engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1795 of 1865

16 OUTLINE

Thermometer (Dry)

Thermometer

(Dry & Wet)

76G16X-633

69G16X-024

DETERMINING THE RELATIVE HUMI-DITY: Read the temperatures of the dry- and v^et-bulb thermometers at the air inlet (evapo-rator inlet). Then bring them into mutual relation on the chart and determine the intersection, which is the relative humidity^ For exampie, if the dry-bulb temperature^ is 90° F. and the wet-bulb temper- ^ ature is 78° F, the relative humidity is ^ 60%.

DRV BUL8 TEMPERATURE

Performance Test

After finishing repairs, be sure to conduct a perfor-

mance test of the air conditioning system as follows.

Procedure

1. Connect the manifold gauge set. (Refer to page

16-8)

2. Run the engine and keep the engine speed at

1750 rpm.

3. Operate the air conditioner at MAX COOLING.

4. Open all windows and doors.

5. Insert a dry-bulb thermometer in the center of the

ventilator outlet.

6. Place a dry and wet thermometer close to the in-

let of the blower inlet.

7. The high pressure should be within 1374—1569

kPa (14.0—16.0 kg/cm2, 200—227 psi).

Note:

If the pressure is too high, pour water on the

condenser; if it is too low, cover the front sur-

face of the condenser.

8. The dry-bulb thermometer at the inlet should be

within 25—35°C (77—95°F).

Operate the air conditioning system in this condi-

tion until the conditions of the high and low pres-

sure gauges and thermometers are stabilized.

Reading the standard performance curve

1. Read the inlet temperature an get the relative hu-

midity from the psychrometric chart.

2. Read the cool air temperature at the air outlet.

3. Determine the difference between the inlet and out-

let dry-bulb temperature.

4. For example, when the difference is 17°C (30.6°F)

and the relative humidity is 60%:

If

the closing point is the upper part of the line, cool-

ing performance is satisfactory.

76G16X-634

READING THE GRAPH: After reading the temperatures of the wet-and dry-bulb thermometers at the evapo-rator air inlet, the relative humidity (%} can be determined Example: If the dry- and wet-bulb temperatures at the evaporator air inlet are 25°

C

and 19 5°C respectively, find the point of intersection of the dotted lines in the graph, which is

