is 0

mmHg) the relation between pedal force and fluid

pressure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) | 1,177 kPa (12 kg/cm2, 171 psi) mia

76G11X-067

2. Start the engine. Depress the brake pedal when

the vacuum reaches 500 mmHg (19.7 inHg).

If the relation between pedal force and fluid pres-

sure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 7,063 kPa (72 kg/cm2, 1,024 psi) min.

76G11X068

11-28

Page 1421 of 1865

POWER BRAKE UNIT 1 1

76G11X-034

INSPECTION OF CHECK VALVE

Note (MTX)

The check valve is pressed into the vacuum

hose. There is an arrow on the hose surface

to indicate direction of installation.

Inspection

1. Disconnect the vacuum hose from the engine.

2. Apply suction and pressure to the hose from the

engine side. Check that air flows only toward the

engine.

If the air passes in both directions or not at all, re-

place the check valve (along with the hose).

REMOVAL

Remove in the sequence shown in the figure, referring to removal note for specially marked parts.

1. Fluid level sensor connector

2. Vacuum switch coupler

(RF, RF-CX)

3. Brake pipe

4. Master cylinder

5. Clutch pipe holder

6. Vacuum hose and check

valve

7. Clevis pin

8. Steering shaft

76G11X-069

9. Power brake unit

10. Gasket

11. Locknut

12. Operating lever

11-29

Page 1424 of 1865

1 1 POWER BRAKE UNIT

Diaphragm

Install the diaphragm to the power piston and plate.

Caution

Check that the diaphragm is well seated in the

groove.

86U11X-052

Rear shell assembly

Assemble the rear shell assembly; carefully guiding

the tube end of the power piston through the dust

seal of the rear shell.

86U11X-053

Front shell and rear shells

Press down the rear shell assembly, and rotate it

clockwise until the matching marks are aligned.

Caution

Fit suitable nuts to two studs of the rear shell

and tighten them to mount the wrench.

76G11X-072

INSPECTION

1. Inspect all rubber parts. Wipe free of fluid and care-

fully inspect all rubber parts for cuts, nicks, and

other damage.

2. Check the power piston for cracks,distortion, chip-

ping, and damaged seats.

3. Inspect the reaction disc rubber for deterioration.

4. Check that the seats of the valve rod and plunger

are smooth and free of nicks and dents.

5. Inspect the front and rear shells for scratches,

scores, pits, dents, and other damage.

6. Check the diaphragm for cuts and other damage.

11—32