• i

•.p-I--!1. fi -GL^TIULB ': "'.L .T.L CL

16—12

Page 1796 of 1865

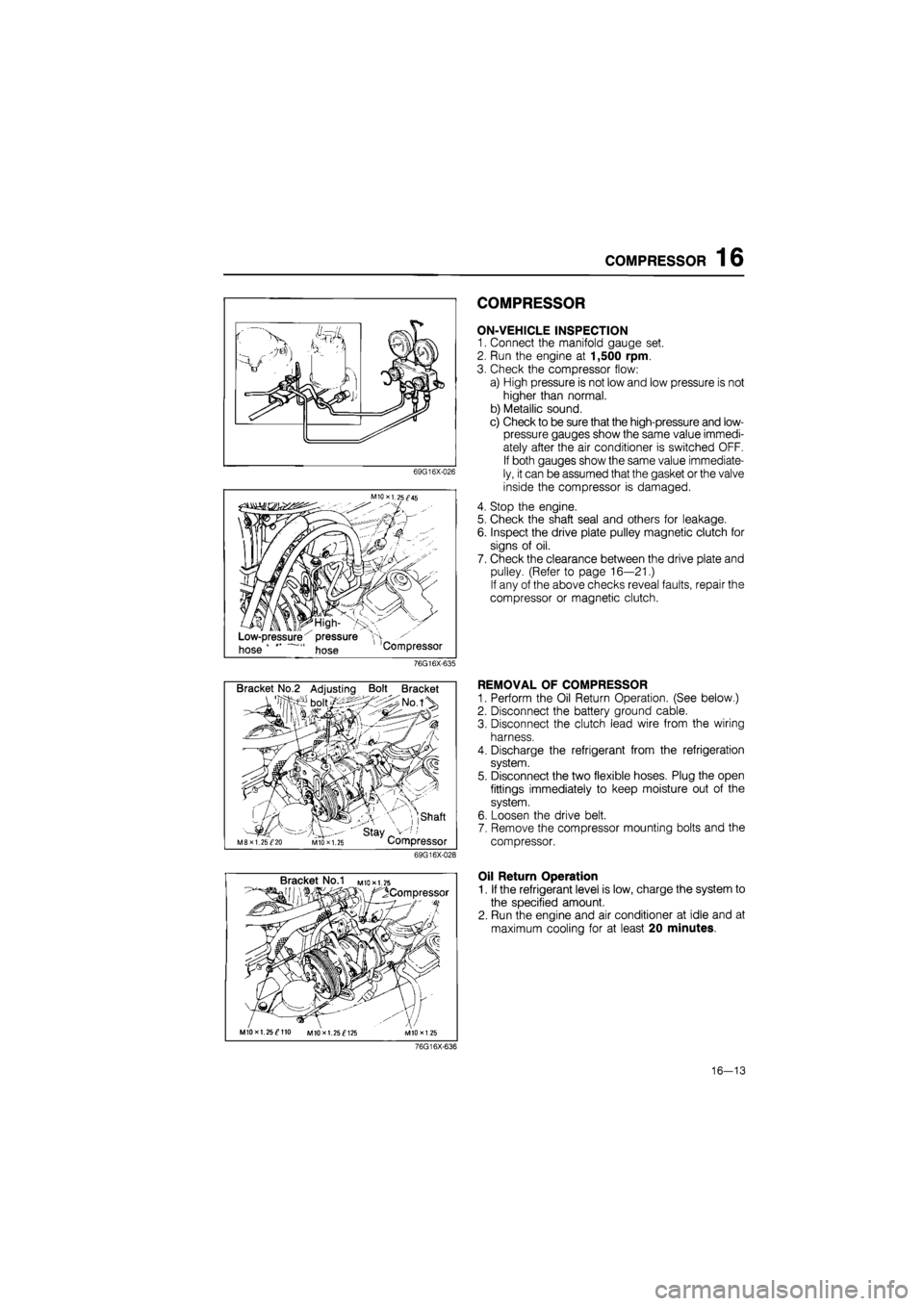

COMPRESSOR 16

69G16X-026

M10X1.25^45

Low-pressure x pressure

hose hose Compressor

COMPRESSOR

ON-VEHICLE INSPECTION

1. Connect the manifold gauge set.

2. Run the engine at 1,500 rpm.

3. Check the compressor flow:

a) High pressure is not low and low pressure is not

higher than normal.

b) Metallic sound.

c) Check to be sure that the high-pressure and low-

pressure gauges show the same value immedi-

ately after the air conditioner is switched OFF.

If both gauges show the same value immediate-

ly, it can be assumed that the gasket or the valve

inside the compressor is damaged.

4. Stop the engine.

5. Check the shaft seal and others for leakage.

6. Inspect the drive plate pulley magnetic clutch for

signs of oil.

7. Check the clearance between the drive plate and

pulley. (Refer to page 16—21.)

If any of the above checks reveal faults, repair the

compressor or magnetic clutch.

76G16X-635

Bracket No.2 Adjusting Bolt Bracket

, ,shaft

' stay _ M8XI. 25^20 MIO X 1.25 Compressor

69G16X-028

REMOVAL OF COMPRESSOR

1. Perform the Oil Return Operation. (See below.)

2. Disconnect the battery ground cable.

3. Disconnect the clutch lead wire from the wiring

harness.

4. Discharge the refrigerant from the refrigeration

system.

5. Disconnect the two flexible hoses. Plug the open

fittings immediately to keep moisture out of the

system.

6. Loosen the drive belt.

7. Remove the compressor mounting bolts and the

compressor.

Bracket No.1 M

to* 1.25

^Compressor

MIOxl. 25^110 MIOxl. 25^125

Oil Return Operation

1. If the refrigerant level is low, charge the system to

the specified amount.

2. Run the engine and air conditioner at idle and at

maximum cooling for at least 20 minutes.

76G16X-636

16—13

Page 1808 of 1865

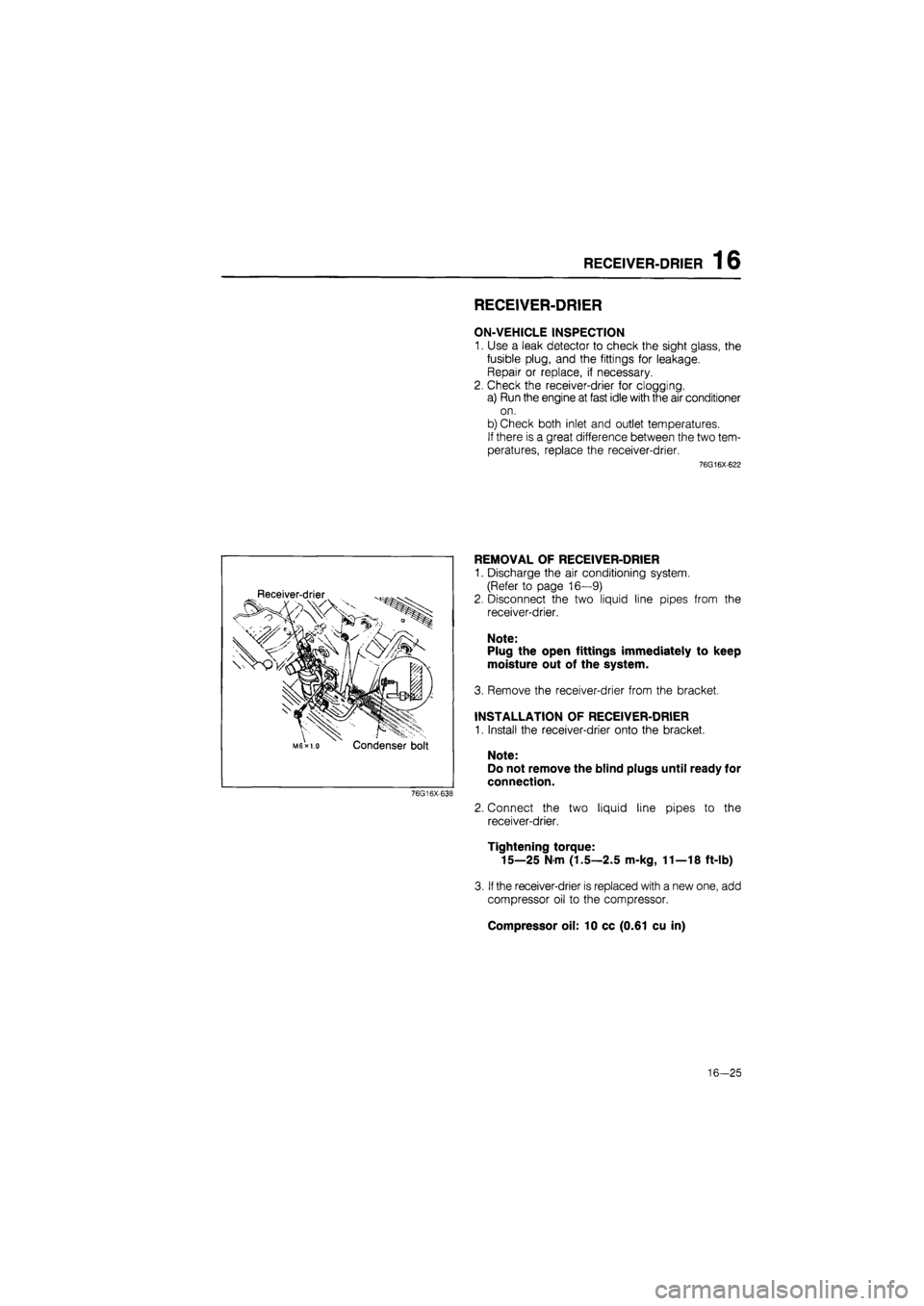

RECEIVER-DRIER 16

RECEIVER-DRIER

ON-VEHICLE INSPECTION

1. Use a leak detector to check the sight glass, the

fusible plug, and the fittings for leakage.

Repair or replace, if necessary.

2. Check the receiver-drier for clogging.

a) Run the engine at fast idle with the air conditioner

on.

b) Check both inlet and outlet temperatures.

If there is a great difference between the two tem-

peratures, replace the receiver-drier.

76G16X-622

Receiver-drier

Condenser bolt

76G16X-638

REMOVAL OF RECEIVER-DRIER

1. Discharge the air conditioning system.

(Refer to page 16—9)

2. Disconnect the two liquid line pipes from the

receiver-drier.

Note:

Plug the open fittings immediately to keep

moisture out of the system.

3. Remove the receiver-drier from the bracket.

INSTALLATION OF RECEIVER-DRIER

1. Install the receiver-drier onto the bracket.

Note:

Do not remove the blind plugs until ready for

connection.

2. Connect the two liquid line pipes to the

receiver-drier.

Tightening torque:

15—25 N m (1.5—2.5 m-kg, 11—18 ft-lb)

3.

If

the receiver-drier is replaced with a new one, add

compressor oil to the compressor.

Compressor oil: 10 cc (0.61 cu in)

16-25

Page 1809 of 1865

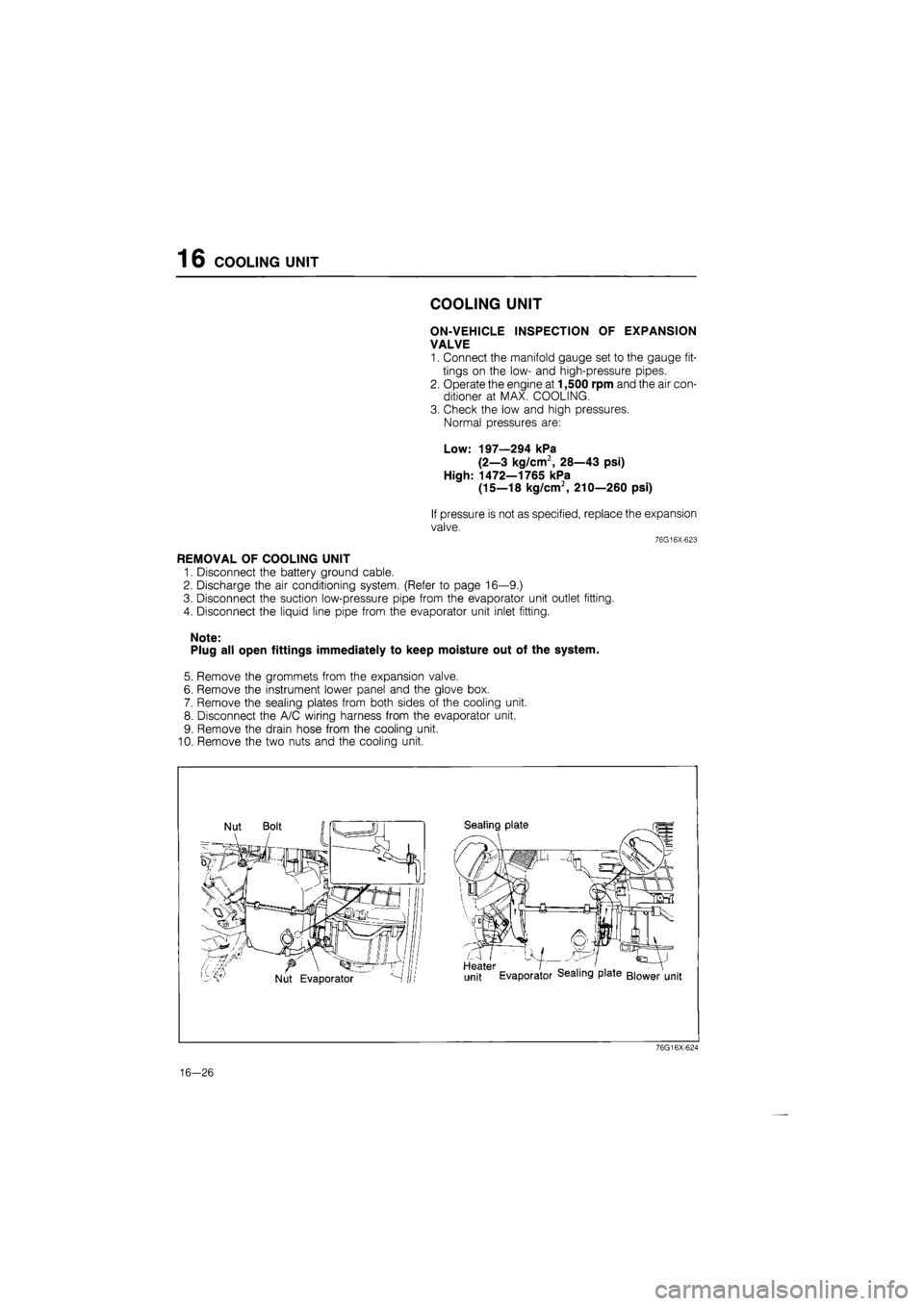

16 COOLING UNIT

COOLING UNIT

ON-VEHICLE INSPECTION OF EXPANSION

VALVE

1. Connect the manifold gauge set to the gauge fit-

tings on the low- and high-pressure pipes.

2. Operate the engine at 1,500 rpm and the air con-

ditioner at MAX. COOLING.

3. Check the low and high pressures.

Normal pressures are:

Low: 197—294 kPa

(2—3 kg/cm2, 28—43 psi)

High: 1472—1765 kPa

(15—18 kg/cm2, 210—260 psi)

If pressure is not as specified, replace the expansion

valve.

76G16X-623

REMOVAL OF COOLING UNIT

1. Disconnect the battery ground cable.

2. Discharge the air conditioning system. (Refer to page 16—9.)

3. Disconnect the suction low-pressure pipe from the evaporator unit outlet fitting.

4. Disconnect the liquid line pipe from the evaporator unit inlet fitting.

Note:

Plug all open fittings immediately to keep moisture out of the system.

5. Remove the grommets from the expansion valve.

6. Remove the instrument lower panel and the glove box.

7. Remove the sealing plates from both sides of the cooling unit.

8. Disconnect the A/C wiring harness from the evaporator unit.

9. Remove the drain hose from the cooling unit.

10. Remove the two nuts and the cooling unit.

76G16X-624

16-26

Page 1815 of 1865

30

TECHNICAL DATA

MEASUREMENT 30— 2

ENGINE (SOHC) 30— 2

ENGINE (DOHC) 30— 8

ENGINE (DIESEL) 30—11

LUBRICATION SYSTEM (GASOLINE) 30—14

LUBRICATION SYSTEM (DIESEL) 30—15

COOLING SYSTEM (GASOLINE) 30—16

COOLING SYSTEM (DIESEL) 30—17

FUEL AND EMISSION CONTROL SYSTEM

(CARBURETOR) 30—18

FUEL AND EMISSION CONTROL SYSTEM

(FUEL INJECTION FE) 30—20

FUEL AND EMISSION CONTROL SYSTEM

(FE DOHC) 30—21

FUEL AND EMISSION CONTROL SYSTEM

(DIESEL) 30—22

ENGINE ELECTRICAL SYSTEM 30—23

CLUTCH 30—25

MANUAL TRANSAXLE 30—26

AUTOMATIC TRANSAXLE

(ELECTRONICALLY CONTROLLED AND

4-SPEED) 30—27

AUTOMATIC TRANSAXLE (3-SPEED) 30—33

FRONT AND REAR AXLES 30—36

STEERING SYSTEM 30—36

BRAKING SYSTEM 30—37

WHEEL AND TIRE 30—38

SUSPENSION 30—38

BODY ELECTRICAL SYSTEM 30—39

STANDARD BOLT AND NUT

TIGHTENING TORQUE 30—40

76G30X-001

Page 1816 of 1865

30 TECHNICAL DATA

0. MEASUREMENT

Item Engine model Coupe/MX-6 Sedan Hatchback

Overall length mm (in) 4,450 (175.2) 4,515 (177.8) 4,515 (177.8)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,690 (66.5)

Overall height (14 inch/13 inch) mm (in) 1,360 (53.5)/1,345 (52.9) 1,410 (55 5)/1,395 (54.9) 1,375 (54.1)/1,360 (53 5)

Wheel base mm (in) 2,515 (99.0) 2,575 (101.4) 2,575 (101.4)

Tread (14 inch/13 inch)

mm (in)

Front 1,455 (57.3)/1,460 (57.5) 1,455 (57.3)/(1,460 (57.5) 1,455 (57.3)/1,460 (57.5) Tread (14 inch/13 inch)

mm (in)

Rear 1,465 (57.7)/1,455 (57.3) 1,465 (57.7)/1,455 (57.3) 1,465 (57 7)/1,455 (57 3)

1

A. ENGINE (SOHC)

12-valve

— Engine model Item FE 12-valve

~vpe

Gasoline, 4-cycle

Cylinder arrangement and number In-line, 4-cylinders

Type

of

combustion chamber Pentroof

Valve system OHC, belt-driven

Bore

x

Stroke

mm (in)

86.0

x

86.0 (3.39

x

3.39)

Total piston displacement

cc

(cu

in)

1,998 (121.9)

Compression ratio 9.5

: 1

Compression pressure

kPa (kg/cm2, psi)-rpm

Standard 1,422 (14.5, 206)—280

Compression pressure

kPa (kg/cm2, psi)-rpm

Minimum 996 (10.2, 144)—280 Compression pressure

kPa (kg/cm2, psi)-rpm Maximum difference

between cylinders 196 (2.0,

28)

Valve timing

IN

Open

BTDC 14°

Valve timing

IN Close ABDC 56° Valve timing

EX Open BBDC 69° Valve timing

EX Close ATDC 13°

Valve clearance

mm (in)

IN 0; Maintenance free Valve clearance

mm (in)

EX 0; Maintenance free

Cylinder head

Heiaht

mm (inl

91.95-92.05 (3.620-3.624)

Distortion

mm (inl

Maximum 0.15 (0.006)

Grinding limit

mm (in)

Maximum 0.20 (0.008)

Valve and valve auide

Valve head diameter

mm (in)

IN 32.4-32.6 (1.276—1.283) Valve head diameter

mm (in)

EX 33.9-34.1 (1.335-1.343)

Valve head thickness (margin)

mm (in)

IN 0.8-1.2 (0.031—0.0471 Valve head thickness (margin)

mm (in)

EX 1.3—1.7 (0.051-0.067)

Valve face angle IN 45° Valve face angle EX 45°

Valve length

mm (in)

IN Standard 115.81 (4.55941

Valve length

mm (in)

IN Minimum 115.31 (4.5398) Valve length

mm (in)

cv Standard 116.21 (4.5752)

Minimum 115.71 (4.55551

Valve stem diameter

mm (in)

IN 6.970-6.985 (0.2744-0.2750) Valve stem diameter

mm (in)

EX 6.965-6.980 (0.2742-0.27481

Guide inner diameter

mm (in)

IN 7.01-7.03 (0,2760-0.2768) Guide inner diameter

mm (in)

EX 7.01-7.03 (0.2760-0.27681

Valve stem

to

guide clearance

mm (in)

IN 0.025-0.060 (0.0010-0.0024)

Valve stem

to

guide clearance

mm (in)

EX 0.030-0.065 (0.0012—0.0026) Valve stem

to

guide clearance

mm (in)

Maximum 0.20 (0.00791

Guide projection (Height "A")

mm (in)

19.8-20.3 (0.780-0.799)

30—2

Page 1818 of 1865

30 TECHNICAL DATA

Item Engine model FE 12-valve

Top 0.20—0.35 (0.008-0.0138)

End gap measured

in

cylinder

mm

(in) Second 0.15—0.30 (0.006-0.012) End gap measured

in

cylinder

mm

(in) Oil (rail) 0.20-0.70 (0.008-0.0276)

Maximum 1.0 (0.039)

Top 1.52-1.54 (0.0598-0.0606)

Ring groove width

in

piston mm (in) Second 1.52-1.54 (0.0598-0.0606)

Oil 4.02-4.04 (0.1583-0.1591)

Top 0.03—0.07 (0.0012—0.0028) Clearance

ot

piston ring

to

ring Second 0.03—0.07 (0.0012-0.0028)

Maximum 0.15(0.006)

Piston pin

Diameter mm (in) 21.974-21.980 (0.8651-0.8654)

Interference

in

connecting

rod

mm (in) 0.013-0.037 (0.0005-0.0015)

Piston

to

piston pin clearance mm (in) 0.008-0.024 (0.0003—0.0009)

Installation pressure N (kg,

lb)

4,900-14,700 (500-1,500, 1,100-3,300)

Connecting rod and connecting rod bearing

Length (Center

to

center) mm (in) 151.95—152.05 (5.982—5.986)

Twisting and bending mm (in) 0.06 (0.0024) max.

Small end bore mm (in) 21.943—21.961 (0.8640-0.8646)

Big end bore mm (in) 54.002-54.017 (2.1261—2.1266)

Big end width mm (in) 26.838-26.890 (1.0566—1.0587)

Connecting rod side clearance

mm

(in) Standard 0.110-0.262 (0.004-0.010) Connecting rod side clearance

mm

(in) Maximum 0.30 (0.012)

Crankshaft

Crankshaft runout mm (in) Maximum 0.03 (0.0012)

Standard size 59.937-59.955 (2.3597—2.3604)

0.25 (0.010) Standard 59.693-59.711 (2.3501-2.3508)

Main journal diameter mm (in)

undersize No.3 59.687-59.705 (2.3499-2.3506) Main journal diameter mm (in) 0.50 (0.020) No. 1,2,4,5 59.443-59.461 (2.3403-2.3410) Main journal diameter mm (in) undersize No.

3

59.437-59.455 (2.3400-2.3407)

0.75 (0.030) No. 1,2,4,5 59.193-59.211 (2.3304-2.3311)

undersize No.

3

59.187-59.205 (2.3302-2.3309)

Main journal taper and out-of-round mm (in) Maximum 0.05 (0.0020)

Standard 50.940-50.955 (2.0055-2.0061)

Crankpin diameter 0.25 (0.010) undersize 50.690—50.705 (1.9957-1.9963)

mm (in) 0.50 (0.020) undersize 50.440-50.455 (1.9858-1.9864)

0.75 (0.030) undersize 50.190-50.205 (1.9760-1.9766)

Crankpin taper and out-of-round

mm (in)

Maximum 0.05 (0.0020)

Main bearing

No. 1,2,4,5 Standard 0.025-0.043 (0.0010—0.0017)

Main journal bearing

oil

No. 1,2,4,5 Maximum 0.08 (0.0031) clearance

mm

(in) No.

3

Standard 0.031—0.049 (0.0012—0.0019) No.

3

Maximum 0.08 (0.0031)

Available undersize bearing mm fin} 0.25 (0.010), 0.50 (0.020), 0.75 (0.030)

Crankpin bearing

Crankpin bearing

oil

clearance

mm

(in) Standard 0.027-0.067 (0.0011-0.0026) Crankpin bearing

oil

clearance

mm

(in) Maximum 0.10 (0.0039)

Available undersize bearina mm (in) 0.25 (0.010), 0.50 (0.020), 0.75 (0.030)

Thrust bearing (center main bearing)

Crankshaft end play mm (in) Standard 0.08-0.18 (0.0031-0.0071) Crankshaft end play mm (in) Maximum 0.30 (0.0118)

Standard 27.94-27.99 (1.100-1.102)

Bearing width

mm (in)

0.25 (0.010) oversize 28.04-28.09 (1.104-1.106) Bearing width

mm (in)

0.50 (0.020) oversize 28.12-28.17 (1.107-1.109)

0.75 (0.030) oversize 28.20—28.25 (1.110—1.112)

30—4

Page 1819 of 1865

TECHNICAL DATA 30

" Engine model Item FE 12-valve

Timing belt

Belt deflection

mm

(in)/98

N

(10 kg,

22 lb)

5.5—6.5 (0.22-0.26)

8-valve

Engine model

Item -••--.

FE 8-valve F8

F6

Engine model

Item -••--. ECE Middle

East

General

ECE General F6

Type Gasoline, 4-cycle

Cylinder arrangement and number In-line, 4-cylinders

Type

of

combustion chamber Multispherical

Valve system OHC, belt-driven

Bore

x

Stroke

mm

(in) 86.0

x

86.0 (3.39

x

3.39) 86.0

x

77.0

(3.39

x

3.03)

81.0

x

77.0 (3.19

x

3.03)

Total piston displacement

cc

(cu

in)

1,998 (121.9) 1,789 (109.1) 1,587 (96.8)

Compression ratio 8.6

: 1

9.0

: 1

Compression pressure kPa (kg/cm2, psi)-rpm

Standard 1,275 (13.0, 185)—270 1,128 (11.5, 164)—270

Compression pressure kPa (kg/cm2, psi)-rpm Minimum 893 (9.1, 129)—270 790 (8.1, 114)—270 Compression pressure kPa (kg/cm2, psi)-rpm Maximum difference

between cylinders 196 (2.0,

28)

Valve timing

IN Open BTDC 16° 20° 17°

Valve timing

IN Close ABDC 54° 65° 56° Valve timing

EX Open BBDC 54° 65° 64° Valve timing

EX Close ATDC 16° 20° 15°

Valve clearance

mm

(in) IN 0.30 (0.012) Valve clearance

mm

(in) EX 0.30 (0.012)

Cylinder head

Height

mm (in)

91.95-92.05 (3.620-3.624)

Distortion

mm

(in) Maximum 0.15 (0.006)

Grinding limit mm (in) Maximum 0.20 (0.008)

Valve and valve guide

Valve head diameter

mm

(in) IN 43.9-44.1 (1.728-1.736) Valve head diameter

mm

(in) EX 35.9-36.1 (1.413-1.421)

Valve head thickness (margin)

mm

(in) IN 0.8—1.2 (0.031-0.047) Valve head thickness (margin)

mm

(in) EX 1.3-1.7 (0.051-0.067)

Valve face angle IN 45° Valve face angle EX 45°

Valve length

mm

(in)

IN Standard 111.89 (4.4051)

Valve length

mm

(in)

IN Minimum 111.39 (4.3854) Valve length

mm

(in)

EX Standard 111.69 (4.3972) Valve length

mm

(in)

EX Minimum 111.19 (4.3776)

Valve stem diameter

mm

(in) IN 8.030-8.045 (0.3161-0.3167) Valve stem diameter

mm

(in) EX 8.025-8.040 (0.3159-0.3165)

Guide inner diameter

mm

(in) IN 8.07-8.09 (0.3177-0.3185) Guide inner diameter

mm

(in) EX 8.07-8.09 (0.3177-0.3185)

Valve stem

to

guide clearance

mm

(in)

IN 0.025-0.060 (0.0010-0.0024)

Valve stem

to

guide clearance

mm

(in) EX 0.030-0.065 (0.0012-0.0026) Valve stem

to

guide clearance

mm

(in)

Maximum 0.20 (0.0079)

Guide projection (Height "A")

mm

(in) 19.1-19.6 (0.752-0.772)

30-5

Page 1820 of 1865

30 TECHNICAL DATA

Engine model FE 8-valve

Item ECE Middle East General

F8 F6

Valve seat

Seat angle IN 45° Seat angle EX 45°

Seat contact width mm (in) IN 1.2—1.6 (0.047-0.063) Seat contact width mm (in) EX 1.2-1.6 (0.047-0.063)

Seat sinking (Measure valve protruding length)

mm (in)

IN Standard 46.5 (1.831) Seat sinking (Measure valve protruding length)

mm (in)

IN Maximum 48.0 (1.890) Seat sinking (Measure valve protruding length)

mm (in) EX Standard 46.5 (1.831)

Seat sinking (Measure valve protruding length)

mm (in) EX Maximum 48.0 (1.890)

Valve spring

Free length mm (in)

Outer

Inner

Standard

Minimum

51.5(2.028)

Standard

44.0 (1.732)

Minimum

43.3 (1.705)

51.2 (2.016)

52.0 (2.047)

50.6 (1.992)

51.5 (2.028)

45.7 (1.799)

44.0 (1.732)

437 (1.720)1

43.3 (1.705)

Out-of-square mm (in) Maximum 1.8 (0.071)

Setting load/height

N

(kg, lb)/mm

(in)

Outer

128(13.1,29) 136.5

(1

44)

Inner

189 (19,2, 42) 141 (1.61)

124 (12.7, 28) 136.5

(1

44)

193 (19.6,43) 141 (1.61)

128 (13.1, 29)/36.5 (1.44)

189 (19.2, 42)/41 (1.61)

Camshaft

Cam lobe height

mm (in)

IN

EX

Standard

Minimum

Standard

Minimum

38.107-38.207 (1.5003-1.5042)

37.957 (1.4944)

38.110-38.210 (1.5004-1.5043)

37.960 (1.4945)

Journal diameter

mm (in)

Front and Rear (No.

1,5)

31.940-32.035 (1.2575-1.2612)

Center (No. 2,3,4)

Out-of-round Maximum

31.910-32.065 (1.2563-1.2624)

0.05 (0.002)

Camshaft bearing

oil

clearance

mm (in)

Front and Rear (No.

1,5)

0.035-0.085 (0.0014-0.00331

Center (No. 2,3,4) 0.065-0.115 (0.0026—0.0045)

Maximum 0.15 (0.0059)

Camshaft runout mm (in) Maximum 0.03 (0.00121

Camshaft end play mm (in) Standard 0.08—0.16 (0.003—0.006)

Maximum 0.20 (0.008)

Rocker arm and rocker arm shaft

Rocker arm inner diameter mm (in) 16.000-16.027 (0.6299-0.6310)

Rocker arm shaft diameter mm (in) 15.966-15.984 (0.6286-0.6293)

Rocker arm

to

shaft clearance

mm (in)

Standard 0.016—0.061 (0.0006-0.0024)

Maximum 0.10 (0.004)

Cylinder block

Heiaht mm

fin)

289.0 (11.38) 268.5 (10.57)

Distortion mm (in) Maximum 0.15 (0.006)

Grindina limit mm (in)

0.20 (0.008)

Cylinder bore diameter

mm (in)

Standard 86.000—86.019 (3.3858—3.3866)

0.25 (0.010) oversize 86.250-86.269 (3.3957-3.3964)

0.50 (0.020) oversize 86.500-86.519 (3.4055-3.4062)

0.75 (0.030) oversize

1.00 (0.039) oversize

81.000-

(3.1890-

-81.019 -3.1897)

81.250-(3.1988-

-81.269

-3.1996) 81.500-(3.2087-

-81.519 -3.2094)

81.750-(3.2185-

-81.769

-3.2192)

82.000-

(3.2283-

-82.019

-3.2291)

Cylinder bore taper and out-of-round mm (in) Maximum 0.019 (0.0007)

Piston

Piston diameter measured at 90°

to pin

bore axis and 18.0

mm

(0.709

in)

below

oil

ring groove

mm (in)

Standard 85.944-85.964 (3.3836—3.3844) 80.944-80.964

(3.1868—3.1876) Piston diameter measured at 90°

to pin

bore axis and 18.0

mm

(0.709

in)

below

oil

ring groove

mm (in)

0.25 (0.010) oversize 86.194—86.214 (3.3935—3.3942) 81.194—81.214

(3.1966-3.1974)

Piston diameter measured at 90°

to pin

bore axis and 18.0

mm

(0.709

in)

below

oil

ring groove

mm (in) 0.50 (0.020) oversize 86.444-86.464 (3.4033-3.4041) 81.444-81.464

(3.2065-3.2072)

30—6

Page 1821 of 1865

TECHNICAL DATA 30

—Engine model

Item -

FE 8-valve

F8 F6

—Engine model

Item -

ECE Middle East General

F8 F6

0.75 (0.030) oversize

—

81.694—81.714

(3.2163-3.2171)

1.00 (0.039) oversize

—

81.944—81.964 (3.2261-3.2269)

Piston and cylinder clearance

mm

(in) Standard 0.036-0.075 (0.0014—0.0030) Piston and cylinder clearance

mm

(in) Maximum 0.15 (0.0059)

Piston ring

Thickness

mm

(in) Top 1.47-1.49 (0.0579-0.0587) Thickness

mm

(in) Second 1.47-1.49 (0.0579—0.0587)

End gap measured

in

cylinder

mm (in)

Top 0.20—0.35 (0.008—0.0138)

End gap measured

in

cylinder

mm (in)

Second 0.15-0.30 (0.006-0.012) End gap measured

in

cylinder

mm (in)

Oil (rail) 0.20—0.70 (0.008—0.0276) End gap measured

in

cylinder

mm (in)

Maximum 1.0 (0.039)

Ring groove width

in

piston

mm

(in)

Top 1.52—1.54 (0.0598-0.0606)

Ring groove width

in

piston

mm

(in) Second 1.52-1.54 (0.0598-0.0606) Ring groove width

in

piston

mm

(in)

Oil 4.02-4.04 (0.1583-0.1591)

Clearance

of

piston ring

to

ring

groove

mm

(in)

Top 0.03-0.07 (0.0012-0.0028) Clearance

of

piston ring

to

ring

groove

mm

(in) Second 0.03-0.07 (0.0012-0.0028) Clearance

of

piston ring

to

ring

groove

mm

(in) Maximum 0.15 (0.006)

Piston pin

Diameter

mm

(in) 21.974—21.980 (0.8651—0.8654)

Interference

in

connecting

rod mm

(in) 0.013—0.037 (0.0005—0.0015)

Piston

to

piston pin clearance

mm

(in) 0.008—0.024 (0.0003-0.0009)

Installation pressure

N

(kg,

lb)

4,900—14,700 (500—1,500, 1,100—3,300)

Connecting rod and connecting rod bearing

Length (Center

to

center)

mm

(in) 151.95-152.05 (5.982-5.986) 135.95—136.05

(5.352-5.356)

Twisting and bending

mm

(in) 0.06 (0.0024) max.

Small end bore

mm

(in) 21.943-21.961 (0.8640-0.8646)

Big end bore

mm

(in) 54.002-54.017 (2.1261—2.1266)

Bia end width

mm

(in) 26.838-26.890 (1.0566—1.0587)

Connecting rod side clearance

mm

(in) Standard 0.110-0.262 (0.004—0.010) Connecting rod side clearance

mm

(in) Maximum 0.30 (0.012)

Crankshaft

Crankshaft runout mm (in)

I

Maximum 0.03 (0.0012)

Main journal diameter

mm (in)

Standard size 59.937-59.955 (2.3597—2.3604)

Main journal diameter

mm (in)

0.25 (0.010) undersize

Standard 59.693—59.711 (2.3051—2.3508)

Main journal diameter

mm (in)

0.25 (0.010) undersize No.

3

59.687—59.705 (2.3499-2.3506) Main journal diameter

mm (in) 0.50 (0.020) undersize

No. 1,2,4,5 59.443-59.461 (2.3403—2.3410) Main journal diameter

mm (in) 0.50 (0.020) undersize No.

3

59.437-59.455 (2.3400—2.3407)

Main journal diameter

mm (in)

0.75 (0.030)

undersize

No. 1,2,4,5 59.193-59.211 (2.3304—2.3311)

Main journal diameter

mm (in)

0.75 (0.030)

undersize No.

3

59.187—59.205 (2.3302—2.3309)

Main journal taper and out-of-round mm (in) Maximum 0.05 (0.0020)

Crankpin diameter mm (in)

Standard 50.940-50.955 (2.0055-2.0061)

Crankpin diameter mm (in)

0.25 (0.010) undersize 50.690-50.705 (1.9957-1.9963) Crankpin diameter mm (in) 0.50 (0.020) undersize 50.440-50.455 (1.9858-1.9864) Crankpin diameter mm (in)

0.75 (0.030) undersize 50.190—50.205 (1.9760-1.9766)

Crankpin taper and out-of-round

mm

(in) Maximum 0.05 (0.0020)

Main bearlna

Main journal bearing

oil

clearance

mm

(in)

No. 1,2,4,5 Standard 0.025-0.043 (0.0010-0.0017)

Main journal bearing

oil

clearance

mm

(in)

No. 1,2,4,5 Maximum 0.08 (0.0031) Main journal bearing

oil

clearance

mm

(in) No.

3

Standard 0.031—0.049 (0.0012—0.0019)

Main journal bearing

oil

clearance

mm

(in) No.

3

Maximum 0.08 (0.0031)

Available undersize bearina

mm

(in) 0.25 (0.010), 0.50 (0.020), 0.75 (0.030)

Crankpin bearing

Crankpin bearing

oil

clearance

mm

(in) Standard 0.027-0.067(0.0011 -0.0026) Crankpin bearing

oil

clearance

mm

(in) Maximum 0.10 (0.0039)

Available undersize bearing

mm

(in) 0.25 (0.010), 0.50 (0.020), 0.75 (0.030)

30-7